Patents

Literature

54results about How to "Good recycling effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

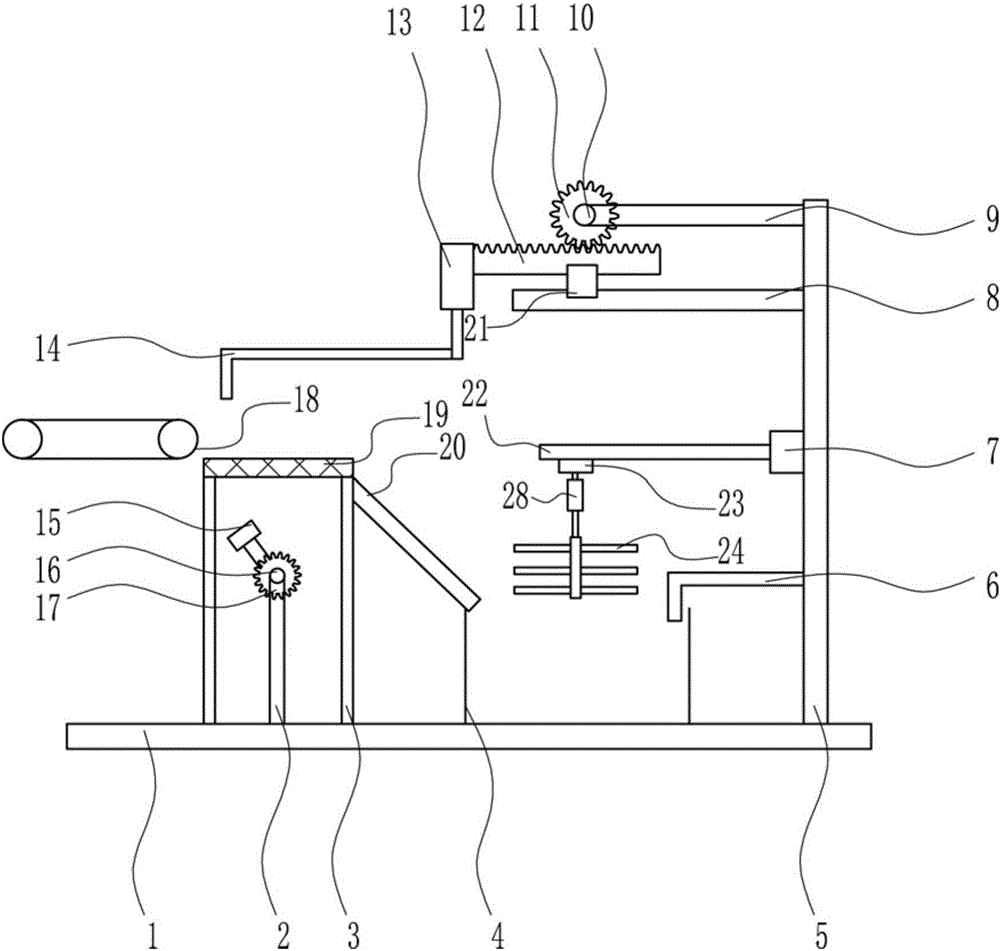

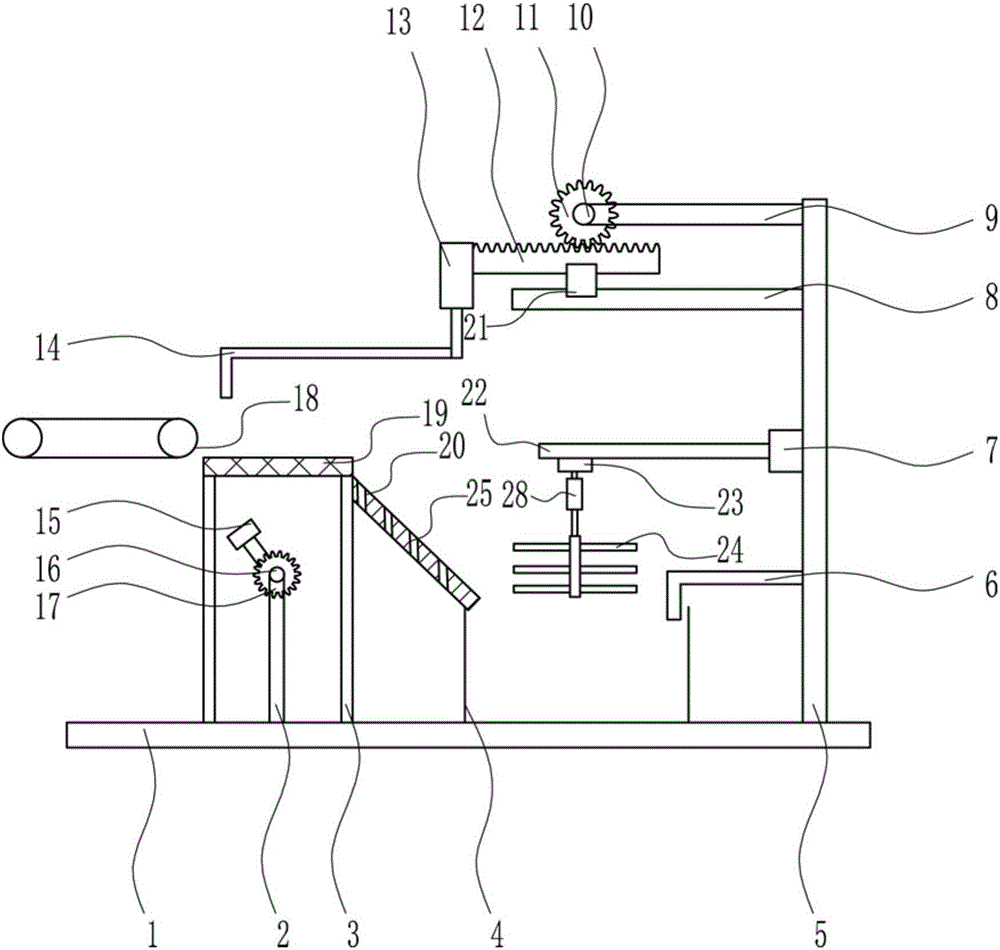

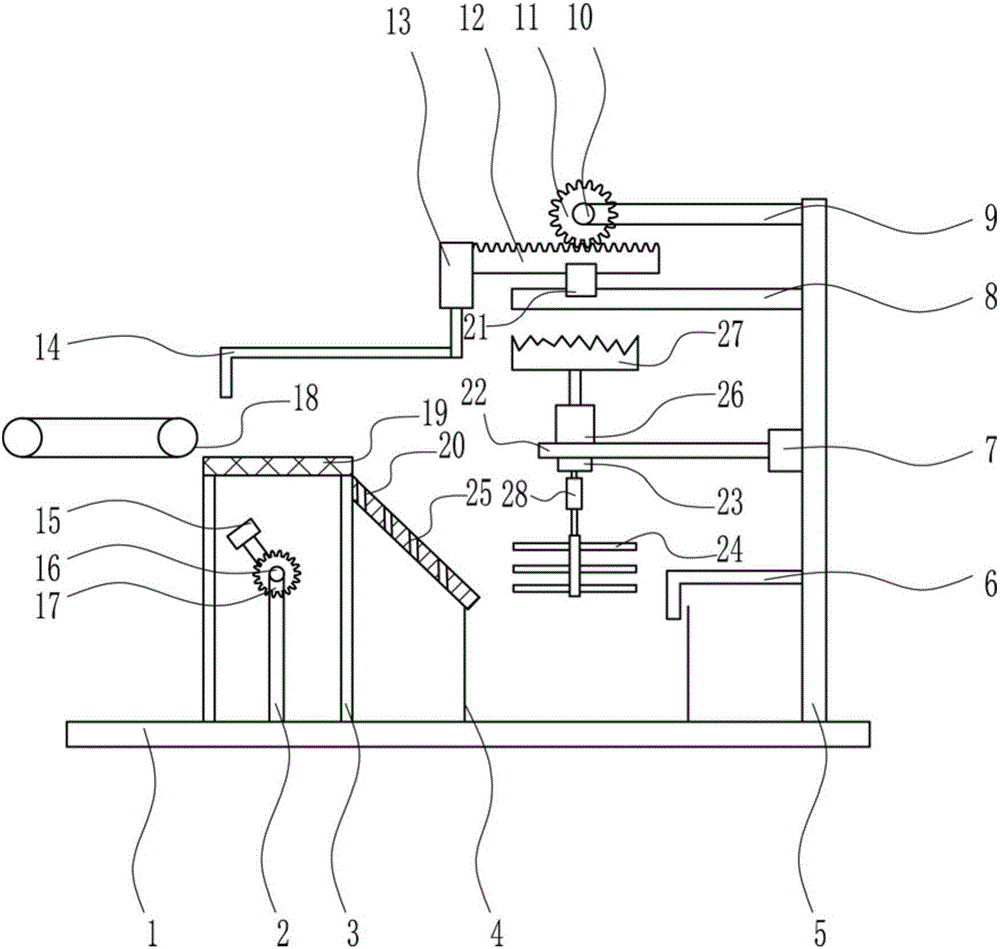

Hardware recycling processing device

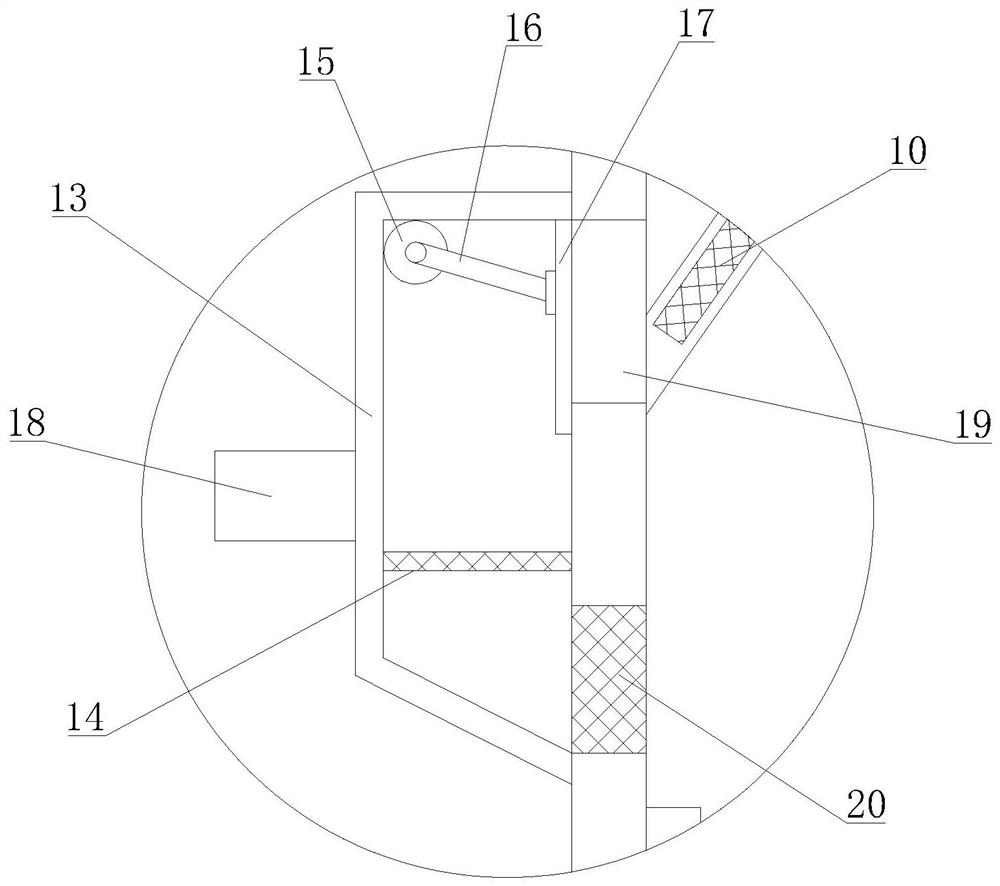

The invention relates to a recycling processing device, in particular to a hardware recycling processing device. The invention provides the hardware recycling processing device, which is easy and convenient in operation, great in saving both time and labour and good in recycling processing effect. In order to solve the technical problems, the invention provides the hardware recycling device. The hardware recycling device comprises a baseboard, a strut I, a net rack, a processing box, a right support, an acid liquor pipe, an electrical machine I, a sliding rail, a strut II, an electrical machine II, a gear I, a rack, a power-driven push rod, a push rod I, a hammer, an electrical machine III, a gear II, a conveying device, a filter screen, a cantboard, a sliding block, a strut III, an electrical machine IV, a stirring pole and an air cylinder. The conveying device is arranged on the top left of the baseboard, and the strut I is arranged on the upper left of the baseboard. According to the invention, the effects of being easy and convenient in operation, great in saving both time and labour and good in recycling processing effect are achieved, and soil pollution can be effectively prevented through hardware recycling processing by using the hardware recycling processing device, and the environment can be protected.

Owner:江苏扬林电气有限公司

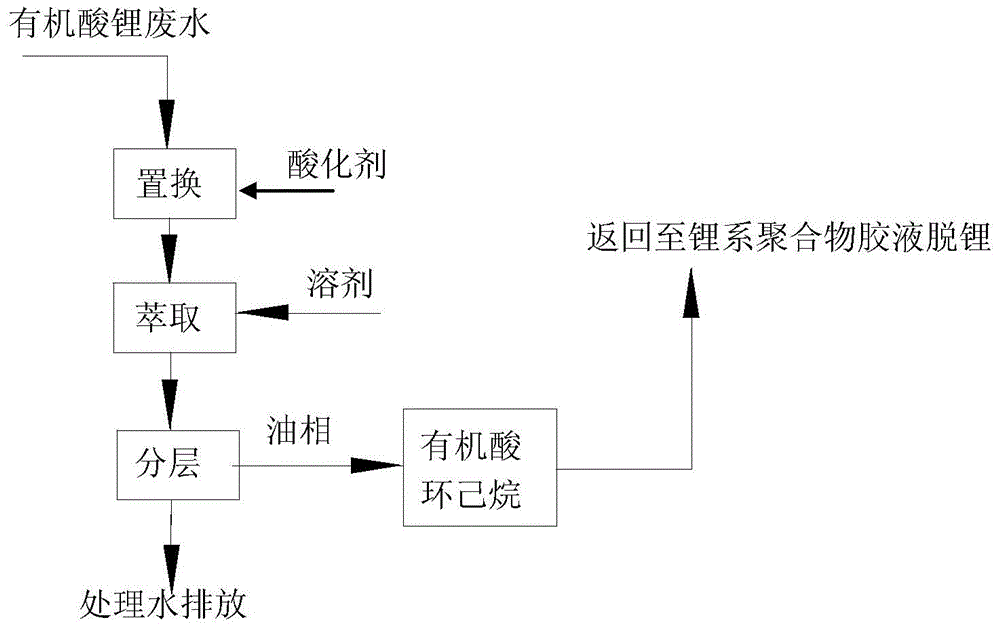

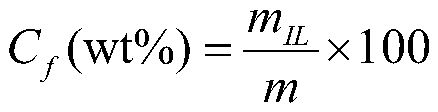

Circulation method for recovering organic acid from organic acid lithium waste water

ActiveCN105016415AHigh transparencyHigh whitenessWater/sewage treatment by extractionOrganic acidLithium

The invention discloses a circulation method for recovering organic acid from organic acid lithium waste water. The circulation method is characterized in that the waste water is generated by lithium deintercalation in a lithium system polymer glue solution through organic acid; solvent and acidifying agents used for polymerization reaction of generated lithium system polymers are added into the waste water for acidifying reaction with organic acid lithium in the waste water, and the pH value of an acidifying reaction endpoint is controlled to be within 3.0-6.9; the organic acid is extracted to be recovered through the solvent, and oil phases obtained after layering are returned into the process of lithium deintercalation of the organic acid. The method can be used for using the original organic acid in a lithium system polymer glue solution lithium deintercalation unit in a circulating mode after the organic acid lithium waste water is treated and restored, meanwhile, COD in the waste water can be effectively reduced, and corrosion to equipment in the treatment process is greatly reduced; the lithium deintercalation cost in the lithium system polymer technology is effectively lowered.

