Cellulose nanocrystal-polyacrylamide double-network hydrogel and preparation method thereof

A technology of polyacrylamide and cellulose, applied in the field of photoinitiated preparation of double-network hydrogel, which can solve the problems of poor water solubility and poor mechanical properties of cellulose, and achieve the effect of enhancing water absorption and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

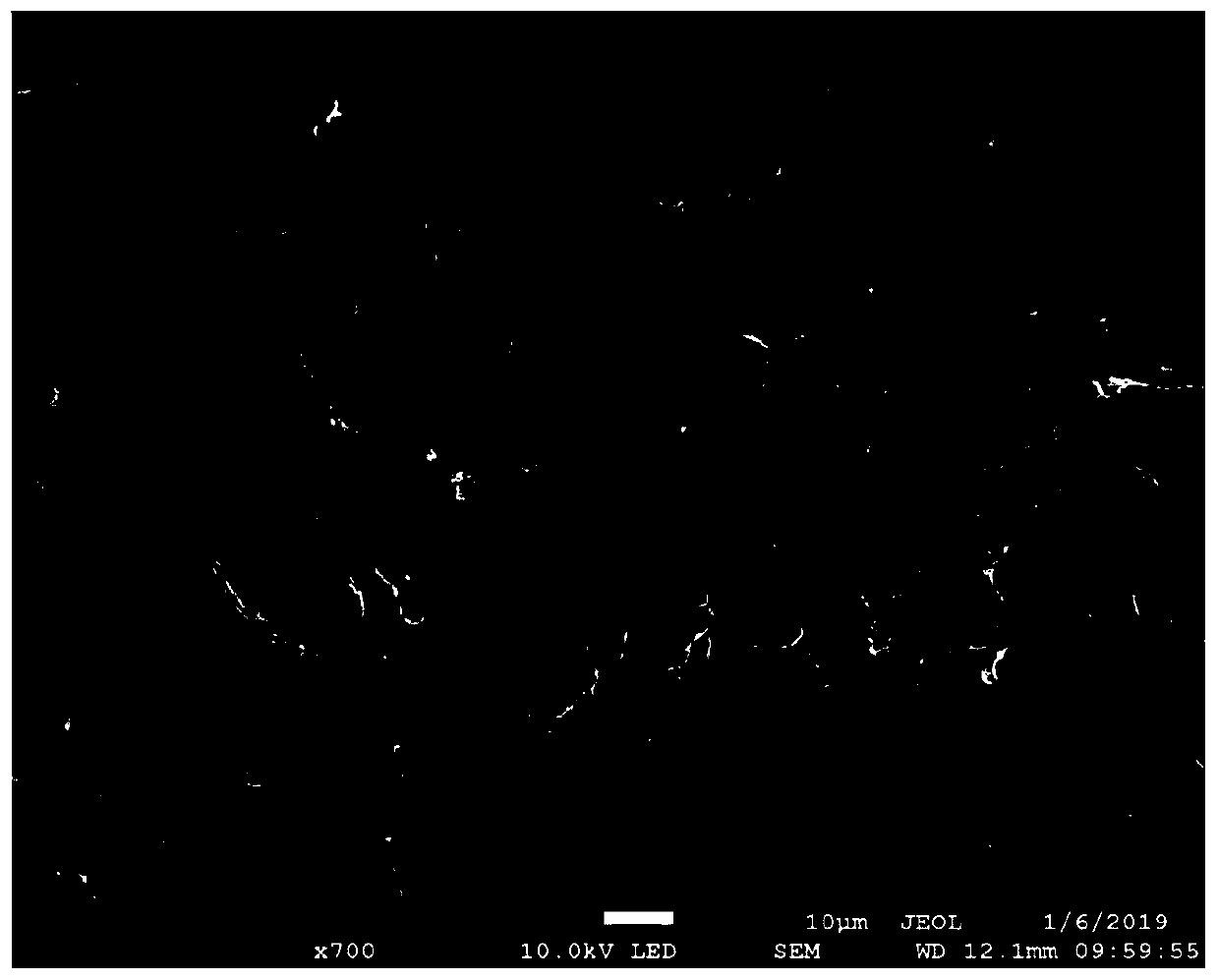

[0033] The first embodiment of the present invention provides a cellulose nanocrystal, polymer cement slurry containing 4wt% cellulose nanocrystal cement slurry and 96wt% acrylamide monomer, prepared by photoinitiation method under the condition of pH=7. A method for acrylamide double network hydrogels.

[0034] The preparation method comprises the steps in turn:

[0035] Step 1: Preparation of cellulose nanocrystals—acid hydrolyze microcrystalline cellulose with 64wt% concentrated sulfuric acid, and then stand still, high-speed centrifugation, and dialysis to obtain cellulose nanocrystal cement slurry, which is prepared with deionized water to pH=7. Concentration is the cement slurry of 10wt%;

[0036] Step 2: Preparation of mixed solution - 0.69g cellulose nanocrystal cement slurry, 1.8g acrylamide, 10.52mg photoinitiator Irgacure2959, 1.18mg N,N'-methylenebisacrylamide, 36μL glutaraldehyde Dissolve together in 10mL deionized water, stir well, heat at 60°C for 20min, and v...

