Buffering air bag with opening preset in air column turning region and method for manufacturing buffering air bag

A cushioning airbag and manufacturing method technology, applied to the cushioning airbag with a preset opening in the turning area of the air column and its manufacturing field, can solve the problems of protruding bottom, protruding outward, and the bent area of the bottom cannot show a flat shape, etc., to achieve Strengthen the cushioning effect, reduce the outer box, and increase the effect of cushioning elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

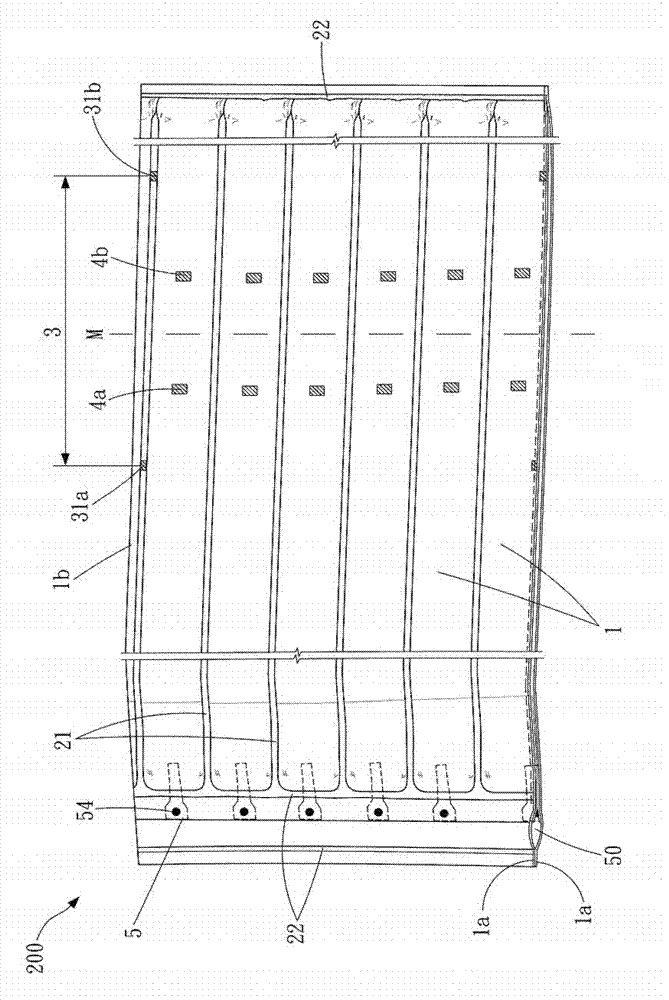

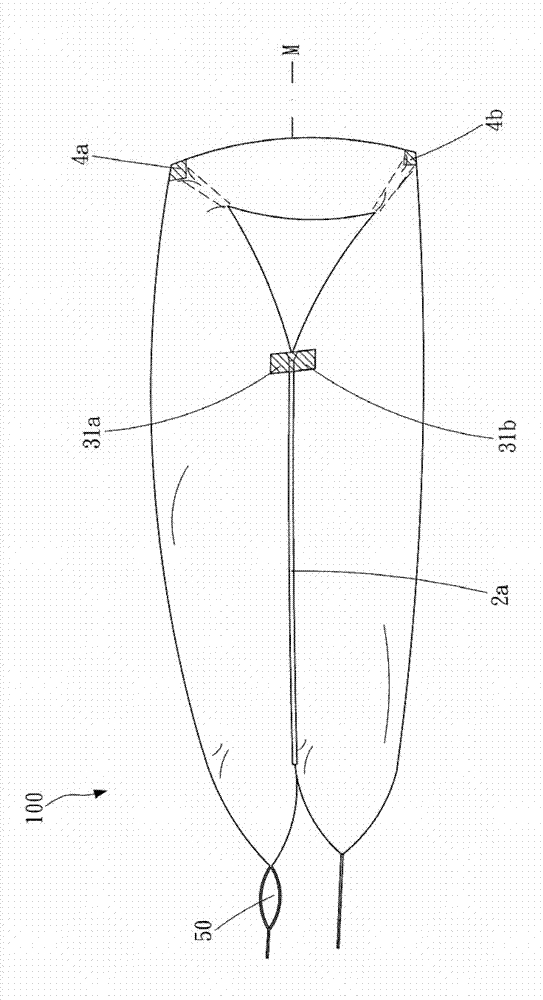

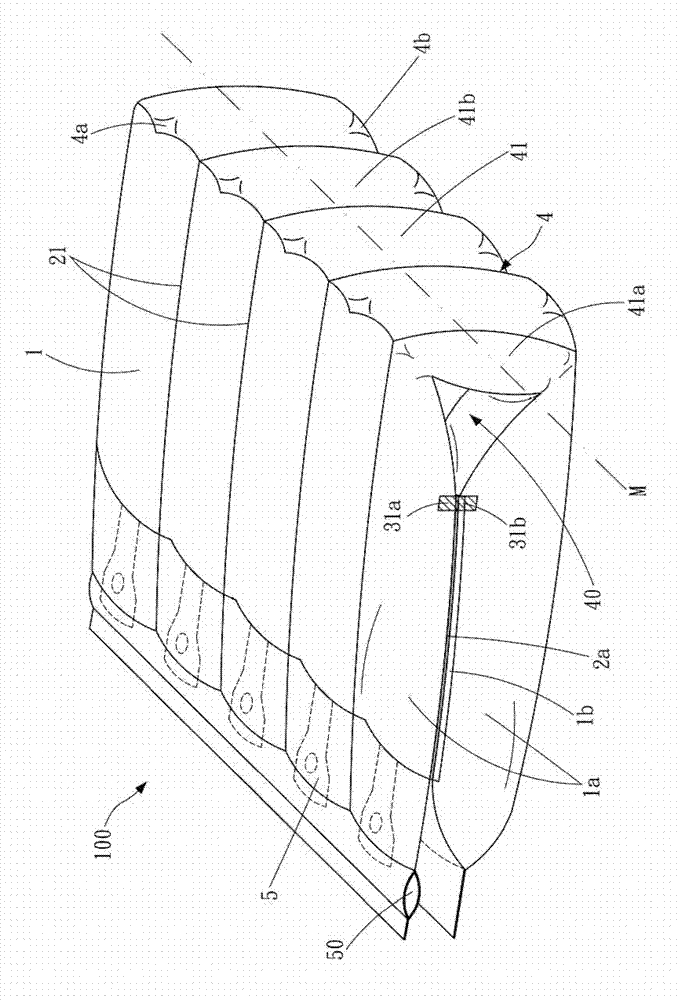

[0077] see figure 1 , figure 2 , image 3 and Figure 4 , which is a buffer air bag with a predetermined opening in the turning area of the air column disclosed in the present invention.

[0078] The buffer air bag with the preset opening in the air column transition area of the embodiment of the present invention includes:

[0079] An air column sheet 200 is composed of a plurality of vertical heat-sealing lines 21 and a plurality of horizontal heat-sealing lines 22 followed by two outer films 1a to form a plurality of air columns 1;

[0080] A plurality of turning points 4a, 4b are formed by heat-sealing the outer films 1a on the air columns 1 or the vertical heat-sealing lines 21;

[0081] A turning midline M, located on the air column sheet 200, substantially parallel to the transverse heat-sealing line 22;

[0082] A plurality of nodes 31a, 31b are located on both sides of the turning centerline M, and are separated from the turning centerline M by a preset dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com