Processing equipment for low heat value wastes and processing method

A technology for processing equipment and waste, applied in the field of harmless treatment and recycling of waste, can solve the problems of waste of resources, low calorific value, and many inorganic minerals, and achieve the effect of saving fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

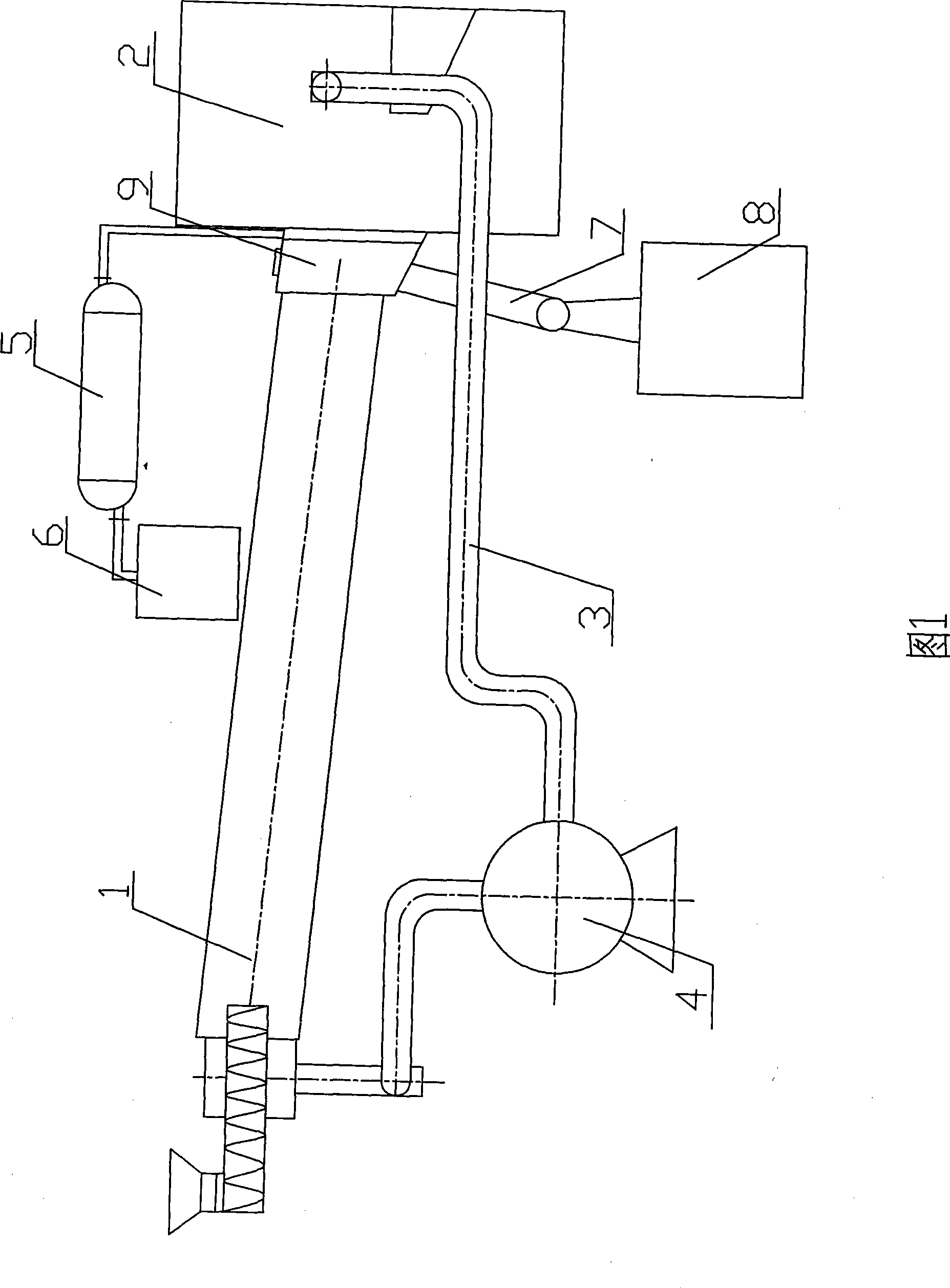

[0019] The low calorific value waste treatment equipment shown in Figure 1 has a rotary kiln 1, an incinerator 2, and a pipeline 3. One end of the pipeline 3 is connected to the rotary kiln 1, and the other end is connected to the feed port of the incinerator 2. The pipeline 3 is provided with a high-temperature blower 4 for forcing the high-temperature gas generated during the incineration of waste in the incinerator 2 into the rotary kiln 1 .

[0020] The high-temperature blower 4 is provided with an air volume adjusting device, and the air volume adjusting device adjusts the air volume by comparing the temperature detected by the temperature sensor with the set required temperature.

[0021] A liquid recovery device is provided at the discharge port of the rotary kiln 1 , and the liquid recovery device has a condenser 5 and a liquid recovery container 6 .

[0022] The discharge port of the rotary kiln 1 is provided with a solid collection device, and the solid collection de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com