Resource utilization method of residual kettle tar in phenylenediamine production

A phenylenediamine and resource-based technology, applied in chemical instruments and methods, organic chemistry, chemical/physical processes, etc., can solve the problems of non-reuse of aromatic amine structural substances, environmental pollution by toxic and harmful gases, and waste of resources. Achieve the effects of rich acidic oxygen-containing groups, efficient resource utilization and reasonable pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

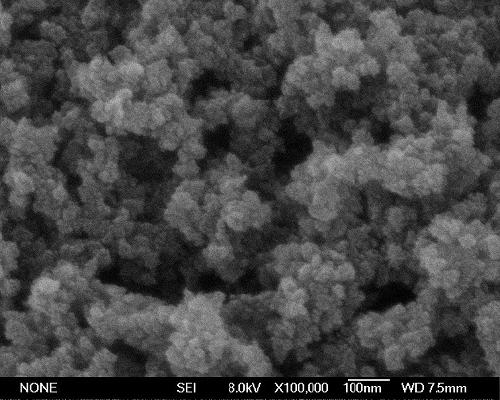

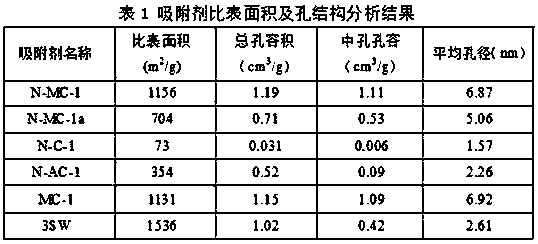

[0027] A method for resource utilization of residual tar in the production of phenylenediamine, using the residual tar in the distillation still in the production process of phenylenediamine as a carbon source and a nitrogen source, wherein the nitrogen content of the residual tar in the still is 15%, and its characteristics for, including the following steps:

[0028] (1) Add 300g of kettle residual tar, 0.3g of acetic acid, and 150g of magnesium acetate into a reaction kettle equipped with a microwave device and a capacity of 1000mL, pass in compressed air, heat up and stir under 500W microwave irradiation conditions for stabilization pretreatment, The stirring speed is 1000rpm to obtain a compound in which the carbon precursor / template precursor is mixed uniformly;

[0029] (2) Transfer the above compound to a tubular atmosphere furnace, and carry out carbonization in the presence of high-purity nitrogen according to the following temperature program: the heating rate is 1°...

Embodiment 2

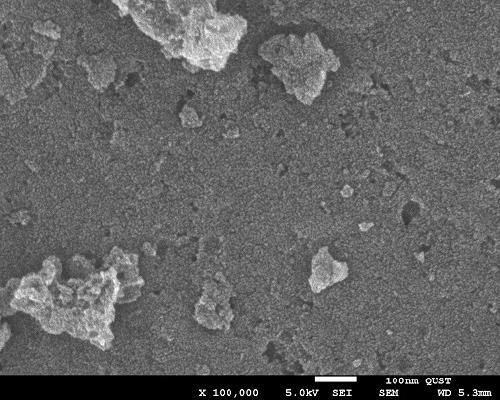

[0033] Using the same phenylenediamine rectification still residual tar as the carbon source and nitrogen source in Example 1, and using the same pretreatment method as in Example 1 to carry out the stabilization pretreatment to the residual tar in the still, the only difference is No template precursor is added; the stabilized pretreated residual tar is directly transferred to the tubular atmosphere furnace, and is carbonized according to the temperature program in the presence of high-purity nitrogen. The flow rate of the protective atmosphere, the heating rate, the maximum carbonization temperature and The carbonization temperature maintenance time is completely consistent with that in Example 1, and the carbonized product is treated with the same method as in Example 1 for template removal, and the obtained carbide is marked as N-C-1.

[0034] Using N-C-1 as the adsorbent, use the same method as step (3) in Example 1 to remove the aniline in the water produced by the hydrog...

Embodiment 3

[0036] Using the same preparation method as C-1 in Example 2, after the carbonization process was completed, water vapor was introduced for high-temperature activation, the steam flow rate was 20mL / min, the activation temperature was 850°C, and the activation time was 5hr. The resulting finished catalyst is designated N-AC-1.

[0037] Using N-AC-1 as the adsorbent, use the same method as step (3) in Example 1 to remove the aniline in the water generated by the hydrogenation reaction of mixed dinitrobenzene, and after a single adsorption, the aniline in the water phase The concentration of aniline decreased from 2000ppm to about 410ppm, and the removal rate of aniline was 79.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com