Owner:CHINA PETROLEUM & CHEM CORP

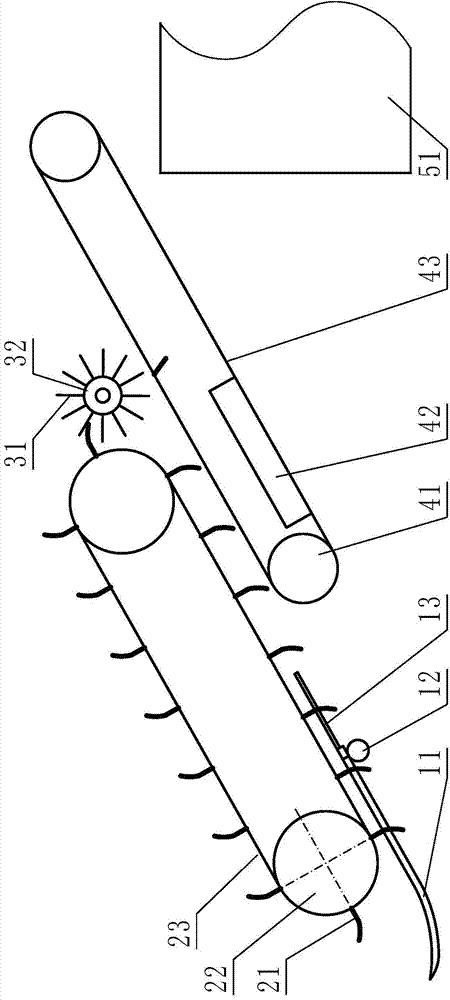

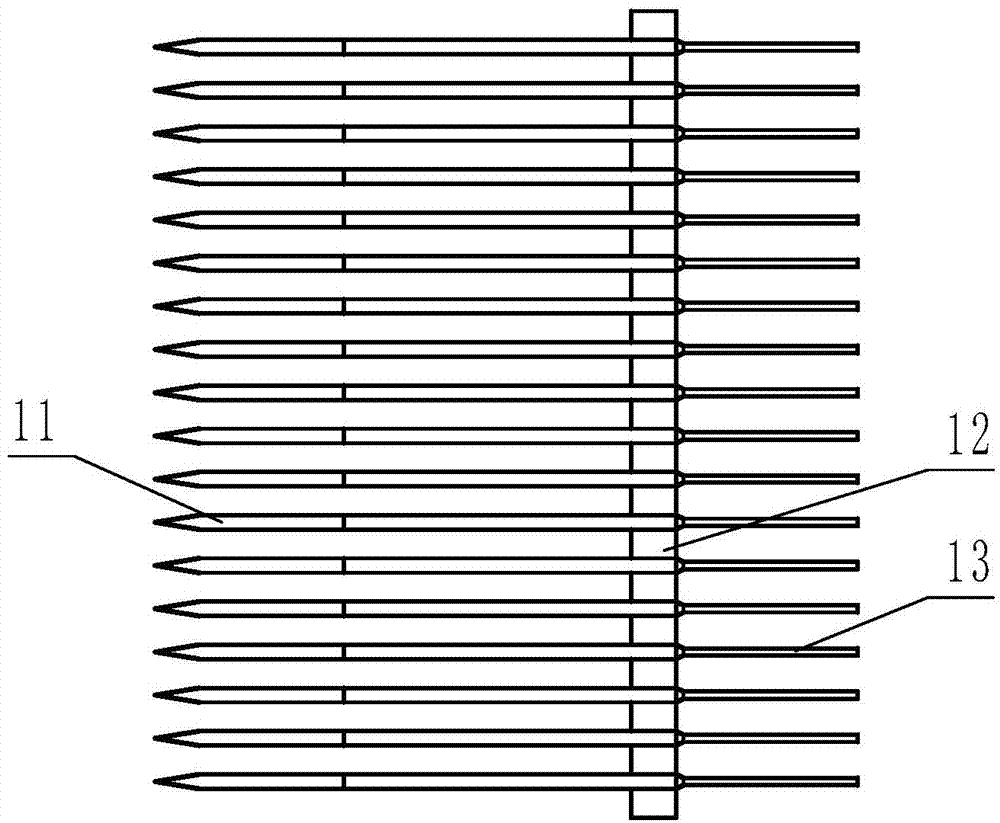

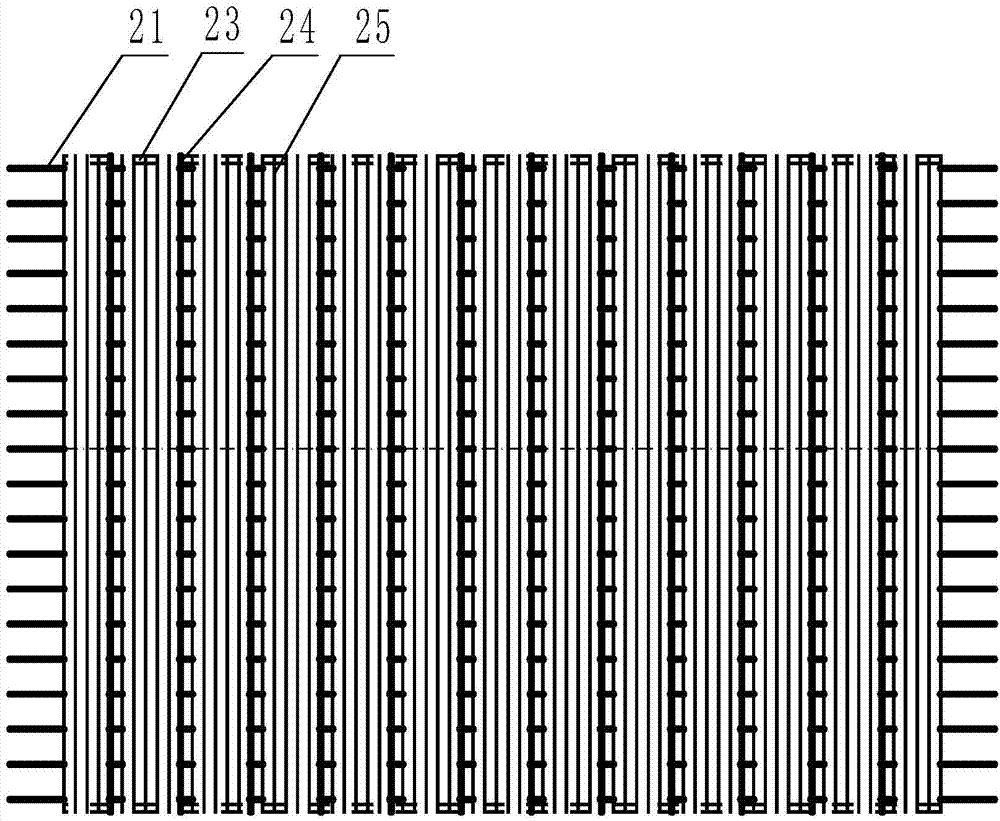

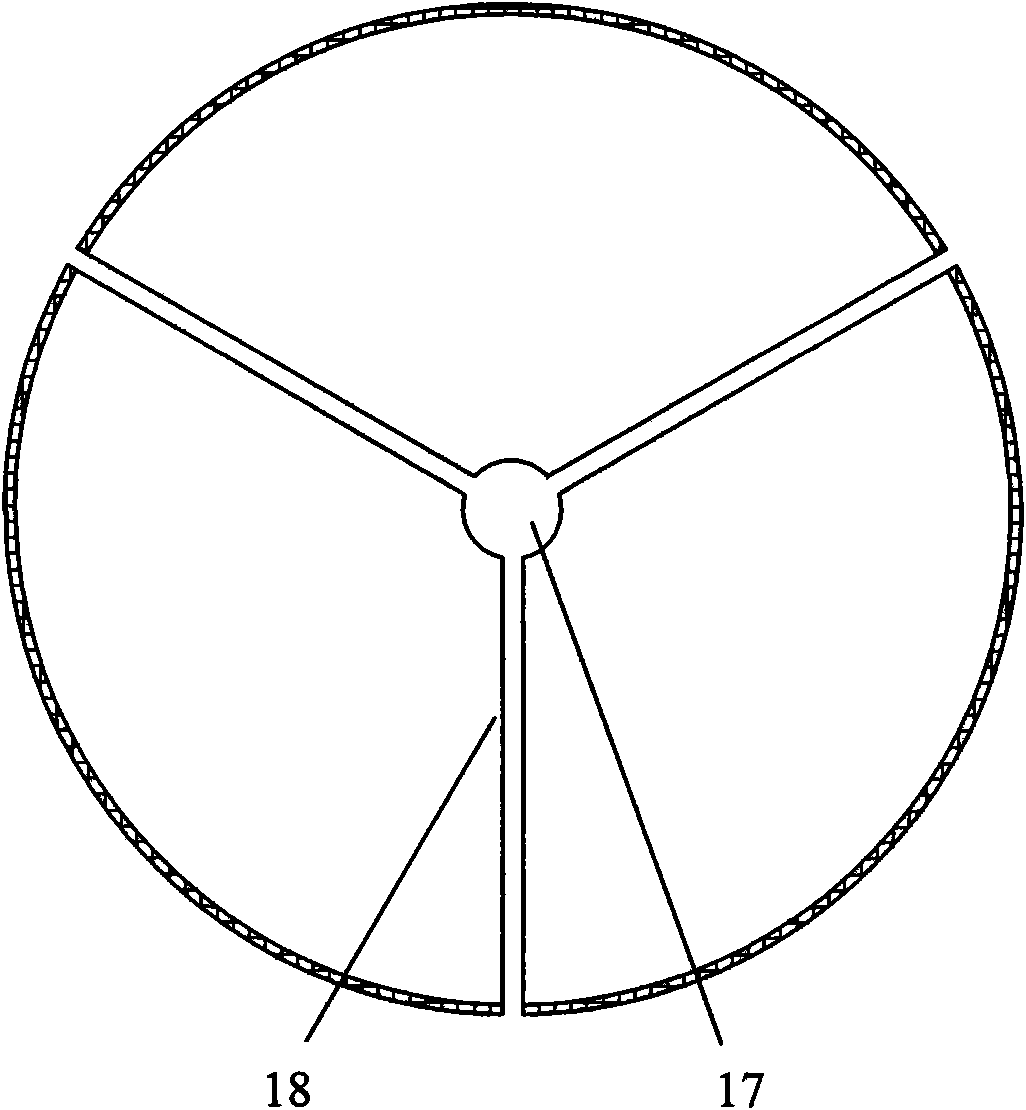

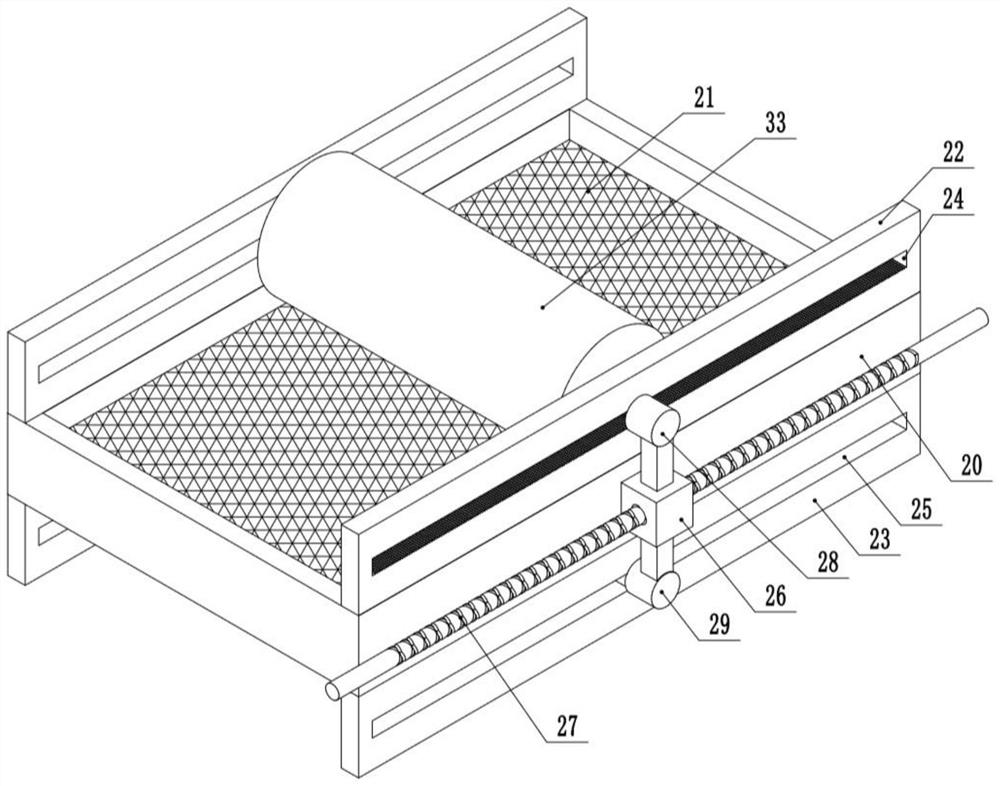

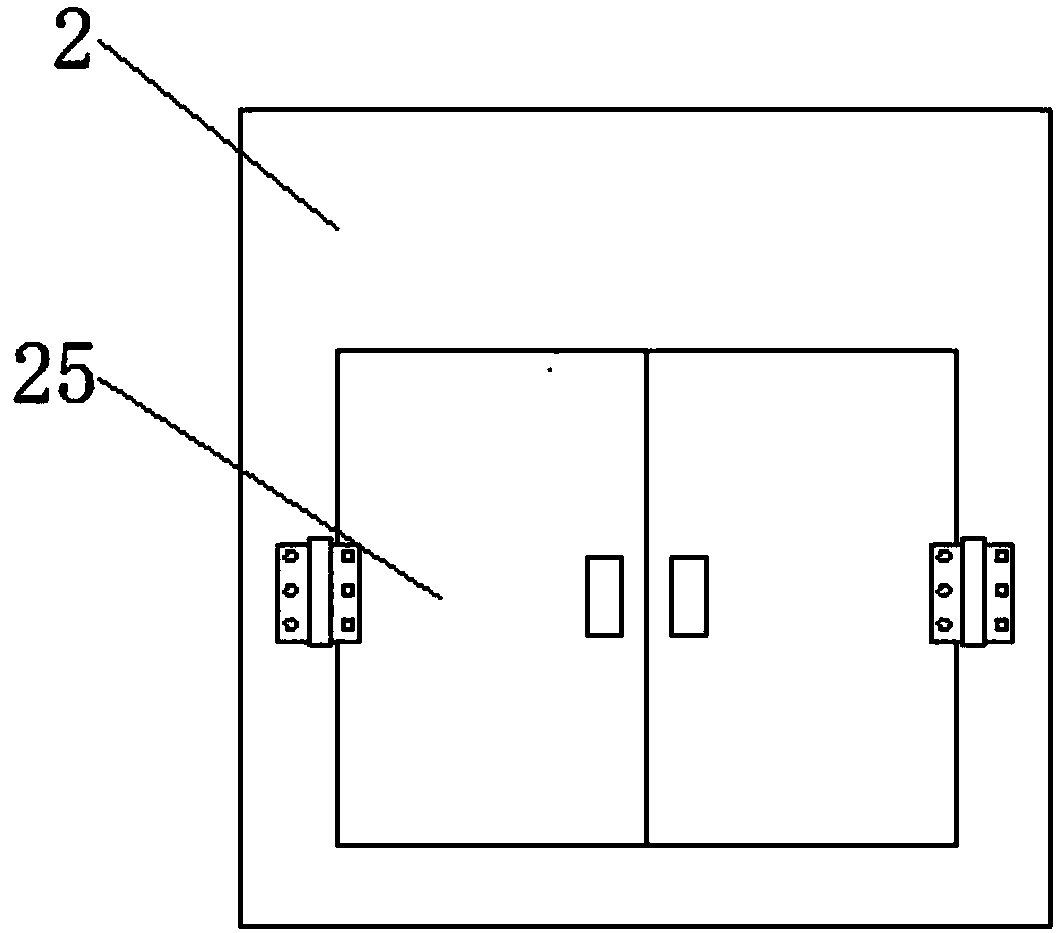

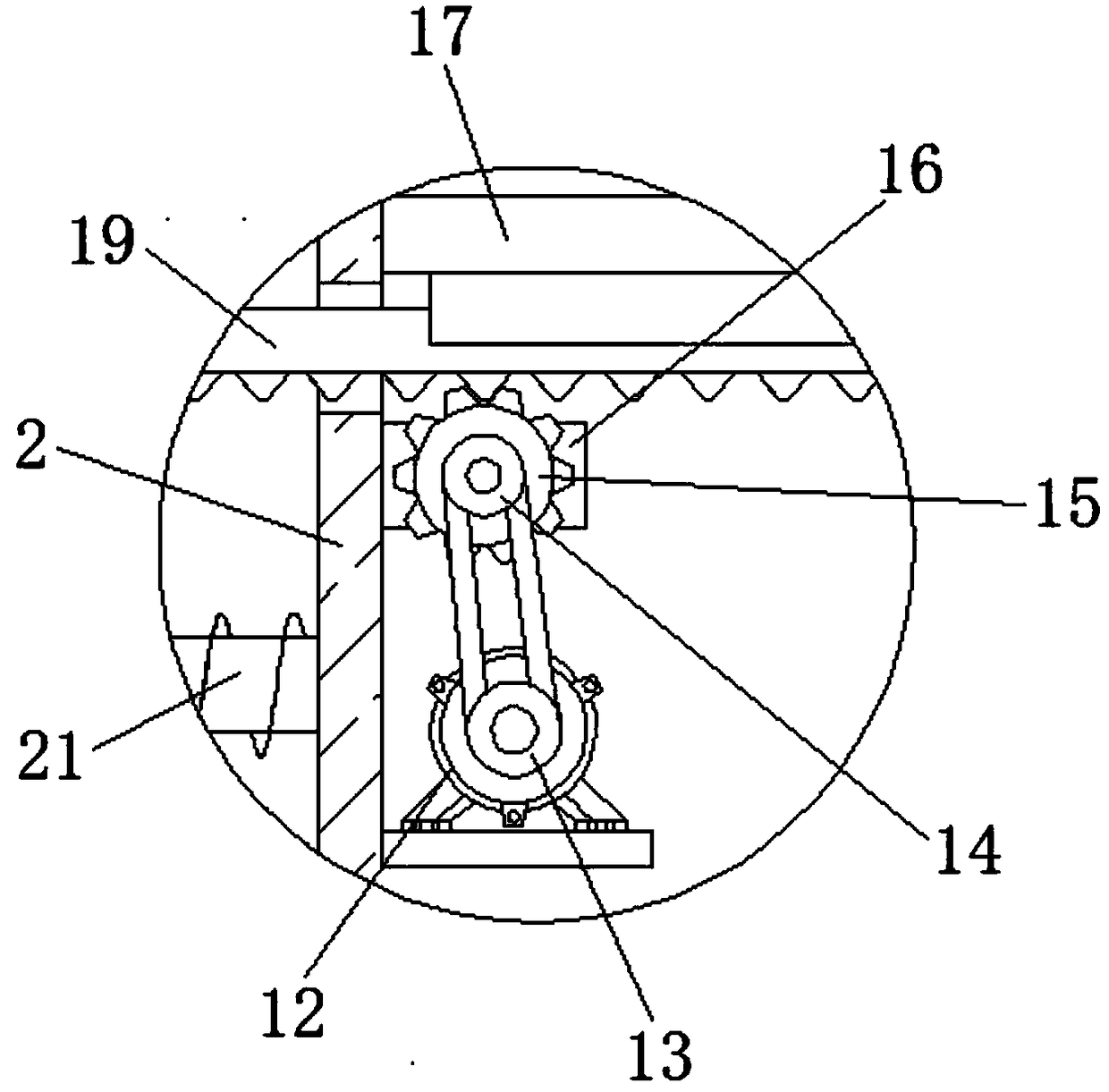

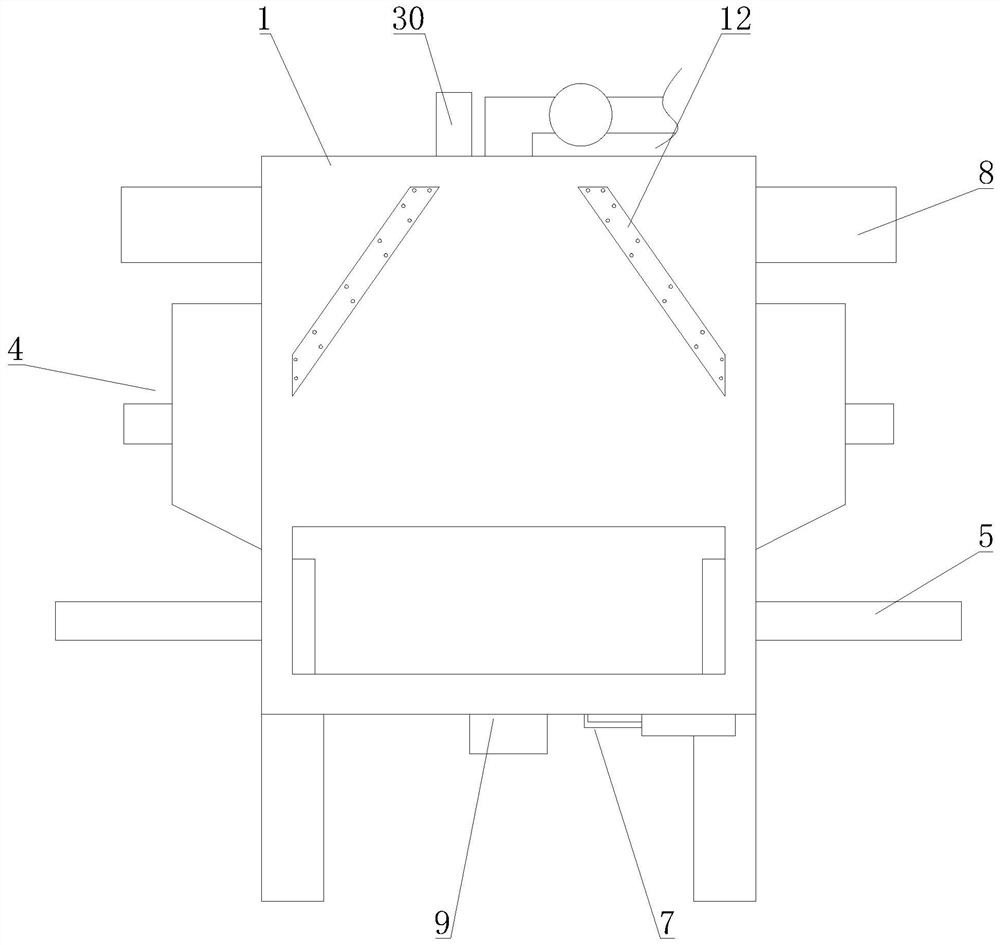

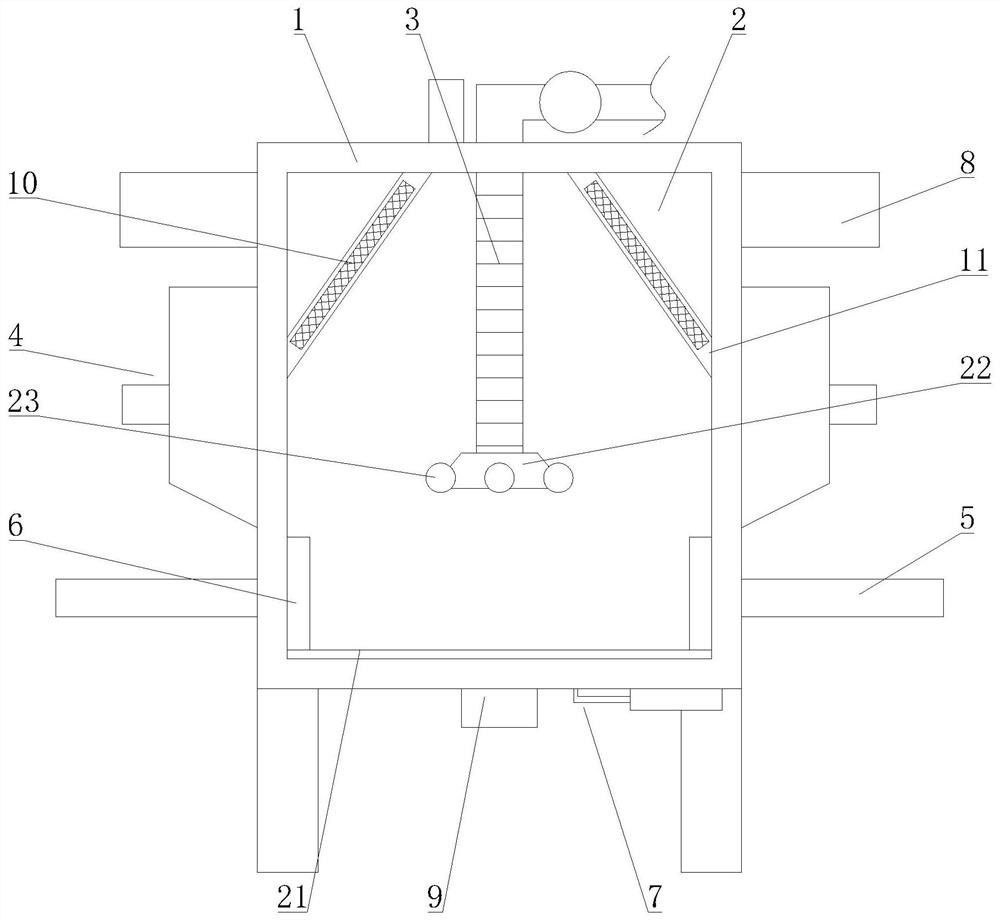

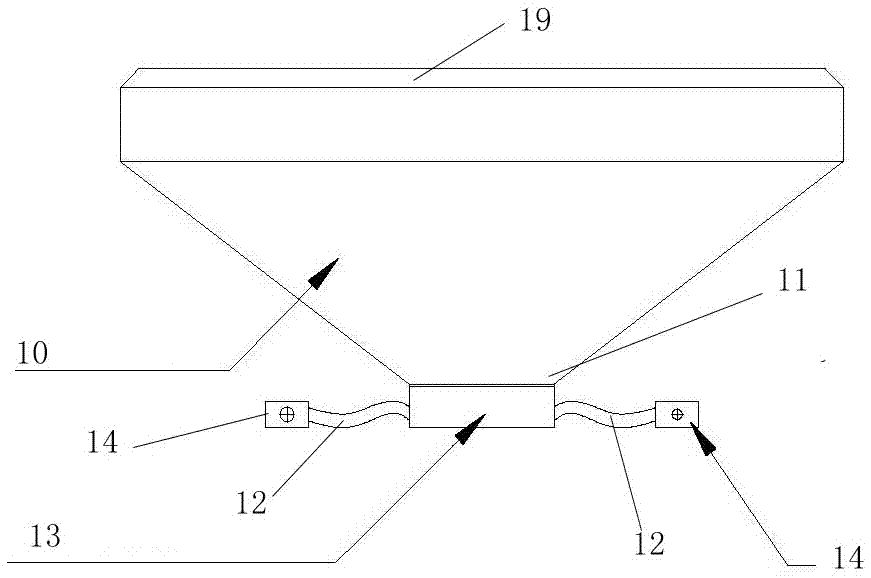

Mulch recycling machine

ActiveCN104322165AGood recycling effectSimple structureGatherer machinesAgricultural engineeringAgricultural science

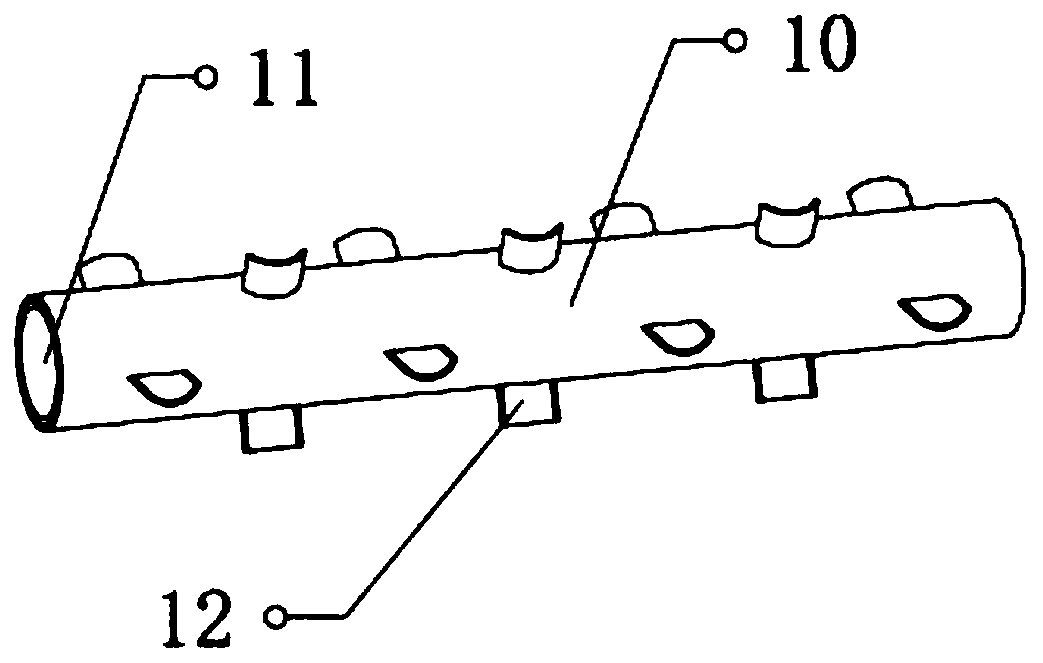

The invention discloses a mulch recycling machine which comprises a suspending frame, a main frame and a transmission mechanism, wherein digging teeth (11) are arranged at the lower part of the main frame, a picking device is arranged on the upper part of the digging teeth (11), the picking device comprises a group of driving wheels (22) and a chain (23) which is arranged on the group of the driving wheels (22), the chain (23) is provided with a horizontal rod (24) and picking teeth (21) which are arranged in an array form, a net sieve (25) is arranged in parallel with the chain (23) and the horizontal rod (24), and a brush roller (32) fully provided with brush hairs (31) and a collecting device are arranged at the back part of the picking device. Compared with the prior art, the mulch recycling machine is good in recycling effect, simple in structure and good in picking efficiency, residue mulch pieces in different sizes can be picked, and particularly, the residue mulch pieces hidden in the ground can be dug, cleaned and recycled.

Owner:乌鲁木齐振兴瑞安塑料机械有限公司

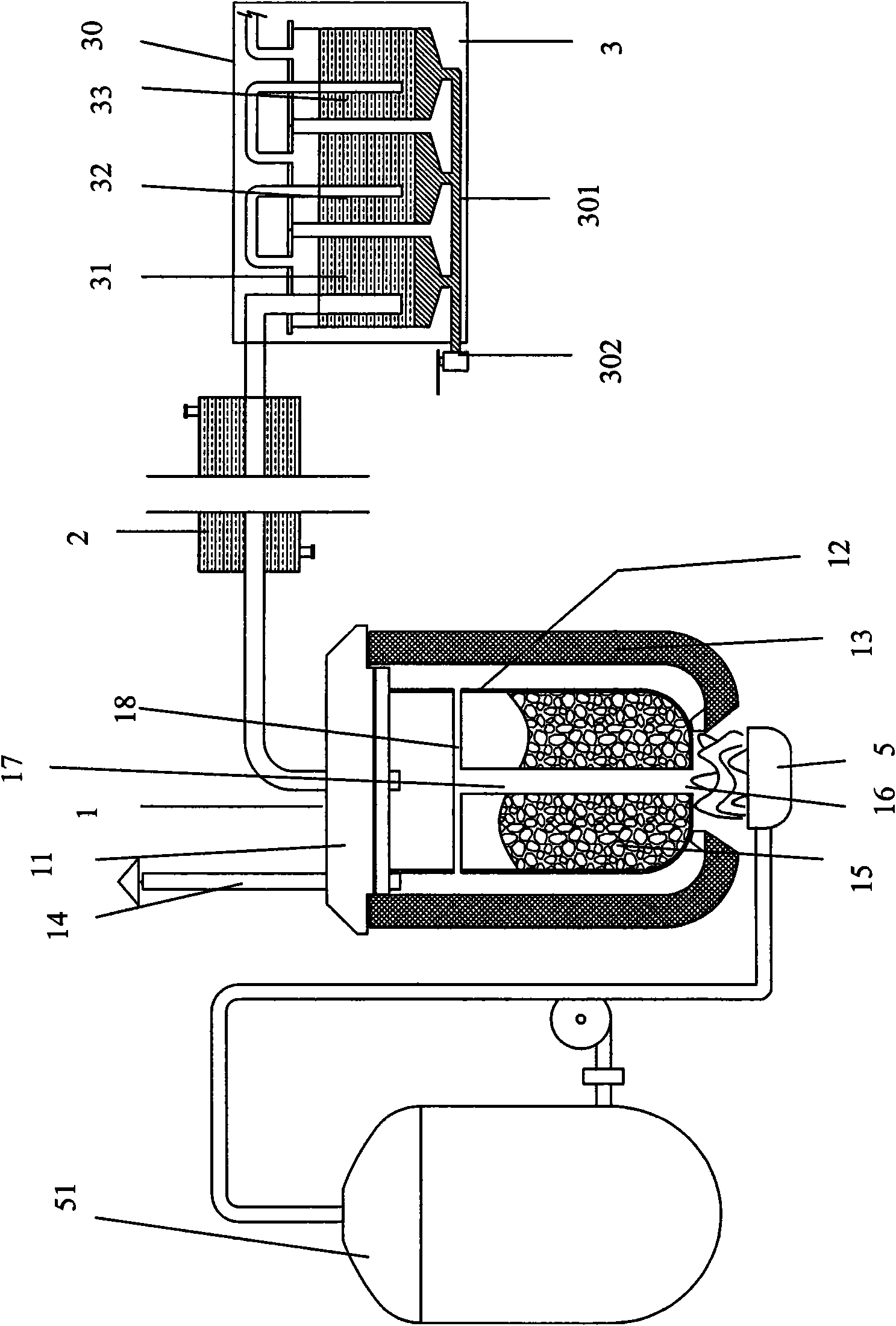

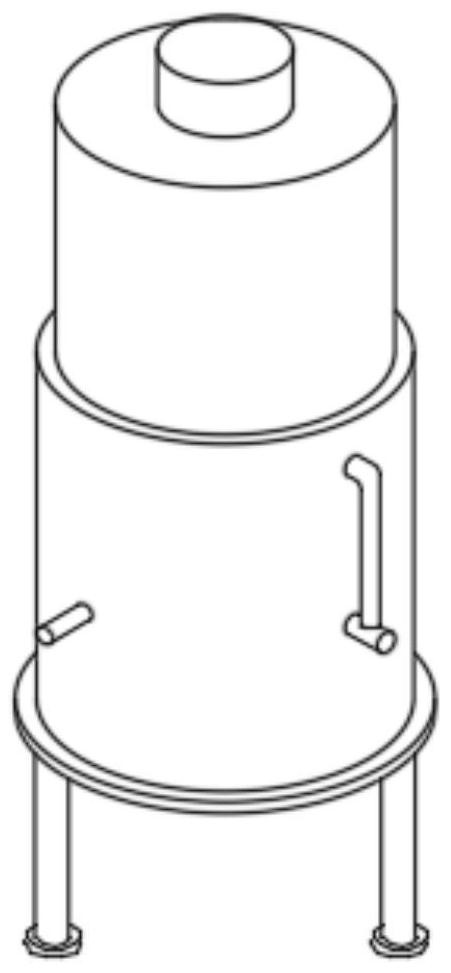

Device and method for recovering glass reinforced plastic by pyrolysis

The invention relates to a device and a method for recovering a glass reinforced plastic by pyrolysis. The recycling device comprises a reaction kettle, a heating device, and an oil and gas separating device, wherein the outside of the reaction kettle is provided with an insulation layer; the reaction kettle is provided with a main body and a cover body; a closed packing chamber is formed on the inside after the main body and the cover body of the reaction kettle are closed; the main body is provided with a heat passing pipe from the bottom part in a penetrating mode; the heat passing pipe isconnected with the bottom part of the reaction kettle and heat passing holes on the side wall; the heat passing holes on the side wall are communicated with the heating device; and the packing chamber is communicated with the oil and gas separating device through a ventilating pipeline. The recovering method comprises the following steps: placing the glass reinforced plastic in the packing chamber, and heating the glass reinforced plastic to between 300 and 600 DEG C; generating an oil and gas mixture by the glass reinforced plastic under an anaerobic environment; and then separating the oil and gas mixture by the oil and gas separating device to obtain an oil layer and a residue in the packing chamber. The recovering device and the recovering method can effectively recover the glass reinforced plastic and solves the problem of difficult recovery of the glass reinforced plastic.

