Rice band cutting-off machine

A cutting machine and rice belt technology, which is applied in the field of rice cake processing, can solve the problems of incomplete cutting, sticky rice belt, and easy sticking of the cutter to achieve good cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

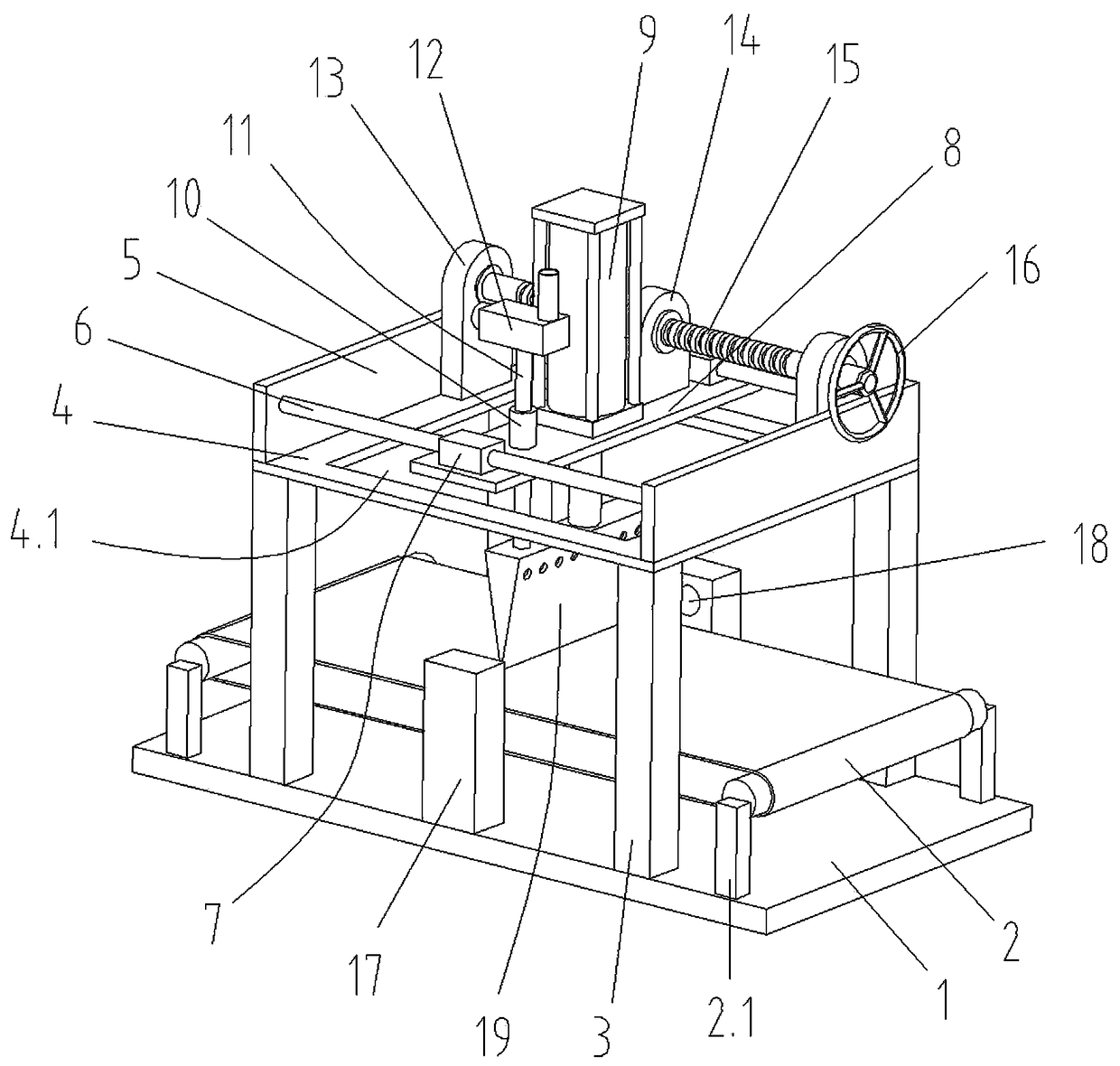

[0019] Such as figure 1 , figure 2 , image 3 As shown, a rice ribbon cutting machine provided by the present invention is characterized in that it includes a base plate 1, and a set of uprights 3 are welded on both sides above the base plate 1. In this embodiment, two upright columns 3 are respectively arranged on both sides above the base plate 1, The four columns 3 support and connect the top plate 4, and the center of the top plate 4 is provided with an opening 4.1, and the opening 4.1 is preferably a square opening.

[0020] The vertical plates 5 are welded symmetrically on both sides above the top plate 4, and two sliding rods 6 are arranged between the two vertical plates 5. The sliding rods 6 preferably adopt cylindrical rods, and slide blocks 7 are slidably connected on each sliding rod 6. The slide block 7 is a square block, and a slide hole is provided in the center of the square block. The slide block 7 is sleeved on the slide bar 6 through the slide hole and ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com