Environmental protection modified melamino-formaldehyde melamine resin foam material and preparation method

A technology for melamine formaldehyde melamine and resin foam, which is applied in the field of environment-friendly modified melamine formaldehyde melamine resin foam material and preparation, can solve the problems of lack of technology and process, and achieve the effects of low production cost, cost reduction and shrinkage reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

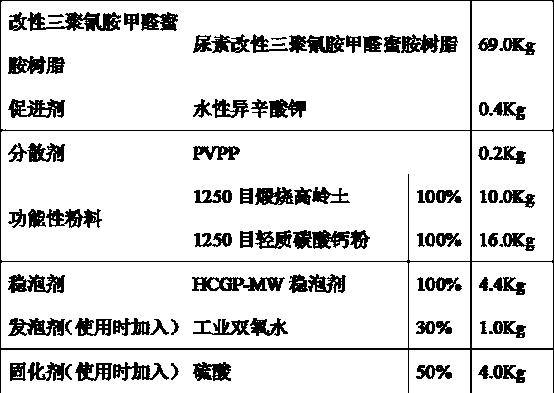

[0026] An environmentally friendly modified melamine-formaldehyde melamine resin foam material provided in this example, its weight percentage composition is shown in Table 1.

[0027] In the present embodiment, the weight percentages of the above-mentioned components are as shown in Table 1:

[0028]

[0029] Note: 1g of hydrogen peroxide can produce 0.33L of oxygen, and 1g of aluminum powder can produce 1.24L of hydrogen.

[0030] Preparation:

[0031] (1) Weigh the modified melamine formaldehyde melamine resin and add it to the stirring tank, then add the accelerator and dispersant and stir for 5-10 minutes, then add the functional powder and stir for 10-15 minutes, add the foam stabilizer and stir for 5-10 minutes, that is Modified melamine formaldehyde melamine resin foaming material is prepared.

[0032] (2) Take the modified melamine-formaldehyde melamine resin foaming material prepared above, add foaming agent and curing agent in turn, stir at high speed for 1-2 m...

Embodiment 2

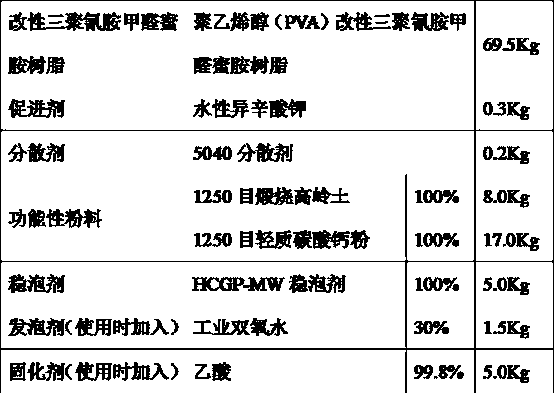

[0034] An environmentally friendly modified melamine-formaldehyde melamine resin foam material provided in this example, its weight percentage composition is shown in Table 2.

[0035] In the present embodiment, the weight percent of above-mentioned each component is as shown in table 2:

[0036]

[0037] Note: 1g of hydrogen peroxide can produce 0.33L of oxygen, and 1g of aluminum powder can produce 1.24L of hydrogen.

[0038] Preparation:

[0039] (1) Weigh the modified melamine formaldehyde melamine resin and add it to the stirring tank, then add the accelerator and dispersant and stir for 5-10 minutes, then add the functional powder and stir for 10-15 minutes, add the foam stabilizer and stir for 5-10 minutes, that is Modified melamine formaldehyde melamine resin foaming material is prepared.

[0040](2) Take the modified melamine-formaldehyde melamine resin foaming material prepared above, add foaming agent and curing agent in turn, stir at high speed for 1-2 minutes...

Embodiment 3

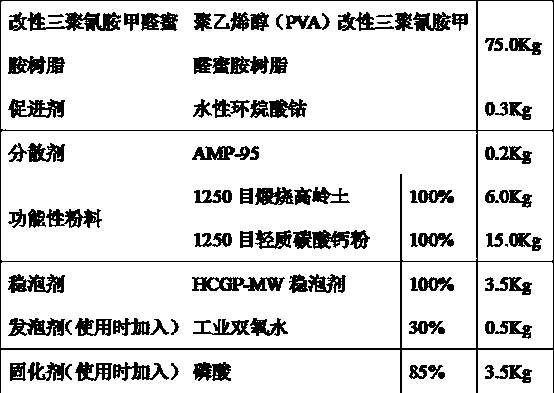

[0042] An environmentally friendly modified melamine-formaldehyde melamine resin foam material provided in this example, its weight percentage composition is shown in Table 3.

[0043] In the present embodiment, the weight percent of above-mentioned each component is as shown in table 3:

[0044]

[0045] Note: 1g of hydrogen peroxide can produce 0.33L of oxygen, and 1g of aluminum powder can produce 1.24L of hydrogen.

[0046] Preparation:

[0047] (1) Weigh the modified melamine formaldehyde melamine resin and add it to the stirring tank, then add the accelerator and dispersant and stir for 5-10 minutes, then add the functional powder and stir for 10-15 minutes, add the foam stabilizer and stir for 5-10 minutes, that is Modified melamine formaldehyde melamine resin foaming material is prepared.

[0048] (2) Take the modified melamine-formaldehyde melamine resin foaming material prepared above, add foaming agent and curing agent in turn, stir at high speed for 1-2 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com