Owner:王凤奎

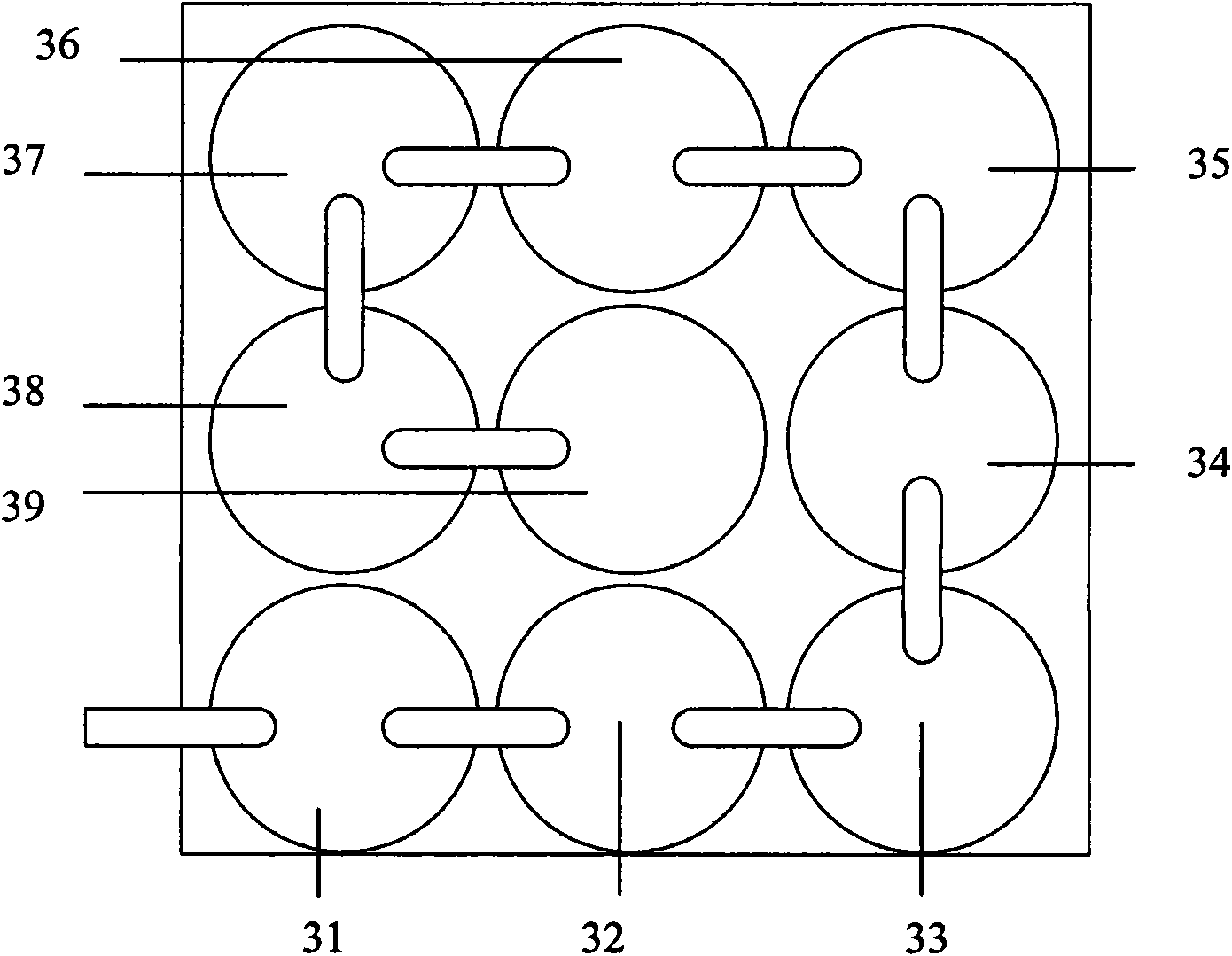

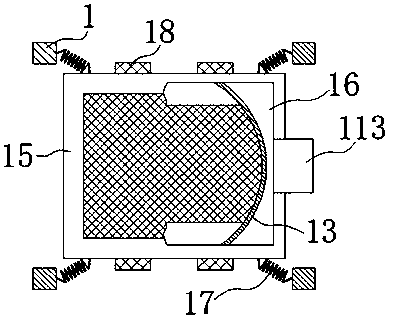

Molding sand dust-free treatment and recovery device for molding sand casting

InactiveCN112475220AGood recycling effectAvoid cloggingSievingScreeningSand castingMechanical engineering

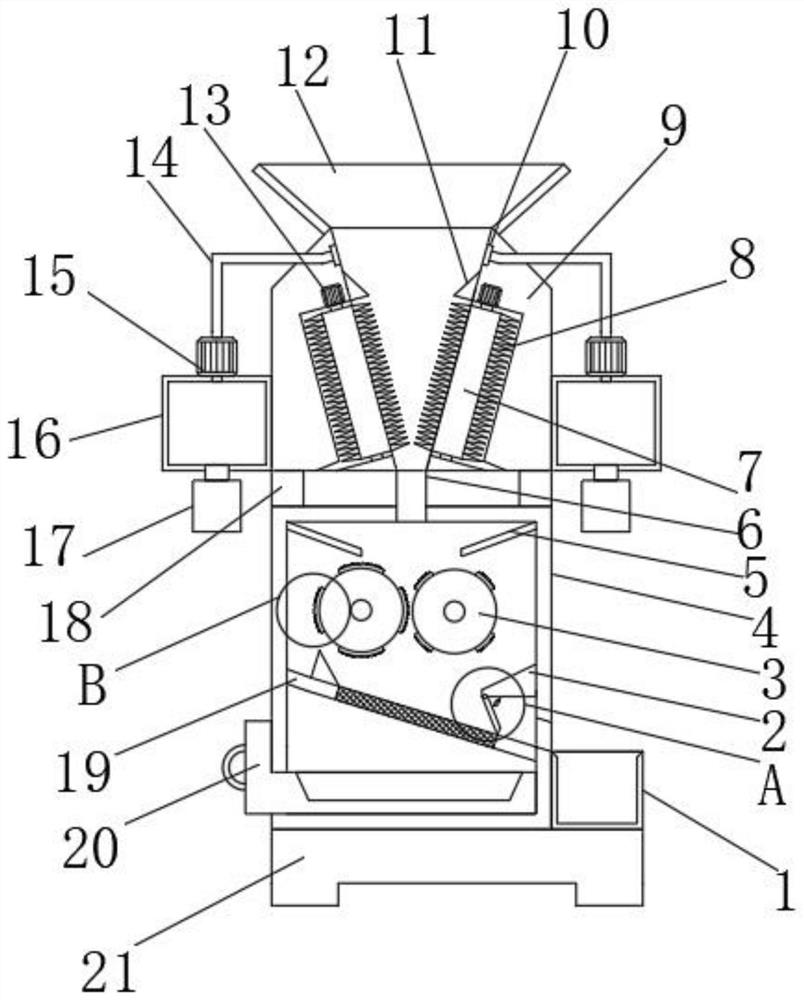

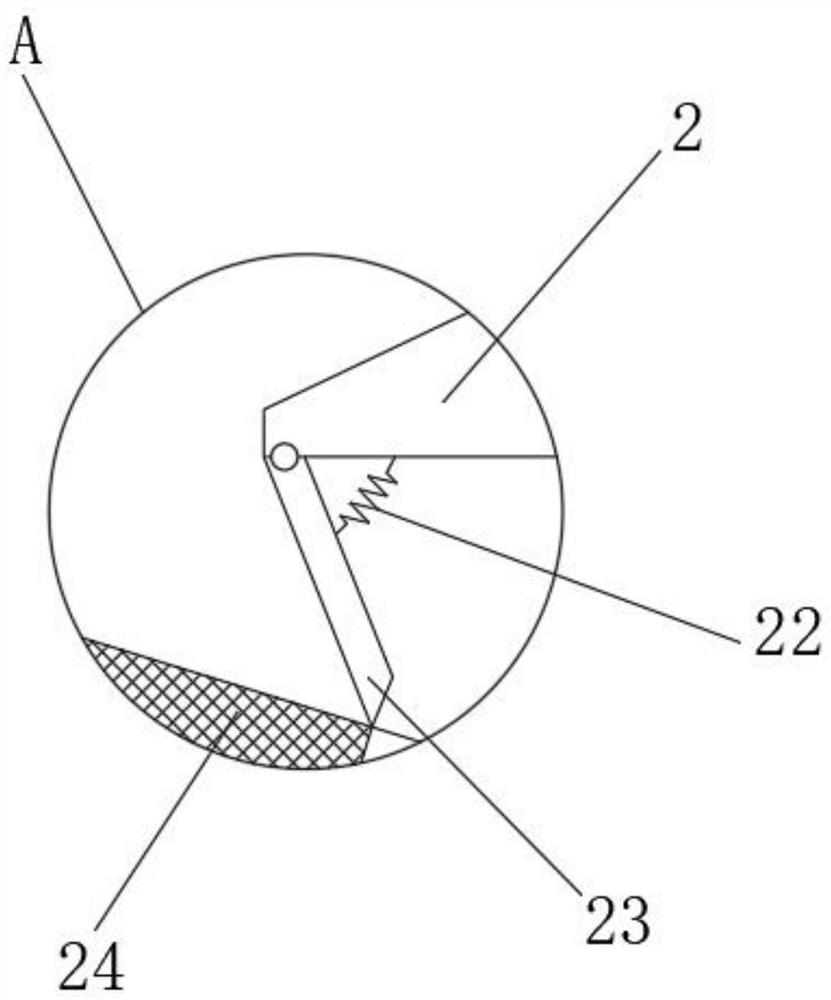

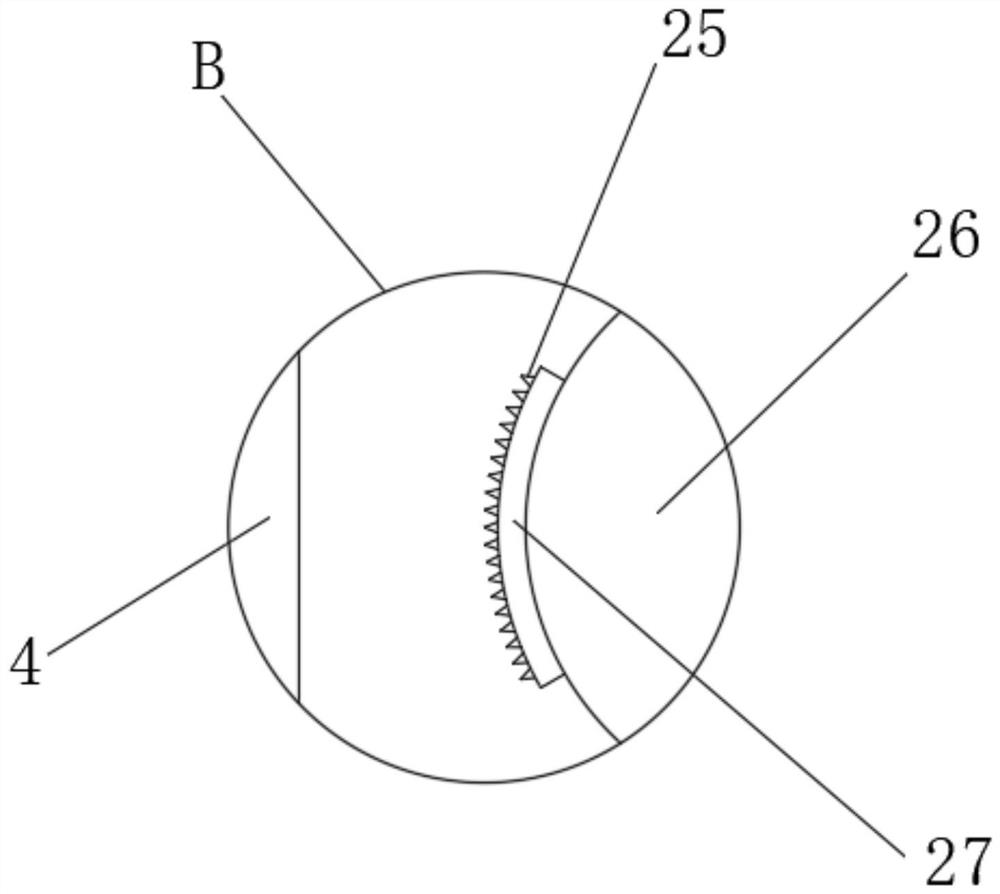

The invention discloses a molding sand dust-free treatment and recovery device for molding sand casting, and relates to the technical field of molding sand recovery. The molding sand dust-free treatment and recovery device comprises a recovery box; a primary crushing device is arranged at the upper part in the recovery box; a screening device is arranged below the primary crushing device; an air inlet hood and an exhaust hood are fixedly connected to the positions, on two sides of the screening device, of the inner wall of the recovery box; a buffering cover is arranged below the screening device; and a discharging conveying belt is arranged between two bases. According to the molding sand dust-free treatment and recovery device, the primary crushing device is arranged, so that caked molding sand polymers can be crushed into small blocks; the screening device is arranged, so that the small-block molding sand polymers can be crushed again to form molding sand monomers and powdery impurities; a filter screen can be prevented from being blocked through a brushing device; a discharging buffering device is arranged, so that the discharging speed can be decreased; and when the screeningdevice and the discharging buffering device work, dust mixed in the molding sand can be blown away through flowing of airflow, so that dust-free recovery and treatment can be achieved, and the recovery and treatment effect on the molding sand is good.

Owner:芜湖锋珉信息科技有限公司

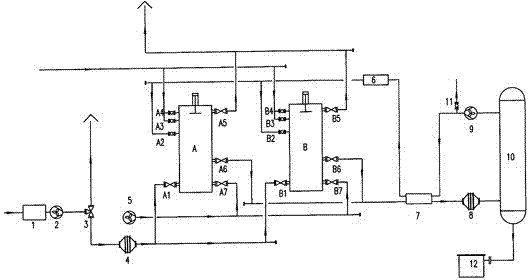

Novel organic waste gas recovery method and system

InactiveCN102476013AGood recycling effectReduce water contentDispersed particle separationWater contentSolvent

The invention relates to a novel organic waste gas recovery method and a novel organic waste gas recovery system, which belong to the field of environmental protection. By the organic waste gas recovery method utilizing activated carbon fibers and utilizing nitrogen gas as a desorption medium, organic waste gas and nitrogen gas can be recovered and reutilized simultaneously by the aid of a fixed-bed adsorber through hot nitrogen gas desorption, wherein the fixed-bed adsorber utilizes activated carbon fibers as adsorbent. Due to hot nitrogen gas desorption, secondary pollutant can be avoided, environment-friendly emission reaching the standards can be realized, an adsorption layer is kept dry, the utilization rate of the activated carbon fibers is increased, and the service life of the activated carbon fibers is prolonged. Since water vapor desorption is omitted, corrosion of equipment is avoided and manufacturing cost of equipment is reduced greatly. In addition, the novel organic waste gas recovery method has excellent effect on recovering solvent with high water solubility or easy to be hydrolyzed and organic waste gas with high boiling point, products recovered by the method is low in water content, solvent quality is high, and operating cost can be reduced.

Owner:DALIAN CHUANGDA TECH TRADE MARKET

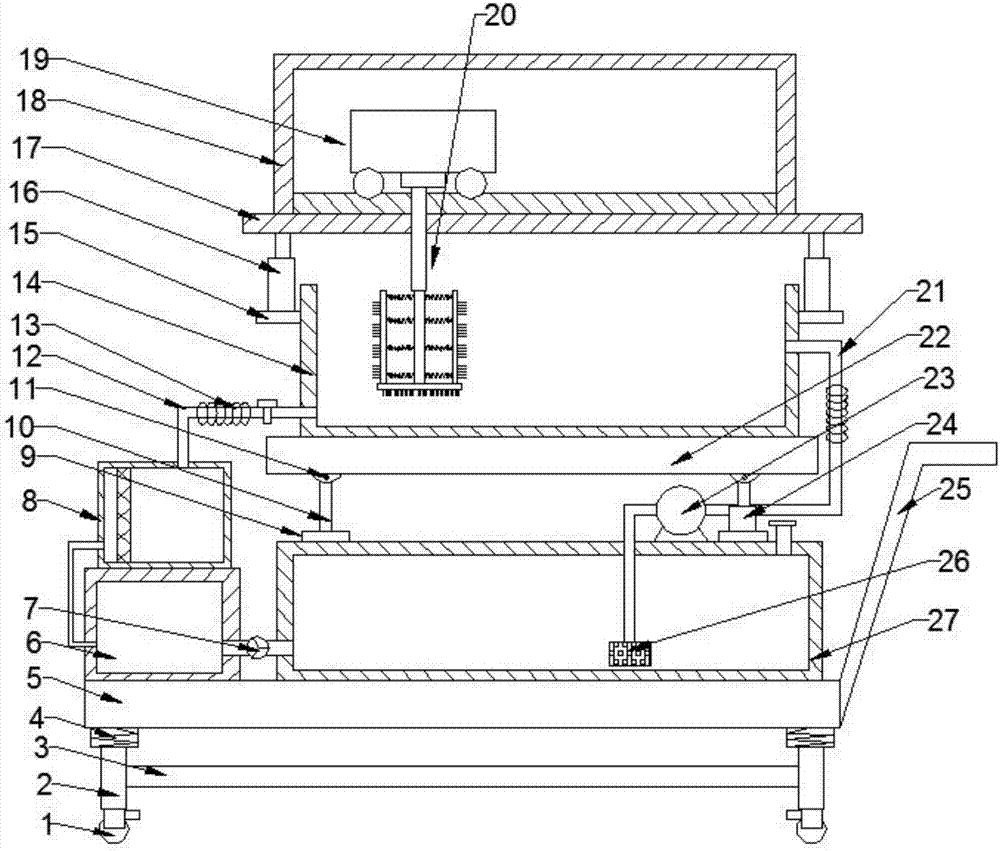

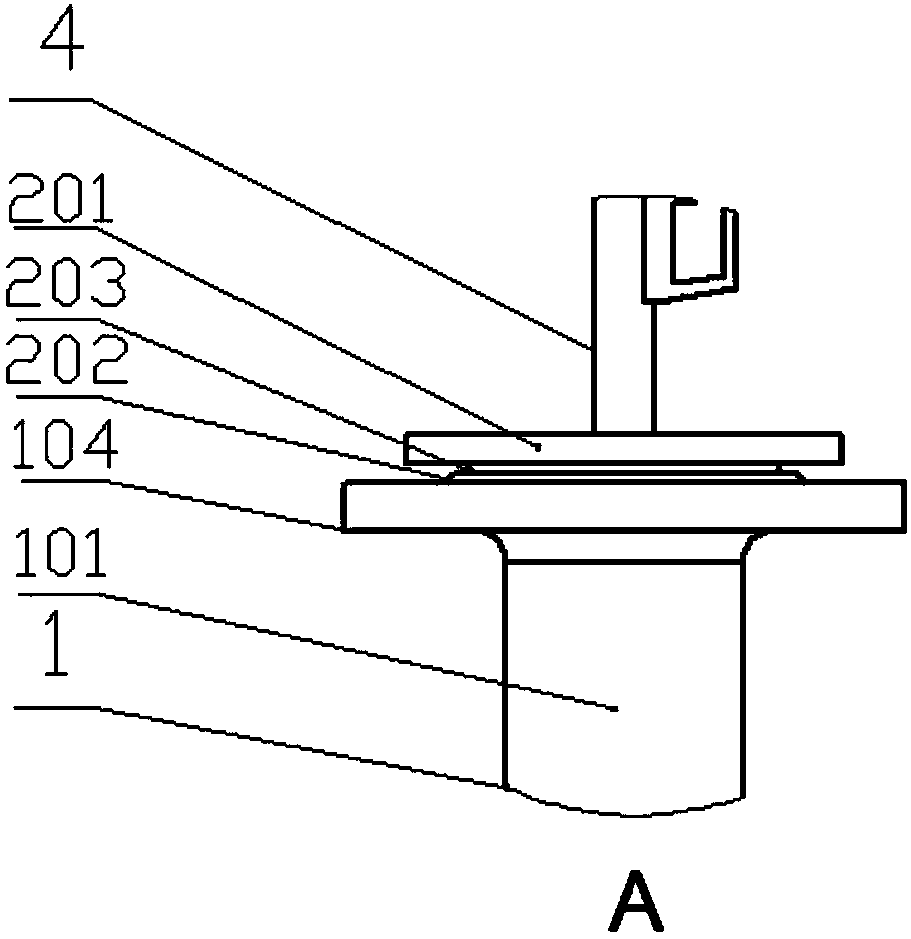

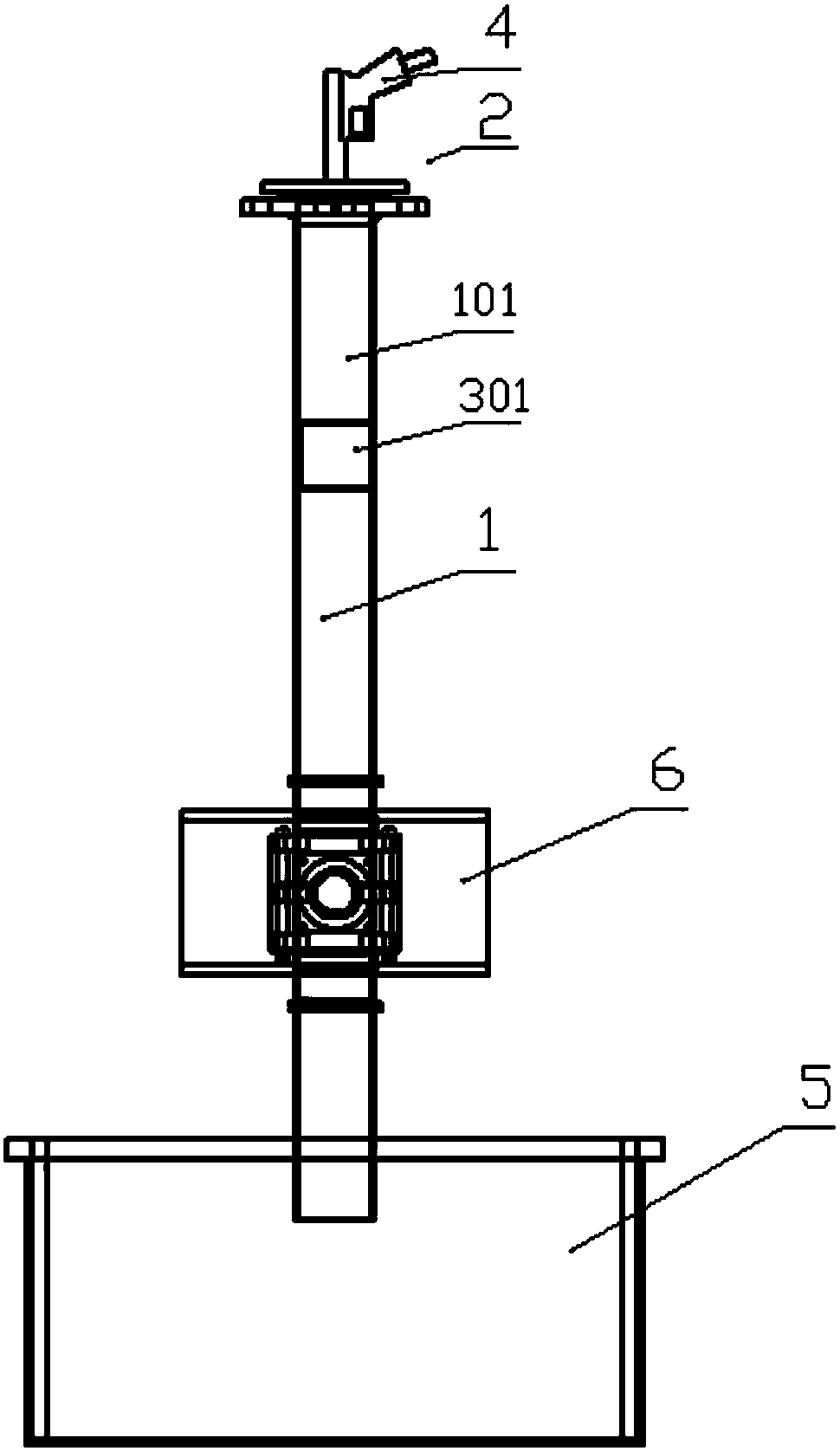

Waste water circulating type remaining concrete recovering and processing device

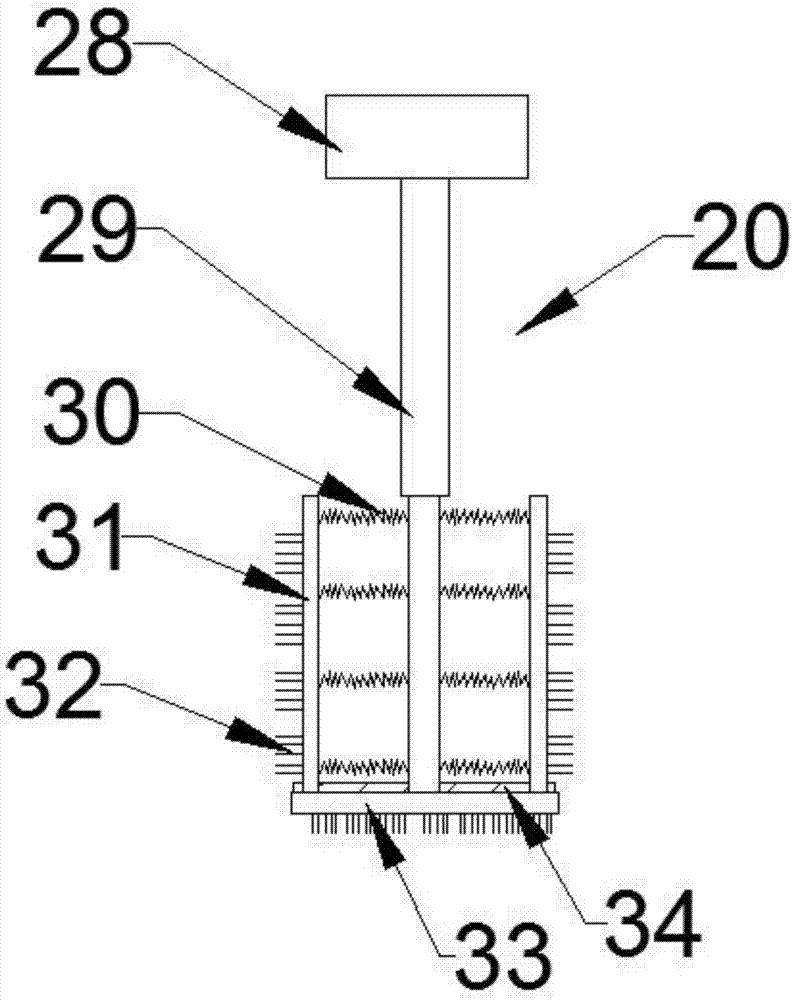

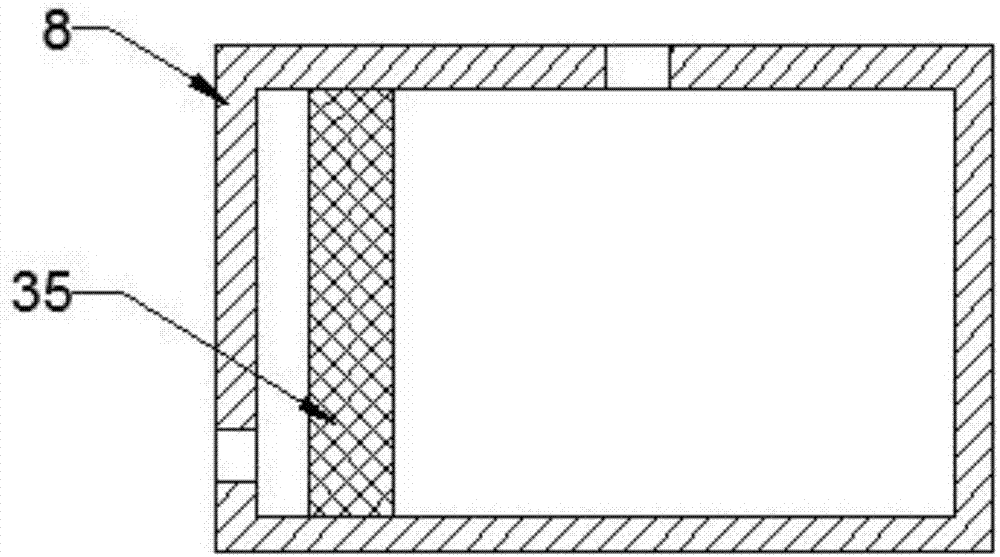

InactiveCN107351259AEasy to cleanEasy outflowDischarging apparatusWater/sewage treatmentHydraulic cylinderBristle

The invention provides a waste water circulating type remaining concrete recovering and processing device and belongs to the field of remaining concrete recovering. The upper end of a supporting column is provided with a carrier plate through a hinge, and the lower end of the right side of the carrier plate is connected with a hydraulic cylinder through a hinge. The right end of a water pump is connected with a filter through a water inlet pipe, and the left end of the water pump is connected with the right side of a washing vessel through the water inlet pipe. A hydraulic telescopic column is fixedly arranged on the upper face of the supporting plate, and a transverse plate is fixedly arranged at the upper end of the hydraulic telescopic column. A scrubbing device is fixedly arranged at the lower end of a walking trolley. A waste water purifying device is fixedly arranged below a sundry collection box. According to the waste water circulating type remaining concrete recovering and processing device, the inner sides of side wall scrubbing plates are arranged on the two sides of a telescopic rod through springs, iron bristles are arranged on the side wall scrubbing plates, and the function of conveniently cleaning away the residual cement paste with relatively-high viscosity is achieved. The waste water circulating type remaining concrete recovering and processing device has the beneficial effects of being simple in structure, high in practicality and good in recovering and processing effect.

