Gypsum-based colored facing mortar and preparation method thereof

A colored finishing mortar and gypsum-based technology, which is applied in the field of building decoration materials, can solve problems such as efflorescence of the facing mortar, and achieve the effects of good durability, improved physical properties, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

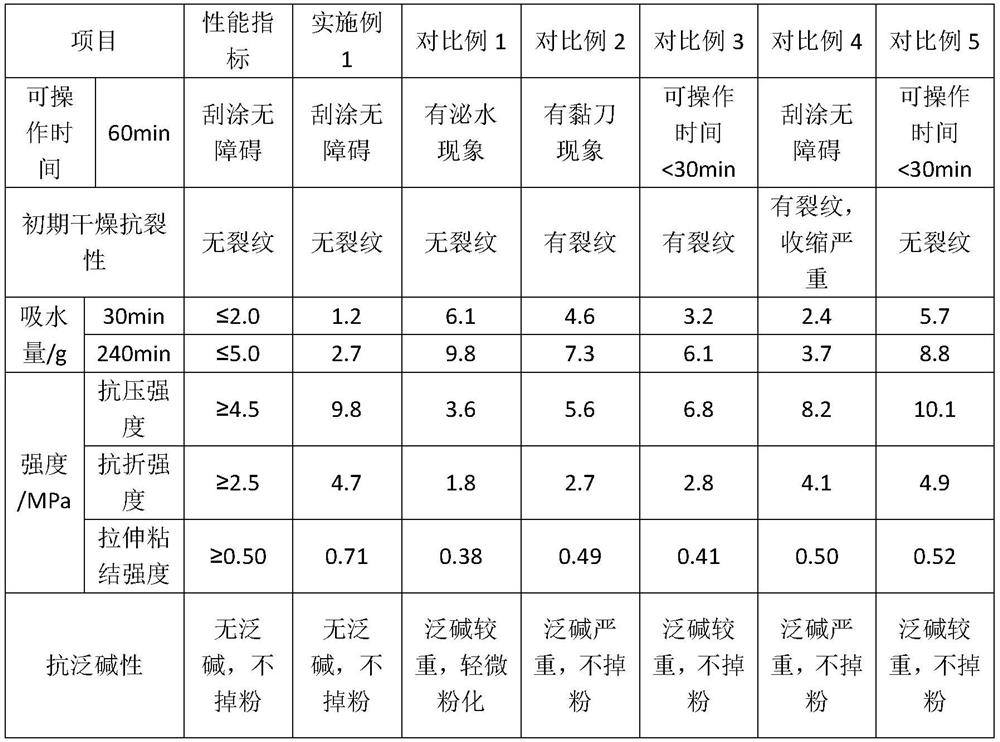

Embodiment 1

[0034] The raw materials used in the gypsum-based colored decorative mortar are as follows by weight: 20 parts of gypsum, 8 parts of aluminate cement, 2 parts of Portland cement, 4 parts of fly ash, 70 parts of quartz sand, 5 parts of additives, 1 part of pigment, The water-cement ratio is 0.66 (the mass ratio of water to the total mass of gypsum, aluminate cement and Portland cement is 0.66).

[0035] Among them, the ratio of redispersible latex powder, water-retaining agent, defoamer, waterproofing agent, and water-reducing agent in the additive is 2:0.15:0.1:0.5:0.6.

[0036] The dispersed latex powder is hydrophobic latex powder and is ethylene-vinyl chloride-vinyl laurate ternary copolymer latex powder.

[0037] The water-retaining agent is hydroxypropyl methylcellulose ether, and its viscosity is 40000mPa·s; the defoamer is silicone defoamer; Sulfonated melamine water reducer; gypsum is hemihydrate gypsum, whiteness ≥ 85%, particle size ≥ 200 mesh; aluminate cement is C...

Embodiment 2

[0043] The difference between the components of Example 2 and Example 1 is that the raw materials used in the gypsum-based colored decorative mortar are as follows in terms of mass ratio and weight: 20 parts of gypsum, 5 parts of aluminate cement, 1 part of Portland cement, 1 part of fly ash, 75 parts of quartz sand, 3 parts of additives, 0.5 parts of pigment, water-cement ratio 0.6.

[0044] Among them, the ratio of redispersible latex powder, water retaining agent, defoamer, water repellent, and water reducing agent in the additive is 4:0.1:0.05:0.2:0.5.

[0045] The dispersed latex powder is hydrophobic latex powder and is ethylene-vinyl acetate copolymer latex powder;

[0046]The water-retaining agent is hydroxyethyl methylcellulose ether with a viscosity of 10000mPa·s; the defoamer is polyether defoamer; the water-repellent is polysiloxane powder water-repellent with an effective content of ≥99%; Sodium sulfamate superplasticizer; gypsum is hemihydrate gypsum, whiteness ...

Embodiment 3

[0052] Embodiment 3 has the same components as in Embodiment 1. The difference is that the raw materials used in the gypsum-based colored facing mortar are as follows in parts by mass: 25 parts of gypsum, 10 parts of aluminate cement, 5 parts of Portland cement, 5 parts of fly ash, 80 parts of quartz sand, 6 parts of additives, 1 part of pigment, water-cement ratio 0.7.

[0053] Among them, the ratio of redispersible latex powder, water retaining agent, defoamer, water repellent, and water reducing agent in the additive is 5:0.2:0.15:0.5:1.

[0054] Dispersed latex powder is hydrophobic latex powder and is vinyl acetate-tertiary vinyl carbonate copolymerized latex powder;

[0055] The water-retaining agent is hydroxypropyl methylcellulose ether, and its viscosity is 40000mPa·s; the defoamer is silicone defoamer; Sulfonated melamine water reducer; gypsum is hemihydrate gypsum, whiteness ≥ 85%, particle size ≥ 200 mesh; aluminate cement is CA-60 aluminate cement; Portland cemen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com