Cement waterproofing coating, and preparation method and application thereof

A waterproof coating and cement technology, applied in cement coatings, coatings, etc., can solve the problem of the elongation at break of waterproof coating film not meeting the standard, and achieve the effect of reducing whitening phenomenon, good compactness, and reducing free precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

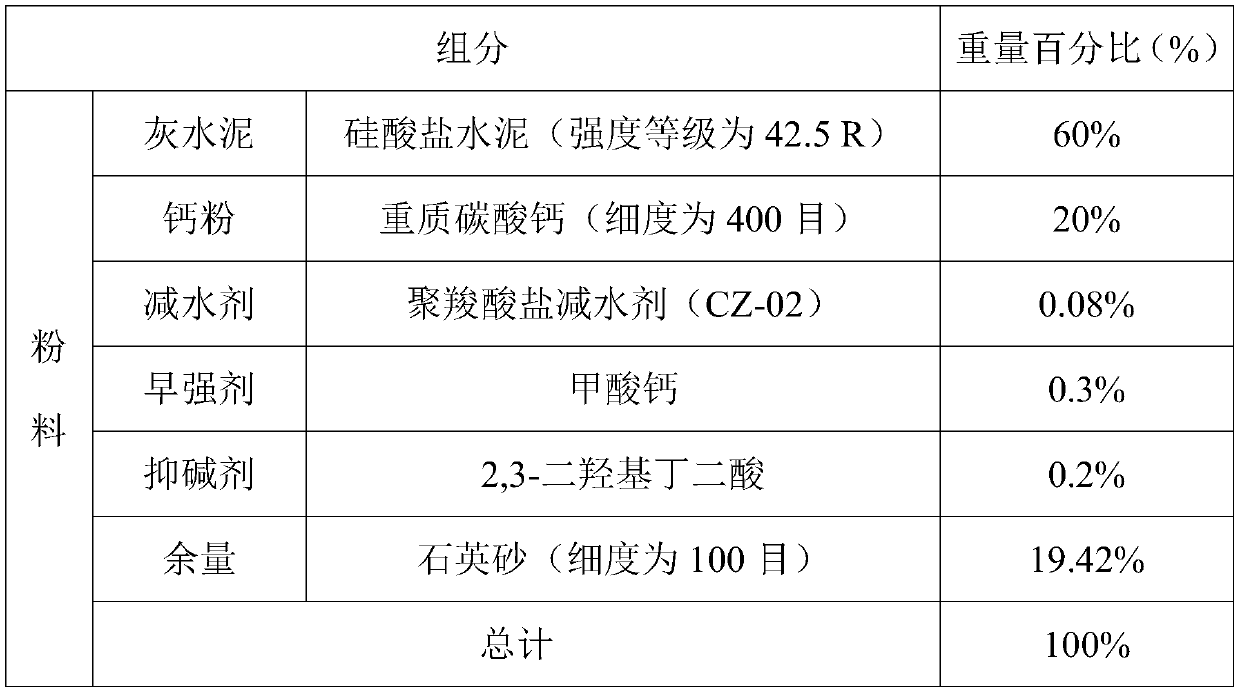

[0070] This embodiment provides a cement waterproof coating, the cement waterproof coating is composed of powder and liquid material, the mass ratio of the powder and liquid material is 1.2:1, the specific composition is as follows:

[0071]

[0072]

[0073] The preparation method of the cement waterproof coating that the present embodiment provides comprises the following steps:

[0074] (1) Mix Portland cement, heavy calcium carbonate, polycarboxylate superplasticizer, calcium formate, tartaric acid and quartz sand at a speed of 300 rpm for 30 minutes according to the formula to obtain powder; , mineral oil defoamer, lauryl alcohol ester, non-associated alkali swelling thickener, nonionic polyurethane thickener and water were mixed and stirred at 1300rpm for 15min to obtain a liquid material;

[0075] (2) Add the powder material to the liquid material, the mass ratio of the powder material and the liquid material is 1.2:1, stir and disperse at a speed of 800rpm for 5m...

Embodiment 2

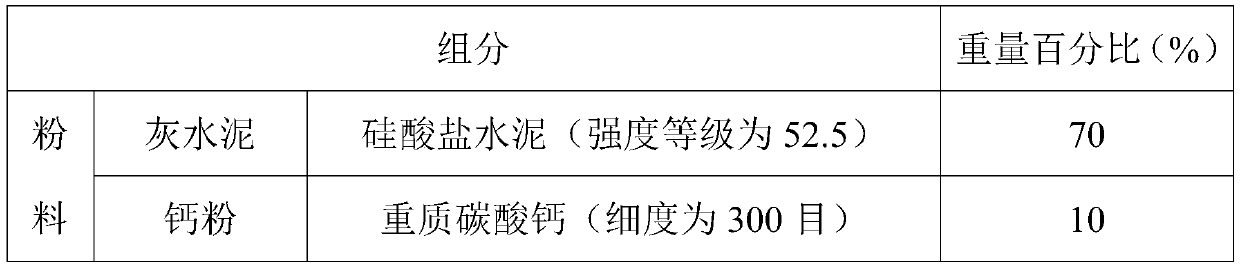

[0077] This embodiment provides a cement waterproof coating, the cement waterproof coating is composed of powder and liquid material, the mass ratio of the powder and liquid material is 1.22:1, the specific composition is as follows:

[0078]

[0079]

[0080] The preparation method of the cement waterproof coating that the present embodiment provides comprises the following steps:

[0081] (1) Mix Portland cement, heavy calcium carbonate, polycarboxylate superplasticizer, calcium formate, tartaric acid and quartz sand at a speed of 300 rpm for 30 minutes according to the formula to obtain powder; , mineral oil defoamer, lauryl alcohol ester, non-associated alkali swelling thickener, nonionic polyurethane thickener and water were mixed and stirred at 1300rpm for 15min to obtain a liquid material;

[0082] (2) Add the powder material to the liquid material, the mass ratio of the powder material and the liquid material is 1.22:1, stir and disperse at a speed of 800rpm for ...

Embodiment 3

[0084] This embodiment provides a cement waterproof coating, the cement waterproof coating is composed of powder and liquid, the mass ratio of the powder and liquid is 1.25:1, the specific composition is as follows:

[0085]

[0086] The preparation method of the cement waterproof coating that the present embodiment provides comprises the following steps:

[0087] (1) Mix Portland cement, heavy calcium carbonate, polycarboxylate superplasticizer, calcium formate, tartaric acid and quartz sand at a speed of 500 rpm for 20 minutes according to the formula to obtain a powder; , mineral oil defoamer, lauryl alcohol ester, non-associated alkali swelling thickener, nonionic polyurethane thickener and water were mixed and stirred at 2000rpm for 10min to obtain a liquid material;

[0088] (2) Add the powder material to the liquid material, the mass ratio of the powder material and the liquid material is 1.25:1, stir and disperse at a speed of 1000rpm for 10min, stand for 2min to br...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com