Owner:ZHENGZHOU AIMOFU INFORMATION TECH CO LTD

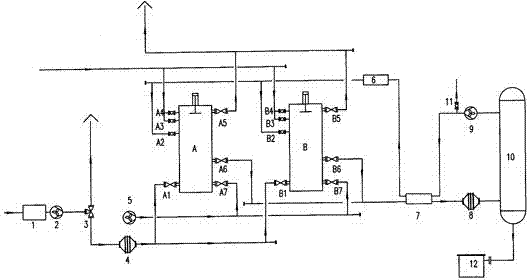

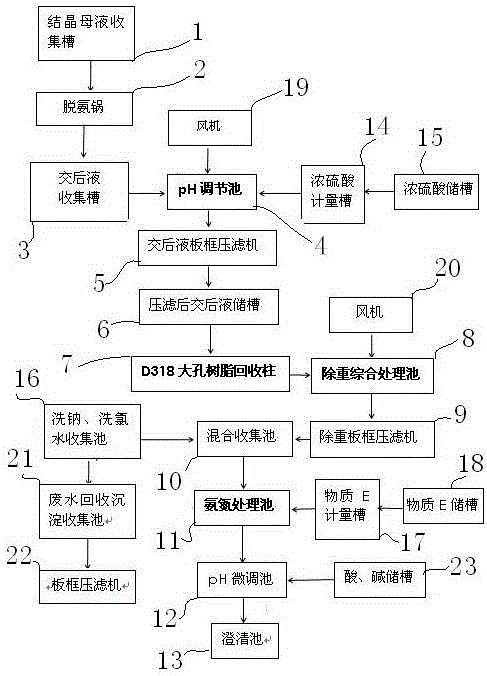

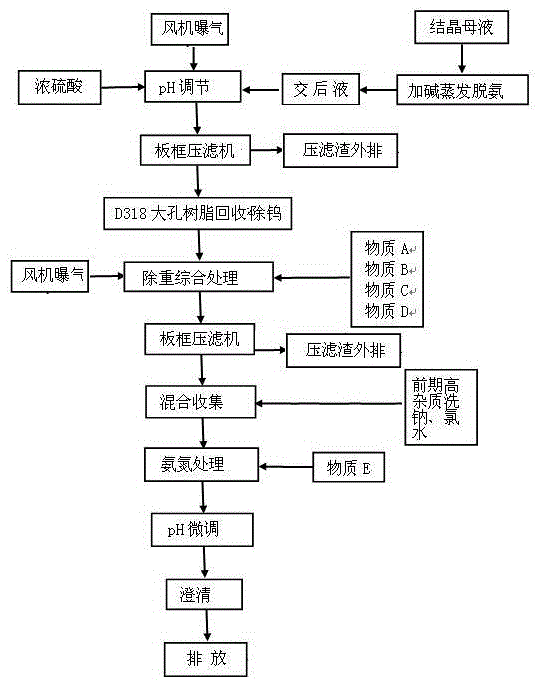

Waste water comprehensive treatment and recycling system and method adopting tungsten smelting ion-exchange method

InactiveCN105461140AGood recycling effectHigh recovery rateWater contaminantsTreatment involving filtrationIon exchangeTungsten

The invention discloses a waste water comprehensive treatment and recycling system and method adopting a tungsten smelting ion-exchange method. The system mainly comprises a crystallization mother liquor collection tank, a deamination pot, a post-exchange liquor collection tank, a pH regulating tank, a post-exchange liquor plate-and-frame filter press, a post-filter-press post-exchange liquor storage tank, a D318 macroporous resin recycling column, a heavy-metal-removal comprehensive treatment tank, a heavy-metal-removal plate-and-frame filter press, a mixed collection tank, an ammonia nitrogen treatment tank, a pH fine adjustment tank and a clarification tank which are sequentially arranged in a communicated mode, the system further comprises a sodium-washing water and chlorine-washing water collection tank, and the sodium-washing water and chlorine-washing water collection tank is connected with the mixed collection tank. The recycling method comprises the steps of deamination treatment of crystallization mother liquor, recycling of tungsten in post-exchange liquor and crystallization mother liquor waste water, comprehensive heavy-metal-removal treatment of the post-exchange liquor and the crystallization mother liquor waste water, recycling and treatment of sodium washing water and chlorine washing water, ammonia nitrogen and COD deep treatment, pH fine adjustment and clarification. By means of the method, a good recycling or treatment effect is achieved for multiple types of constituents in the waste water, and the waste water comprehensive treatment and recycling system and method have the advantages of being short in flow, low in investment cost and the like.

Owner:JIANGXI RARE EARTH & RARE METALS TUNGSTEN GRP

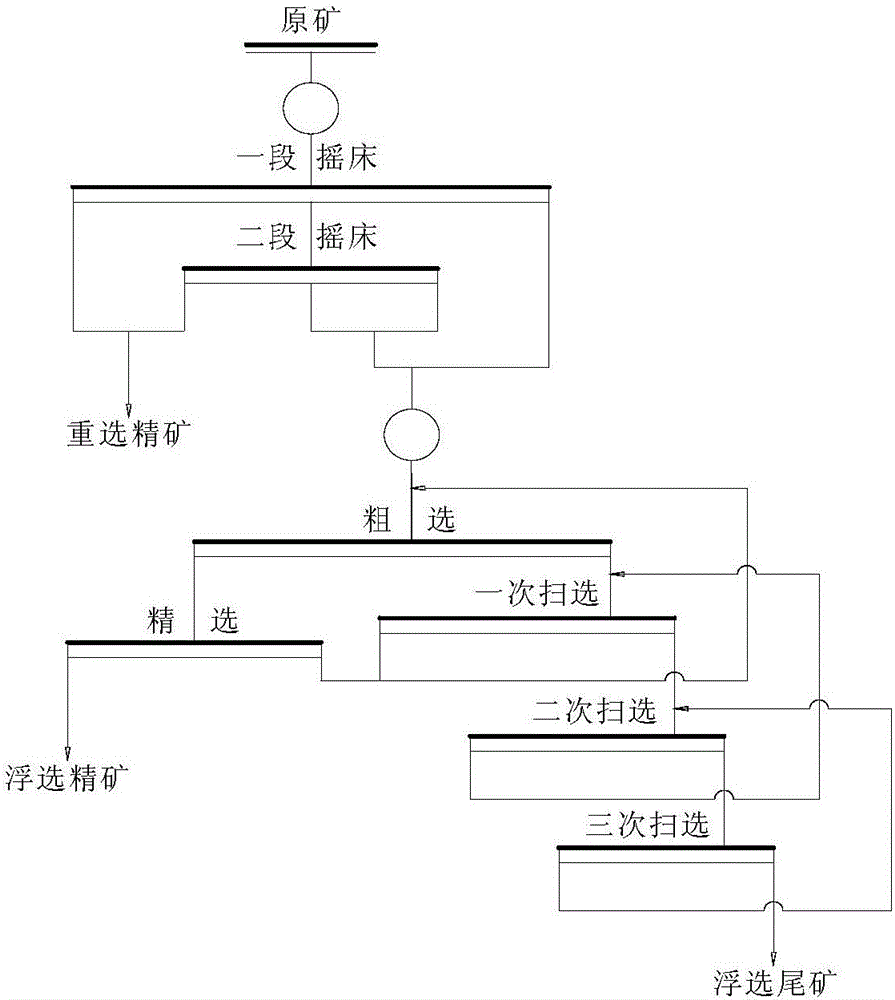

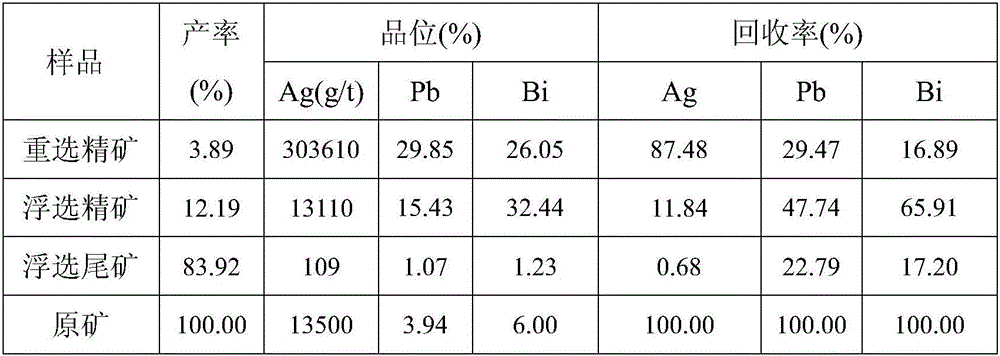

Method for recovering valuable metals from waste refractories by virtue of reselection-kerosene aggregative flotation combined process

ActiveCN106269170AGood recycling effectEfficient recyclingSolid separationProcess efficiency improvementKeroseneXanthate

The invention discloses a method for recovering valuable metals from waste refractories by virtue of a reselection-kerosene aggregative flotation combined process. The method comprises the following steps of crushing waste refractory original ores, performing primary wet-type ball milling, and then performing reselection by virtue of a two-stage table, thereby obtaining a table concentrate product; recovering coarse particle metals from the table concentrate, mixing table middlings with tailings, performing secondary wet-type ball milling, and performing floatation recovery by utilizing coal oil as an auxiliary collecting agent, xanthate and ethyl thio carbamate as collecting agents and terpineol as a blowing agent, so as to recover micro-fine particle metals. By virtue of reselecting and recovering coarse particle metals, and combining with floatation, collection of the micro-fine particle metals is strengthened, and finally efficient recovery of valuable metals in waste refractory bricks is realized. The method has relatively high economic value.

Owner:CENT SOUTH UNIV

Concrete smashing robot convenient to discharge

InactiveCN108514908AEasy dischargeImprove protectionGrain treatmentsArchitectural engineeringWorkload

The invention discloses a concrete smashing robot convenient to discharge. The concrete smashing robot convenient to discharge comprises a bottom plate, wherein a tank is fixedly connected to the topprat of the bottom plate; a protection cover is fixedly connected between one side of the tank and the top part of the bottom plate; a first motor is fixedly connected to a position, located in the protection cover, on one side of the tank through a connecting block; a bidirectional screw rod is fixedly connected to one end of an output shaft of the first motor through a coupler; one end, far awayfrom the first motor, of the bidirectional screw rod penetrates through the tank and extends into the tank. The concrete smashing robot convenient to discharge provided by the invention relates to the technical field of concrete smashing equipment, and can be used for smashing concretes and then conveniently discharging the concretes, so that the workload of working personnel is reduced, the timeis saved, the smashing efficiency of the concretes and the working efficiency of the working personnel are improved, an effect on well recycling the concretes is achieved, and the cost during a building construction process is reduced.

Owner:海宁鼎合工程技术开发有限公司

Sludge discharging and garbage removing device for sewage treatment

PendingCN111924995AGood recycling effectEasy to clean and maintainSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSewage treatmentSewage

The invention discloses a sludge discharging and garbage removing device for sewage treatment. The device comprises a shell, a filtering assembly, a water discharging pipe, a garbage collecting assembly, a first driving air cylinder, a sludge scraping plate and a flow control assembly. Two groups of filtering assemblies are arranged on the shell, the garbage collecting assembly is arranged outsidethe shell corresponding to the filtering assembly, a water outlet end of a drainage pipe is connected with external water storage equipment, a water inlet end extends into the shell and is positionedbetween the two groups of the filtering assemblies, the first driving air cylinder is arranged at the bottom of the shell, the sludge scraping plate is driven by the first driving air cylinder and isin sliding connection with the bottom of the shell, and the flow control assembly is arranged at the bottom of the shell. The filtering assembly and the garbage collecting assembly are arranged to bematched, the filtering plate which is obliquely arranged and convenient to mount and dismount is used for separating garbage in sewage, the collecting cover is used for recycling the garbage, the garbage separating and recycling effects are good, a drainage pipe floating on the water surface is arranged to suck upper-layer sewage, so that the mud-water separation effect is good, and a flow control assembly is arranged, so that automatic sludge discharge and speed-controlled sludge discharge are realized.

Owner:刘雪莲

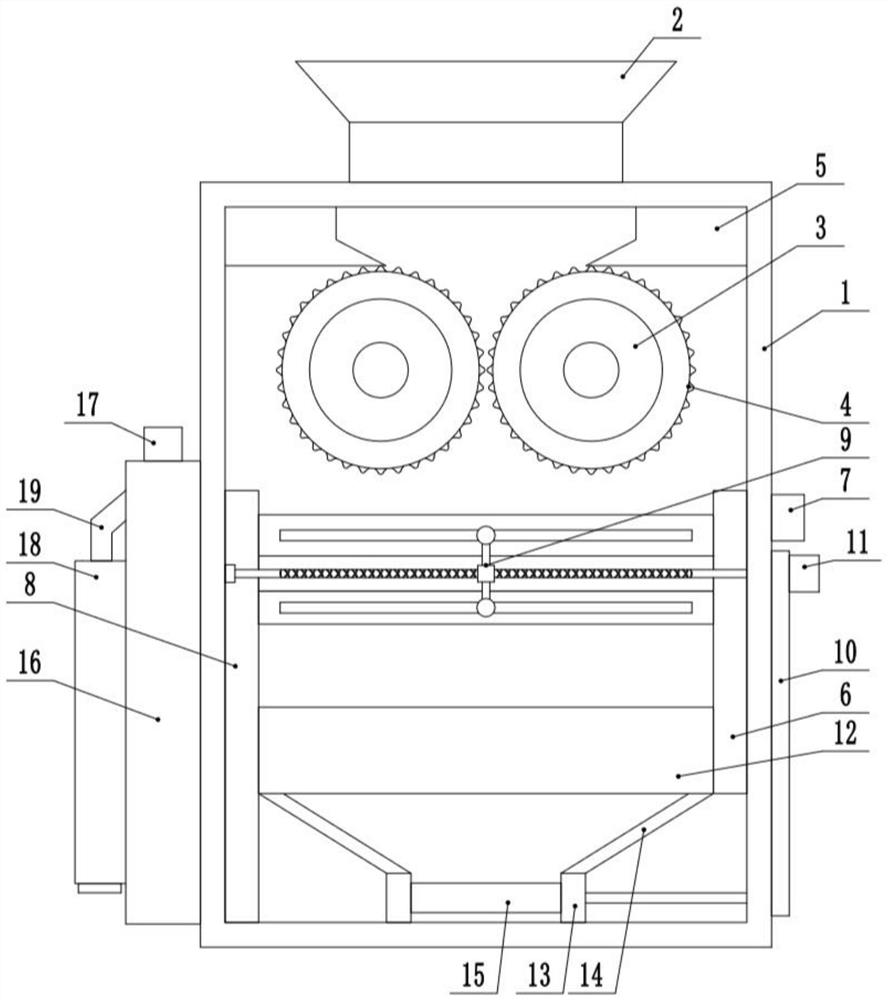

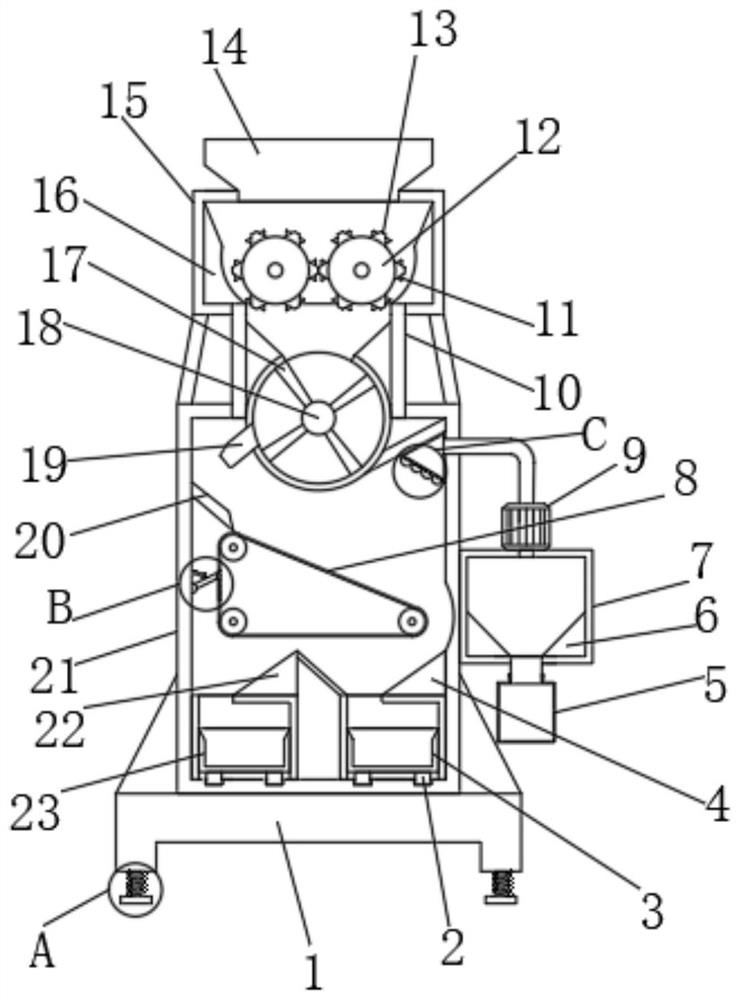

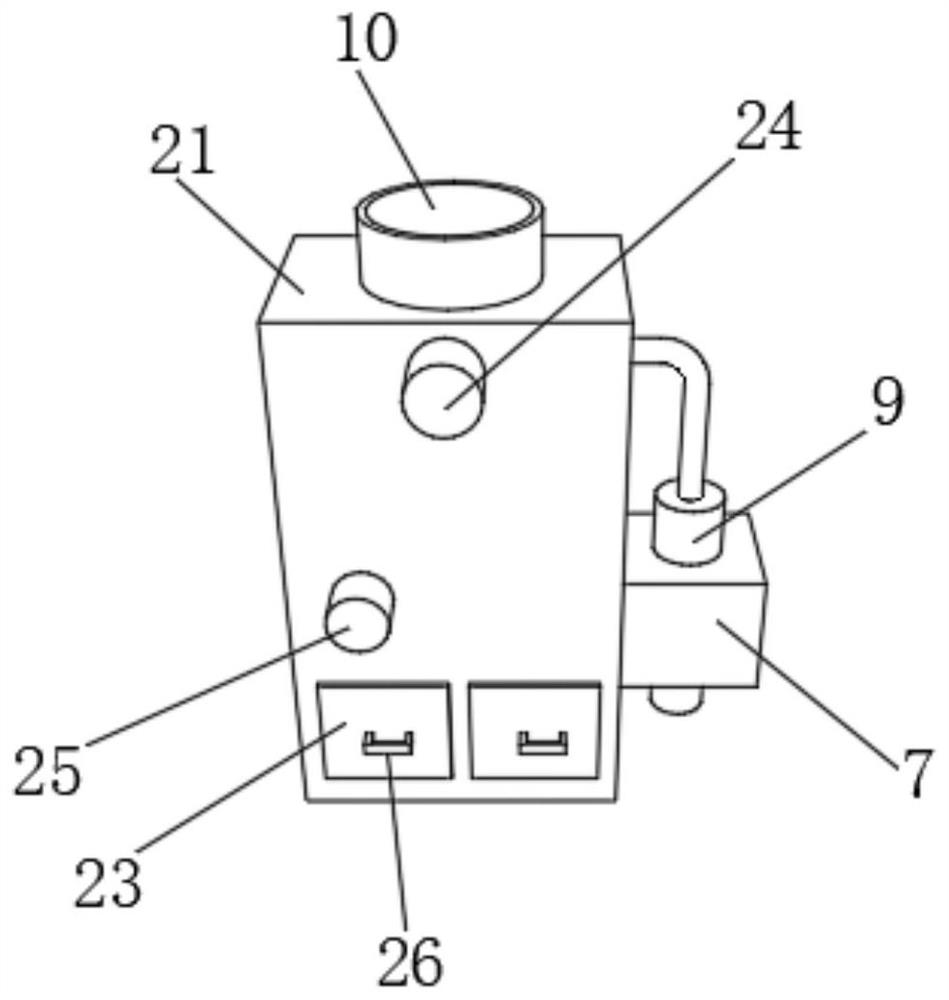

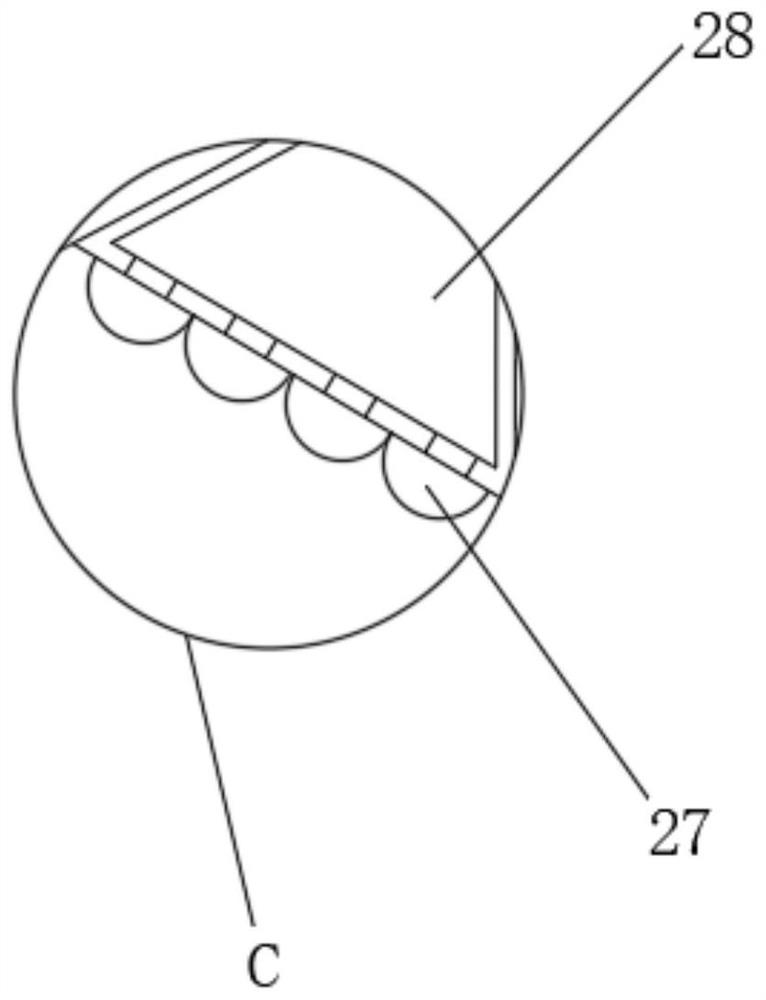

Recovery device for waste neodymium iron boron magnetic materials and using method

ActiveCN111686864AGood recycling effectConvenient without manual cleaningDispersed particle filtrationGrain treatmentsMetallurgyWaste material

The invention discloses a recovery device for waste neodymium iron boron magnetic materials, and relates to the technical field of waste neodymium iron boron processing. According to the recovery device for the waste neodymium iron boron magnetic materials, the recovery device comprises a feeding device, the feeding device comprises a machine shell, a first crushing roller, a second crushing roller, a first rotating rod and a second rotating rod; the inner part of the machine shell is hollow; the first crushing roller is arranged in the inner part of the machine shell and located above a material collecting box; the second crushing roller is arranged in the inner part of the machine shell; the first rotating rod is arranged in the inner part of the machine shell and located below the firstcrushing roller; the second rotating rod is arranged in the inner part of the machine shell and located below the first crushing roller; a material conveying device is arranged on one side of the feeding device; a collecting device is arranged below the material conveying device; a rotating device is arranged in the inner part of the material conveying device; and a screening device is arranged in the inner part of the feeding device. The recovery device for the waste neodymium iron boron magnetic materials is used for solving the problems that in the prior art, when waste neodymium iron boron is used for treating surface waste, all the surface waste cannot be effectively and rapidly shaken off, and the waste neodymium iron boron obtained after waste removing cannot be rapidly discharged,so that blocking is caused.

