Processing method of large diameter connection flange plate

A processing method and large-diameter technology, applied in the field of flanges, can solve the problems of low processing accuracy, inability to improve production efficiency, and inability to reduce processing costs, and achieve the effects of improving processing accuracy, scientific and reasonable processing methods, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

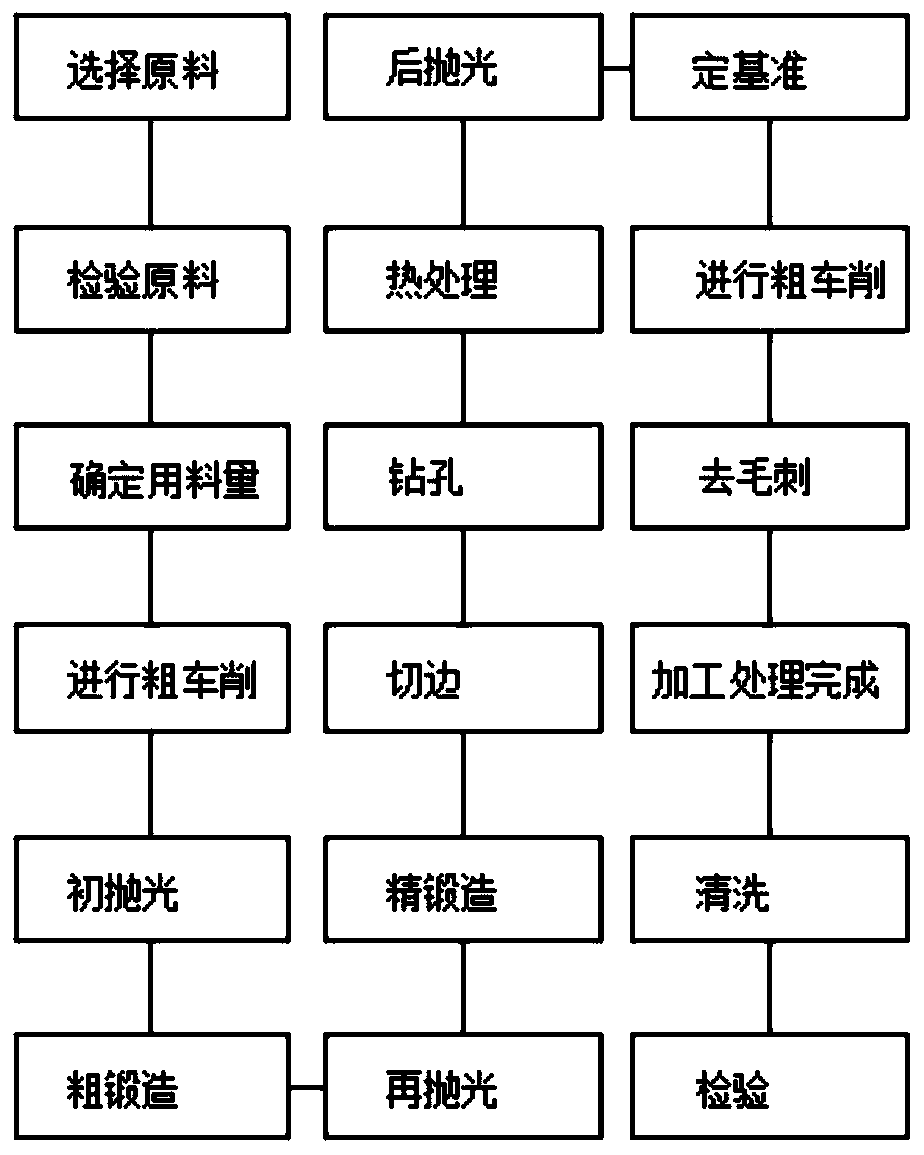

[0033] A method for processing a large-diameter connection flange, comprising the following steps:

[0034] S1: Select the raw material, select the raw material of 45 steel material;

[0035] S2: Inspect raw materials, inspect raw materials with reference to standards, and prevent bad materials from affecting processing;

[0036] S3: Determine the amount of material used, and determine the amount of material used and the size of the flange according to the drawings;

[0037] S4: Carry out rough turning, use cemented carbide steel turning tool grade YT5 for rough turning, the amount of material required for cutting, choose 12° for the front angle and 8° for the back angle of rough turning, the size of the tool holder is 16×25mm2, pa≤3mm , and when the workpiece diameter is 140mm, f=0.8~1.2rmm;

[0038] S5: Initial polishing, polishing the material for the first time to make the surface of the material smooth;

[0039] S6: Rough forging, heat treatment for forging, the temper...

Embodiment 2

[0053] A method for processing a large-diameter connection flange, comprising the following steps:

[0054] S1: Select the raw material, select the raw material of 45 steel material;

[0055] S2: Inspect raw materials, inspect raw materials with reference to standards, and prevent bad materials from affecting processing;

[0056] S3: Determine the amount of material used, and determine the amount of material used and the size of the flange according to the drawings;

[0057] S4: Carry out rough turning, use cemented carbide steel turning tool grade YT5 for rough turning, the amount of material required for cutting, the front angle of rough turning is 15° and the back angle is 6°, the size of the tool holder is 16×25mm2, pa≤3mm , and when the workpiece diameter is 140mm, f=0.9~1.4rmm;

[0058] S5: Initial polishing, polishing the material for the first time to make the surface of the material smooth;

[0059] S6: Rough forging, heat treatment for forging, the temperature env...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com