Conductive concrete composition capable of being rapidly cured and molded, preparation method and application thereof

A conductive concrete, fast curing technology, applied in the field of conductive concrete materials, can solve the problem of less research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

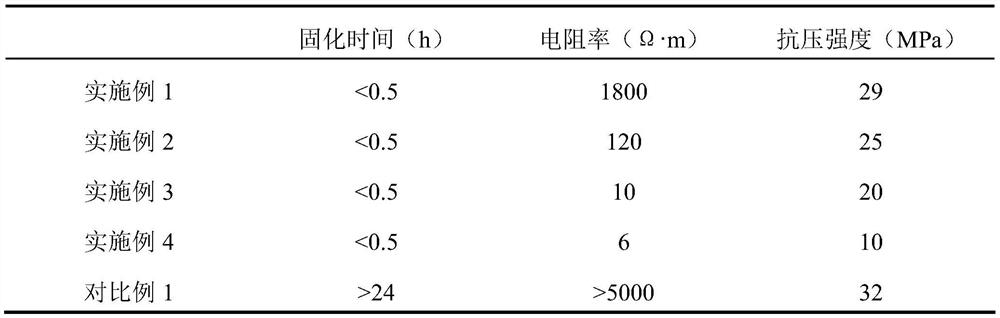

Examples

preparation example Construction

[0030] Another aspect of the embodiments of the present invention provides the preparation method of any one of the aforementioned conductive concrete compositions that can be quickly cured and molded, which includes: quickly curing cement, graphene, graphene dispersant, conductive filler and water Mixing, stirring and dispersing to prepare the rapidly curing and forming conductive concrete composition.

[0031] Further, the preparation process of the rapidly solidified conductive concrete composite material is:

[0032] The first step is to add the fast-curing cement powder into the high-speed mixer, then start stirring, then add the semi-solid dispersed graphene slurry and other conductive fillers, stir and disperse at high speed for 15-20 minutes, and then stir at low speed for 2-3 minutes , to prepare a conductive concrete composite material that can be quickly solidified.

[0033] In the second step, based on the conductive concrete composite material prepared in the first...

Embodiment 1

[0039] The composition of the conductive concrete composition that can be cured rapidly in the present embodiment is as follows:

[0040] Phosphorus magnesium cement: 100 parts, 3-day compressive strength is 48.1MPa, 3-day flexural strength is 7.1MPa.

[0041] Graphene: 0.05 parts.

[0042] Graphene dispersant: 0.5 parts

[0043] Conductive filler: graphite (5 parts), carbon fiber (1 part), carbon black (24 parts).

[0044] Mixing water: 25 parts, tap water in Ningbo City.

[0045] The preparation steps are as follows:

[0046] Add the fast-curing cement powder into the high-speed mixer, then start stirring, then add the semi-solid dispersed graphene slurry and conductive filler, carry out high-speed stirring and dispersing for 15-20 minutes, and then stir at low speed for 2-3 minutes. Cured into a conductive concrete composition.

[0047] Based on the conductive concrete composite material prepared above, add water and a small amount of water reducer to make conductive c...

Embodiment 2

[0049] The composition of the conductive concrete composition that can be cured rapidly in the present embodiment is as follows:

[0050] Phosphorus magnesium cement: 100 parts, 3-day compressive strength is 48.1MPa, 3-day flexural strength is 7.1MPa.

[0051] Graphene: 0.5 parts.

[0052] Graphene dispersant: 1 part

[0053] Conductive filler: graphite (15 parts), carbon fiber (1 part), carbon black (14 parts).

[0054] Mixing water: 25 parts, tap water in Ningbo City.

[0055] The preparation steps are as follows:

[0056] Add the fast-curing cement powder into the high-speed mixer, then start stirring, then add the semi-solid dispersed graphene slurry and conductive filler, carry out high-speed stirring and dispersing for 15-20 minutes, and then stir at low speed for 2-3 minutes. Cured and formed conductive concrete composite

[0057] Based on the conductive concrete composite material prepared above, add water and a small amount of water reducer to make conductive con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com