Owner:XINFENG BAOGANG XINLI RARE EARTH

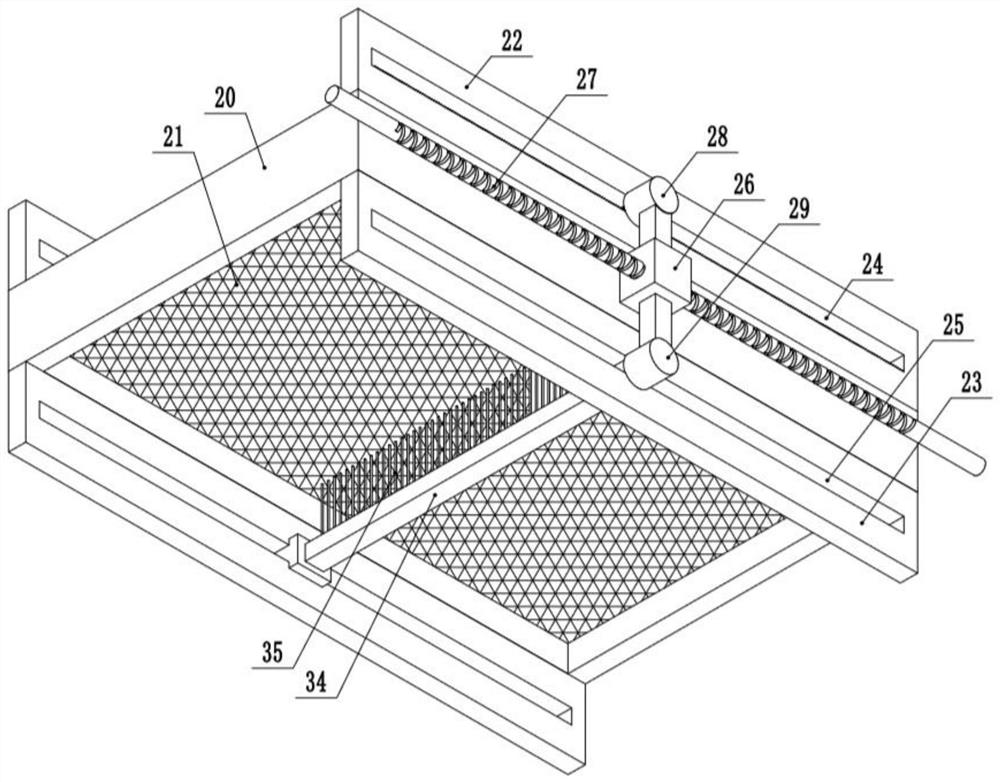

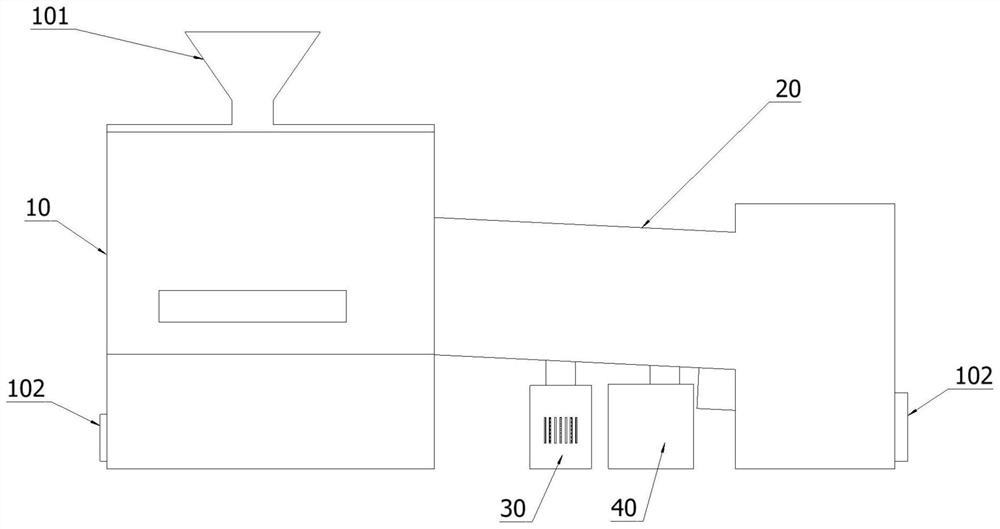

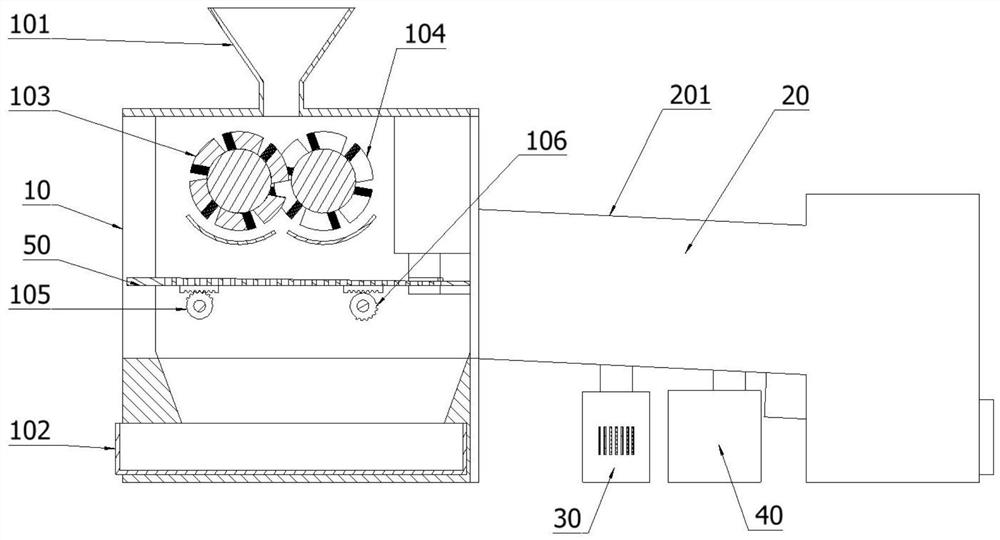

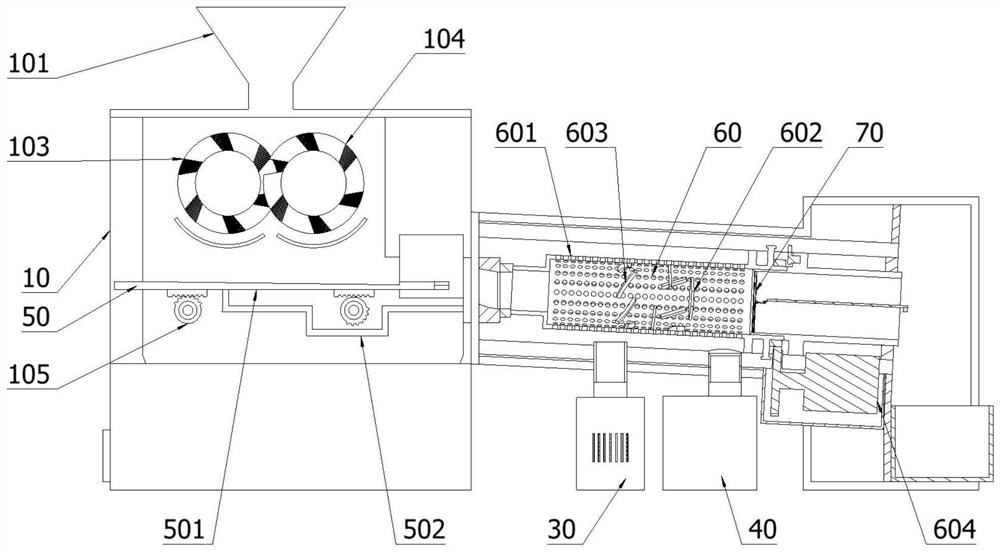

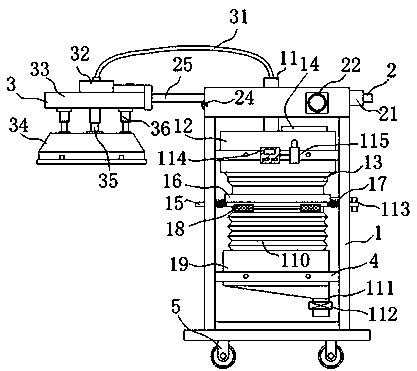

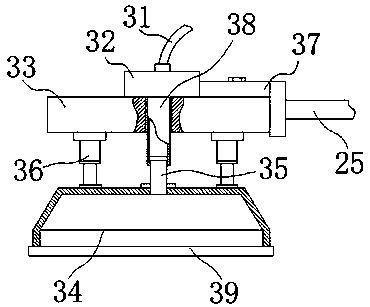

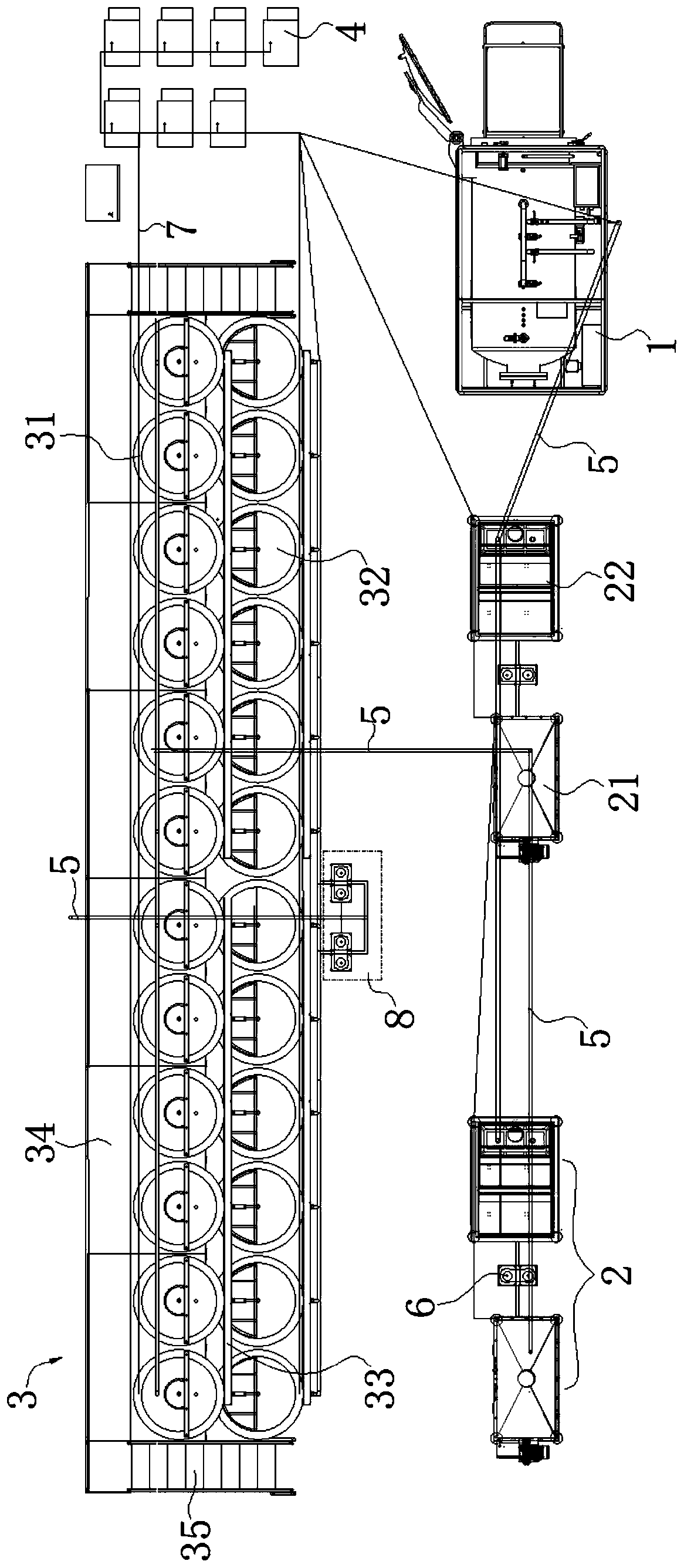

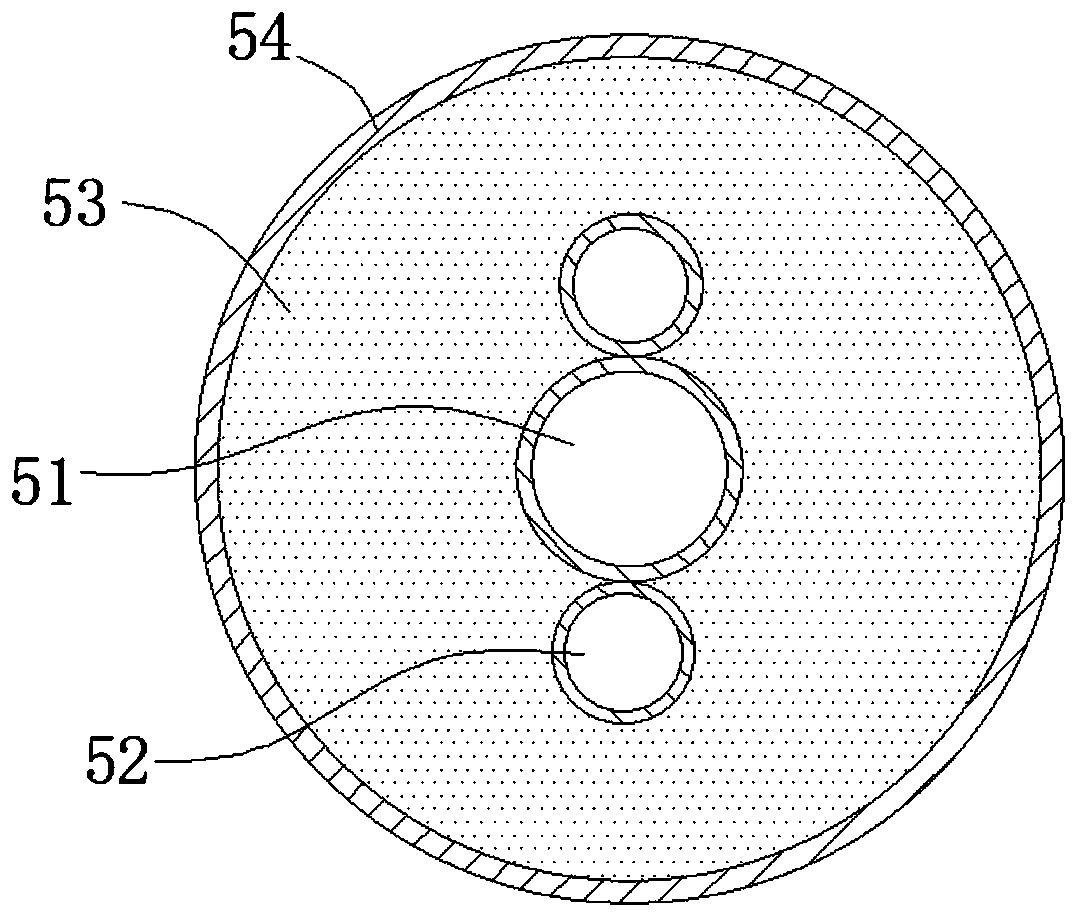

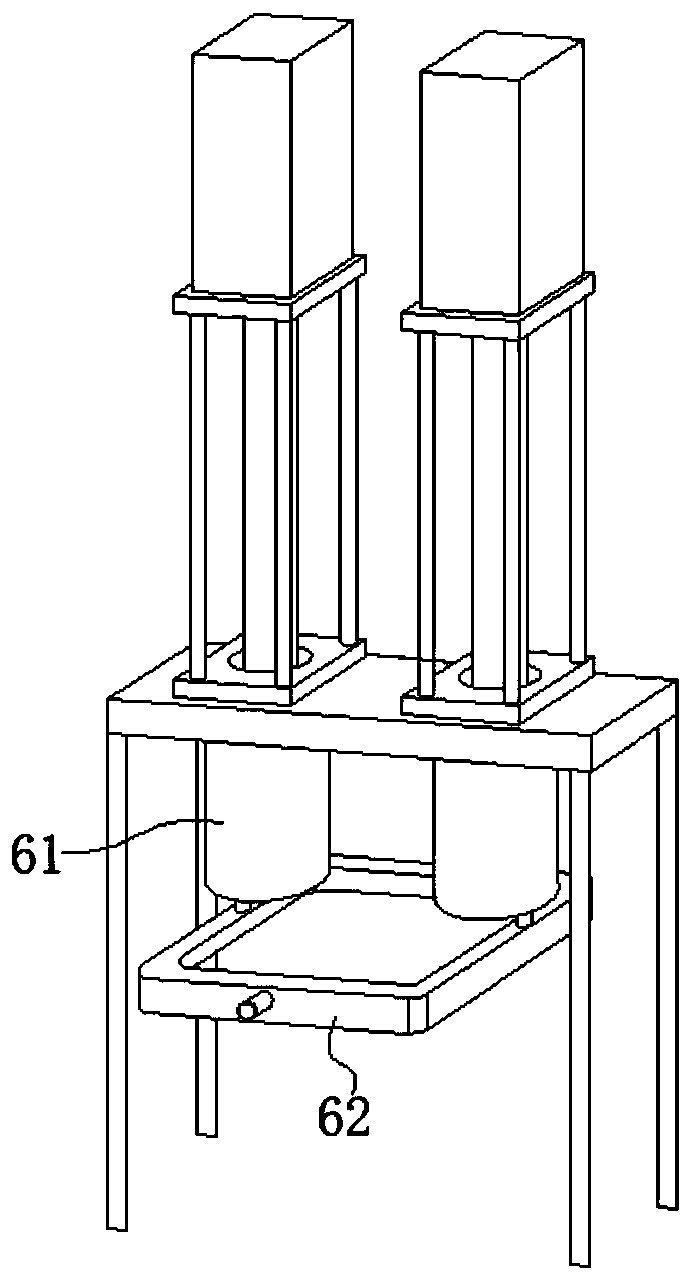

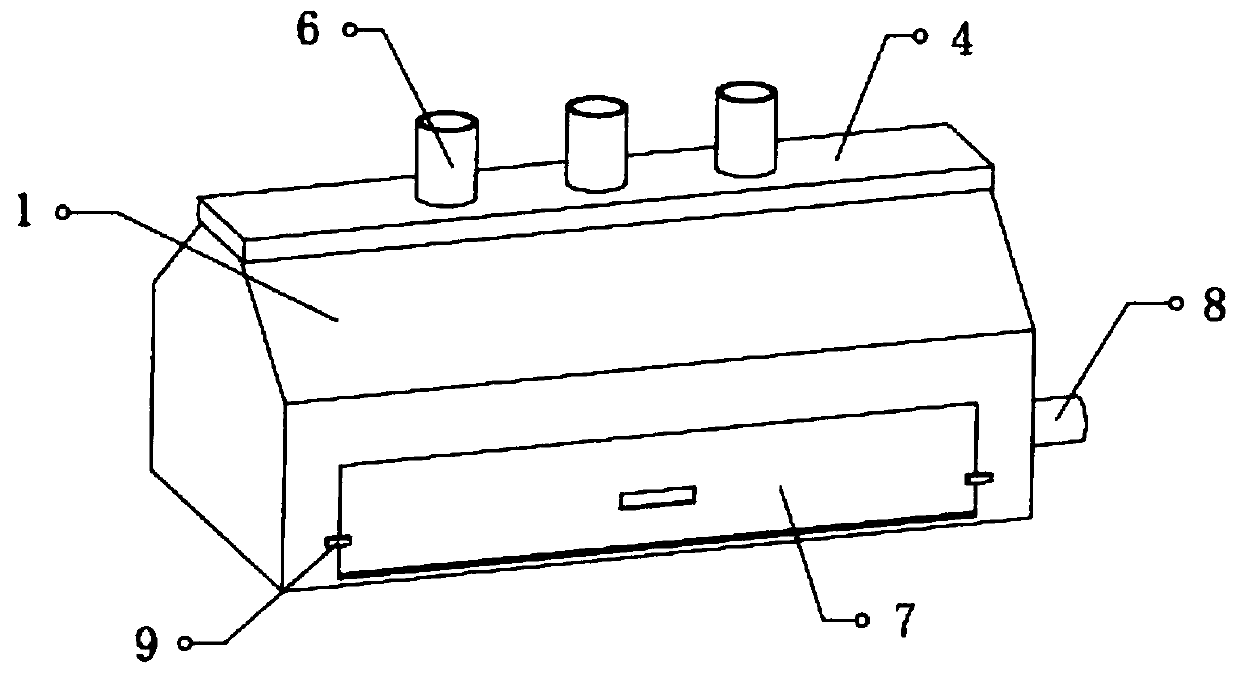

Metal 3D printer powder recovery device

The invention discloses a metal 3D printer powder recovery device which comprises a rack, a transverse moving mechanism and a powder suction mechanism. The transverse moving mechanism is installed onthe upper portion of the rack, and the powder suction mechanism is installed on the side portion of the transverse moving mechanism. Residual powder on a workbench is sucked through the powder suctionmechanism and conveyed to a screening device on the rack, and the screening device heats and screens contained impurities, so that the residual powder is recycled; different from manual recycling ofthe powder, the working efficiency is high, and the recycling effect is good; by positioning the workbench, a powder suction cover covers the workbench to suck the residual powder; by means of a connecting mode of canvas folding pipes and springs, a vibration exciter cannot generate large vibration on the rack while conducting vibration screening on a screen frame; and different from a conventional powder recovery device fixed below the workbench, the powder recovery device can be used on workbenches of various models and sizes and is high in applicability.

Owner:安徽中健三维科技有限公司

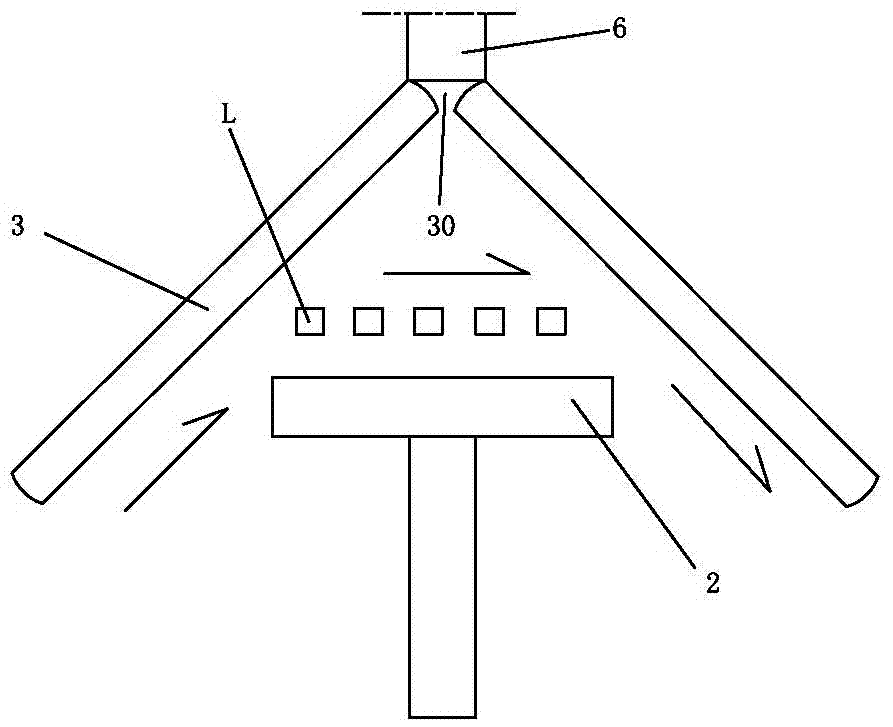

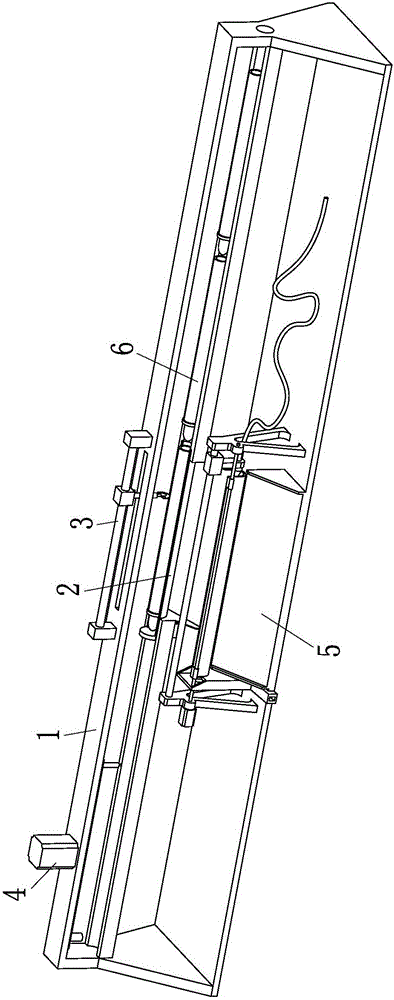

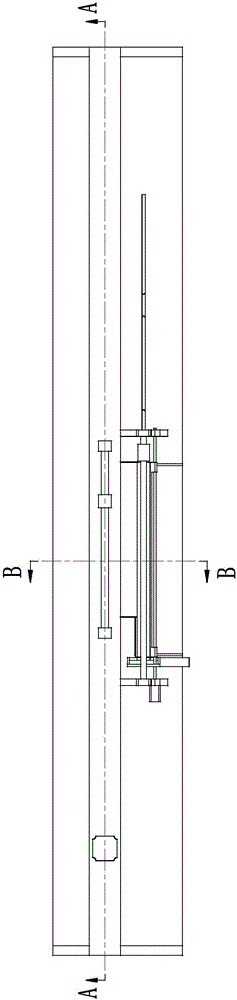

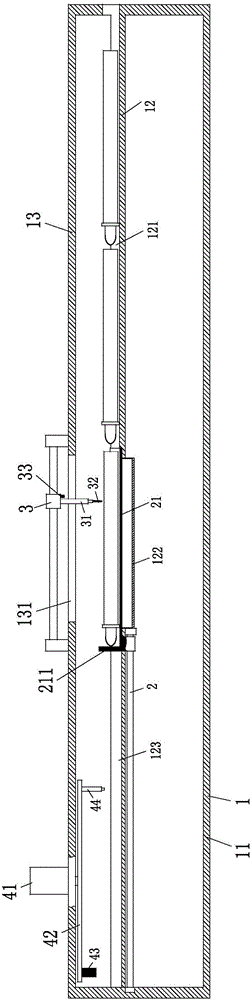

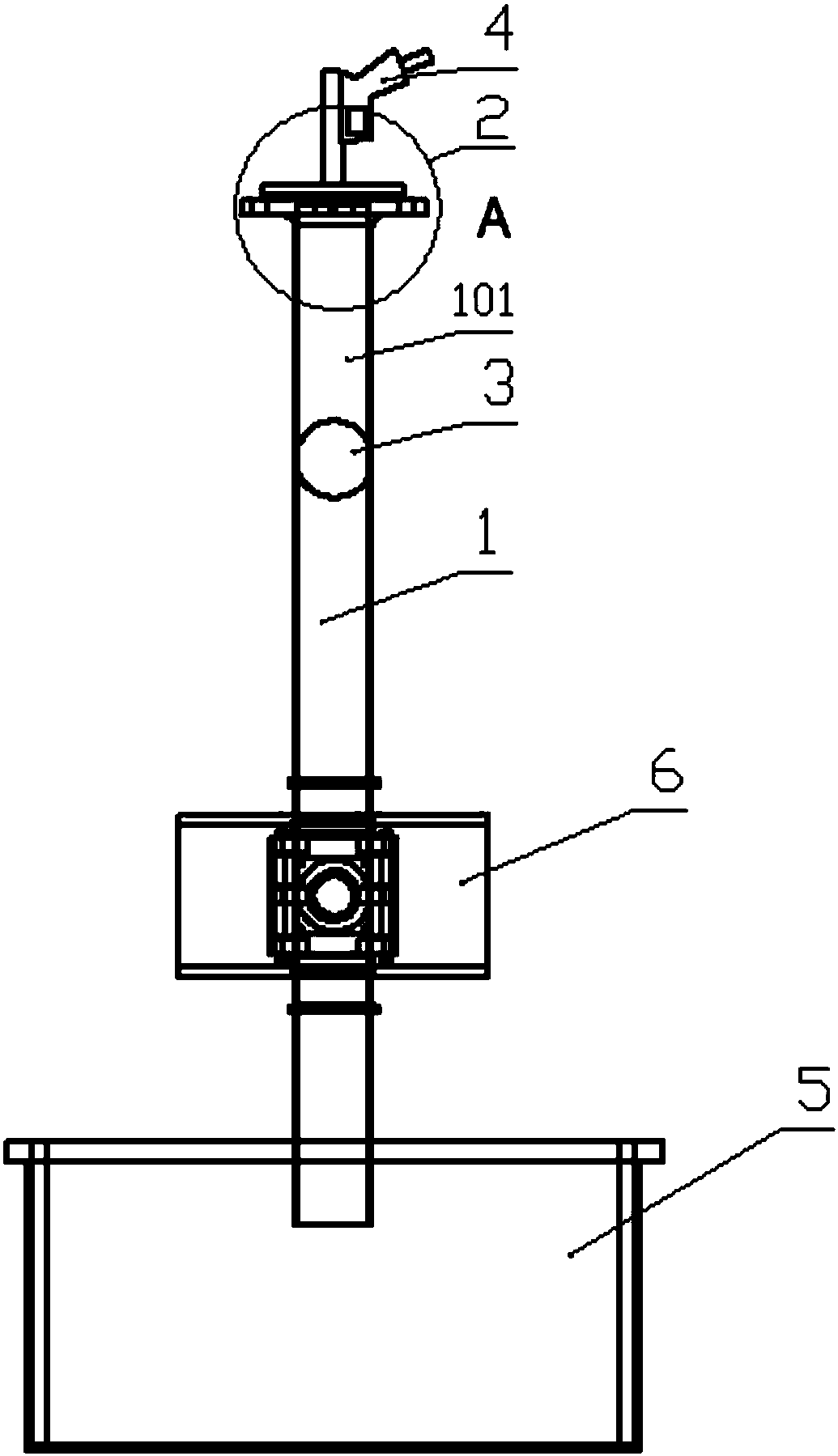

Spraying system with vertical spraying chamber for aluminum profiles

PendingCN107442347AGood recycling effectImprove recycling effectLiquid surface applicatorsCoatingsAgricultural engineeringTextile

