Method for recycling and applying discarded rare earth polishing powder into crystal glass

A rare earth polishing powder, crystal glass technology, applied in polishing compositions containing abrasives, chemical instruments and methods, other chemical processes, etc., can solve the problems of inefficiency, consumption, secondary pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

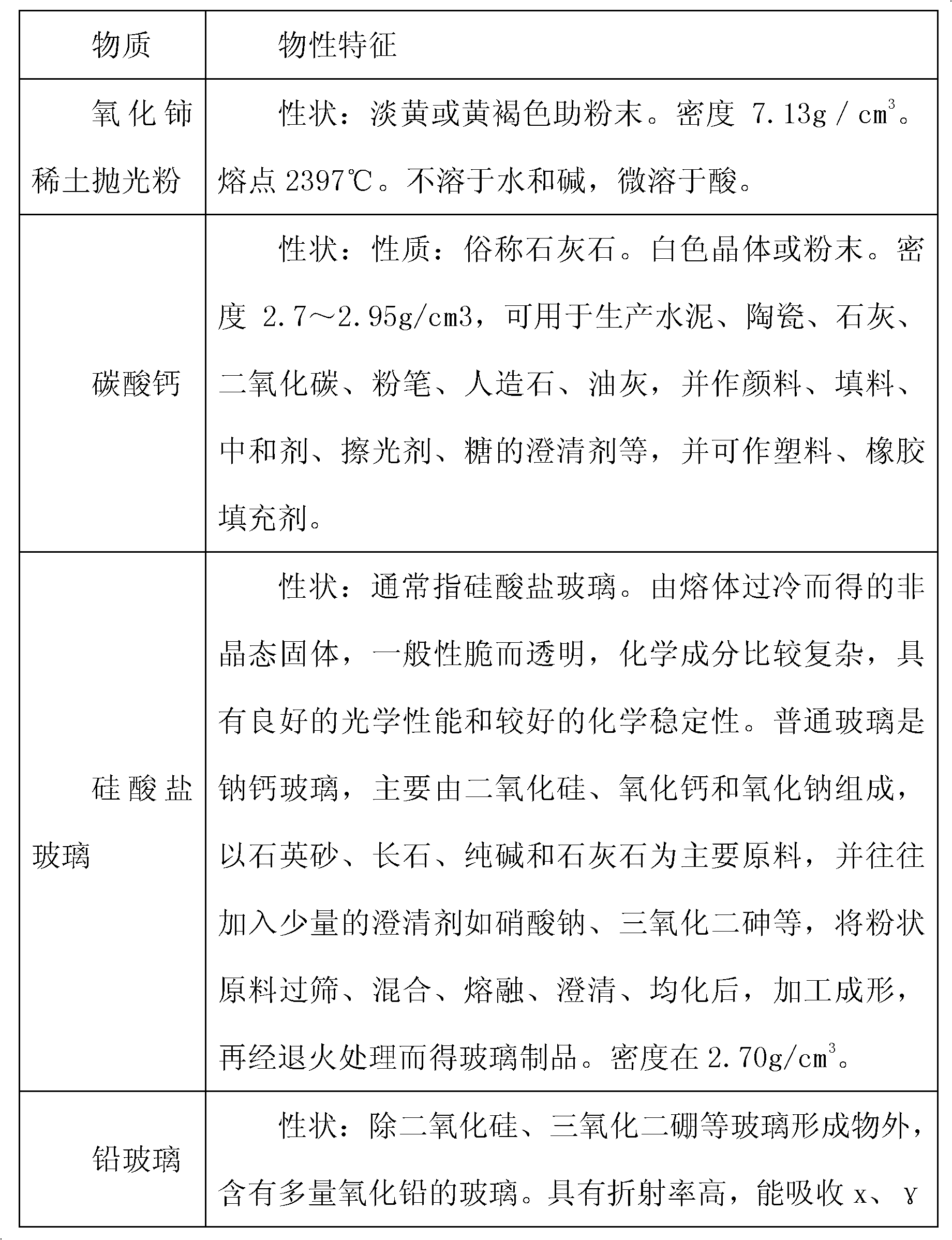

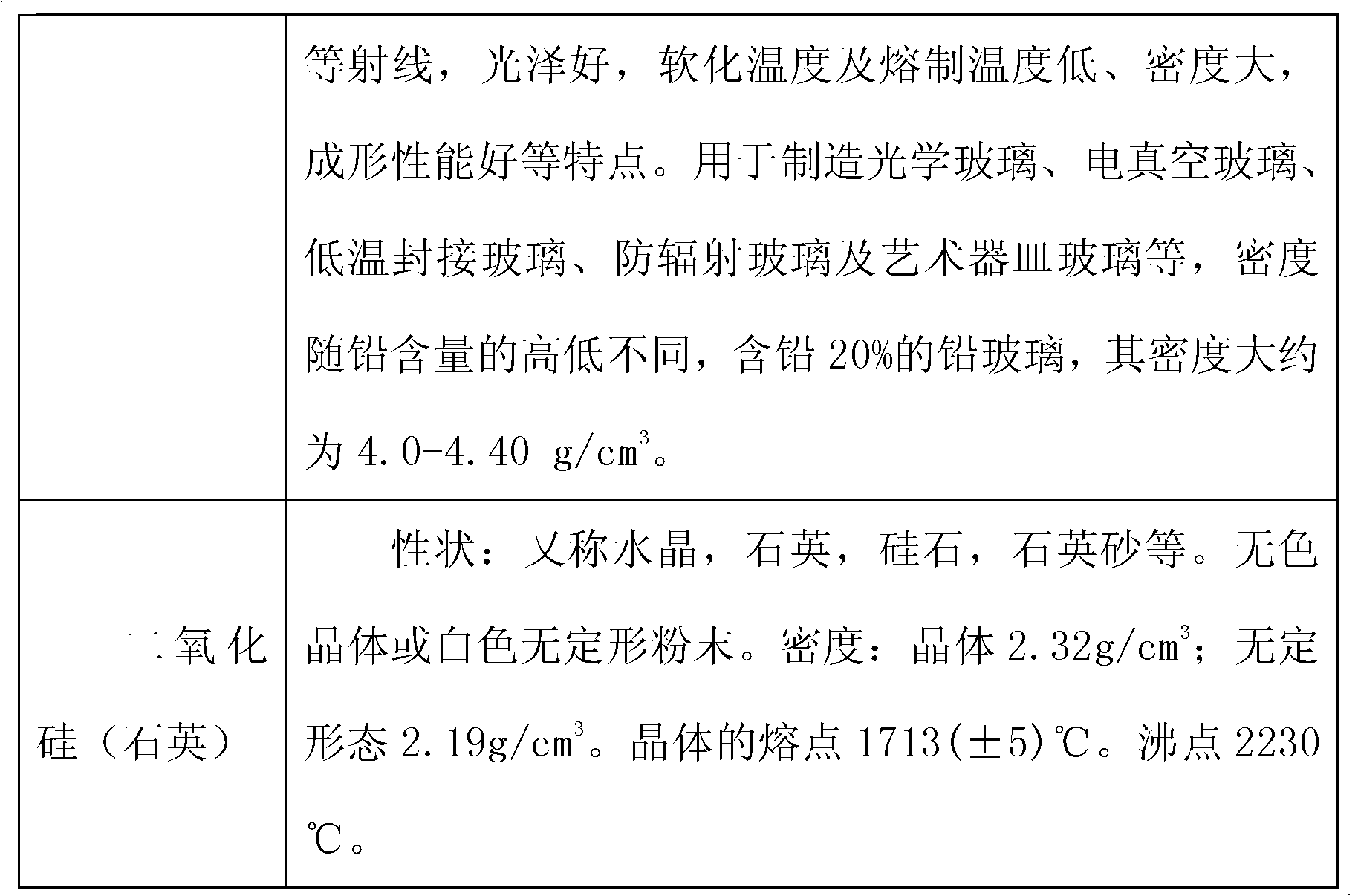

Image

Examples

Embodiment 1

[0060] (1) Gravity separation on a shaking table to remove light components and purify rare earth polishing powder residue

[0061] Take 50Kg of rare earth polishing powder waste and sieve through a 1m long vibrating sieve to remove large particles and foreign matter. The sieve size is 0.5mm. Use the pulping machine to pulp the waste residue of each fraction into a slurry with a concentration of 20%. 2 Gravity separation is carried out on a shaker with the same specifications, and the heavy fraction is collected. After dry weighing measurement and test analysis, the rare earth recovery rate is 70.3%, and the rare earth purity is 80.1%.

[0062] (2) Dilute nitric acid dissolves non-glass impurities

[0063] Take 100g of dried rare earth polishing powder residue after re-selection on a shaker in a 250ml beaker, add 100g of water to make a slurry, stir evenly, heat up to 50°C, and then slowly add dilute nitric acid solution with a concentration of 1.0mol / L, Stop adding dilute ...

Embodiment 2

[0072]The gravity separation process is the same as in Example 1, except that the size of the vibrating sieve is 1 mm. After weighing measurement and test analysis: the rare earth recovery rate is 75.2%, the rare earth purity is 78.6%, and the gravity purification efficiency is slightly low. The amount of subsequent dilute nitric acid and hydrofluoric acid was increased to 30ml and 40ml respectively, the recovery rate of rare earth was 94.6%, the purity of rare earth reached 88%, and the abrasive volume of polishing powder was 52.6%.

Embodiment 3

[0074] The gravitational separation process was the same as in Example 1, except that the concentration of the separated slurry before the gravimetric separation was 25%. After weighing, measurement and test analysis: the rare earth recovery rate is 68.4%, and the rare earth purity is 83.2%. The amount of subsequent dilute nitric acid and hydrofluoric acid remains unchanged, the recovery rate of rare earth is 95.6%, the purity of rare earth reaches 91%, and the amount of abrasive polishing powder is 54.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com