Solvent-resistant polyurethane composite and preparation method thereof

A composite material and polyurethane technology, applied in the field of organic compounds, can solve the problems of poor mechanical properties and solvent resistance of polyurethane materials, limit the use of polyurethane materials, and adverse effects of production operations, etc., to achieve good dynamic mechanical properties and slow down damage , the effect of increasing the crosslink density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

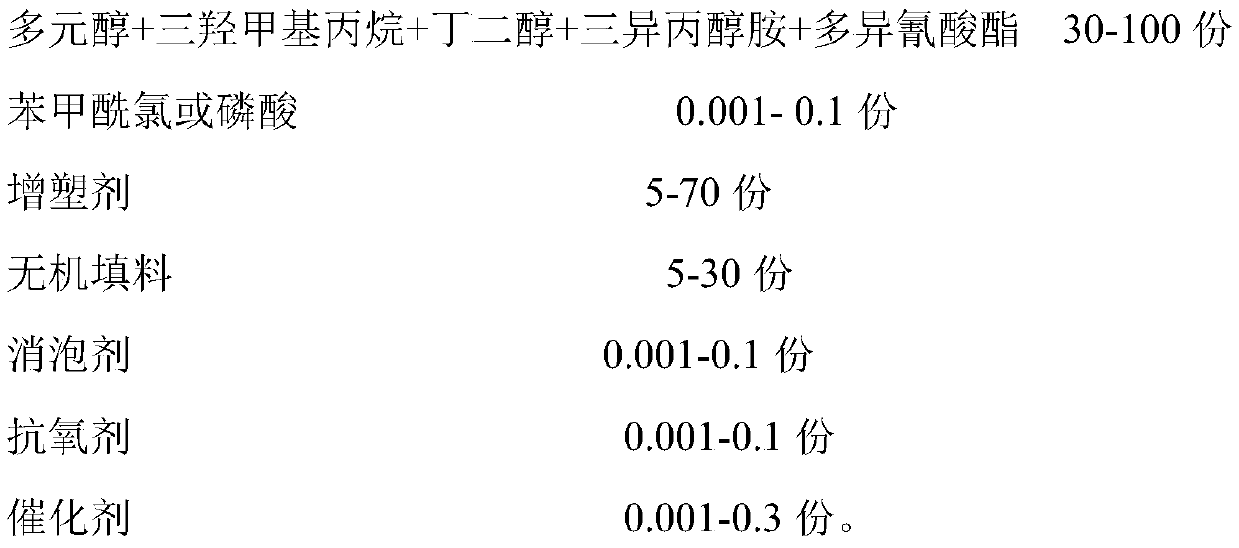

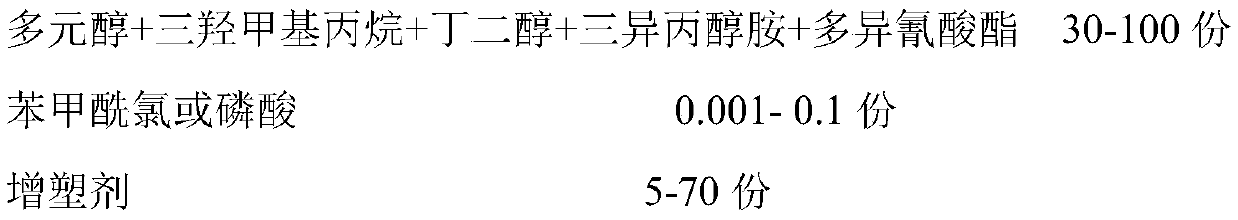

Method used

Image

Examples

Embodiment example 1

[0039] 1 Preparation of solvent-resistant polyurethane composites.

[0040] 1.1 Preparation of Component A

[0041] Weigh 300g of polyadipate polyol (weight average molecular weight: 2000Mw) in component A in a container with agitator, polysuccinate polyol (weight average molecular weight: 2000Mw) in component A 700g, 0.5g of benzoyl chloride in component A, component B: 300g of dimethoxyethyl phthalate, component C: 150g of molecular sieve, 0.3g of antioxidant in component E, the antioxidant The agent is a phenolic antioxidant, specifically antioxidant-264, chemical name 2,6-di-tert-4-methylphenol, stirred in an environment of 80-100°C, and the mixed material is uniformly dispersed using a colloid mill.

[0042]Weigh 1000g of the dispersed mixed material in a closed container with a stirrer and vacuum dehydrate it for 2.5 hours under the environment of 115±5°C. The vacuum degree of dehydration is between 0.095-0.01mpa. When the temperature is lowered below 60°C, add 200g of...

Embodiment example 2

[0055] 1 Preparation of solvent-resistant polyurethane composites.

[0056] 1.1 Preparation of Component A

[0057] Weigh polyadipate polyol (weight average molecular weight 2000Mw) in A component in a container with stirrer, 500g, polysuccinate polyol (weight average molecular weight 2000Mw) 500g, benzoyl chloride / Phosphoric acid mixture 0.5g, B component dimethoxyethyl phthalate 100g, C component: inorganic filler white carbon black 145g, titanium dioxide 5g, E component antioxidant 0.3g (same as

Embodiment 1

[0058] Example 1), stirring in an environment of 80-100° C., and using a colloid mill to evenly disperse the mixed material.

[0059] Weigh 1000g of the dispersed mixed material in a closed container with a stirrer and vacuum dehydrate it for 2.5 hours under the environment of 115±5°C. The vacuum degree of dehydration is between 0.095-0.01mpa. When the temperature drops below 60°C, add 232g of F component (F component is liquefied diphenylmethane diisocyanate), slowly heat to 80±5°C, and keep it warm for 1.5 hours, which is the prepared prepolymer. Analyze the prepolymer The NCO% content of the body can be used.

[0060] 1.2 Preparation of component B

[0061] Weigh component D in a closed container with a stirrer: butanediol 31g, trimethylolpropane 11g, component B: dimethoxyethyl phthalate 300g, component E: catalyst 0.5g , defoamer 0.5g (same as embodiment 1), antioxidant 0.5g (same as embodiment 1), catalyzer is a lead catalyst, vacuum dehydration 2.5 hours under the env...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com