Adjustable efficient cutting and grinding device for pipeline machining

An adjustable, pipeline technology, used in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve problems such as poor fixing effect, inability to determine the location of pipelines, and increasing the length range of building pipelines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

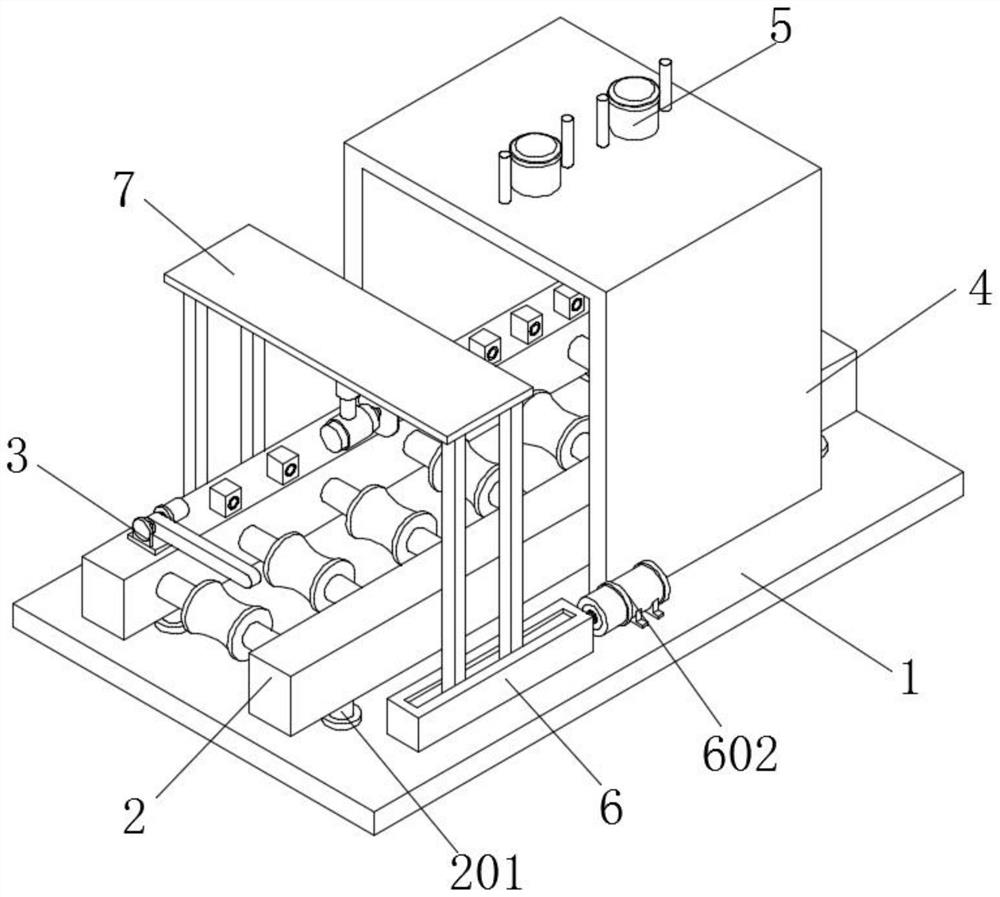

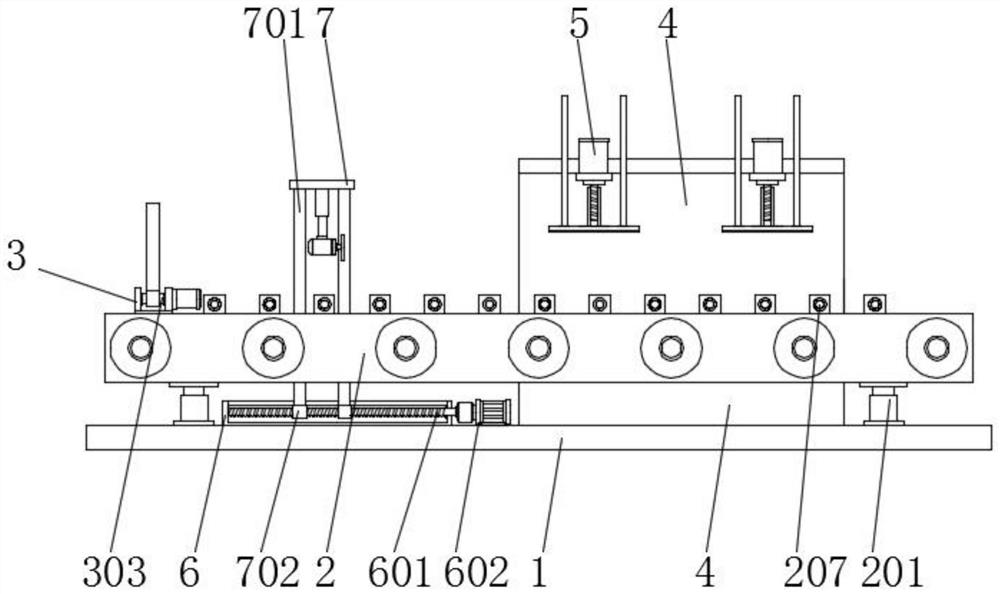

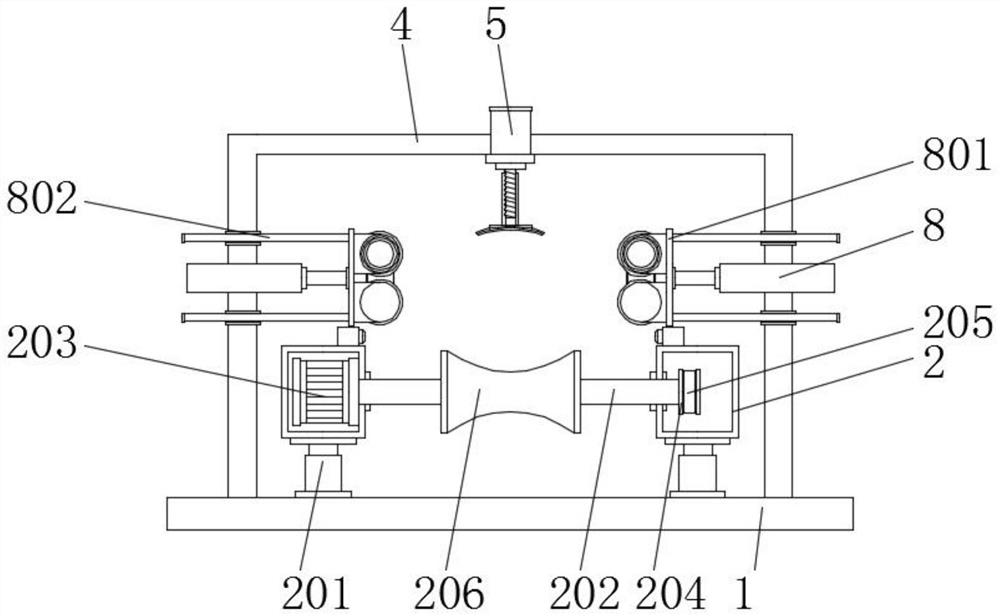

[0041] Embodiment 1 comprises a base plate 1, the top of the base plate 1 by a bolt mounted symmetrically arranged two lift pins 201, lift rod 201 supporting a pair of top floor, the lift rod 201 to ensure stability, the worker can adjust the lift rod according to length 201 controls the height of the support tube 2, to facilitate different thickness normal pipeline processing, the lifting rod 201 is attached to the top of the support tube 2, the lift lever 201 to the top of the support tube 2 is supported, to ensure that the support tube 2 stability, between the inner tube 2 through the two sets of support 202 is attached to a transmission rod, a set of inner support tube 2 is attached to the motor 203, the output of the motor 202 and drive rod 203 connected to active, the drive lever 202 away from the motor 203 One end of the first transmission wheel 204 is mounted, a first drive wheel 204 located on the other set of support of the inner tube 2, plural sets of first drive wheel ...

Embodiment 2

[0043] Embodiment 2 comprises a base plate 1, the top of the tube 2 is supported by a bolt mounting seat 3 is mounted, is mounted inside the movable seat 3 is mounted pawl 303, the side of the mounting seat 3 is attached to the servo motor 301, servo the output of the motor 301 