Method for producing semi-finished products or components comprising a metallic carrier and a curable coating with fiber-reinforced synthetic material

A metal carrier and synthetic material technology, applied in the direction of metal layered products, chemical instruments and methods, coatings, etc., can solve the problems of high automation consumption, expensive, high-cost semi-finished products or components, and achieve the effect of improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

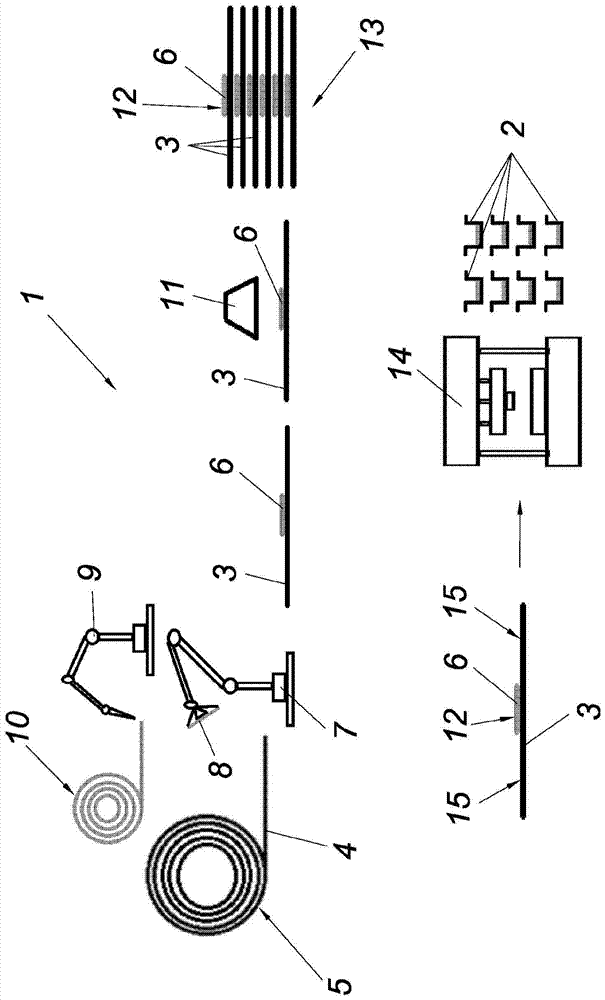

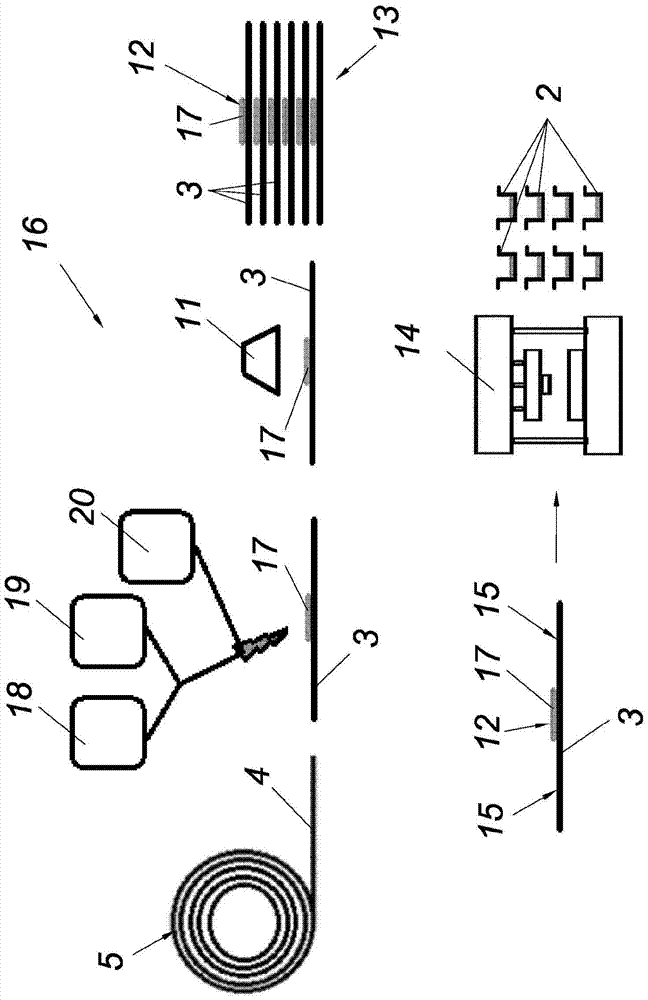

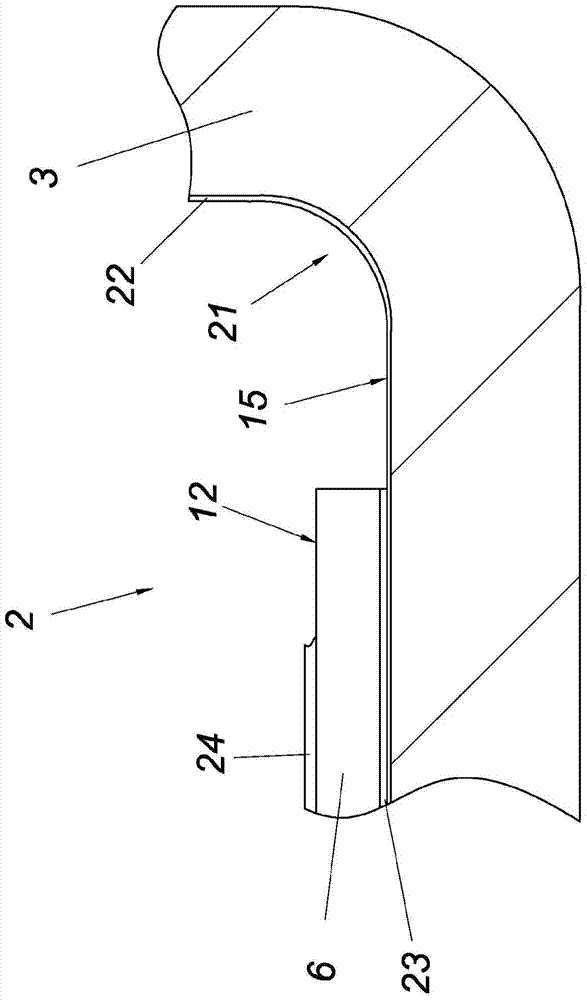

[0023] according to figure 1 The shown method sequence 1 for producing a component 2, in a first step, a curable coating 6 with fiber-reinforced synthetic material (FVK) is applied to the metal detached from a coil 4 of steel sheet 5 on carrier 3. The metal carrier 3 may also have previously been cleaned or chemically pretreated on the side to be coated, but this will not be explained in detail. A robot 7 is provided for applying the coating 6 , which receives the blank 8 of the robot 9 . For this purpose, the robot arm 9 cuts the fabric 10 pre-impregnated with a synthetic material matrix according to the area of the metal carrier 3 to be coated. The coated metal carrier 3 is then subjected to partial curing by means of a drying or curing device 11 , whereby the coating 6 forms at least one anti-adhesion surface 12 . As a result, the metal carriers 3 can also easily be laid into stacks 13 and thus, for example, temporarily stored or prepared for further transport. In par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com