Preparation method of polyurethane modified phenolic resin composition for semiconductor packaging

A technology of polyurethane modification and phenolic resin, which is applied in the direction of epoxy resin glue, adhesive type, adhesive, etc., can solve the problems of poor compatibility, high interfacial tension, and inability to take into account other properties of materials, and achieve weather resistance and mechanical properties. Excellent strength, reduced stress, lower dielectric constant and lower water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

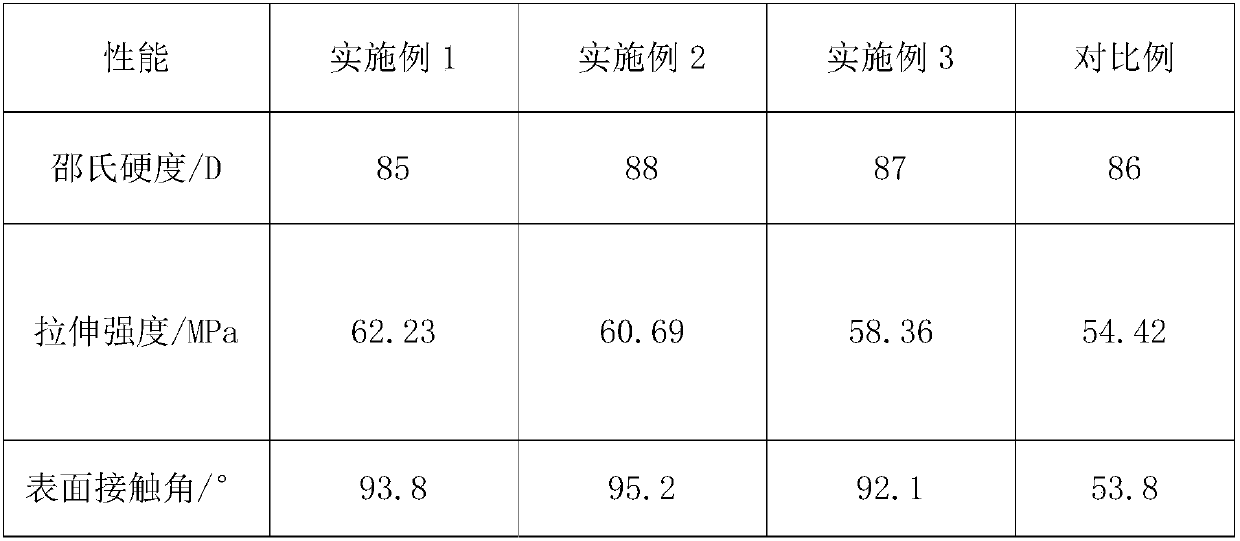

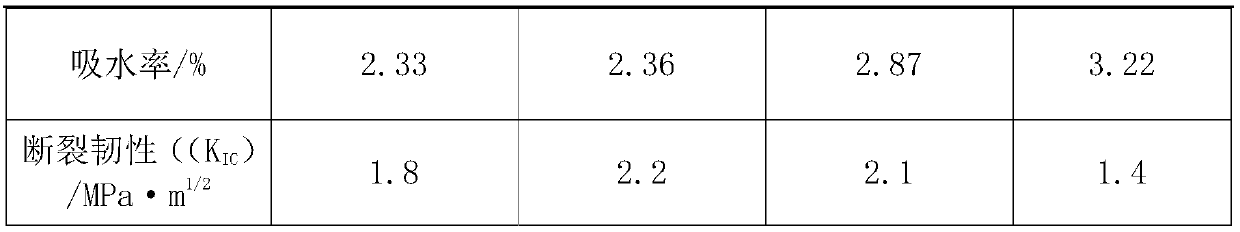

Examples

Embodiment 1

[0028] Add 450ml of isopropanol, 336g of hexafluorobisphenol A, 100g of bisphenol A to a 2-liter reaction kettle with a thermometer, a stirrer and a reflux condenser, and stir at 60°C to make the hexafluorobisphenol A and bisphenol A fully dissolve. Then 5 g of oxalic acid was added and the temperature was raised to 80°C. Add a total of 90g of paraformaldehyde in batches, about 10g for the first feeding, and about 8g for each subsequent feeding. Control the feeding time within 45 minutes. After feeding, the temperature was raised to 95°C, and the reaction was vigorously stirred for about 5 hours. The temperature was raised to 160° C., and the mixture was distilled under reduced pressure under a vacuum of -0.8 MPa, and the solvent was condensed and recovered through a condenser to obtain a fluorine-containing phenolic resin preparatory solution.

[0029] Add isophorone diisocyanate (IPDI) and polyphenolic propane into another reaction kettle in a molar ratio of 2:1, and reac...

Embodiment 2

[0031] Add 450 ml of toluene, 400 g of trifluoromethyl phenol, 50 g of phenol and 8 g of benzoic acid to a 2-liter reaction kettle with a thermometer, a stirrer and a reflux condenser, and stir at 60°C to fully dissolve the trifluoromethyl phenol and phenol. . Then 8 g of benzoic acid were added and the temperature was raised to 80°C. Then 60 g of paraformaldehyde was dissolved in methanol at a ratio of 1:6, and added to the trifluoromethylphenol and phenol solution at a drop rate of 1 drop per second. Control the feeding time within 45 minutes. After feeding, the temperature was raised to 95°C, and the reaction was vigorously stirred for about 5 hours. The temperature was raised to 160° C., and the mixture was distilled under reduced pressure under a vacuum of -0.8 MPa, and the solvent was condensed and recovered through a condenser to obtain a fluorine-containing phenolic resin preparatory solution.

[0032] Toluene diisocyanate (TDI) and polyethylene glycol were added in...

Embodiment 3

[0034] Add 450 ml of toluene and 500 g of hexafluorobisphenol A, 250 g of p-cresol and 6 g of salicylic acid into a 2-liter reactor with a thermometer, a stirrer and a reflux condenser at the same time, and stir at 60 °C to make hexafluorobisphenol A. Phenol A and p-cresol were fully dissolved. Then 6 g of salicylic acid was added and the temperature was raised to 80°C. Then, 90 g of paraformaldehyde was dissolved in methanol at a ratio of 1:6, and added to the solution of hexafluorobisphenol A and p-cresol at a drop rate of 1 drop per second. Control the feeding time within 45 minutes. After feeding, the temperature was raised to 95°C, and the reaction was vigorously stirred for about 5 hours. The temperature was raised to 160° C., and the mixture was distilled under reduced pressure under a vacuum of -0.8 MPa, and the solvent was condensed and recovered through a condenser to obtain a fluorine-containing phenolic resin preparatory solution.

[0035] Add isophorone diisocy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com