Water-borne touch oil and preparation method thereof

A tactile water-oil and water-based polyurethane technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve problems such as poor economic benefits, poor product quality, and increased production costs, and achieve reduced production costs, good product quality, and economical High benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

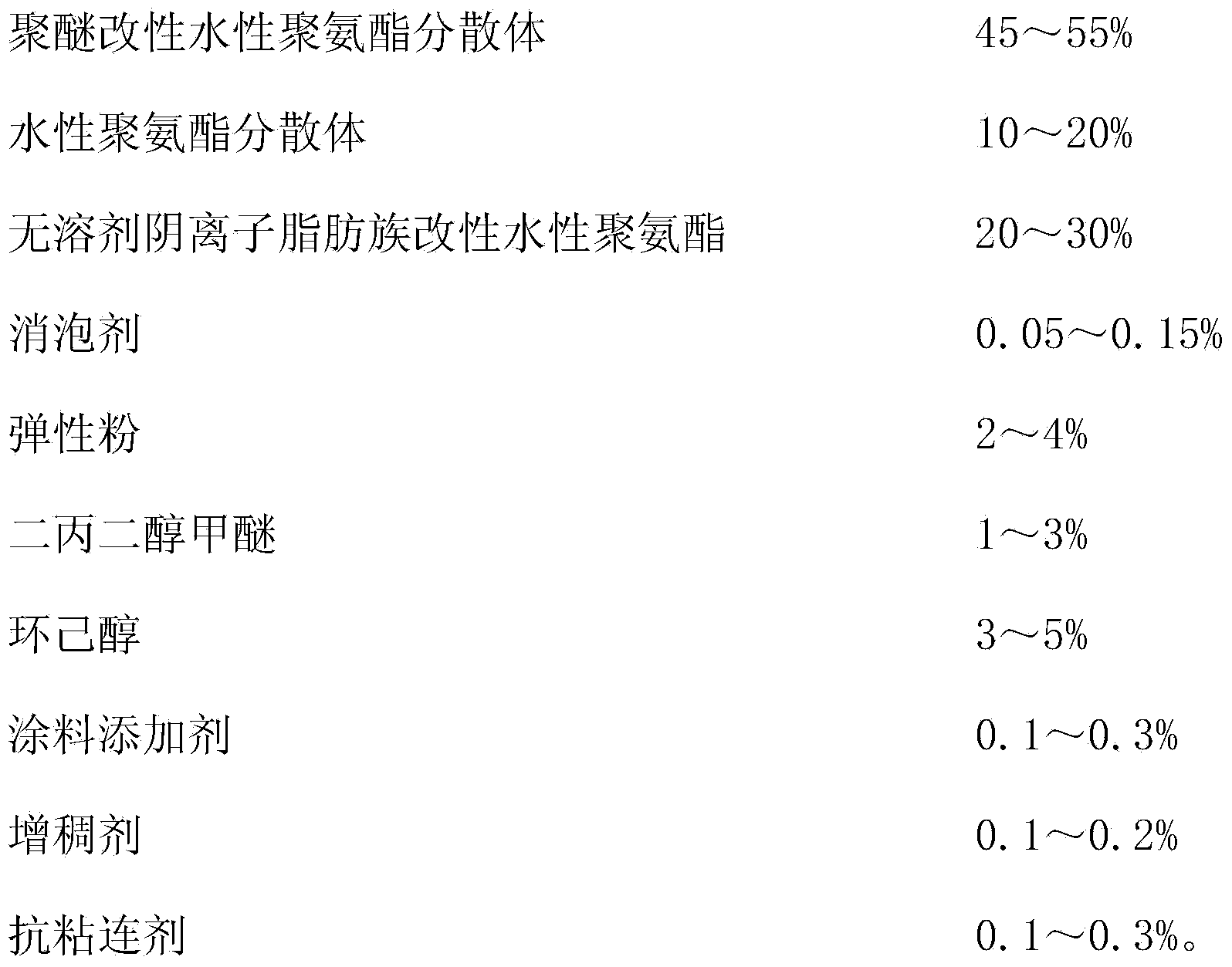

[0036] A kind of tactile water oil of the present embodiment comprises the following raw materials in mass percentage:

[0037]

[0038] The polyether-modified water-based polyurethane dispersion in this embodiment is the polyether-modified water-based polyurethane dispersion of the model Esacote PU980 produced by Ningbodi Specialty Chemicals (Shanghai) Co., Ltd.

[0039] The defoamer in this example is Dehydran 1293 produced by Corning Chemical (China) Co., Ltd.

[0040] The elastic powder in this embodiment is the elastic powder of model 5070D produced by Dainichi Seika (Shanghai) Chemical Co., Ltd.

[0041] The coating additive in this embodiment is the additive model DC-51 produced by Dow Corning Company.

[0042] The thickener of this embodiment is a water-based polyurethane associative thickener.

[0043] The anti-blocking agent in this embodiment is a polymer grade anti-blocking agent.

[0044] A preparation method of tactile water oil, comprising the following pr...