The invention relates to a spraying system with a vertical spraying chamber for aluminum profiles; the spraying system comprises a vertical spraying chamber composed of curtain cloth. The vertical spraying chamber is composed of three pieces of curtain cloth, the adjacent pieces are perpendicular to each other, and a gap is provided between every two adjacent pieces. The top of the vertical spraying chamber is open to its bottom, and a recycling device is connected to the lower end of the vertical spraying chamber. The spraying system also comprises a spraying column vertically arranged, nozzles transversely arranged side by side are movably connected to the spraying column, the nozzles are received in the vertical spraying chamber formed by the curtain cloth. A powder recycling air pipe arranged outside a gap is arranged from top to bottom along the gap and is connected with a recycling fan, and the recycling fan is connected with a powder supply center that is connected with the nozzles. The novel spraying system provided herein can recycle waste powder better.

Owner:XINGFA ALUMINUM CHENGDU

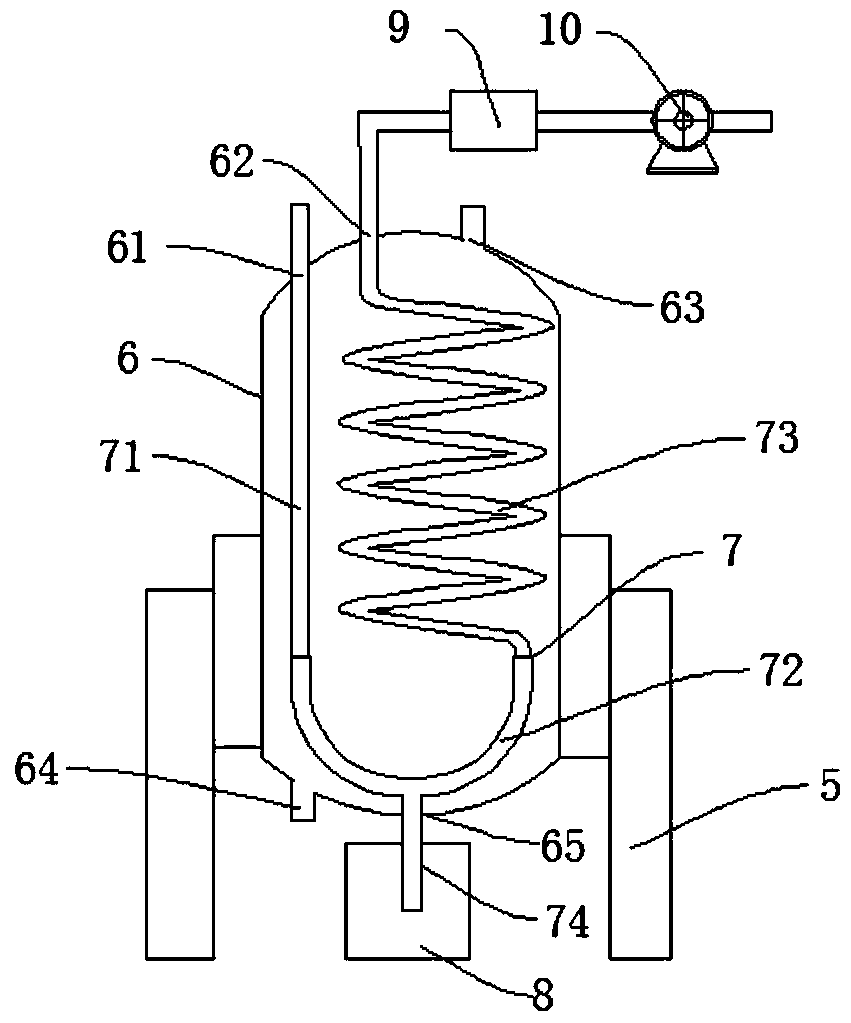

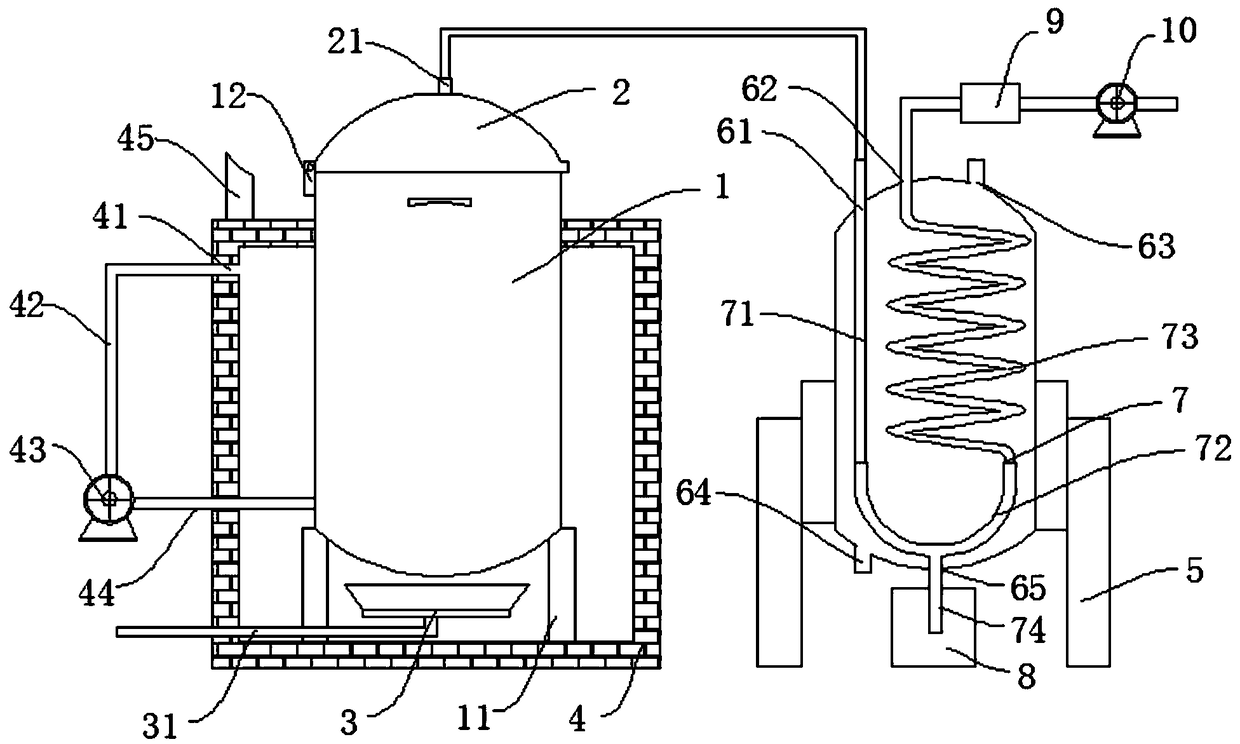

Wax recovery treatment system and method applied to precision casting

PendingCN111575056AImprove recycling efficiencyQuality assurancePetroleum wax refiningFoundry mouldsThermodynamicsHeat conservation

The invention provides a wax recovery treatment system and method applied to precision casting. The system comprises a dewaxing kettle, a wax-water separation device, a dewatering and standing device,a steam generation device and a pneumatic wax pumping cylinder. The method comprises a dewaxing step used for dewaxing a mold shell, a wax-water separation step used for carrying out precipitation separation on the wax water generated by the dewaxing kettle, and a dewatering and standing step used for dewatering and standing the wax liquid. In the wax-water separation step, wax water generated bythe dewaxing kettle is subjected to preliminary precipitation for a certain period of time, so that the wax water is separated from sand powder, and then the wax water is heated to remove water. In the dewatering and standing step, a copper pipe is wound on the surface side of a dewatering bucket or / and a standing bucket, and the copper pipe is communicated with the steam generation device to obtain circulating steam to achieve heat preservation. The dewaxing, wax-water separation, dewatering and standing, wax discharging and other procedures can be automatically achieved, the wax recovery treatment efficiency is greatly improved, the recycling treatment effect is good, the recycled wax quality is good, and the quality of a secondarily-machined wax mold is guaranteed.

Owner:中山市铸友自动化机械设备有限公司

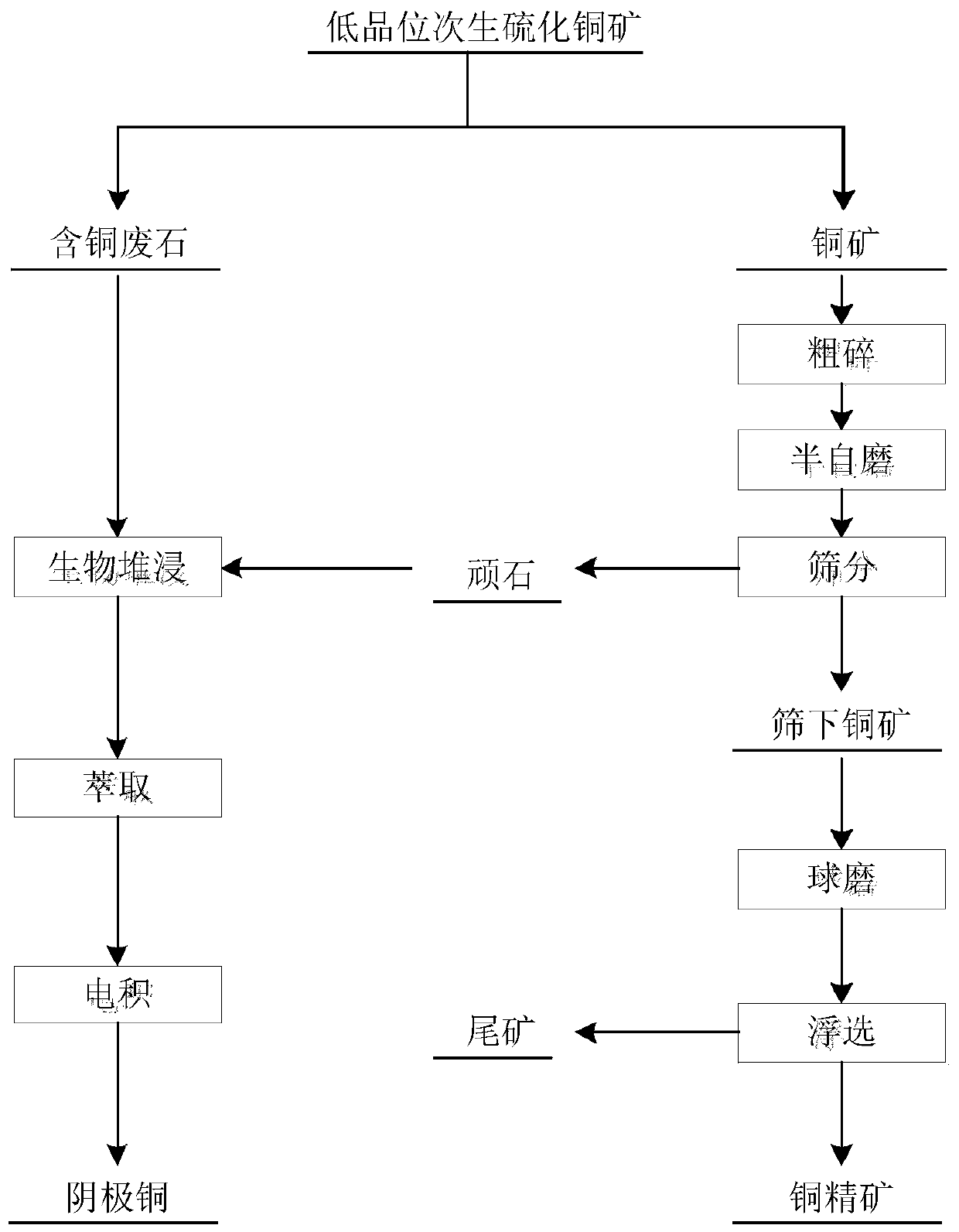

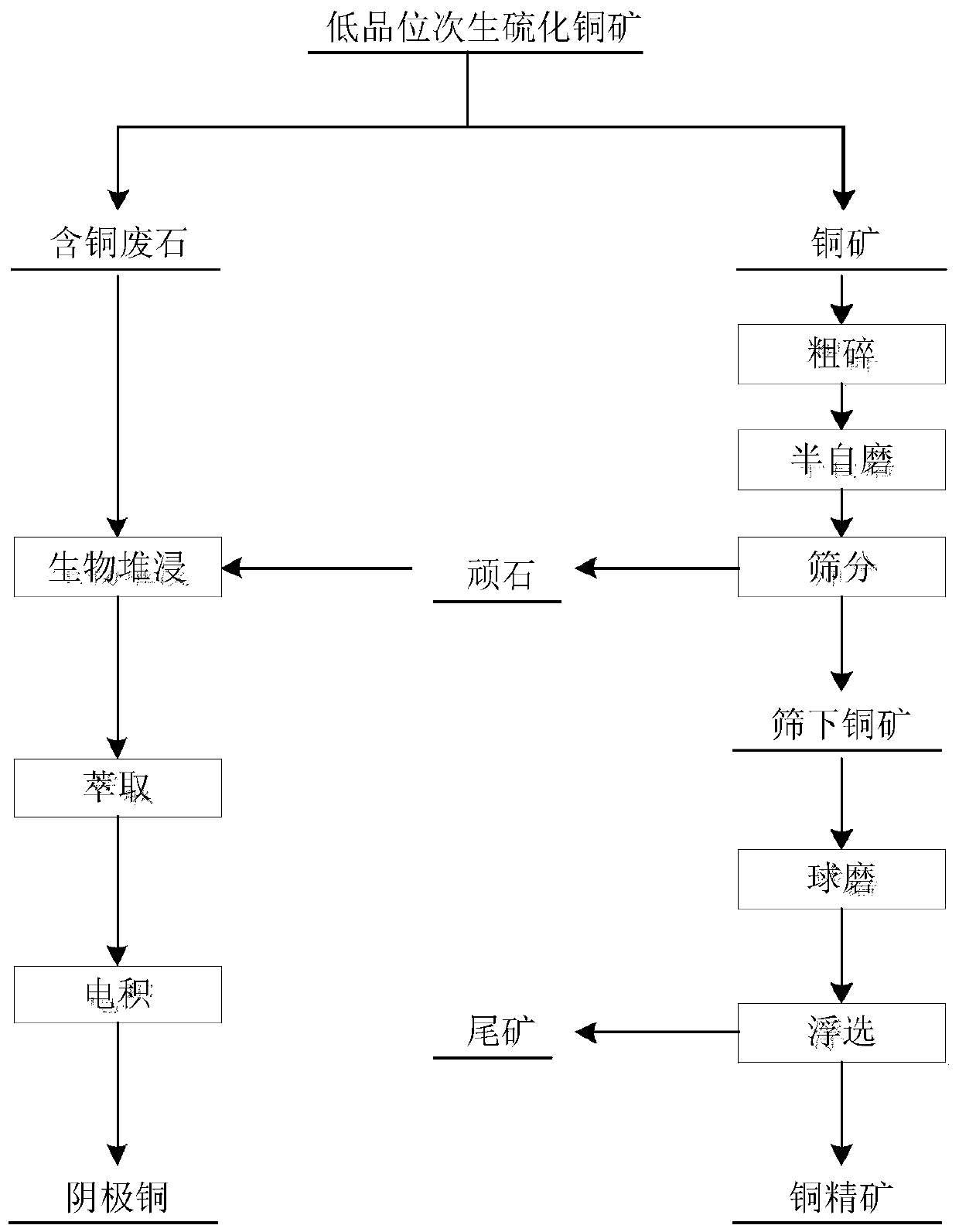

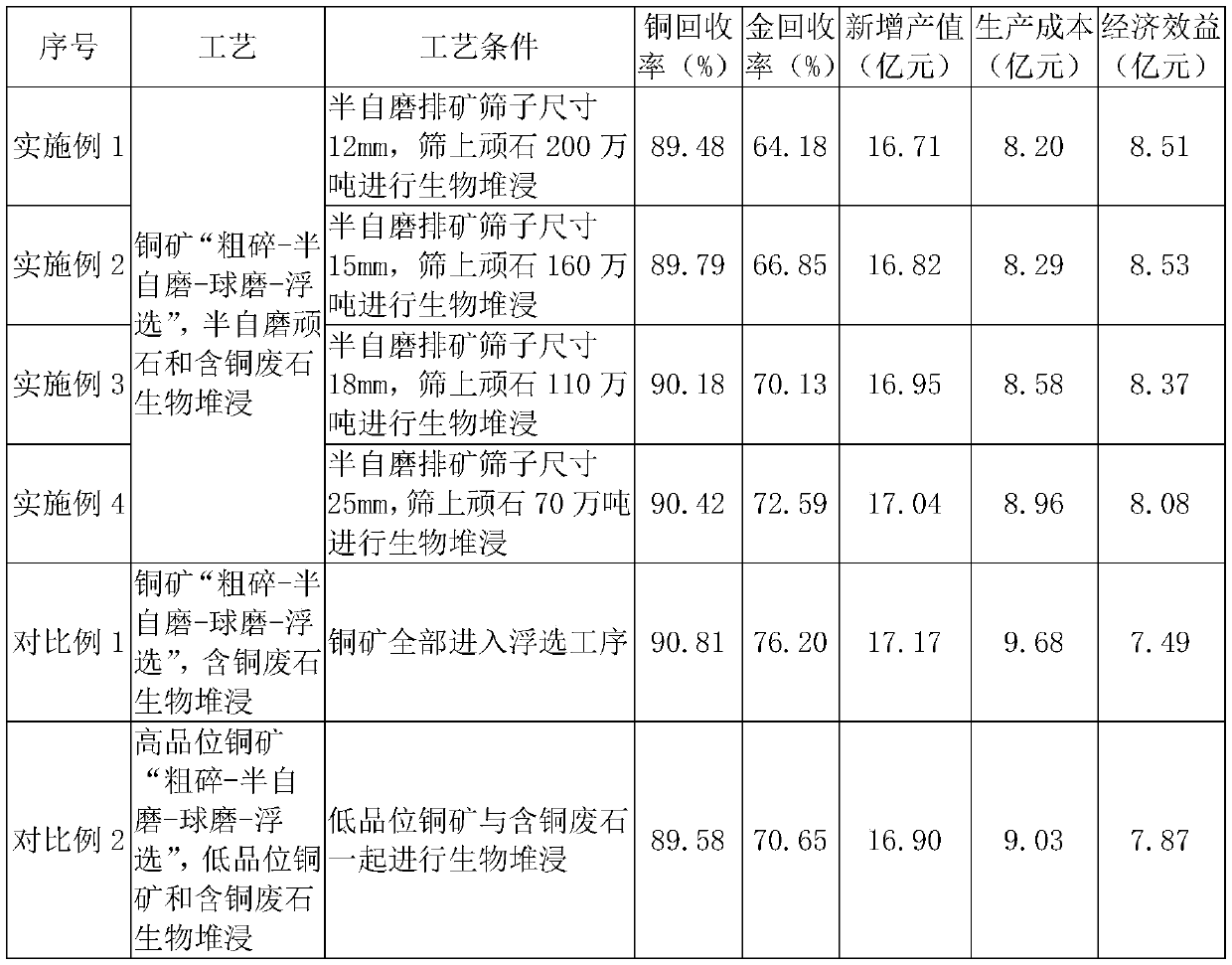

Method for efficiently recovering copper from low-grade secondary copper sulfide ore

ActiveCN109971944AComprehensive recycling effect is goodGood recycling effectPhotography auxillary processesProcess efficiency improvementLow gradedSieve

The invention relates to a method for efficiently recovering copper from low-grade secondary copper sulfide ore. The method comprises the following sequential process steps and conditions that (1) classification is performed, specifically, the low-grade secondary copper sulfide ore is classified into copper ore and copper-containing waste stone according to industrial boundary grades; (2) coarse grinding, semi-autogenous grinding and screening are performed, specifically, conventional coarse grinding, semi-autogenous grinding and screening are performed on the copper core in sequence, and high-grade copper ore under a sieve and hard stone on the sieve are separated; (3) ball-milling and floatation are performed, specifically, conventional ball-milling and floatation are performed on the high-grade copper ore in sequence, and the product copper concentrate is obtained; (4) heap bioleaching is performed, specifically, the hard stone serves as a heaping-up framework for the screened-out copper-containing waste stone, and conventional heap bioleaching is performed after the copper-containing waste stone and the hard stone are mixed uniformly, and lixivium is separated; and (5) extraction and electrodeposition are performed, specifically, conventional extraction and electrodeposition are performed on the lixivium, and the product cathode copper is obtained. By means of the method provided by the invention, valuable metal such as copper can be comprehensively recovered from the ore without any industrial mining value, the production cost can also be lowered, the advantages of thegreat economic, ecological and social benefits are manifested, and the method is applicable to mining application.

