Double component additive sealing organic silicon material for electric kettle and preparation method thereof

An electric kettle, two-component technology, applied in the directions of adhesive additives, non-polymer adhesive additives, adhesives, etc., can solve the problems of long curing time, low production efficiency, difficulty in meeting export, etc., and achieve good anti-aging performance. , Fast bonding and curing, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

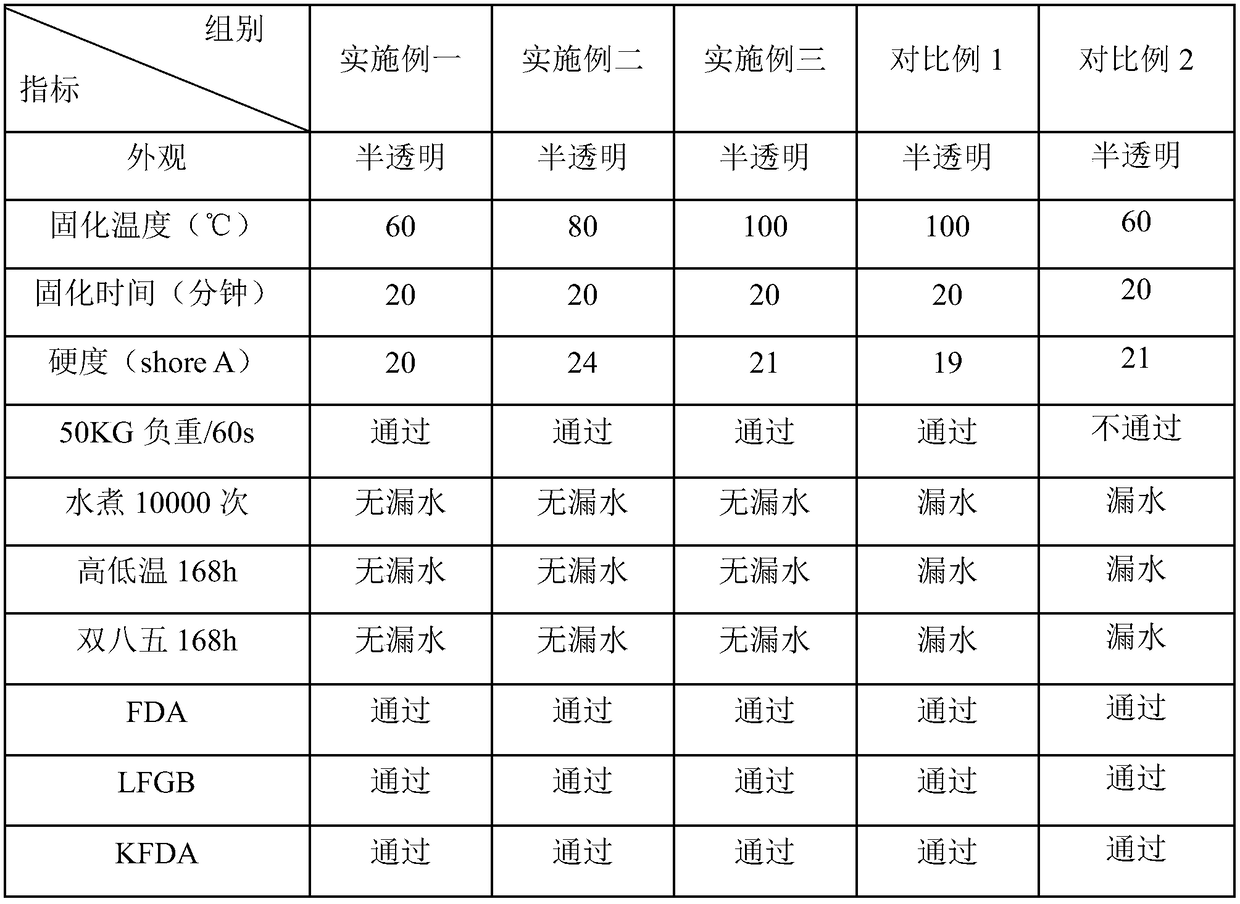

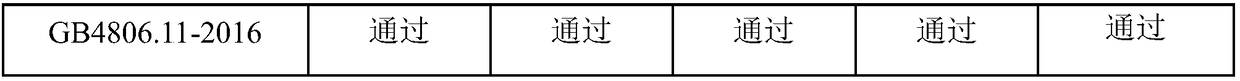

[0030] Example 1: Two-component addition molding sealing silicone material for electric kettle

[0031] The two-component addition molding sealing silicone material for electric kettle includes equal mass of component A and component B; component A includes raw materials of the following mass parts: 85 parts of vinyl polysiloxane, 16 parts of white carbon black, The binder is 3 parts and the catalyst is 0.3 parts; the B component includes the following parts by mass of raw materials: 85 parts of vinyl polysiloxane, 16 parts of white carbon black, 9 parts of hydrogen-containing silicone oil, and 0.08 parts of inhibitor.

[0032] The structural formula of the adhesive is: R 1 [(CH 3 ) 2 SiO 2 / 2 ] m [CH 3 R 2 SiO 2 / 2 ] n (CH 3 ) 2 SiR 1 ; Where R 1 Is epoxy group, R 2 Is hydrogen, m+n=17; vinyl polysiloxane is a vinyl-terminated silicone oil with a viscosity of 20000 mPa.s and a vinyl mass percentage of 0.08%; the white carbon black is a hydrophilic fumed white carbon black, The avera...

Embodiment 2

[0037] Example 2 Two-component addition molding sealing silicone material for electric kettle

[0038] The two-component addition molding sealing silicone material for electric kettle includes equal mass of component A and component B; component A includes the following raw materials by mass: 70 parts of vinyl polysiloxane, 8 parts of white carbon black, The binder is 2 parts and the catalyst is 0.2 parts; the B component includes the following materials in parts by mass: 70 parts of vinyl polysiloxane, 8 parts of white carbon black, 4 parts of hydrogen-containing silicone oil, and 0.05 parts of inhibitor.

[0039] The structural formula of the adhesive is: R 1 [(CH 3 ) 2 SiO 2 / 2 ] m [CH 3 R 2 SiO 2 / 2 ] n (CH 3 ) 2 SiR 1 ; Where R 1 Is methoxy, R 2 Is vinyl, m+n=18; vinyl polysiloxane is pendant vinyl silicone oil, its viscosity is 5000mPa.s, and the vinyl mass percentage is 1.2%; the white carbon black is precipitation method white carbon black. The average particle size is 6 μm; ...

Embodiment 3

[0041] Example 3 Two-component addition molding sealing silicone material for electric kettle

[0042] The two-component addition molding sealing silicone material for electric kettle includes equal mass of component A and component B; component A includes raw materials of the following mass parts: 100 parts of vinyl polysiloxane, 25 parts of white carbon black, 4 parts of adhesive and 0.4 parts of catalyst; the B component includes the following materials in parts by mass: 100 parts of vinyl polysiloxane, 25 parts of white carbon black, 16 parts of hydrogen-containing silicone oil, and 0.12 parts of inhibitor.

[0043] The structural formula of the adhesive is: R 1 [(CH 3 ) 2 SiO 2 / 2 ] m [CH 3 R 2 SiO 2 / 2 ] n (CH 3 ) 2 SiR 1 ; Where R 1 Is an acyloxy group, R 2 Selected from vinyl, m+n=16; vinyl polysiloxane is a vinyl terminated oligosiloxane with a viscosity of 10000 mPa.s and a vinyl mass percentage of 0.1%; silica is hydrophobic Fumed white carbon black with an average specifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com