Method and device for removing fragments in electrode material

A technology for electrode materials and debris, applied in the field of removing debris and devices in electrode materials, can solve problems such as reducing battery performance, and achieve the effects of environmentally friendly treatment methods, obvious effects, and good treatment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

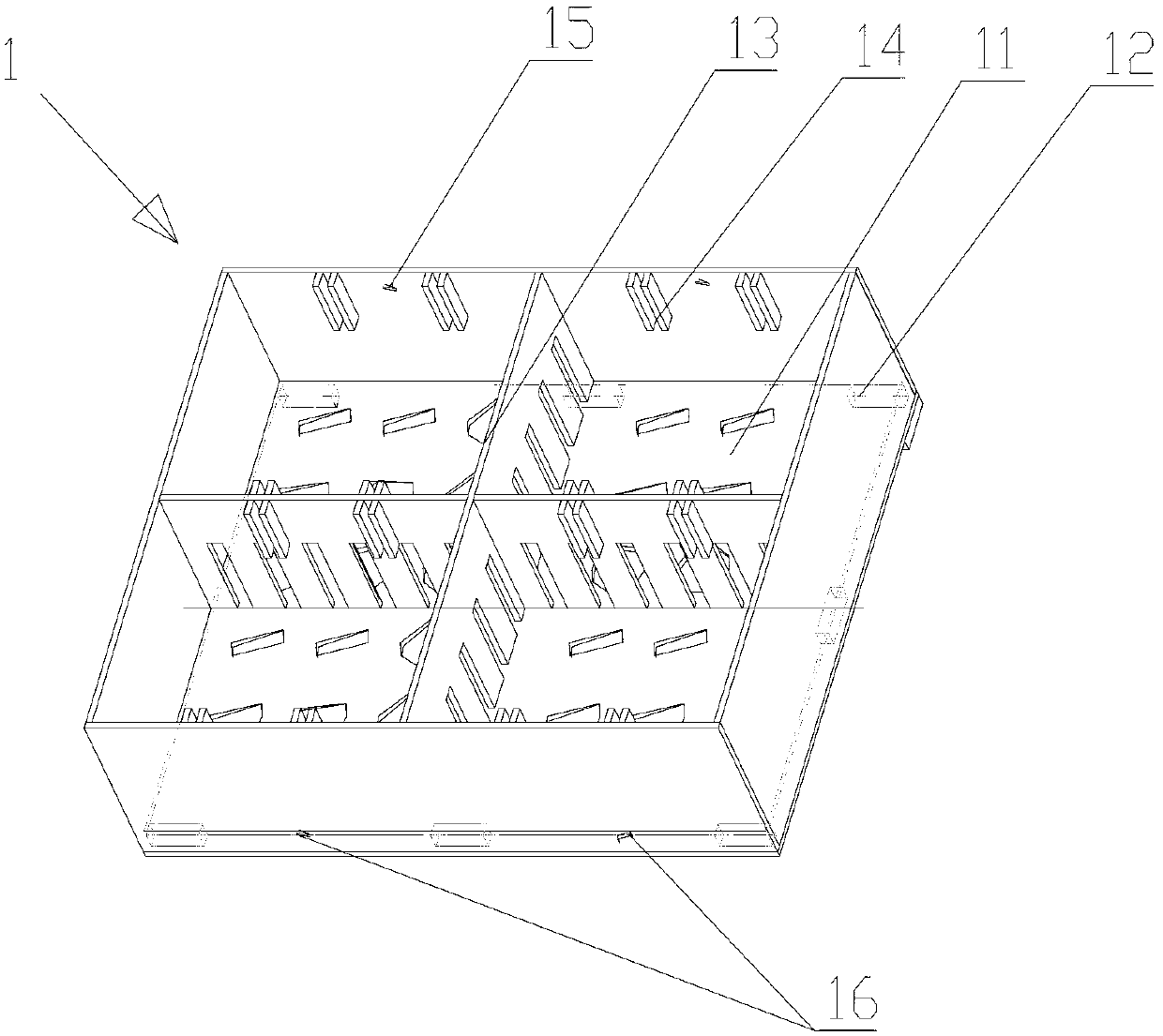

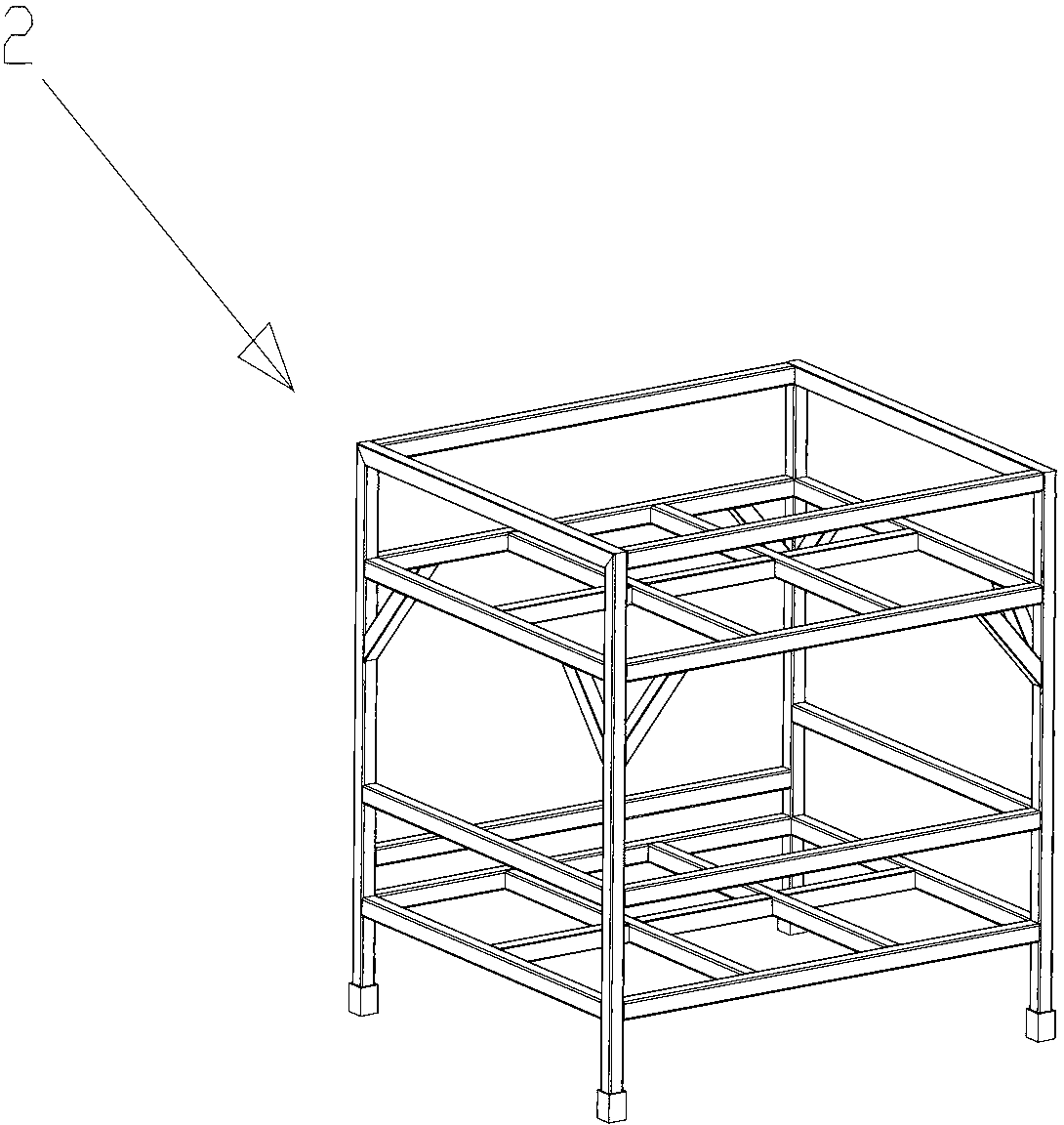

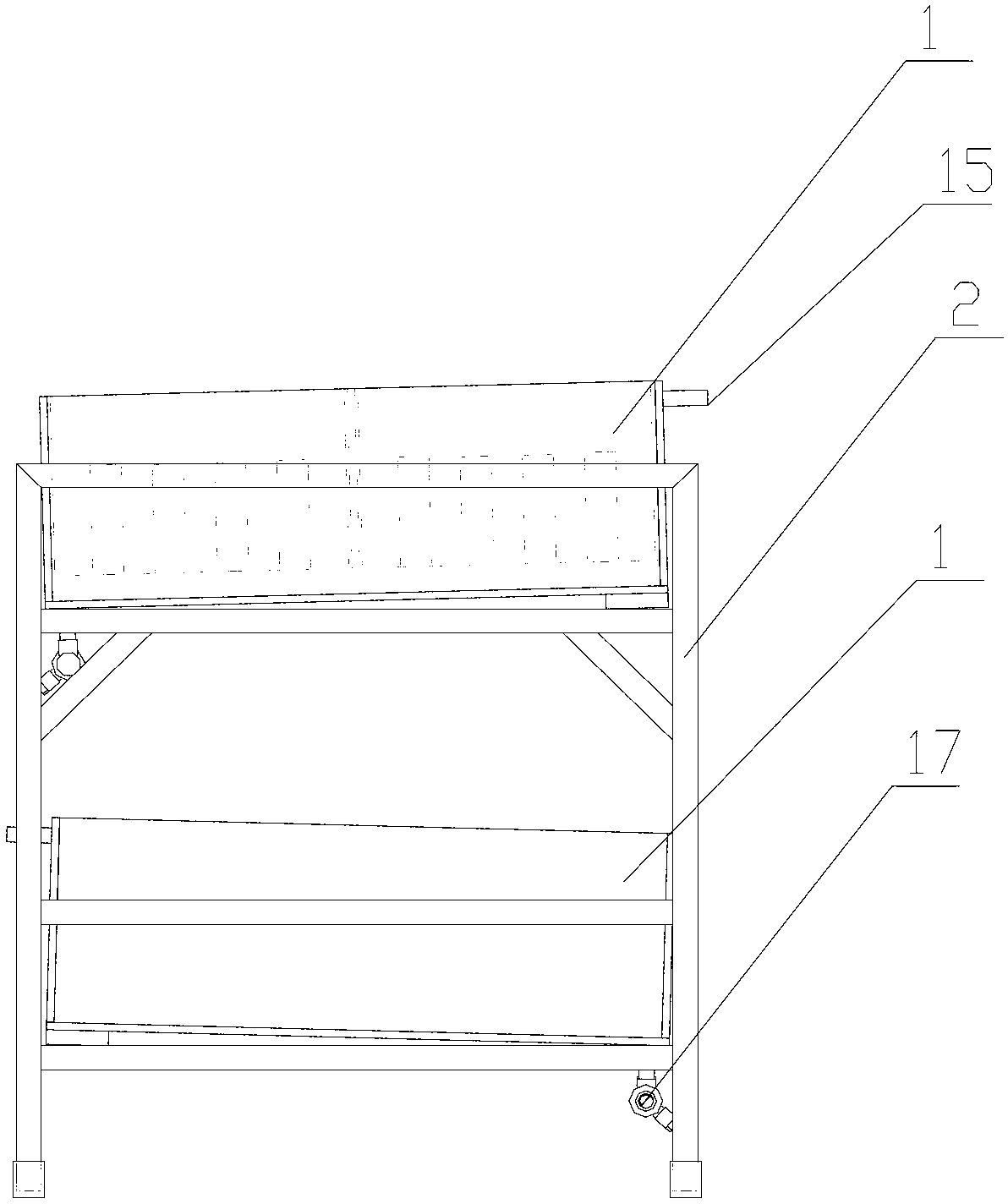

[0025] figure 1 A schematic diagram showing a water tank in a chip removing device according to the present invention. The water tank 1 is provided with a net plate 11 near the bottom, and the net plate 11 is supported on the bottom plate of the water tank by several pads 12 . The mesh plate 11 is a perforated plate with holes for the passage of wash water (usually distilled or deionized water). Obviously, the mesh panel 11 can also be a metal mesh, as long as it has the required strength and rigidity. The mesh plate 11 is used as a device to support the electrode material, so that the electrode material (take carbon felt as an example below) can be "suspended" in the water tank. The distilled water or deionized water flowing through the surface of the carbon felt can pass through the mesh plate downwards and flow out through the water outlet. In this context, the term "suspension device" is used to refer to the mechanism that supports the carbon felt so that all sides of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com