Asphalt smoke treatment system for loading area of asphalt stirring station

A technology of asphalt mixing plant and asphalt flue gas, which is applied in gas treatment, mixer accessories, smoke and dust removal, etc., can solve the problems of reduced thermal efficiency, low purification efficiency, and high cost, and achieve the effect of reducing resource waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below through specific embodiments.

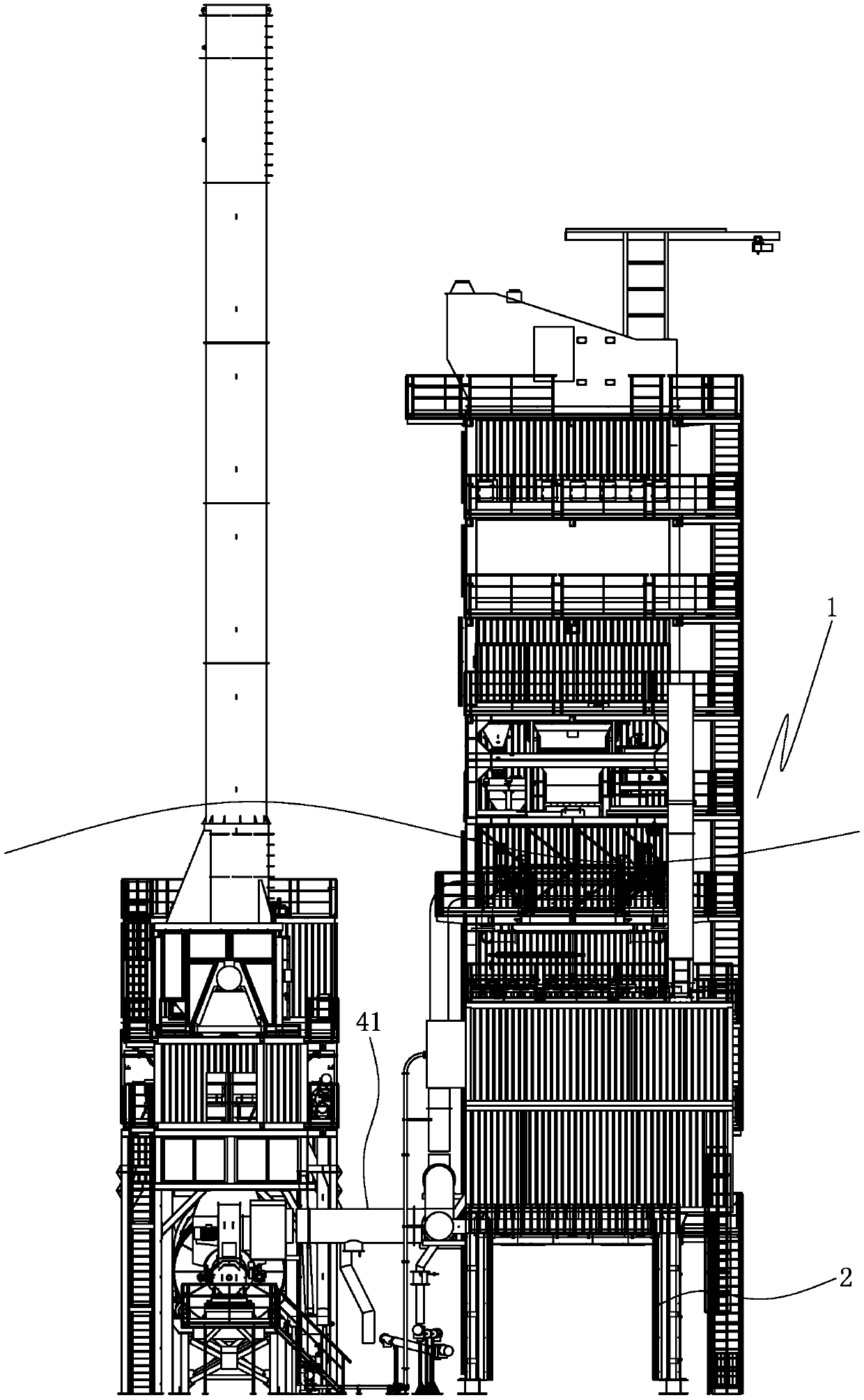

