Anti-dazzle liquid, and preparation method and application thereof

An anti-glare and anti-glare film technology, which is applied in applications, household appliances, instruments, etc., can solve the problems of not being able to obtain an anti-glare layer, large fog, etc., and achieve reduced scratches, excellent wear resistance, and good anti-glare sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

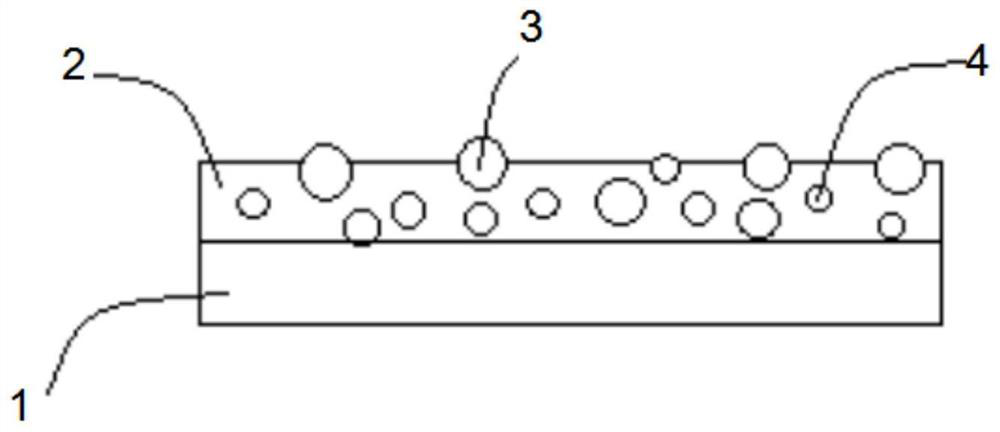

Image

Examples

preparation example Construction

[0051] The second aspect of the embodiment of the present application provides a method for preparing an anti-glare liquid, comprising the following steps:

[0052] S01. Provide each component according to the anti-glare liquid;

[0053] S02. Mixing the first organic particles and the second organic particles with an organic solvent to obtain a first mixture;

[0054] S03. Mixing the UV hardening liquid, the auxiliary agent and the first mixture to obtain the anti-glare liquid.

[0055] The preparation method of the anti-glare liquid provided in the second aspect of the present application, the preparation method only needs to simply mix the various components uniformly to obtain the anti-glare liquid.

[0056] In step S01, the types and addition amounts of the components of the antiglare liquid are selected as discussed above, and will not be repeated here to save space.

[0057] In step S02, the first organic particle and the second organic particle are mixed with an organ...

Embodiment 1

[0068] Antiglare liquid and its preparation method and application

[0069] anti glare fluid

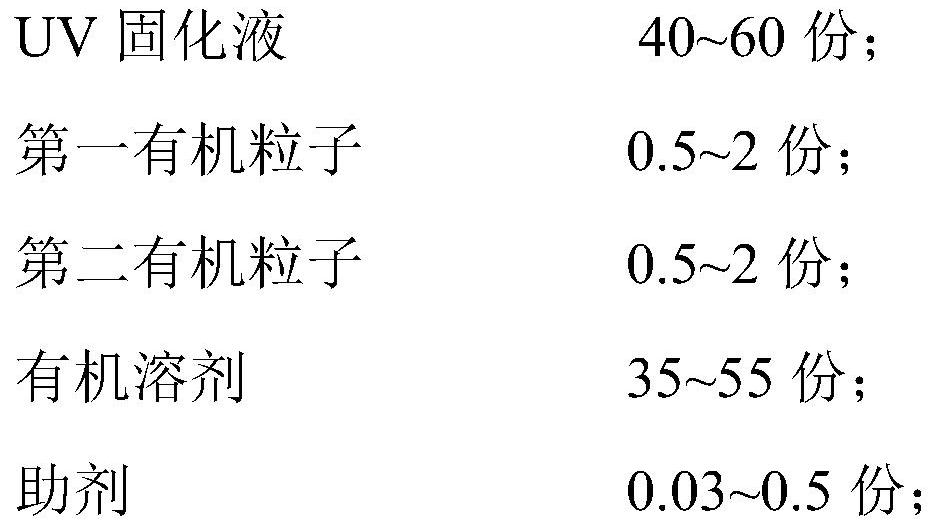

[0070] The antiglare liquid includes the following components in weight percentage:

[0071]

[0072] Wherein, the first organic particles are selected from polystyrene particles with a particle size of 3.5 microns; the second organic particles are selected from polymethyl methacrylate particles with a particle size of 1.8 microns;

[0073] Organic solvent is selected from butyl acetate;

[0074] The auxiliary agent is selected from the leveling agent YCK1310;

[0075] UV curing liquid is selected from UV-3621, including

[0076] Acrylic 45%,

[0077] Propylene Glycol Monomethyl Ether 50%,

[0078] Photoinitiator 5%.

[0079] Preparation method of antiglare liquid

[0080] According to the antiglare liquid of Example 1, each component is provided; the first organic particle and the second organic particle are mixed with an organic solvent to obtain the first mixture; the ...

Embodiment 2

[0085] Antiglare liquid and its preparation method and application

[0086] anti glare fluid

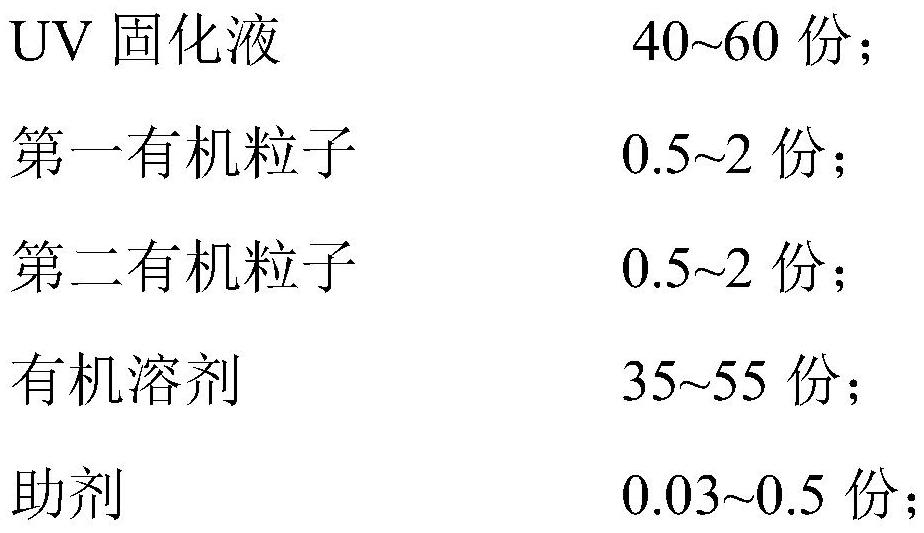

[0087] The antiglare liquid includes the following components in weight percentage:

[0088]

[0089] Wherein, the first organic particles are selected from polystyrene particles with a particle size of 3.5 microns; the second organic particles are selected from polymethyl methacrylate particles with a particle size of 1.8 microns;

[0090] Organic solvent is selected from propylene glycol monomethyl ether;

[0091] The auxiliary agent is selected from the leveling agent YCK1310;

[0092] UV curing liquid is selected from PC15-8120, including

[0093] Acrylic 60%,

[0094] Butyl acetate 35%,

[0095] Photoinitiator 5%,

[0096] Preparation method of antiglare liquid

[0097] According to the antiglare liquid of Example 2, each component is provided; the first organic particle and the second organic particle are mixed with an organic solvent to obtain the first mixture; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com