Method for treating wastewater of phosphate fire retardant production process

A technology of production process and treatment method, which is applied in the field of wastewater treatment of phosphate ester flame retardant production process, can solve the problems of high-concentration organic wastewater that is not easy to biodegrade, and is not feasible, so as to achieve outstanding treatment effect, increase yield, and realize The effect of zero emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

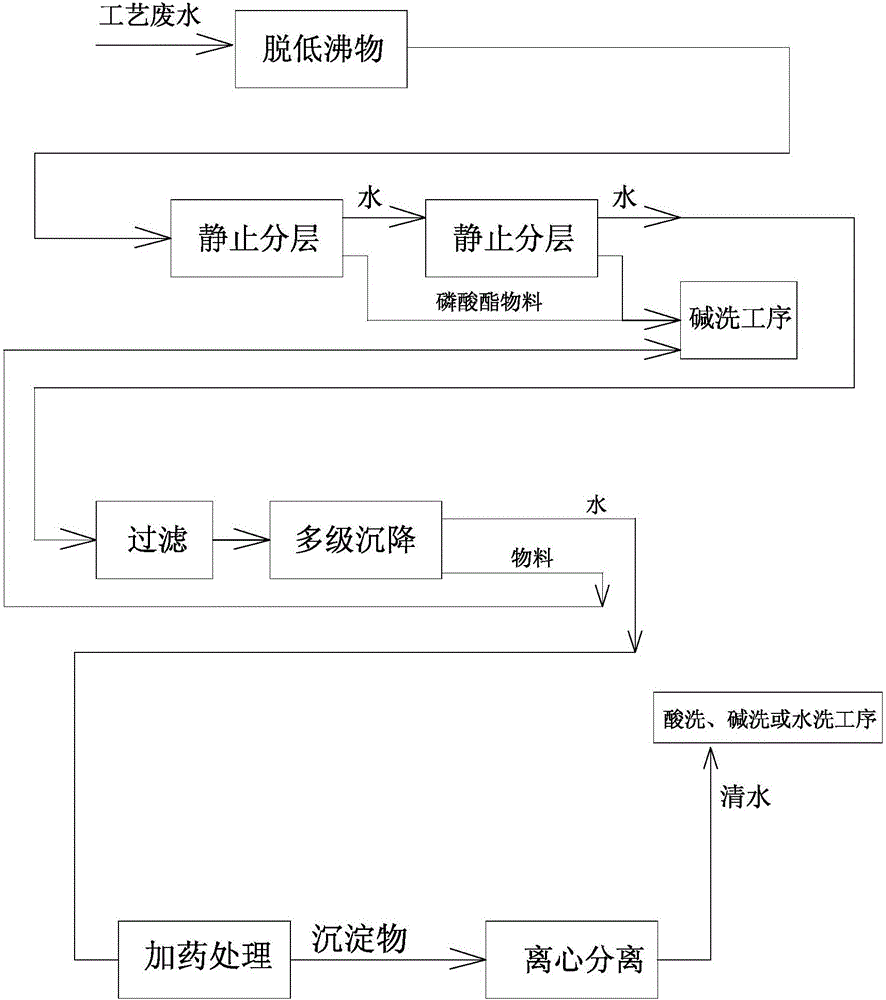

Embodiment 1

[0030] The method for the treatment of waste water in the production process of phosphate ester flame retardant, its steps are as follows:

[0031] 1) Put the process wastewater generated during the preparation of phosphate ester flame retardants into high-temperature and high-vacuum devices (such as thin-film evaporators, rectification towers, kettles, etc.) boiling point substances;

[0032] 2) After step 1) the phosphate ester wastewater treated by removing low boiling matter enters the wastewater stratification tank for static stratification, and the phosphate ester material obtained in the lower part of the wastewater stratification tank is reused to the alkali washing process in the phosphoric acid ester post-treatment , filter the wastewater obtained from the upper part of the wastewater stratification box, filter out the solid residue in the wastewater, and control the mass content of phosphate in the filtered wastewater to be within 1%;

[0033] 3) The waste water fi...