and the rotation shaft 303 is connected to the pawl 303 outward is mounted movable rod 302, the support tube mounting base 2 pair of top 3 is fixed, easy to install turn base 3 medial 303 of the support, to complete the sanding pipe when the need for cutting by the movable rod 302 to block the pipe to prevent the pipe to move, after completion of the cutting, the servo motor 301 controls the rotation of the pawl 303, the pawl 303 to drive the active lever 302 outward tilt, so that the conduit may be normally transmitted out, after cutting out piped out, the servo motor 301 is running backward reverse rotation drive pawl 303 to drive the active lever 302 continues back to the original block of the pipeline; ...

Embodiment 3

[0045] Embodiment 3 comprises a base plate 1, the top of the base plate 1 by a bolt with a supporting frame 4, a pair of support plate supporting frame 4, to ensure stable support frame 4, and support frame 4 is located outside of the lift lever 201, the top support frame 4 is attached to a control motor through 5, conveniently supported by the support frame 4 is fixed to the control of the motor 5, the output of the control motor 5 there is mounted screw 501, the screw 502 threaded sleeve 501 is mounted outside , the bottom end of the inner threaded sleeve 502 is attached to the lifting plate 503, bottom plate 503 of the lifting plate 504 is attached to grinding, the top plate 503 is attached to the lift slider guide 505, the guide slider 505 positioned within the threaded sleeve 502 of the two side, the control operation of the motor 5 driven by the output of the screw 501 is rotated, the inner screw thread 501 of the inner sleeve 502 rotates drive screw is moved downward throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com