Automatic cooling traction equipment for plastic extruded strip

A technology for automatic cooling and traction equipment, which is applied in the field of automatic cooling traction equipment, can solve the problems of uneconomical use, influence of normal quality operation, too tight or too loose state of clamping strips, etc., to improve product quality and cooling effect Good, driving force reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

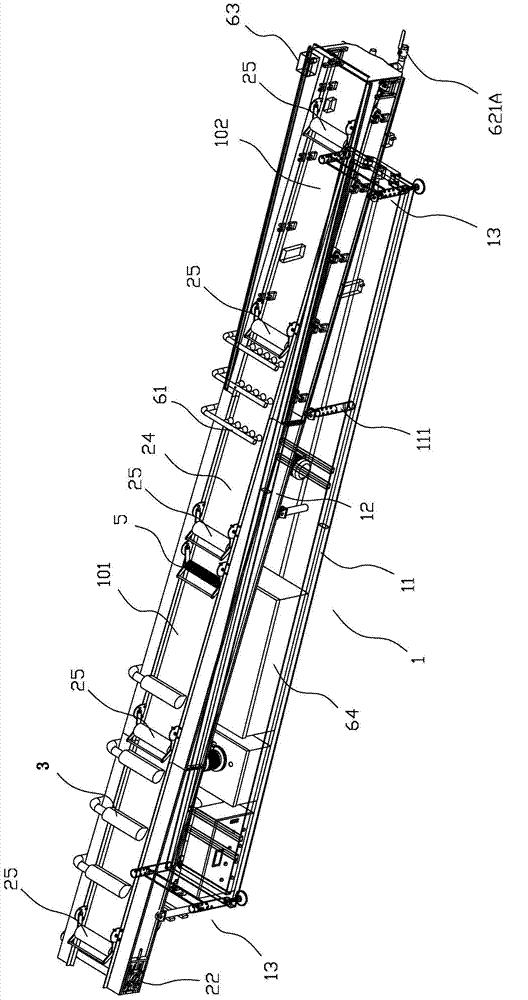

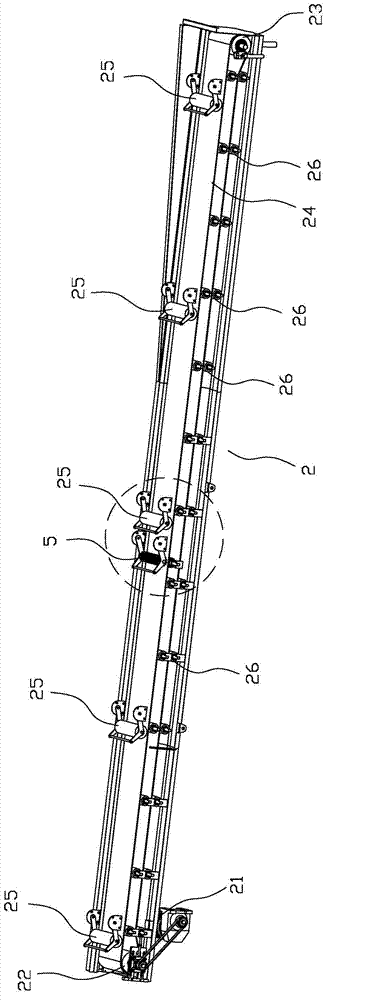

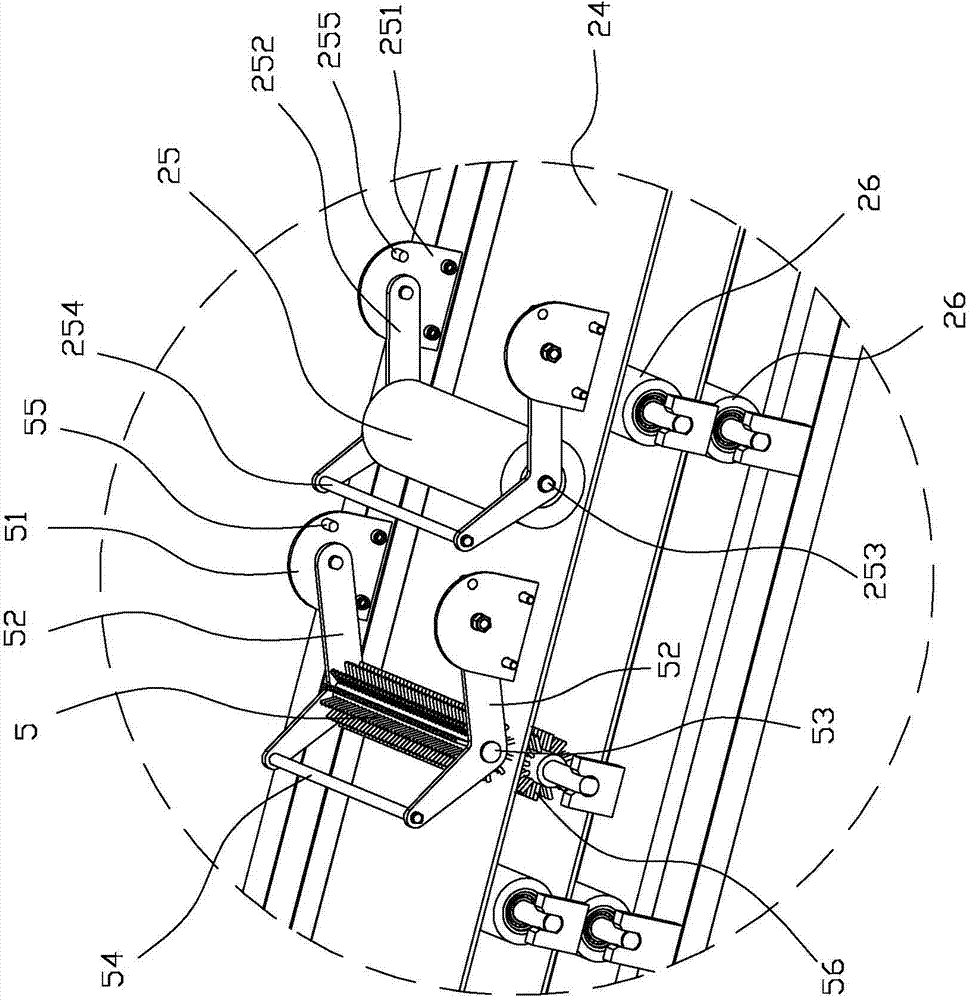

[0030] Please refer to Figure 1 to Figure 8 As shown, it shows the specific structure of the preferred embodiment of the present invention, including: including a frame 1 and a traction device 2 and an air-drying device 3 installed on the frame.

[0031] Such as figure 1 As shown, the frame 1 is provided with an accommodating tank 101, the frame 1 is preferably an adjustable elevating frame, the height of the rear end of the elevating frame 1 is adjusted to be greater than the height of the front end, so that the front end of the accommodating tank 101 has a water Space 102, and adjust the inclination angle of the metal conveyor belt in the traction device described below.

[0032] The frame 1 includes a fixed frame base 11, a movable frame platform 12 and a lifting device 13, the two ends and the middle part of the fixed frame base 11 are respectively provided with fixed sleeves 111, and a lifting device 13 is installed at each fixed sleeve 111; Lifting devices can also be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com