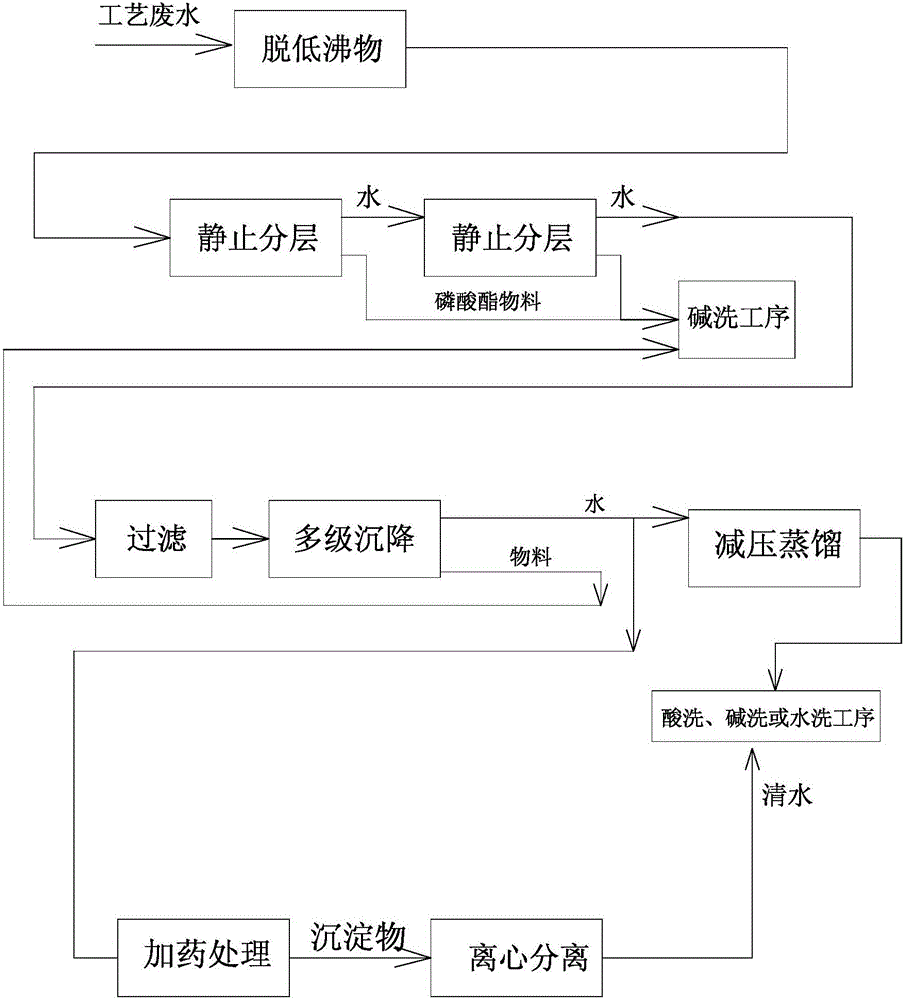

Embodiment 2

[0039] The method for the treatment of waste water in the production process of phosphate ester flame retardant, its steps are as follows:

[0040] 1) Put the process wastewater generated during the preparation of phosphate ester flame retardants into high-temperature and high-vacuum devices (such as thin-film evaporators, rectification towers, kettles, etc.) boiling point substances;

[0041] 2) After step 1) the phosphate ester wastewater treated by removing low boiling matter enters the wastewater stratification tank for static stratification, and the phosphate ester material obtained in the lower part of the wastewater stratification tank is reused to the alkali washing process in the phosphoric acid ester post-treatment , filter the wastewater obtained from the upper part of the wastewater stratification box, filter out the solid residue in the wastewater, and control the mass content of phosphate in the filtered wastewater to be within 1%;

[0042] 3) The waste water fi...