Embodiment 2

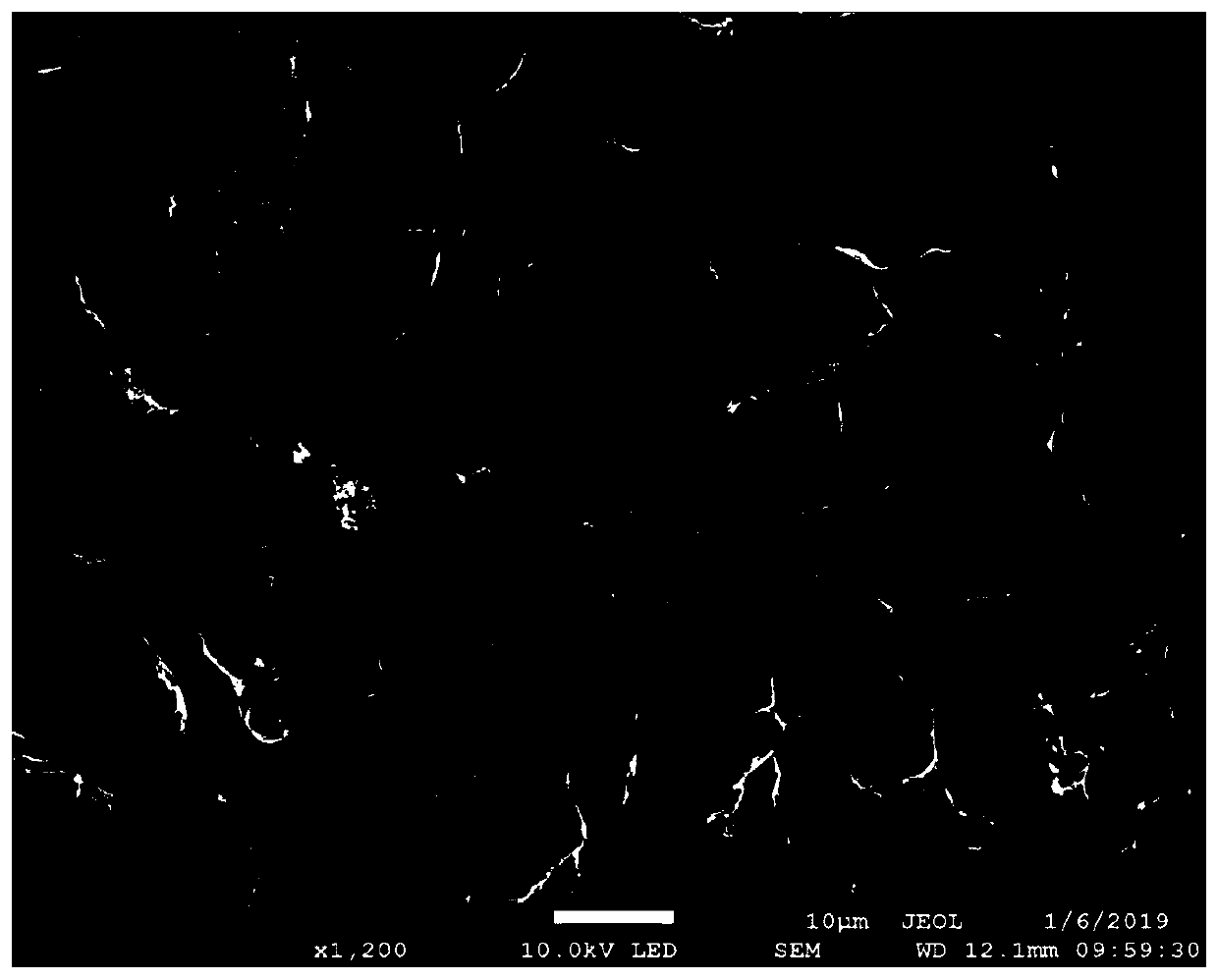

[0040] The second embodiment of the present invention provides a cellulose nanocrystal, polymer cement slurry containing 8wt% cellulose nanocrystal cement slurry and 92wt% acrylamide monomer, prepared by photoinitiation method under the condition of pH=7. A method for acrylamide double network hydrogels.

[0041] The preparation method comprises the steps in turn:

[0042] Step 1: Preparation of cellulose nanocrystals—acid hydrolyze microcrystalline cellulose with 64wt% concentrated sulfuric acid, and then stand still, high-speed centrifugation, and dialysis to obtain cellulose nanocrystal cement slurry, which is prepared with deionized water to pH=7. Concentration is the cement slurry of 10wt%;

[0043] Step 2: Preparation of mixed solution - 1.38g cellulose nanocrystal cement slurry, 1.8g acrylamide, 10.52mg photoinitiator Irgacure2959, 1.18mg N,N'-methylenebisacrylamide, 36μL glutaraldehyde in sequence Dissolve together in 10mL deionized water, stir well, heat at 60°C for...

Embodiment 3

[0047] The third embodiment of the present invention provides a cellulose nanocrystal, polymer cement slurry containing 12wt% cellulose nanocrystal cement slurry and 88wt% acrylamide monomer, prepared by photoinitiation method under the condition of pH=7. A method for acrylamide double network hydrogels.

[0048] The preparation method comprises the steps in turn:

[0049]Step 1: Preparation of cellulose nanocrystals—acid hydrolyze microcrystalline cellulose with 64wt% concentrated sulfuric acid, and then stand still, high-speed centrifugation, and dialysis to obtain cellulose nanocrystal cement slurry, which is prepared with deionized water to pH=7. Concentration is the cement slurry of 10wt%;

[0050] Step 2: Preparation of mixed solution - 2.07g cellulose nanocrystal cement slurry, 1.8g acrylamide, 10.52mg photoinitiator Irgacure2959, 1.18mg N,N'-methylenebisacrylamide, 36μL glutaraldehyde in sequence Dissolve together in 10mL deionized water, stir well, heat at 60°C for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com