Owner:ZIJIN MINING GROUP

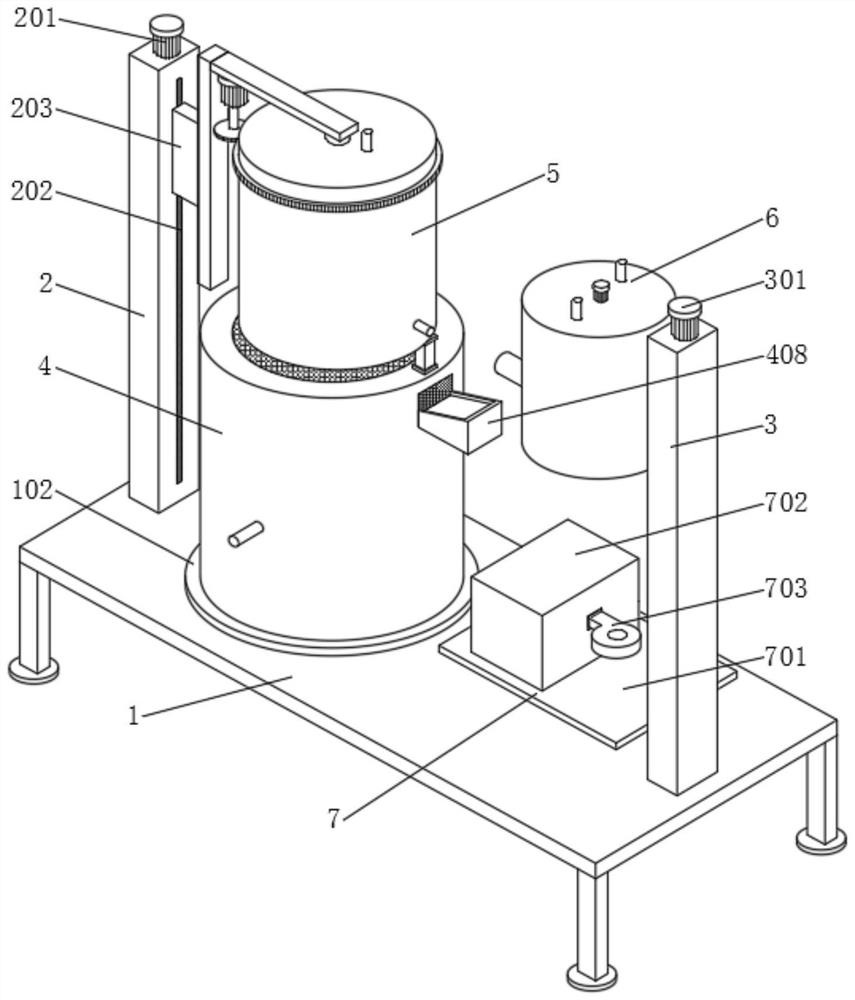

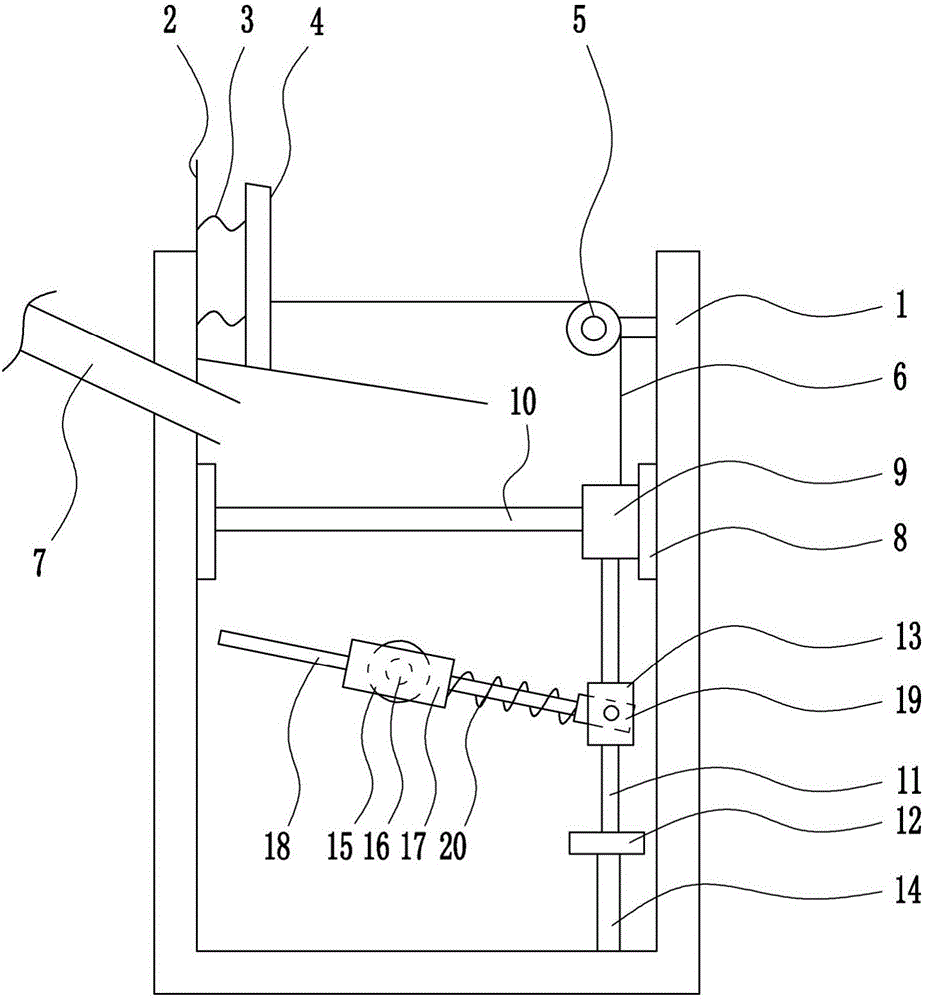

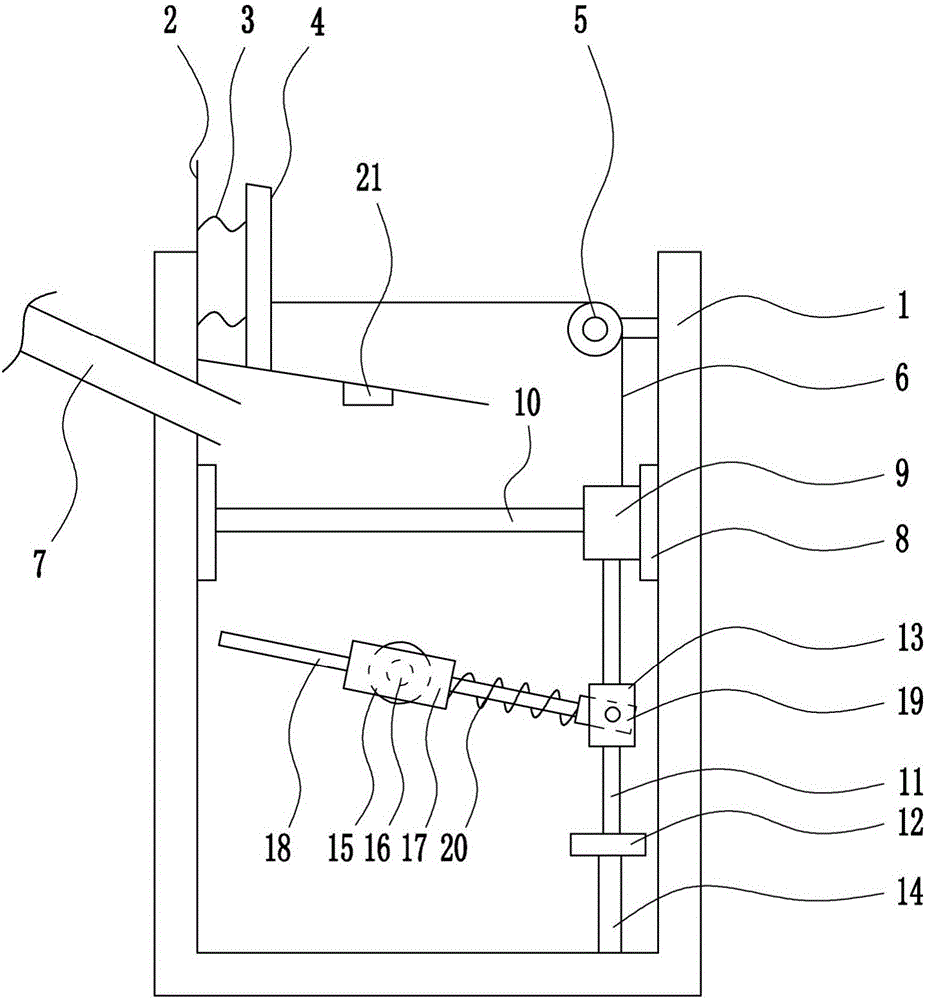

Refill recycling platform based on environmental protection concept

ActiveCN106736398AWide range of applicationsGood recycling effectTransportation and packagingSolid waste disposalHollow coreEngineering

The invention relates to the field of stationery recycling machines, in particular to a refill recycling platform based on the environmental protection concept. The refill recycling platform comprises a machine frame, a refill conveying device, a refill cutting device, a point feeding device and an oil blowing device. The machine frame comprises a bottom plate, a middle frame and a top frame. The refill conveying device comprises a refill sliding block and a first driving device capable of making the refill sliding block move horizontally left and right. The refill cutting device comprises a vertical telescopic mechanism, a second driving device capable of making the vertical telescopic mechanism move horizontally left and right, an endotherm knife and a color recognition sensor. The point feeding device comprises a point feeding motor, a point feeding rotary plate, an electromagnet and a refill pushing air cylinder. The oil blowing device comprises a supporting plate rack, a refill containing cavity, a hollow-core board, an ink storage bin, an air nozzle and a third driving device capable of making the air nozzle move horizontally left and right. The refill recycling platform is wide in application range, meanwhile, sealing oil in waste refills can be automatically recycled or a mixture of ink and the sealing oil is recycled, the recycling effect is good, and resources are saved.

Owner:颍上县永安塑业有限公司

Method for recycling ardealite

InactiveCN104724746AIncrease profitGood recycling effectRare earth metal oxides/hydroxidesCalcium/strontium/barium sulfatesDesorptionRare earth

The invention discloses a method for recycling ardealite. The method comprises the following steps: (1) doping water and a grinding aid into ardealite to prepare ardealite slurry; (2) treating the ardealite slurry by using a 3.5-6.2% sulfuric acid solution to leach out solid phosphorus; (3) treating the ardealite slurry treated in the step (2) by using an 8-10% of sulfuric acid solution to leach out rare earth metals; (4) adjusting the pH value by using sulfuric acid, adsorbing the rare earth metals by using a cation exchanger, and performing desorption by using a desorption agent; (5) precipitating the rare earth metals from the solution by using oxalic acid; (6) rinsing, drying and roasting insoluble compounds of the rare earth metals; (7) performing a method of recycle leaching; and (8) performing separation by crystallization on calcium sulfate in a secondary mother solution in the step (3), and washing and drying. According to the method disclosed by the invention, phosphorus, rare earth metals and calcium sulfate in ardealite are leached out by stages, the leaching rate is high, the purity is high, the whole technological process is stable, the implementation manner is simple and effective, and the utilization ratio of resources is greatly improved.

Owner:WEIFANG UNIVERSITY

In-tube paste recovery device

PendingCN108584041AGood recycling effectReduce manufacturing costLiquid materialPackaging machinesToothpasteEngineering

The invention provides an in-tube paste recovery device. The in-tube paste recovery device comprises a tube. A sealing structure for tube sealing is arranged at a tube inlet. A flexible squeezing partis arranged in the tube and is in gapless fit with the inner wall of the tube. A compressed gas source communicates with the interior of a tube section located between the sealing structure and the flexible squeezing part. The in-tube paste recovery device has an excellent recovery effect on in-tube paste, especially on attached paste in the tube with certain viscosity, in the product line changing and cleaning processes of toothpaste production, by adopting the in-tube paste recovery device, in-tube toothpaste can be effectively recovered, recycling of in-tube paste is achieved, and the toothpaste production cost is greatly reduced.

Owner:CHONGQING DENCARE CORP

Cutting fluid recovery device for machining

InactiveCN111196945AAvoid cloggingGood recycling effectMagnetic separationLubricant compositionEngineeringImpurity

The invention belongs to the technical field of machining, and particularly relates to a cutting fluid recovery device for machining. In order to solve the problem that in the prior art, a flat-plate-shaped filter screen is used for filtering and recycling cutting fluid, and blocking is likely to happen, the following scheme is put forward: the device comprises a box body; fixing pieces are fixedto the bottoms of the two ends between the inner walls of the two sides of the box body; a filter screen plate is fixed between the outer walls of the tops of the two fixing pieces; the filter screenplate is arranged to be of a box-shaped structure with an opening in the bottom, the middle of the outer wall of the top of the filter screen plate is arranged to be of an arc-shaped structure protruding upwards, the two ends of the outer wall of the top of the filter screen plate are both arranged to be inclined faces inclining downwards, and storage cavities are formed between the two ends of the filter screen plate and the inner walls of the two ends of the box body. The filtered solid impurities are scoured downwards along the inclined face, so that the blockage of meshes due to the fact that the solid impurities are flatly laid on the filter screen plate can be avoided, the solid impurities are scoured into the storage cavity to be accumulated, and the long-time effective operation offiltering and recycling operation is ensured.

Owner:任路明

Retreatment method for tailing materials generated by comprehensive treatment of waste incinerator residues

ActiveCN108218323AImprove recycling efficiencyGood recycling effectSievingScreeningSlagMaterials science

The invention provides a retreatment method for tailing materials generated by comprehensive treatment of waste incinerator residues. Multistage screening and sorting steps are set in the retreatmentmethod and are used for efficiently recovering metallic aluminum in the tailing materials; meanwhile, the recovered tailing materials are specifically modified and can be used for producing baking-free bricks, so that recycling rate and resource recovery rate of wastes are improved.

Owner:扬州市同创再生资源有限公司

Environment-friendly waste battery recovery and treatment device

InactiveCN111804412ACrushed fullyImprove crushing qualityDirt cleaningGrain treatmentsProcess engineeringMechanical engineering

The invention belongs to the technical field of environment-friendly machines and particularly provides an environment-friendly waste battery recovery and treatment device. Aiming at the problems thata recovery and treatment device in the patent is poor in grinding effect, batteries cannot be smashed sufficiently, and waste battery treatment quality is poor, the following scheme is put forward, the environment-friendly waste battery recovery and treatment device comprises a base, a second smashing box is fixed to one side of the outer wall of the top of the base through screws, two motors arefixed to the outer wall of one side of the second smashing box through screws, output shafts of the two motors are connected with a first smashing roller and a second smashing roller through couplerscorrespondingly, arc-shaped plates are arranged on the outer wall of the first smashing roller and the outer wall of the second smashing roller correspondingly, and smashing tooth boxes are arrangedon the outer walls of the arc-shaped plates. According to the environment-friendly waste battery recovery and treatment device, in the rotating process of the two smashing rollers, under the effect ofsmashing teeth, fragments are further grinded, then the good recovery and treatment effect can be achieved, the batteries can be smashed fully, the battery smashing quality is high, and the battery recovery efficiency is improved.

Owner:吴槚婷

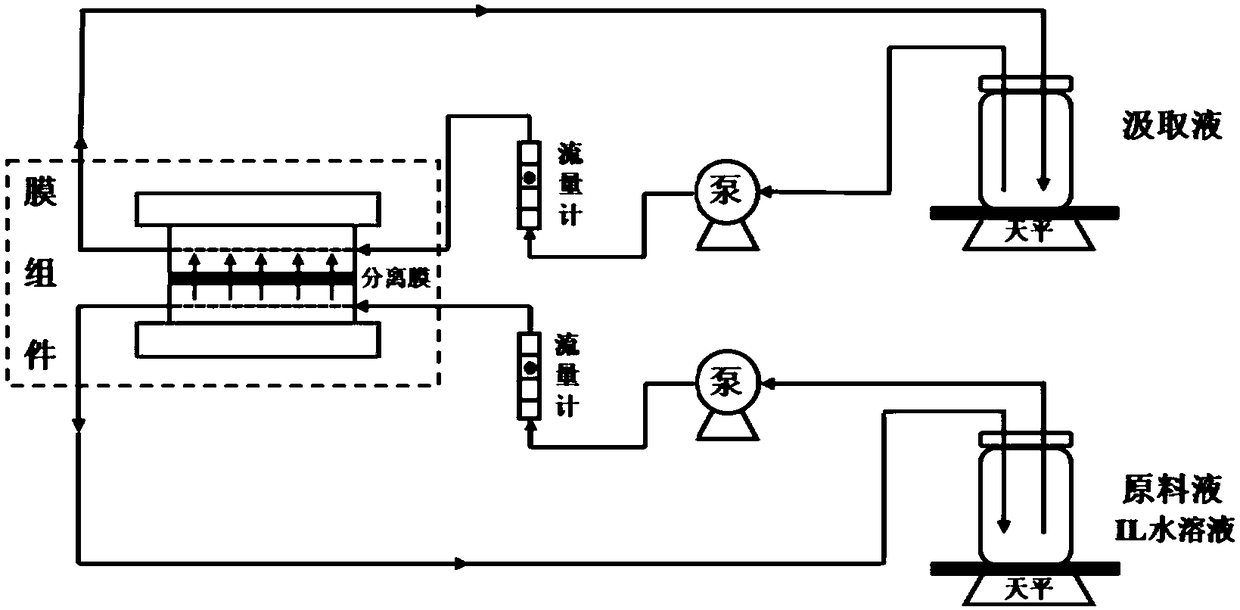

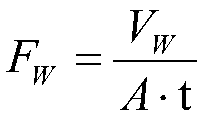

Forward osmosis concentration method of ionic liquid water solution

ActiveCN108889124AReduce energy consumptionGood recycling effectMembranesReverse osmosisIonChemistry

The invention discloses a forward osmosis concentration method of an ionic liquid water solution. The forward osmosis concentration method comprises the step of enabling a to-be-concentrated ionic liquid water solution and absorbing liquid to respectively circularly flow through two sides of a forward osmosis film, wherein the osmotic pressure of the to-be-concentrated ionic liquid water solutionis lower than that of the absorbing liquid, the forward osmosis film is a thin-layer composite film with a polyamide active layer, a separating membrane with a codeposition active layer, a separatingfilm with a two-dimensional nanomaterial active layer or a forward osmosis separation film prepared from cellulose triacetate or sulfonated polyether sulfone. The effluent flux of a concentrated ionicliquid water solution can reach 5L.m<-2>.h<-1>-3L.m<-2>.h<-1>, the ionic liquid water solution can be concentrated to 70wt%-90wt%, so that the forward osmosis concentration method has huge application prospects in the recycling field of ironic liquid.

Owner:ZHEJIANG UNIV

Recovery processing method for discharge water of circulating water system

InactiveCN105621731AIncrease profitRealize environmental protection and water savingMultistage water/sewage treatmentWater useActivated carbon filtration

The invention relates to a recovery processing method for discharge water of a circulating water system. The method can remove particles, organic matters and most salt in the discharge water of the circulating water system. The discharge water of the circulating water system is sent to a static state mixer, is fully mixed with a flocculating agent added by a medicine adding apparatus, and is filtered by a self-cleaning filter to remove precipitate and large granule impurity. The filtered water passes through a pH value adjusting apparatus, then is sent to an activated carbon filter, and enters into a nanofiltration membrane apparatus through a pressure pump. The produced water from the nanofiltration membrane can be taken as water for production, concentrated water is returned to a water inlet end of the static state mixer. For prolonging the life of the nanofiltration membrane, regular and fast flushing of the nanofiltration membrane can be set. The method has the advantages of high comprehensive utilization rate and good recovery processing effect, and the recycle-water accounts for about 97% of total water amount.

