Steel plate conveying belt for conveying metal plates, and preparation method thereof

A technology for metal sheets and conveyor belts, which is applied in the field of conveyor belts, can solve problems such as poor shock absorption performance, and achieve the effects of enhancing scratch resistance, reducing energy consumption, and less loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

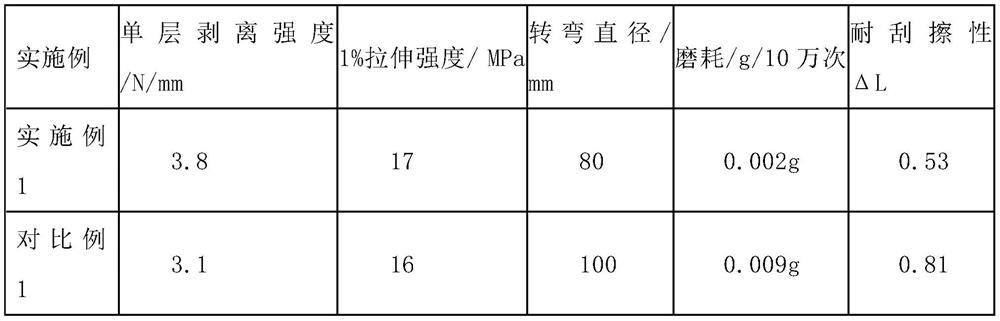

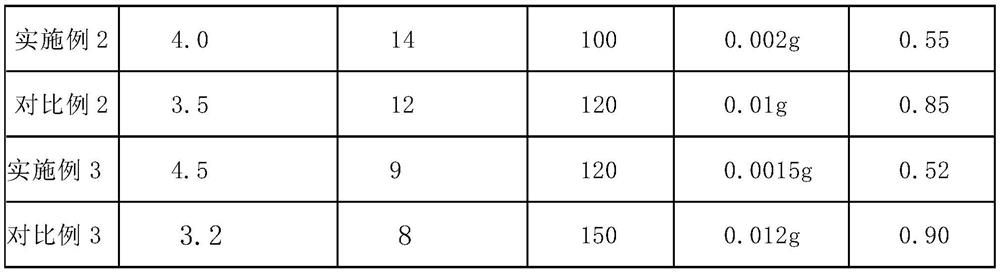

Examples

Embodiment 1

[0030] The steel plate conveyer belt that is used for metal plate conveying in this embodiment is prepared by following steps:

[0031] (1) The high-strength fabric skeleton is composed of warp threads and weft threads, the warp threads are composed of polyarylate liquid crystal fibers and polyester fibers, the polyarylate liquid crystal fibers are 20%, and the weft threads are composed of polyester monofilaments;

[0032] (2) coat PU glue at the bottom of both sides of the high-strength fabric skeleton, and dry to obtain the high-strength fabric skeleton coated with PU glue;

[0033] (3) Mix 100 parts of foamed TPU particles with a diameter of 3-5 mm and 10 parts of solvent-free two-component polyurethane glue, mix them evenly at 60 ° C, and apply them to the coated PU prepared in step (2) within 3 minutes The high-strength fabric skeleton of the glue is baked in an oven at 120°C for 10 minutes, the surface is slightly dry, covered with a cold water roll and cooled to 40°C, p...

Embodiment 2

[0040] The conveyor belt used for sheet metal conveying in this embodiment is prepared by the following steps:

[0041] (1) The high-strength fabric skeleton is composed of warp threads and weft threads, the warp threads are composed of polyarylate liquid crystal fibers and polyester fibers, the polyarylate liquid crystal fibers are 40%, and the weft threads are composed of polyester monofilaments;

[0042] (2) coat PU glue at the bottom of both sides of the high-strength fabric skeleton, and dry to obtain the high-strength fabric skeleton coated with PU glue;

[0043] (3) Mix 100 parts of foamed TPU particles with a diameter of 3-5 mm and 40 parts of solvent-free two-component polyurethane glue, mix them evenly at 80 ° C, and apply them to the coated PU prepared in step (2) within 4 minutes with a spatula The high-strength fabric skeleton of the glue is baked in an oven at 100°C for 5 minutes, the surface is slightly dry, covered with a cold water roll and cooled to 50°C, and...

Embodiment 3

[0050] The conveyor belt used for sheet metal conveying in this embodiment is prepared by the following steps:

[0051] (1) The high-strength fabric skeleton is composed of warp threads and weft threads, the warp threads are composed of polyarylate liquid crystal fibers and polyester fibers, the polyarylate liquid crystal fibers are 50%, and the weft threads are composed of polyester monofilaments;

[0052] (2) coat PU glue at the bottom of both sides of the high-strength fabric skeleton, and dry to obtain the high-strength fabric skeleton coated with PU glue;

[0053] (3) Mix 100 parts of foamed TPU particles with a diameter of 3-6 mm and 50 parts of solvent-free two-component polyurethane glue, mix them evenly at 70 ° C, and apply them to the coated PU prepared in step (2) within 10 minutes with a spatula The high-strength fabric skeleton of the glue is baked in an oven at 120°C for 10 minutes, the surface is slightly dry, covered with cold water rolls and cooled to 60°C, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com