Fly ash leaching solution treatment method and system

A treatment method and a treatment system technology, which are applied in the field of fly ash leaching solution treatment method and its system, can solve problems such as fly ash leaching solution pollution, and achieve the effects of good water quality, low energy consumption, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

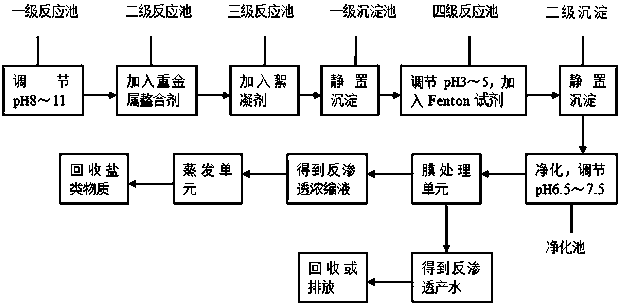

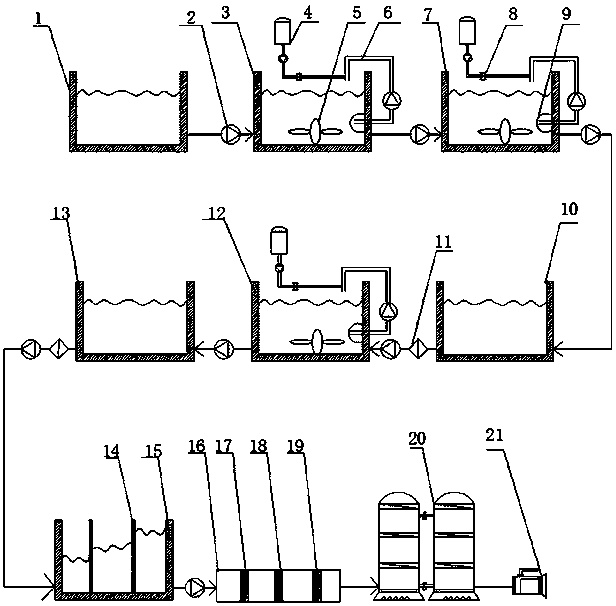

Method used

Image

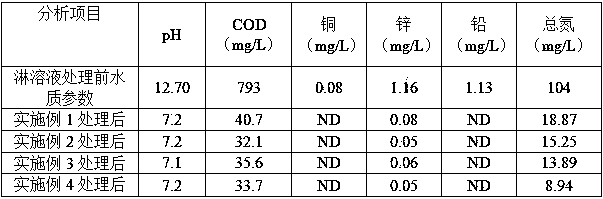

Examples

Embodiment 1

[0060] A method for treating fly ash leaching solution, comprising the following steps:

[0061] (1) Pass the fly ash leaching solution into the primary reaction tank, add hydrochloric acid to adjust its pH value to 10;

[0062] (2) After adjusting the pH value, lead the fly ash leaching solution to the secondary reaction pool, add a heavy metal chelating agent with a total weight of 0.08% of the fly ash leaching solution, stir slowly for 20 minutes, and carry out metal chelation reaction to produce metal chelate Precipitated particles;

[0063] (3) Lead the drenching solution in step (2) to the tertiary reaction tank, add flocculant, and stir slowly for 5 minutes, so that the precipitated particles of metal chelate are transformed into precipitated alum flower particles;

[0064] (4) Pass the mixed liquid in step (3) to the primary sedimentation tank, and let it settle for 2 hours to make it settle completely;

[0065] (5) Pass the supernatant in the first-stage sedimentati...

Embodiment 2

[0074] A method for treating fly ash leaching solution, comprising the following steps:

[0075] (1) Pass the fly ash leaching solution into the primary reaction tank, add hydrochloric acid to adjust its pH value to 10.5;

[0076] (2) After adjusting the pH value, lead the fly ash leaching solution to the secondary reaction tank, add a heavy metal chelating agent of 0.10% of the total weight of the fly ash leaching solution, stir slowly for 25 minutes, and carry out metal chelation reaction to produce metal chelate Precipitated particles;

[0077] (3) Lead the drenching solution in step (2) to the tertiary reaction tank, add flocculant, and stir slowly for 5 minutes, so that the precipitated particles of metal chelate are transformed into precipitated alum flower particles;

[0078] (4) Pass the mixed liquid in step (3) to the primary sedimentation tank, and let it settle for 2.5 hours to make it settle completely;

[0079] (5) Pass the supernatant in the first-stage sedimen...

Embodiment 3

[0088] A method for treating fly ash leaching solution, comprising the following steps:

[0089] (1) Pass the fly ash leaching solution into the primary reaction pool, and add hydrochloric acid to adjust its pH value to 8;

[0090] (2) After adjusting the pH value, pass the fly ash leaching solution to the secondary reaction tank, add a heavy metal chelating agent with a total weight of 0.12% of the fly ash leaching solution, stir slowly for 20-30 minutes, and carry out metal chelation reaction to produce metal chelation Compound precipitation particles;

[0091] (3) Lead the drenching solution in step (2) to the tertiary reaction tank, add flocculant, and stir slowly for 5 minutes, so that the precipitated particles of metal chelate are transformed into precipitated alum flower particles;

[0092] (4) Pass the mixed liquid in step (3) to the primary sedimentation tank, and let it settle for 2 hours to make it settle completely;

[0093] (5) Pass the supernatant in the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com