Laptop cooling pad, injection molding system for producing same and injection molding process for producing same

An injection molding system, notebook technology, applied in the direction of instruments, electrical digital data processing, digital data processing parts, etc., can solve the problems of general cushioning effect, easy to slip, not soft enough, etc., to achieve good cushioning effect and adhesion. Good and productive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

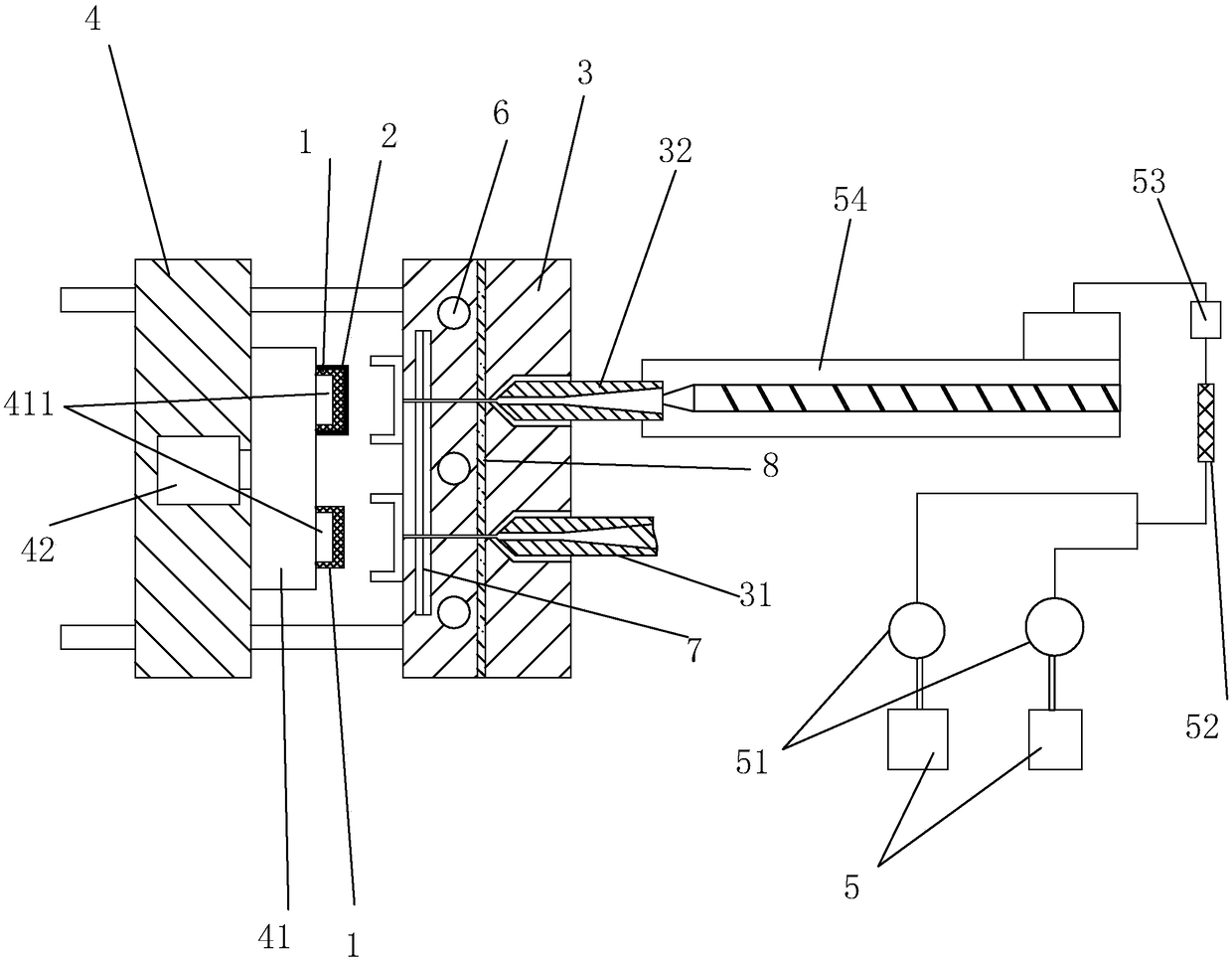