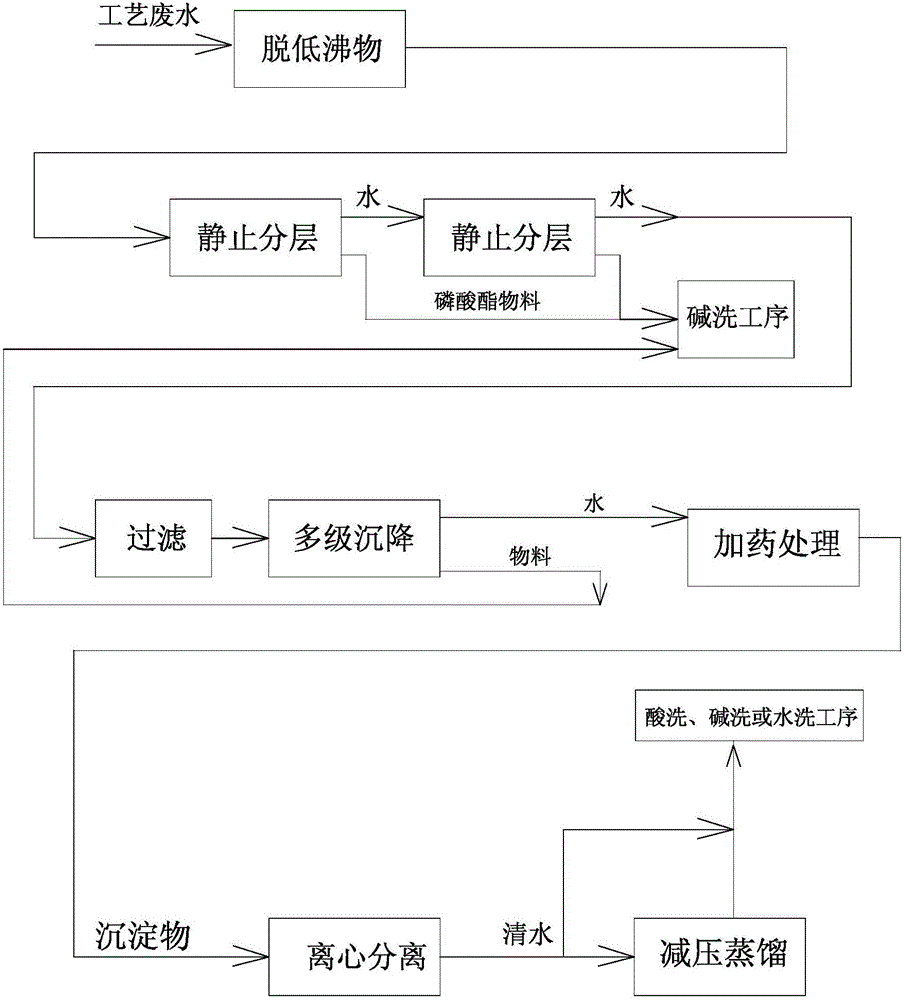

Embodiment 3

[0047]The method for the treatment of waste water in the production process of phosphate ester flame retardant, its steps are as follows:

[0048] 1) Put the process wastewater generated during the preparation of phosphate ester flame retardants into high-temperature and high-vacuum devices (such as thin-film evaporators, rectification towers, kettles, etc.) boiling point substances;

[0049] 2) After step 1) the phosphate ester wastewater treated by removing low boiling matter enters the wastewater stratification tank for static stratification, and the phosphate ester material obtained in the lower part of the wastewater stratification tank is reused to the alkali washing process in the phosphoric acid ester post-treatment , filter the wastewater obtained from the upper part of the wastewater stratification box, filter out the solid residue in the wastewater, and control the mass content of phosphate in the filtered wastewater to be within 1%;

[0050] 3) The waste water fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com