Tea dehydrating and drying method

A drying method and drying technology, applied in the direction of tea processing before extraction, can solve the problems of quality, poor taste, insufficient yield of spring tea, and bitter taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

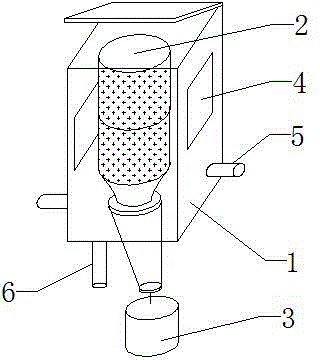

[0017] Embodiment 1: as figure 1 The tea dehydration dryer, which includes a shell 1 with a cover and a drain pipe, a drum 2 is arranged inside the shell 1, and a small drainage hole and an annular spacer are provided on the wall of the drum 2, and the drum 2 The bottom is provided with a sprocket or a pulley, and is connected with the motor 3 through a transmission mechanism. The housing 1 and the drum 2 are made of iron, preferably stainless steel.

[0018] Before the drying process of tea making, the centrifuge dehydration method of the above-mentioned tea dehydration dryer is used to assist the drying of tea leaves. The speed is 2000-2500 rpm, the diameter of the drum is 0.25 meters, and the centripetal acceleration can reach 6000-8500 m / s 2 . The centrifugation time is 5-6 minutes, which can shake off the moisture, pectin and tea juice contained in the tea leaves, remove the bitterness and enhance the chestnut aroma, and then take out the tea leaves and continue drying ...

Embodiment 2

[0021] Such as figure 1 According to the tea dehydration dryer, on the basis of embodiment 1, there are vent pipes 5 on both sides of the housing 1, and while the tea leaves are dehydrated by a centrifuge, dry hot air at 150 ° C is introduced from the vent pipe 5 to heat the tea leaves. When the pectin and tea juice in the tea water are thrown out, the tea leaves can be dried, and the drying speed is faster.

Embodiment 3

[0023] Such as figure 1 According to the tea dehydration dryer, on the basis of embodiment 2, heating plates 4 are provided on both sides of the inner wall of the housing 1, and the heating plates 4 can be infrared heating devices or electric heating wire heating devices. While the tea leaves are dehydrated by a centrifuge, air is blown in from the ventilation pipe 5, and the heating plate 4 is energized, and the tea leaves can also be dried when the pectin and tea juice of the tea moisture are thrown out, and the drying speed is also very fast. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com