Method for continuously processing degradation-resistant wastewater by means of microwave catalysis

A technology for wastewater treatment and refractory degradation, applied in the direction of light water/sewage treatment, etc., can solve the problems of small amount of treated water, difficult solid-liquid separation, short service life of catalysts, etc., to achieve large treatment capacity, improve treatment efficiency, and increase treatment capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

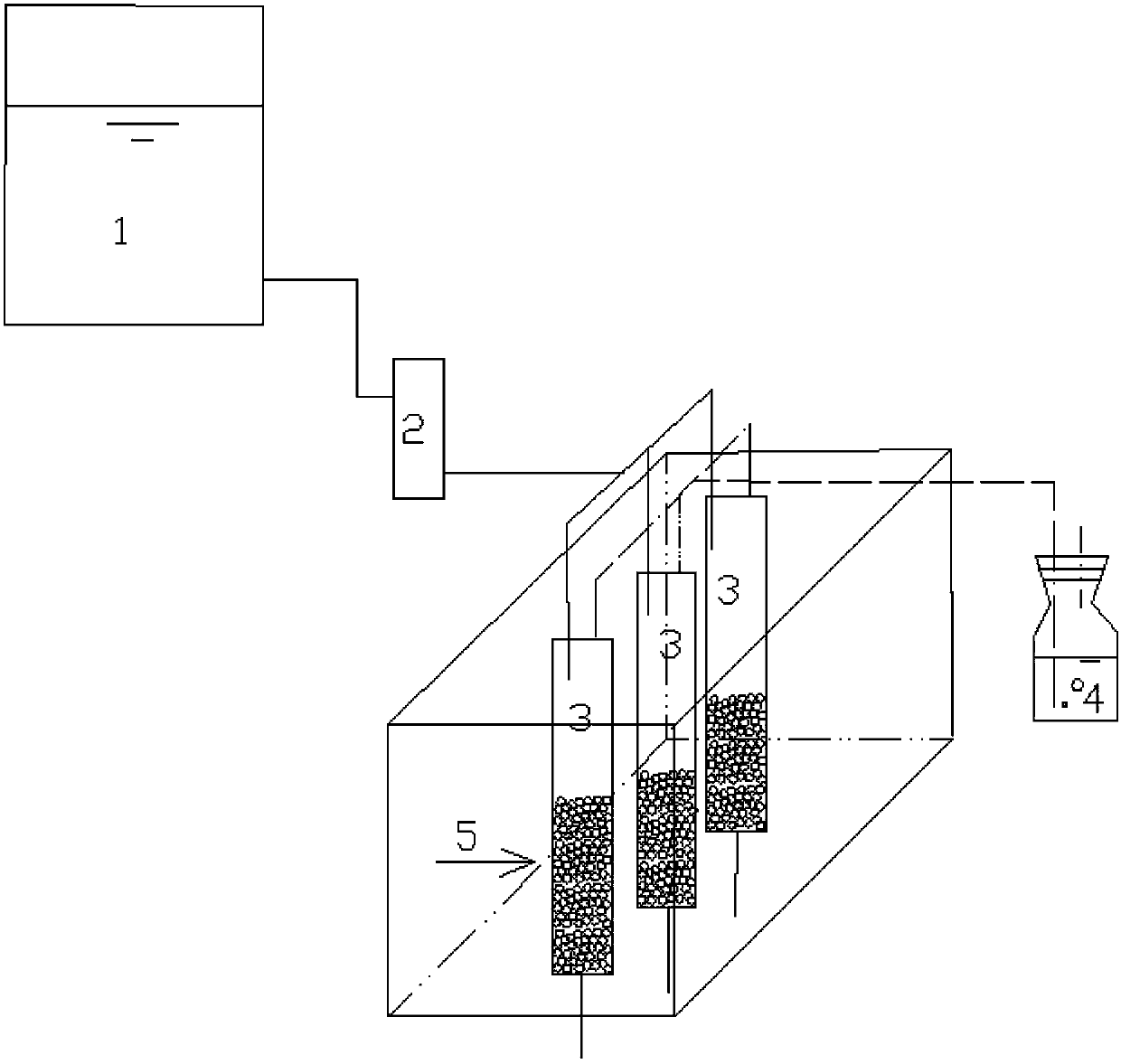

Method used

Image

Examples

Embodiment 1

[0022] The walnut shell is ground and carbonized to make carbonized material mixed with binder, which is molded in a molding machine, dried and activated, and then cut into granular activated carbon catalysts with a diameter of about 2mm.

[0023] The above granular activated carbon catalyst was filled into a quartz tube with a diameter of 24 mm to a height of 80 mm to form a fixed bed of granular activated carbon catalyst. A fixed bed of granular activated carbon catalyst was set perpendicular to the microwave direction and the ground in a microwave field with a microwave power of 500 W. The 2000mg / l simulated ammonia nitrogen wastewater was passed into the fixed bed at a flow rate of 20ml / min. The ammonia nitrogen concentration before and after treatment was determined by Nessler reagent spectrophotometry. The ammonia nitrogen concentration after treatment was 140 mg / l, and the ammonia nitrogen removal rate was 94%; after the same batch of granular activated carbon was conti...

Embodiment 2

[0025] The walnut shell is ground and carbonized to make carbonized material mixed with binder, which is molded in a molding machine, dried and activated, and then cut into granular activated carbon catalysts with a diameter of about 2mm.

[0026] The above granular activated carbon catalyst was filled into a quartz tube with a diameter of 24 mm to a height of 80 mm to form a fixed bed of granular activated carbon catalyst. A fixed bed of granular activated carbon catalyst was set perpendicular to the microwave direction and the ground in a microwave field with a microwave power of 500 W. The 2000mg / l simulated ammonia nitrogen wastewater was passed into the granular activated carbon column at a flow rate of 40ml / min. The ammonia nitrogen concentration before and after treatment was measured by Nessler reagent spectrophotometry, and the ammonia nitrogen removal rate was 91%.

Embodiment 3

[0028]The walnut shell is ground and carbonized to make carbonized material mixed with binder, which is molded in a molding machine, dried and activated, and then cut into granular activated carbon catalysts with a diameter of about 2mm.

[0029] The above granular activated carbon catalyst was filled into a quartz tube with a diameter of 24 mm to a height of 80 mm to form a fixed bed of granular activated carbon catalyst. The granular activated carbon catalyst fixed bed was set perpendicular to the microwave direction and the ground in a microwave field with a microwave power of 800 W. The actual coking wastewater was passed through the granular activated carbon column at a flow rate of 20 ml / min. The ammonia nitrogen concentration before and after the reaction was determined by Nessler reagent spectrophotometry. The ammonia nitrogen concentration before the reaction was 6270 mg / L, and the concentration after the reaction was 420 mg / L. The ammonia nitrogen removal efficiency ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com