Owner:MULTIPLE GLOBAL WATER EQUIP CHINA CO LTD

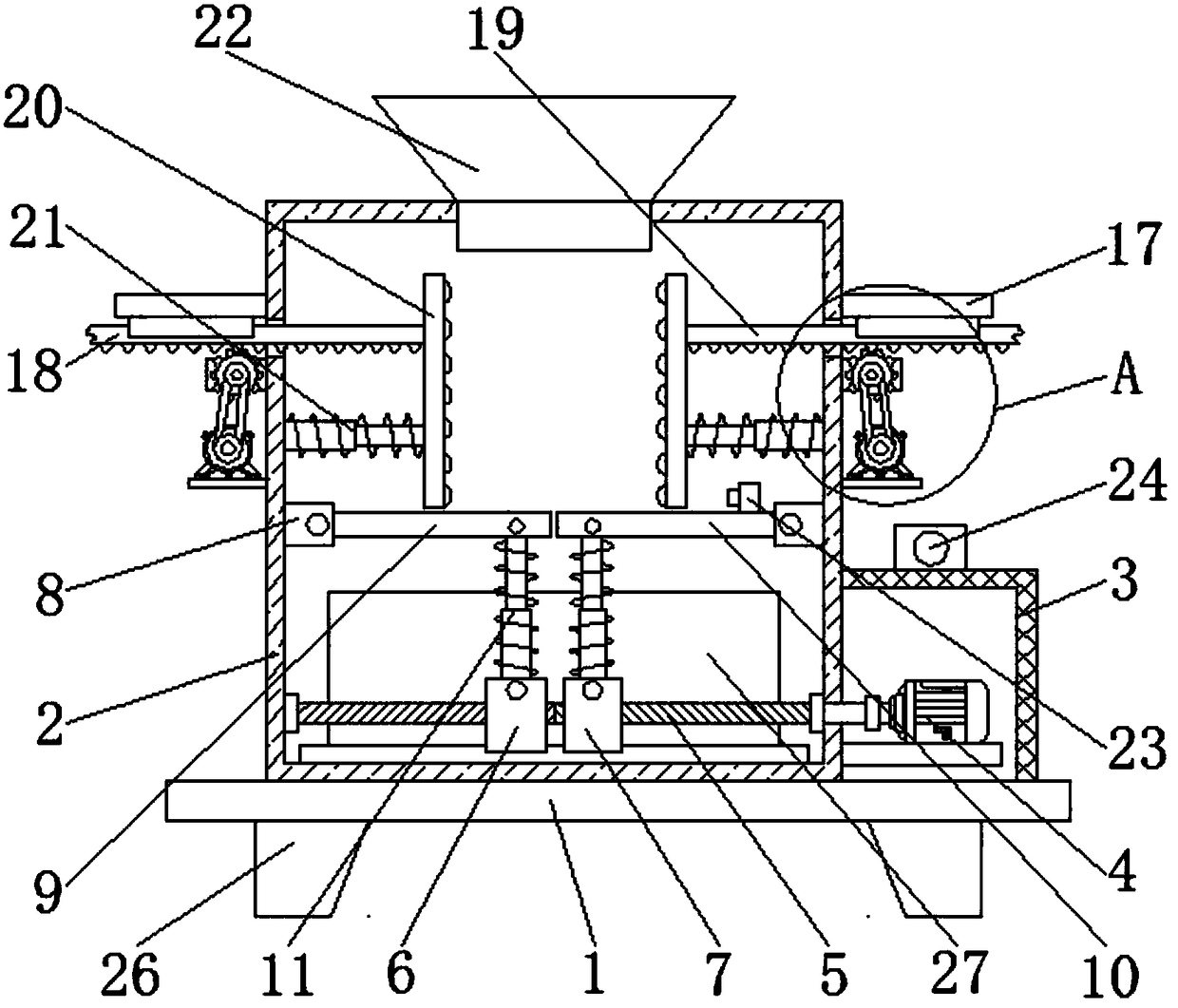

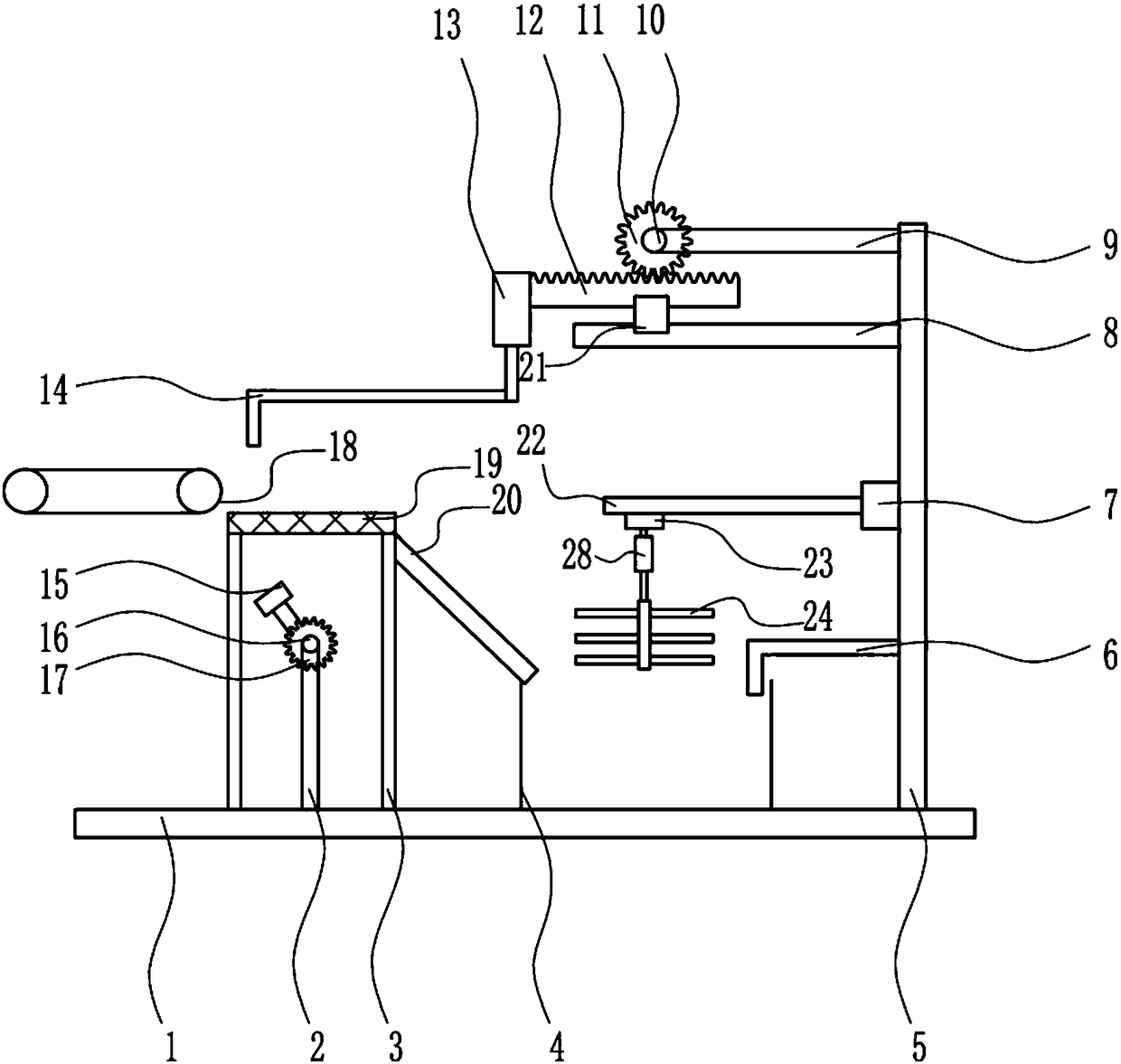

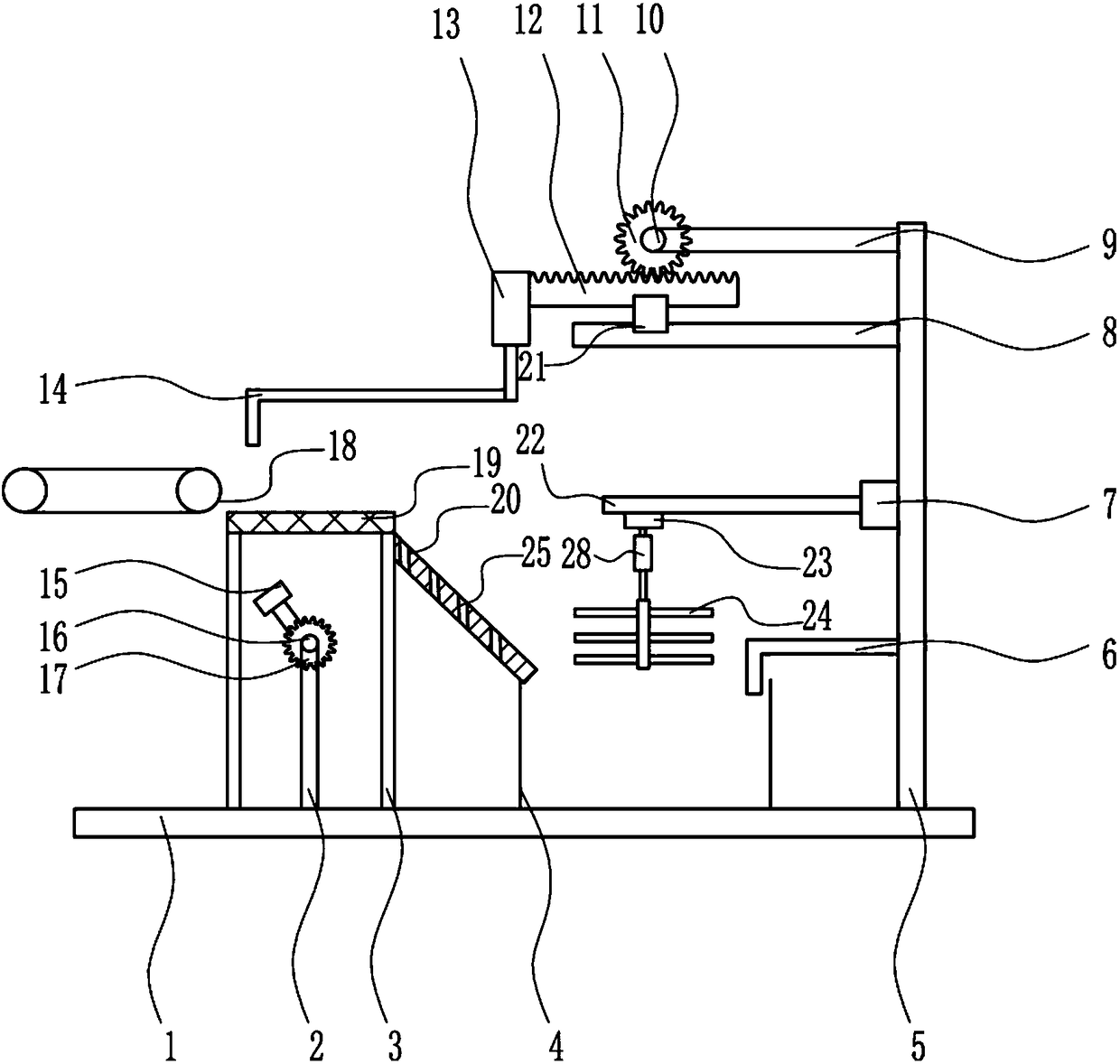

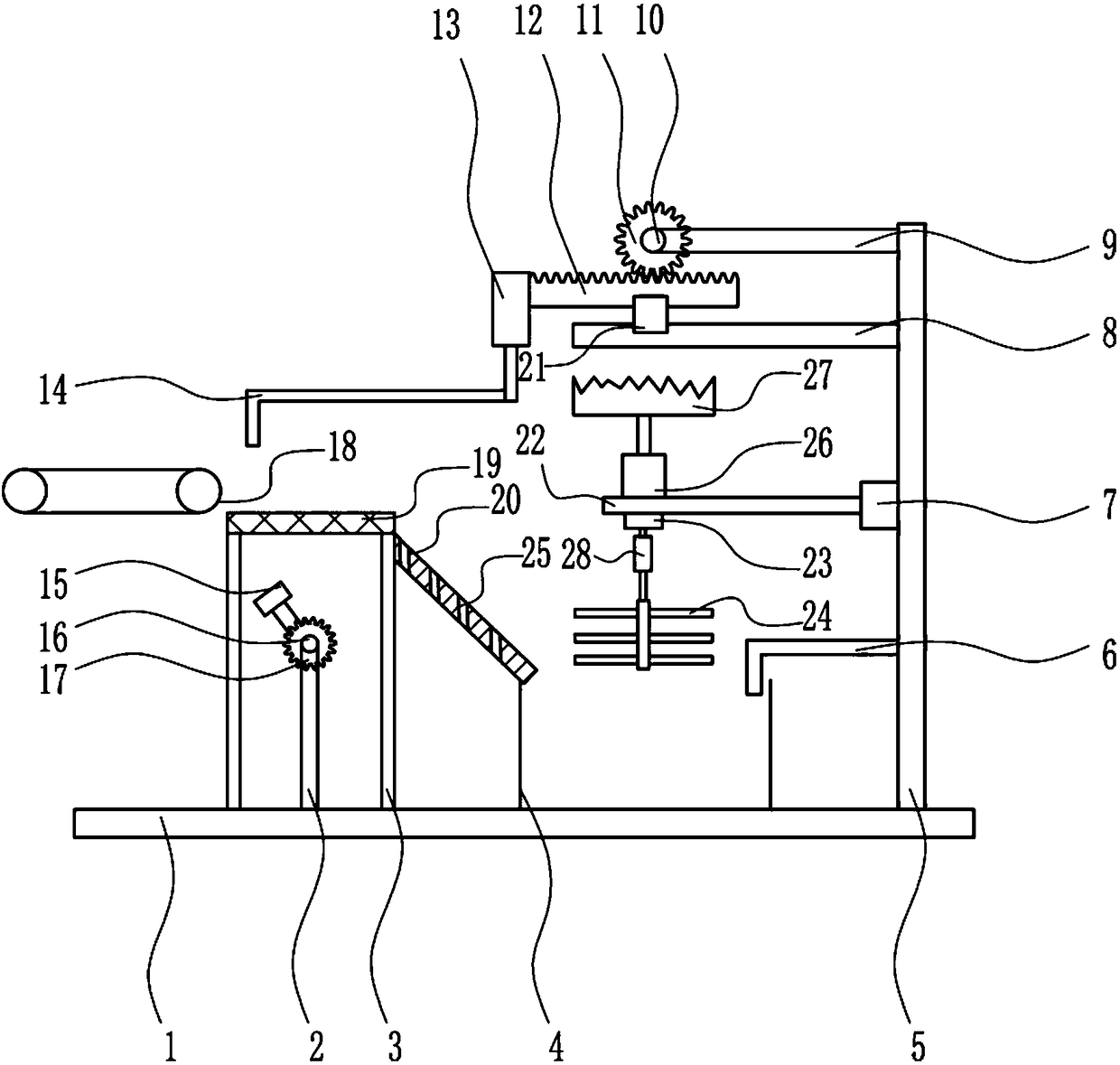

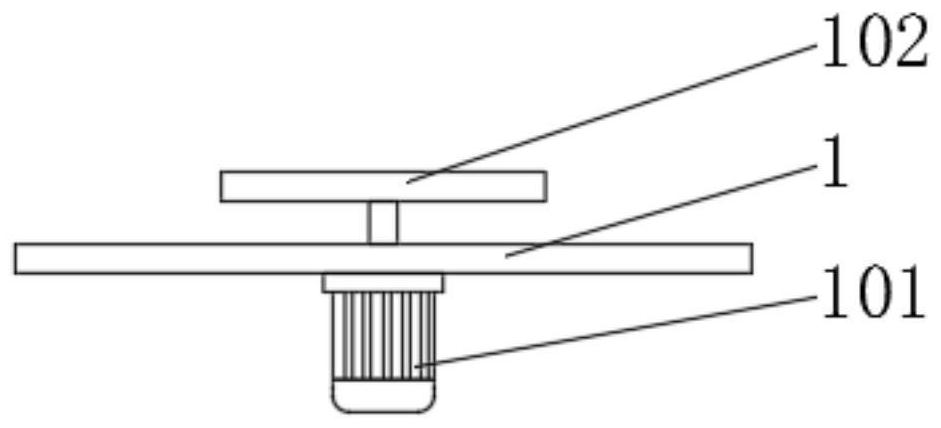

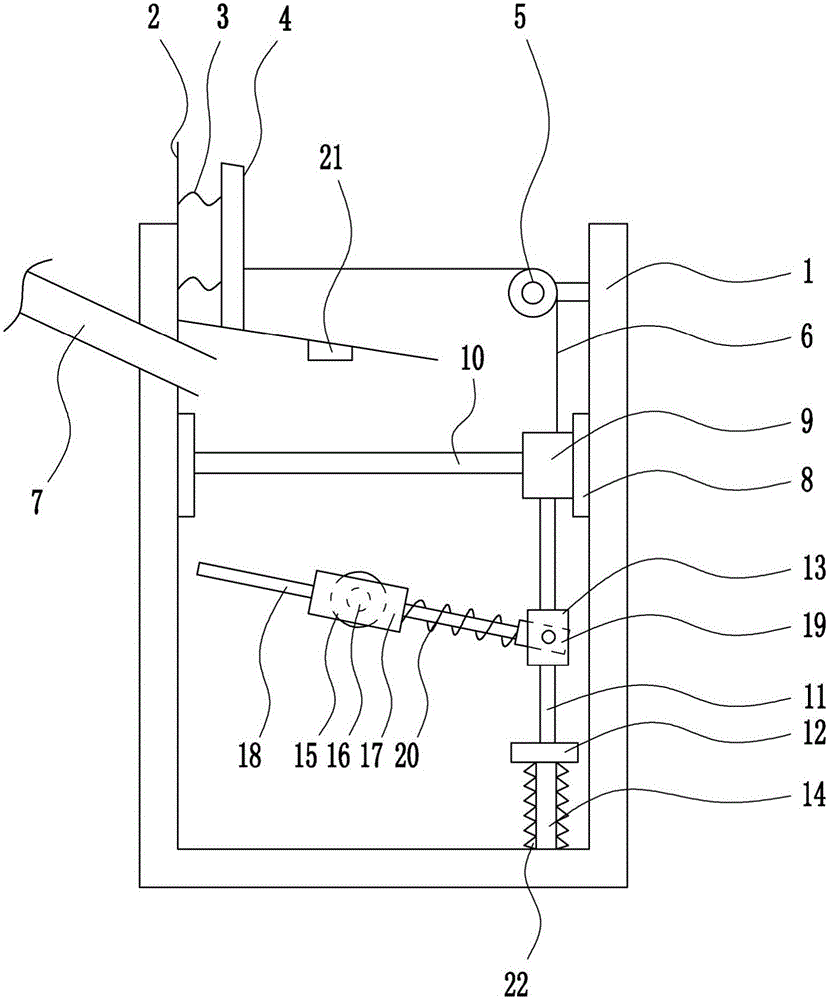

A hardware recycling device

The invention relates to a recycling processing device, in particular to a hardware recycling processing device. The invention provides the hardware recycling processing device, which is easy and convenient in operation, great in saving both time and labour and good in recycling processing effect. In order to solve the technical problems, the invention provides the hardware recycling device. The hardware recycling device comprises a baseboard, a strut I, a net rack, a processing box, a right support, an acid liquor pipe, an electrical machine I, a sliding rail, a strut II, an electrical machine II, a gear I, a rack, a power-driven push rod, a push rod I, a hammer, an electrical machine III, a gear II, a conveying device, a filter screen, a cantboard, a sliding block, a strut III, an electrical machine IV, a stirring pole and an air cylinder. The conveying device is arranged on the top left of the baseboard, and the strut I is arranged on the upper left of the baseboard. According to the invention, the effects of being easy and convenient in operation, great in saving both time and labour and good in recycling processing effect are achieved, and soil pollution can be effectively prevented through hardware recycling processing by using the hardware recycling processing device, and the environment can be protected.

Owner:江苏扬林电气有限公司

Improved copper powder recovery device

InactiveCN106319217AGood recycling effectSimple structureProcess efficiency improvementEngineeringAsphalt

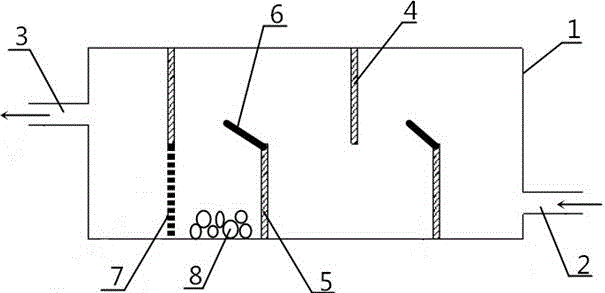

The invention relates to an improved copper powder recovery device. The device includes a recovery tank, a liquid inlet disposed on one side of the recovery tank, a liquid outlet disposed on the other side of the recovery tank, a plurality of upper baffle plates vertically connected inside a top plate of the recovery tank, and a plurality of lower baffle plates vertically connected inside a bottom plate of the recovery tank. Adjacent upper baffle plates and lower baffle plates are in staggered arrangement up and down. One ends of the lower baffle plates are also connected to anti-backflow sloping plates that incline along a water inflow direction. A filter plate is connected to the lower end of the upper baffle plate close to the liquid inlet, the bottom of the filter plate is connected inside the bottom plate of the recovery tank, and the filter plate is a porous plate, on which a detachable filter cloth or asphalt felt is attached. A plurality of tennis balls are placed in the recovery tank space between the filter plate and an adjacent lower baffle plate. The copper powder recovery device provided by the invention can achieve omnidirectional interception and deposition of copper powder in wastewater, and has the advantages of significant recovery effect, simple structure, and strong treatment capacity.

Owner:王勤

Oxidation tank waste liquid recovery device

PendingCN114230077AGood recycling effectImprove response and efficiencyWater/sewage treatment by centrifugal separationSpecific water treatment objectivesAlkaline waterReaction chamber

The invention relates to an oxidation tank waste liquid recovery device which comprises a base, a first support is fixed to one side of the top of the base, a second support is fixed to the other side of the top of the base, a reaction chamber is arranged at the position, close to the middle, of the top of the base, and the reaction chamber is located between the first support and the second support. A centrifugal mechanism for separating impurities from the waste liquid is arranged on one side, close to the reaction chamber, of the first support, a feeding mechanism is arranged on one side, close to the reaction chamber, of the second support, the feeding mechanism is used for introducing alkaline water into the reaction chamber to generate neutralization reaction with the waste liquid, and a heating mechanism is arranged below the feeding mechanism. The problems that according to an existing oxidation tank waste liquid recycling device, harmful impurities in waste liquid cannot be sorted, consequently, the impurities are not filtered in place, the recycling effect is poor, meanwhile, the waste liquid is only subjected to simple reaction in a reaction kettle, the reaction effect is poor, and the waste liquid recycling efficiency is low are solved.

Owner:ANHUI LANT ALUMINUM

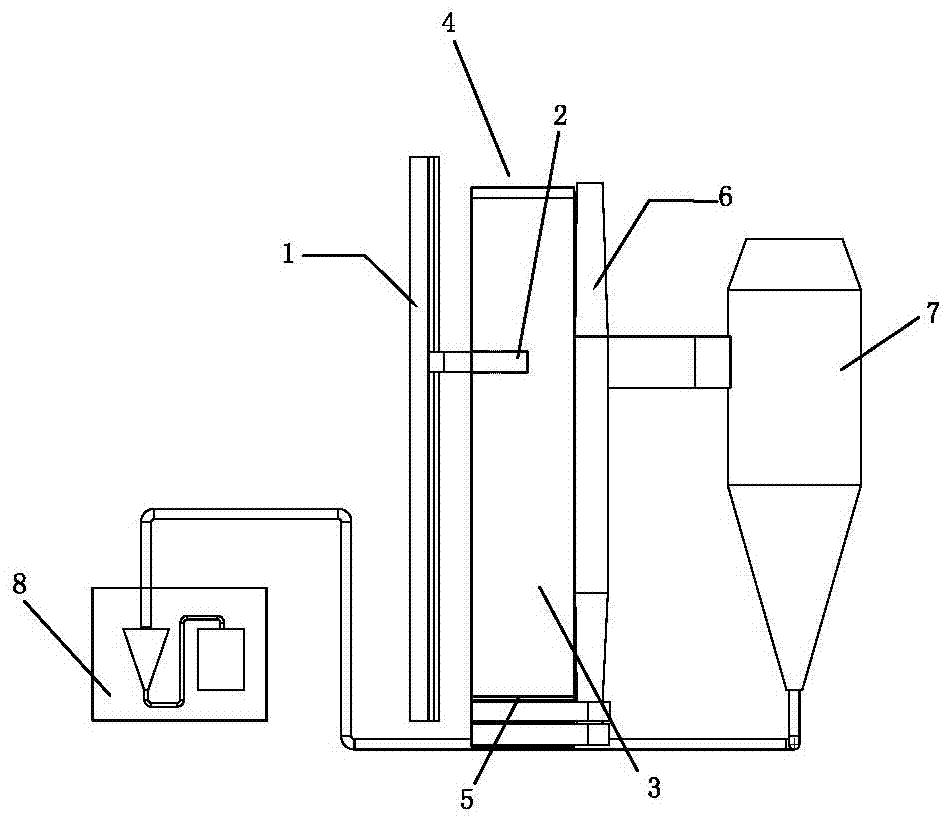

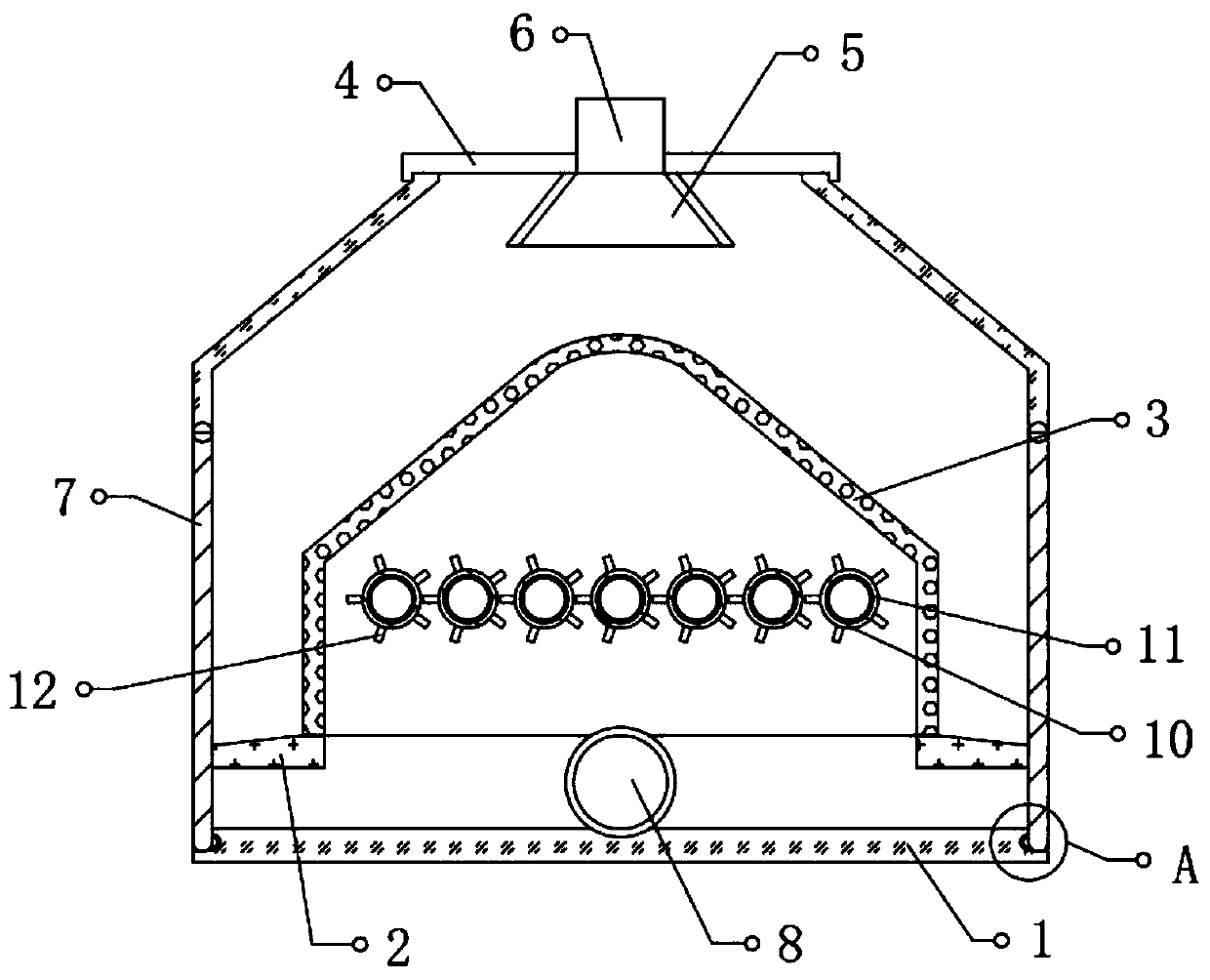

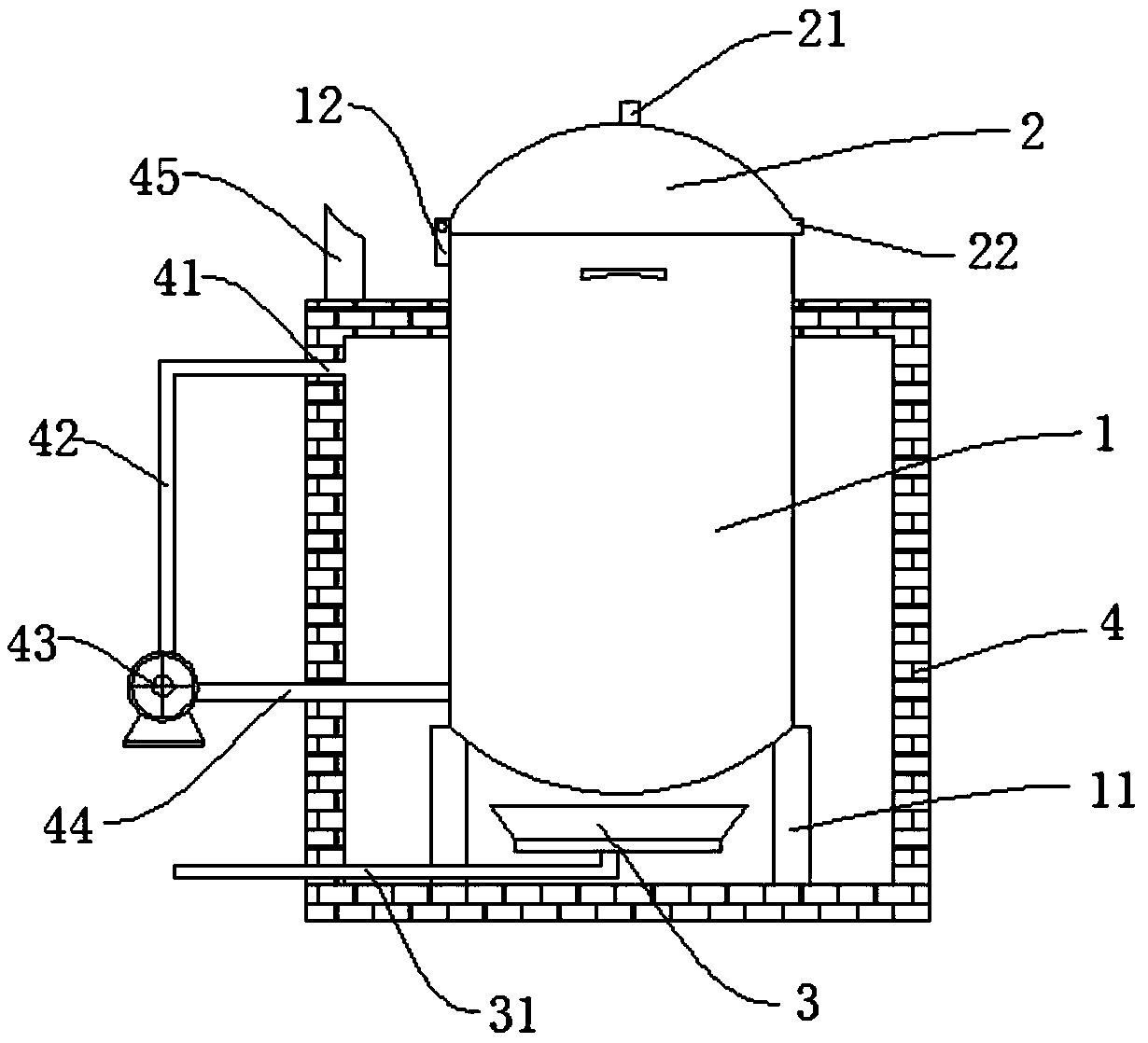

Straw carbonization system

PendingCN108913161ASimple structureEasy feedingGas treatmentDispersed particle filtrationCombustorBrick

The invention discloses a straw carbonization system. The straw carbonization system comprises a straw carbonization furnace and a flue gas recovery treatment device; the straw carbonization furnace comprises a carbonization furnace body, a carbonization furnace cover and a burner, the carbonization furnace cover is arranged on the furnace mouth of the carbonization furnace body, the burner is arranged just under the carbonization furnace body, and the carbonization furnace cover is provided with a gas outlet tube communicated with the carbonization furnace body; the straw carbonization furnace further comprises a heat insulation shell constructed by heat insulation bricks, and the heat insulation shell is provided with venting holes; the top end of the carbonization furnace body extends out of the top of the heat insulation shell; and the flue gas recovery treatment device is communicated with the gas outlet tube. The straw carbonization system is used to solve the technical problemsof large heat loss, unsatisfactory carbonization effect and low condensation efficiency in the prior art.

Owner:河南博顿生物科技有限公司

Environment-friendly waste paper water soaking type recycling device

ActiveCN106732993AGood recycling effectImprove work efficiencyGrain treatmentsWater pipeEnvironmental resistance

The invention relates to an environment-friendly waste paper recycling device, in particular to an environment-friendly waste paper water soaking type recycling device. The environment-friendly waste paper water soaking type recycling device is good in recycling effect, high in work efficiency and high in practicability and saves time and labor. In order to achieve the technical aims, the environment-friendly waste paper water soaking type recycling device comprises a recycling box, a breaking box, a first spring, a first blade, a roller wheel, a pull wire, a water pipe, a first baffle, a first sliding block, a first sliding rod, a second sliding rod and the like; the right side of the breaking box is connected with the first spring, the right end of the first spring is connected with the first blade, the right wall in the breaking box is connected with the roller wheel, the pull wire is wound on the roller wheel, and the upper end of the pull wire is connected with the first blade. The effects of being good in recycling effect, high in work efficiency and high in practicability and saving time and labor are achieved, and due to the device, the great support and help are provided for the environmental protection cause.

Owner:徐州利华环保科技有限公司

Waste shell recovery and treatment device for electronic product manufacturing

InactiveCN111822086AEfficient recyclingGood recycling effectDispersed particle filtrationDirt cleaningCouplingProcess engineering

The invention belongs to the technical field of electronic product manufacturing, and particularly relates to a waste shell recovery and treatment device for electronic product manufacturing. In orderto solve the problems that scrap iron in a shell can not be recovered effectively through a recovery and treatment device in the above patent, the scrap iron and plastic can not be separated for treatment, and consequently the recovery and treatment effects are poor, the following scheme is provided; the waste shell recovery and treatment device comprises a base, and a separating box is fixed tothe top outer wall of the base by screws; a servo motor is fixed to the outer wall of one side of the separating box by screws, and an output shaft of the servo motor is connected with a transmissionroller through a coupling; and the outer wall of the transmission roller is sleeved with a conveyor belt mechanism. According to the waste shell recovery and treatment device, scrap iron on a magneticbelt can be scraped and falls into a bushel iron collecting tank through a scraping plate for collection; other crushed aggregates fall into a plastic collecting tank for collection, and the scrap iron in the shell can be recovered effectively; and the scrap iron and the plastic can be separated for treatment, and the recovery and treatment effects are better.

Owner:SUZHOU CHUANGMING SOFTWARE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com