Method for processing nylon internal polygon and special cutter thereof

A processing method and polygonal technology, applied in the direction of planer/slotting cutters, manufacturing tools, metal processing equipment, etc., can solve the problems of rough processing surface and unsatisfactory use requirements, and achieve good product quality and convenient manufacturing technology , The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] This embodiment is the processing method of nylon inner hexagon. The diameter of the inner hexagon in this embodiment is 10mm.

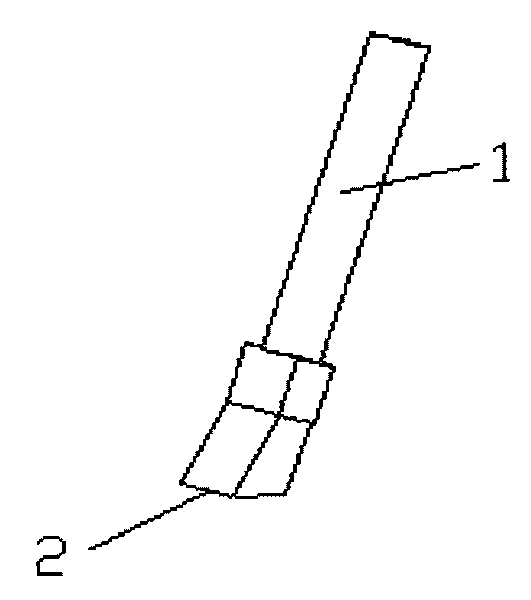

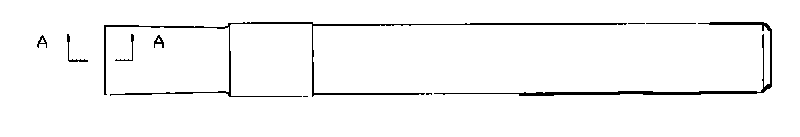

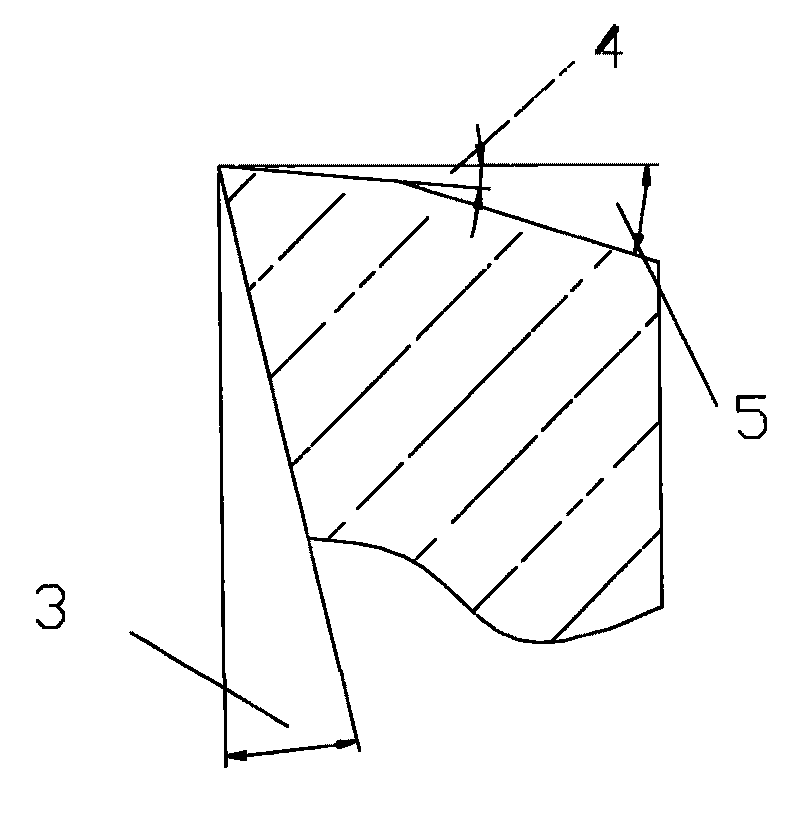

[0019] In this embodiment, the cutter for processing nylon inner hexagon is a special cutter, including a handle 2 and a cutting edge 1 . It is a straight shank single-side insertion knife, and the width of the cutting edge is equal to the side length of the inner hexagon, that is, the width of the cutting layer is the same as the side length of the inner hexagon. The tool material is general W6M 0 5C r Made of 4V2 high-speed steel, its quenching hardness is HRC63-66. There is a chip removal angle between the rake face and the flank of the tool, wherein the rake angle 3 is 10°, the rake angle 4 of the relief angle is 7°, and the relief angle 5 of the relief angle is 12°.

[0020] The processing procedure of this embodiment is:

[0021] The first step is to install the fixture. First, fix the dividing head on the workbench of the machinin...

Embodiment 2

[0026] This embodiment is the processing method of nylon inner octagon. The diameter of the inner octagon of this embodiment is 20mm.

[0027] In this embodiment, the cutter for processing nylon inner octagon is a special cutter, including a handle 2 and a cutting edge 1 . It is a single-side insertion knife with a straight handle, and the width of the cutting edge is equal to the side length of the inner octagon, that is, the width of the cutting layer is the same as the side length of the inner octagon. The tool material is general W6M 0 5C r Made of 4V2 high-speed steel, its quenching hardness is HRC63-66. There is a chip removal angle between the rake face and the flank of the tool, wherein the rake angle 3 is 12°, the rake angle 4 of the relief angle is 10°, and the relief angle 5 of the relief angle is 15°.

[0028] The processing procedure of this embodiment is:

[0029] The first step is to install the fixture. First, fix the dividing head on the workbench of the...

Embodiment 3

[0034] This embodiment is the processing method of nylon inner hexagon. The diameter of the inner hexagon in this embodiment is 32 mm.

[0035] In this embodiment, the cutter for processing nylon inner hexagon is a special cutter, including a handle 2 and a cutting edge 1 . It is a tapered shank single-side insertion knife, and the width of the cutting edge is equal to the side length of the inner hexagon, that is, the width of the cutting layer is the same as the side length of the inner hexagon. The tool material is general W6M 0 5C r Made of 4V2 high-speed steel, its quenching hardness is HRC63-66. There is a chip removal angle between the rake face and the flank of the tool, wherein the rake angle 3 is 8°, the rake angle 4 of the relief angle is 6°, and the relief angle 5 of the relief angle is 9°.

[0036] The processing procedure of this embodiment is:

[0037] The first step is to install the fixture. First, fix the dividing head on the workbench of the machining ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com