Cement mortar for fixing low-medium level radioactive sundries and preparation method thereof

A radioactive and cement technology, which is applied in the field of cement-fixed mortar preparation of low and medium level radioactive miscellaneous wastes, can solve problems such as the difficulty in meeting the performance of cement mortar, and achieve the effects of strong engineering operability, simple production process and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

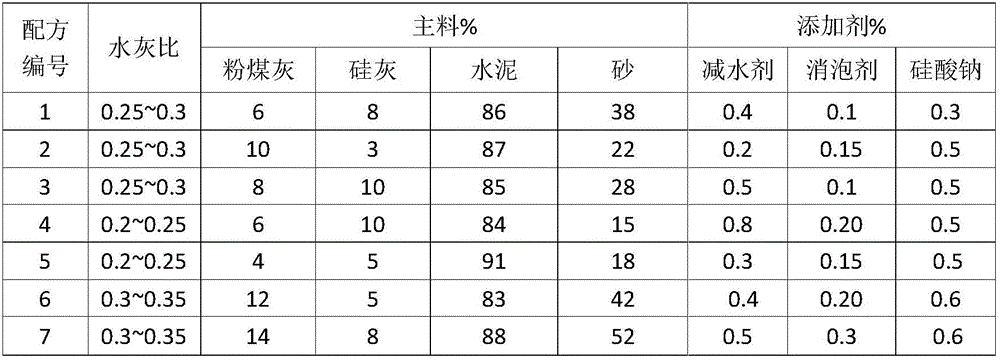

[0032] The preparation method of the cement fixing mortar used for low and medium level radioactive sundries comprises the following steps:

[0033] (1) dispersing the additive in water to make a wet material; mixing fly ash, silica fume, cement and sand evenly to make a dry material, the additive is selected from water reducers, defoamers and sodium silicate;

[0034] (2) After mixing the wet material and dry material evenly, transfer to the cement mortar mixer to stir the mortar. The mixing time is 10 to 20 minutes. After the mortar is prepared, it is divided into poly In the vinyl mold, after the vibration and exhaust are completed on the vibrating table, put it into the curing box for curing. The curing temperature is 25±5°C and the relative humidity is ≥90%. After 28 days of curing, take it out and demould to make a cement mortar sample.

[0035] The testing methods for fluidity, compressive strength and impermeability testing of cement mortar samples are as follows:

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com