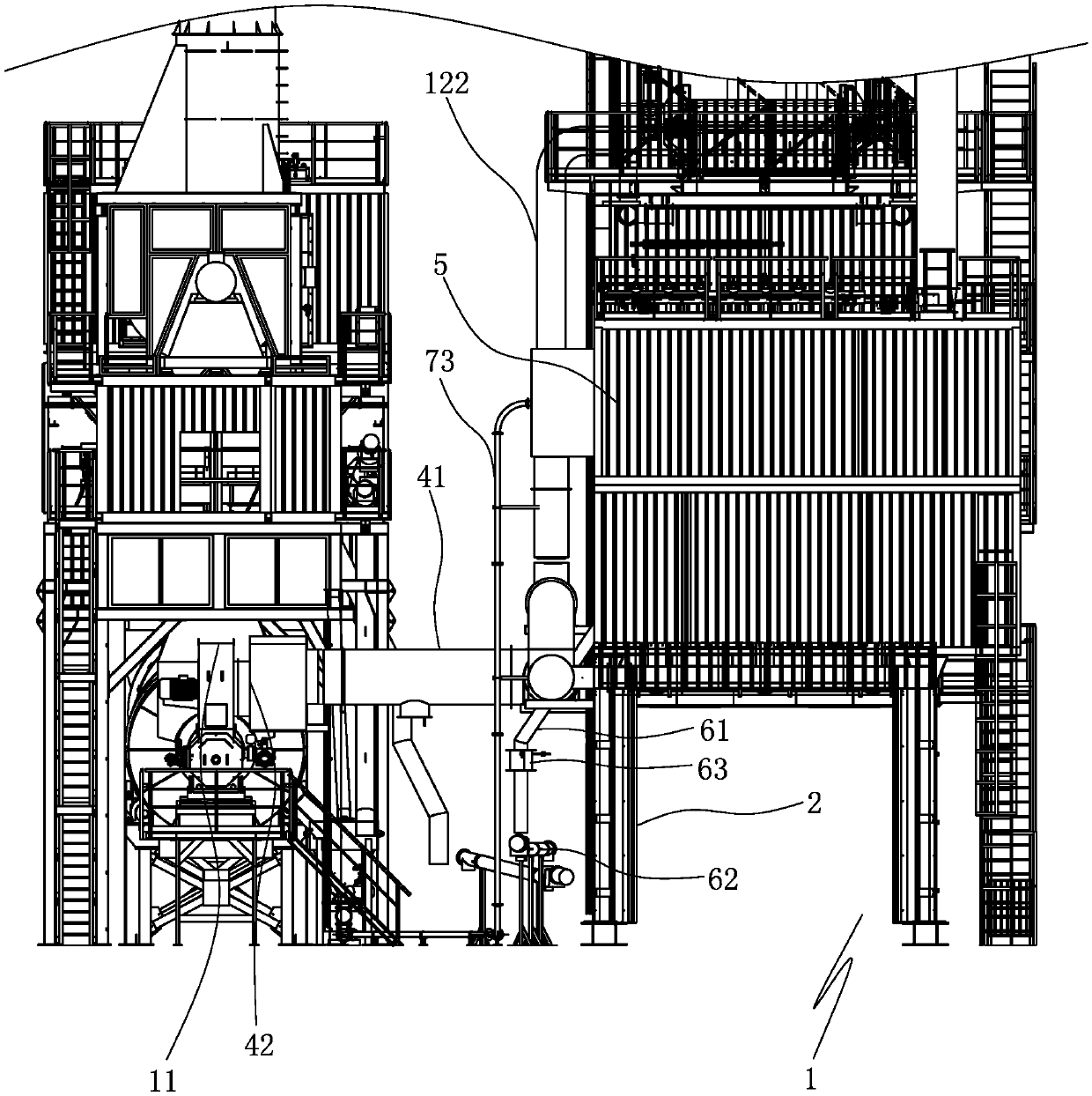

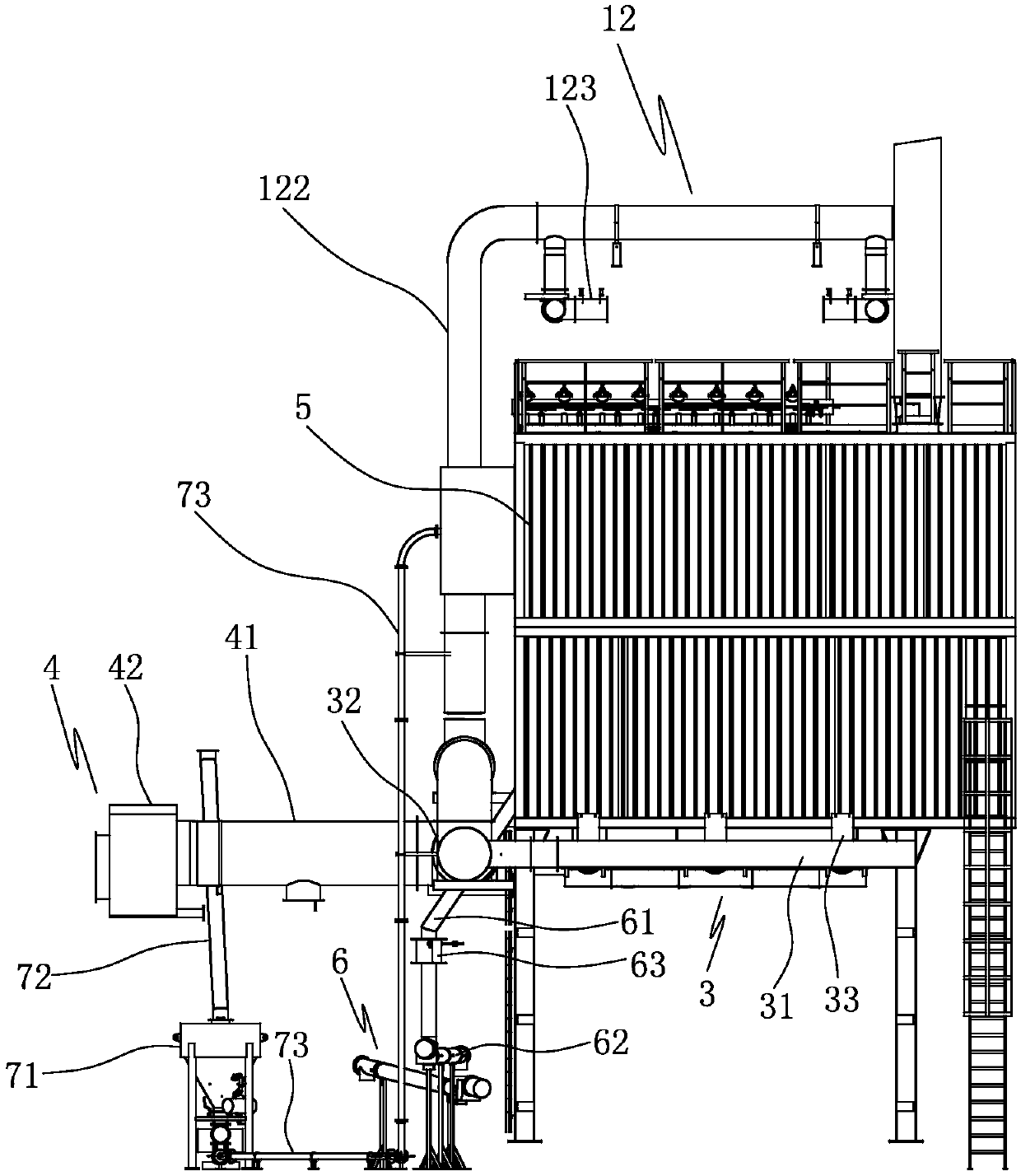

[0037] refer to Figure 1 to Figure 9 As shown, an asphalt fume treatment system in the loading area of an asphalt mixing plant includes a loading workshop 2, a workshop dust collection device 3, a burner intake device 4, a smoke powder processing device 5, a recycled powder conveying device 7 and a smoke powder Conveyor 6.

[0038] The asphalt mixing plant includes an asphalt mixture production building 1, a burner 11, a drying drum 14, a finished product bin, a mixing tank, an exhaust gas treatment device 13 and a dust collection assembly 12. The burner 11 is connected to the output end of the drying drum 14 for Supply heat to the drying drum 14; the finished product warehouse is used to store the asphalt mixture; the waste treatment device 13 is connected to the input end of the drying drum 14, and is used to process the exhaust gas coming out of the drying drum 14; The material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com