Embodiment 2

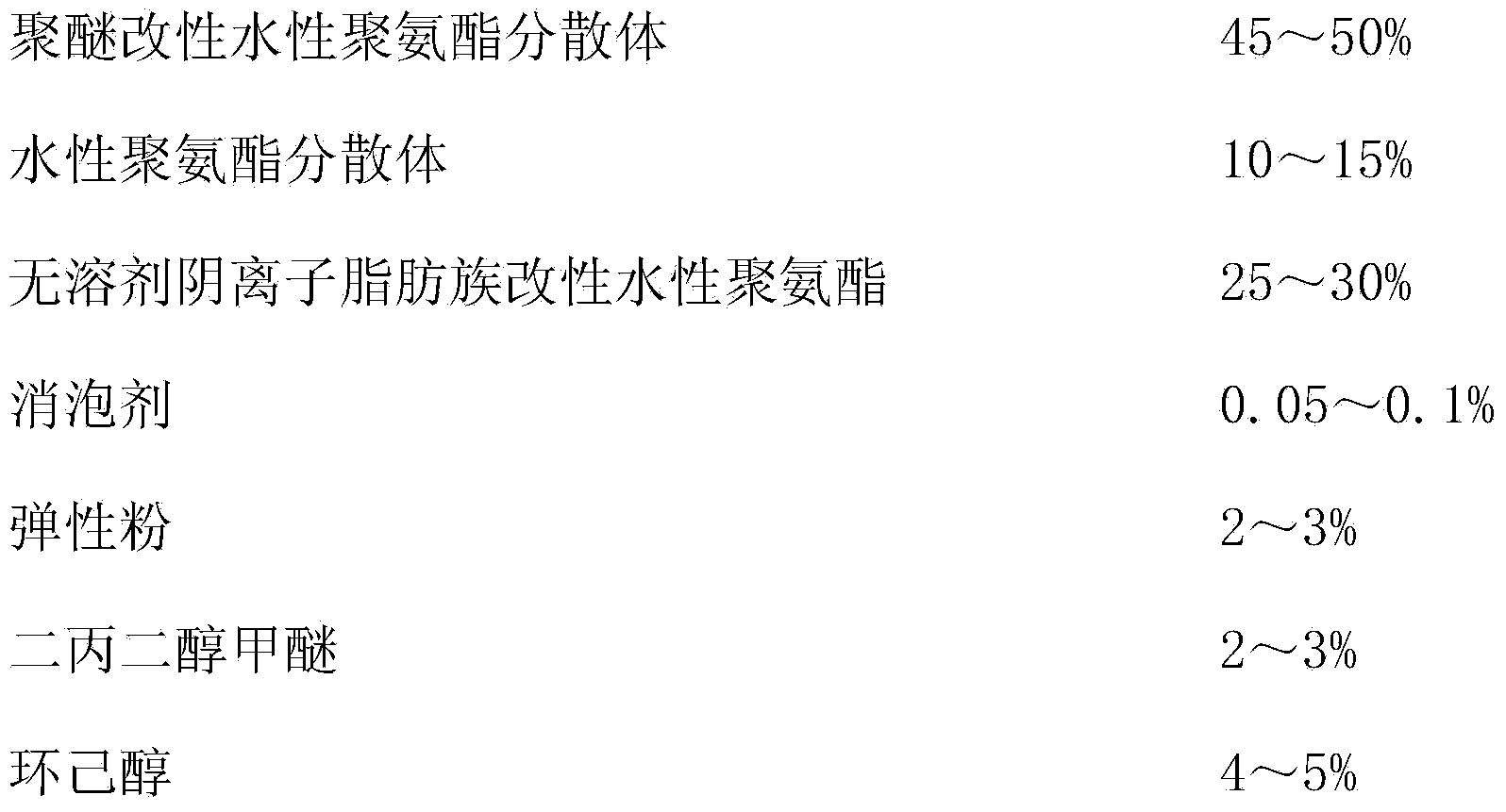

[0051] A kind of tactile water oil of the present embodiment comprises the following raw materials in mass percentage:

[0052]

[0053] A preparation method of tactile water oil, comprising the following processing steps:

[0054] Step A, pouring the polyether-modified waterborne polyurethane dispersion, the waterborne polyurethane dispersion, and the solvent-free anionic aliphatic modified waterborne polyurethane into the mixing tank in sequence;

[0055] Step B, slowly add the defoamer dropwise while stirring slowly, the stirring speed is 300r / min, and the dropping time is 50 minutes;

[0056] Step C. After the defoamer is added dropwise, adjust the stirring speed to 600r / min, continue stirring, and gradually add elastic powder, and the adding time is 70 minutes;

[0057] Step D, when the elastic powder is added completely, add dipropylene glycol methyl ether, cyclohexanol, paint additives and anti-blocking agent, and continue to stir for 20 minutes;

[0058]Step E. Ta...

Embodiment 3

[0061] A kind of tactile water oil of the present embodiment comprises the following raw materials in mass percentage:

[0062]

[0063] A preparation method of tactile water oil, comprising the following processing steps:

[0064] Step A, pouring the polyether-modified waterborne polyurethane dispersion, the waterborne polyurethane dispersion, and the solvent-free anionic aliphatic modified waterborne polyurethane into the mixing tank in sequence;

[0065] Step B, slowly add the defoamer dropwise while stirring slowly, the stirring speed is 500r / min, and the dropping time is 30 minutes;

[0066] Step C. When the defoamer is added dropwise, adjust the stirring speed to 800r / min, continue stirring, and gradually add elastic powder, and the adding time is 50 minutes;

[0067] Step D, when the elastic powder is added completely, add dipropylene glycol methyl ether, cyclohexanol, coating additives and anti-blocking agent, and continue to stir for 40 minutes;

[0068] Step E. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com