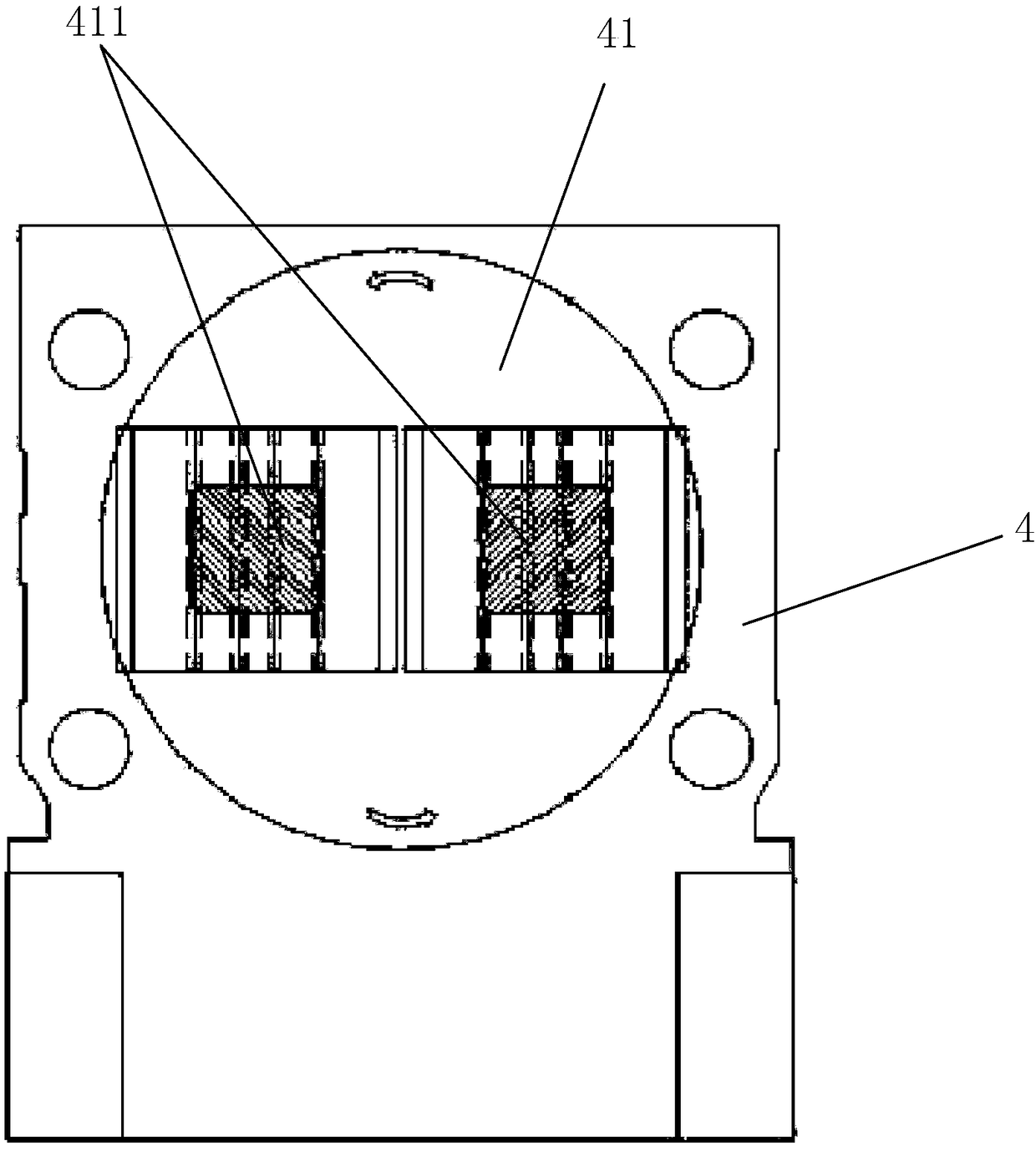

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

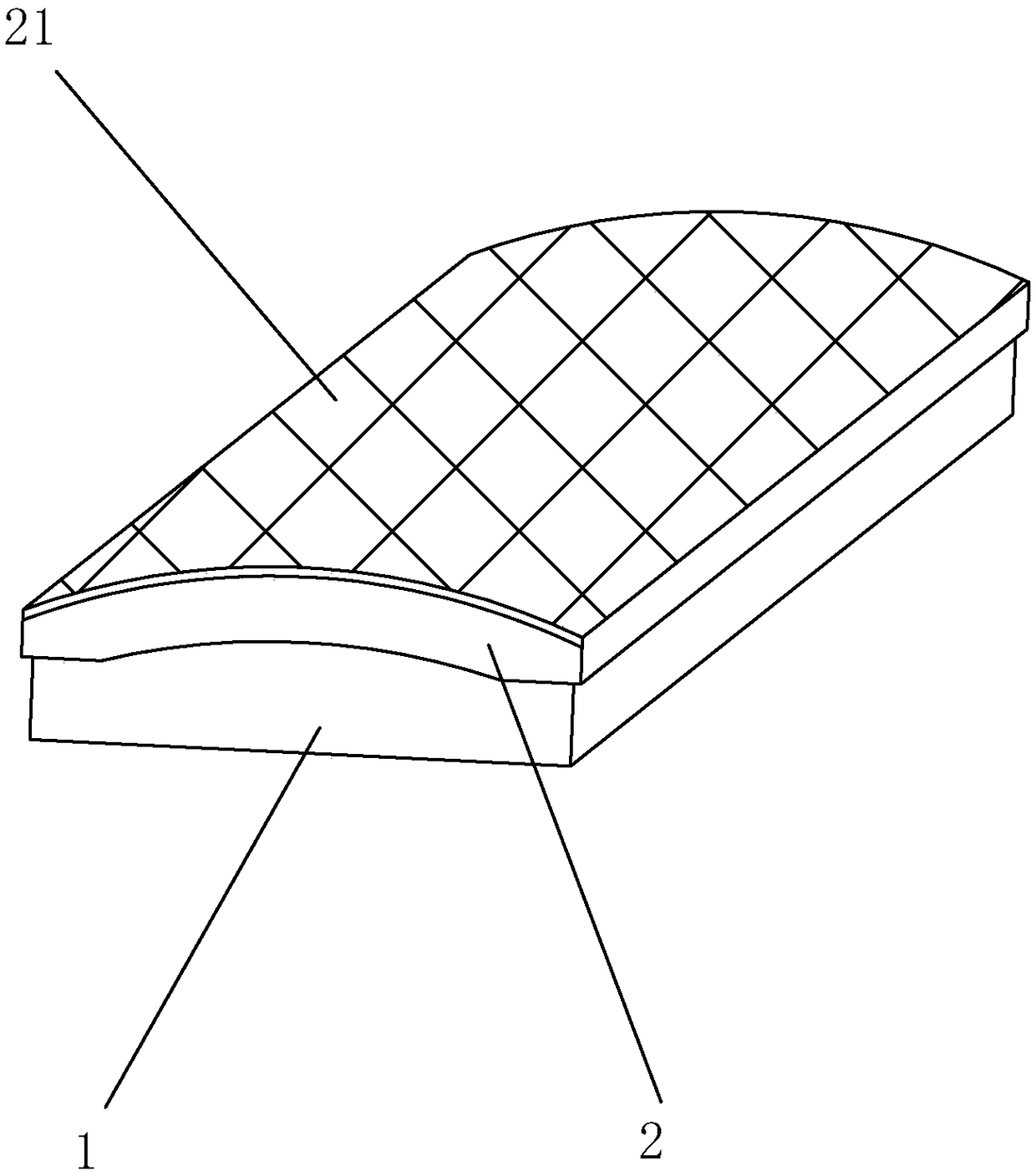

[0036] A notebook foot pad, as shown in the figure, it includes a foot pad core 1 formed by injection molding of thermoplastics, the bottom surface of the foot pad core 1 is bonded with an LSR layer 2 for contacting the placement surface of the notebook, and the LSR layer 2 binds the foot The pad core 1 is half packed, the foot pad core 1 is installed on the bottom case of the notebook through buckles or glue, and the LSR layer 2 is in contact with the desktop and other placement surfaces. LSR layer 2 is a mixture of silica gel and vinyl and reinforcing fillers, which can be cured at high temperature, has good flexibility and excellent cushioning effect; the thickness of LSR layer 2 is between 0.2mm-0.5mm, and the thickness of LSR layer 2 is 0.2mm When it is between -0.5mm, the fluidity decreases, which is convenient for curing after setting.

[0037] Foot p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com