Waste shell recovery and treatment device for electronic product manufacturing

A technology for recycling and processing electronic products, which is applied in the field of recycling and processing devices for waste shells used in the production of electronic products, and can solve problems such as poor recycling and processing effects, inability to recycle scrap iron, and inability to separate and process scrap iron and plastics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

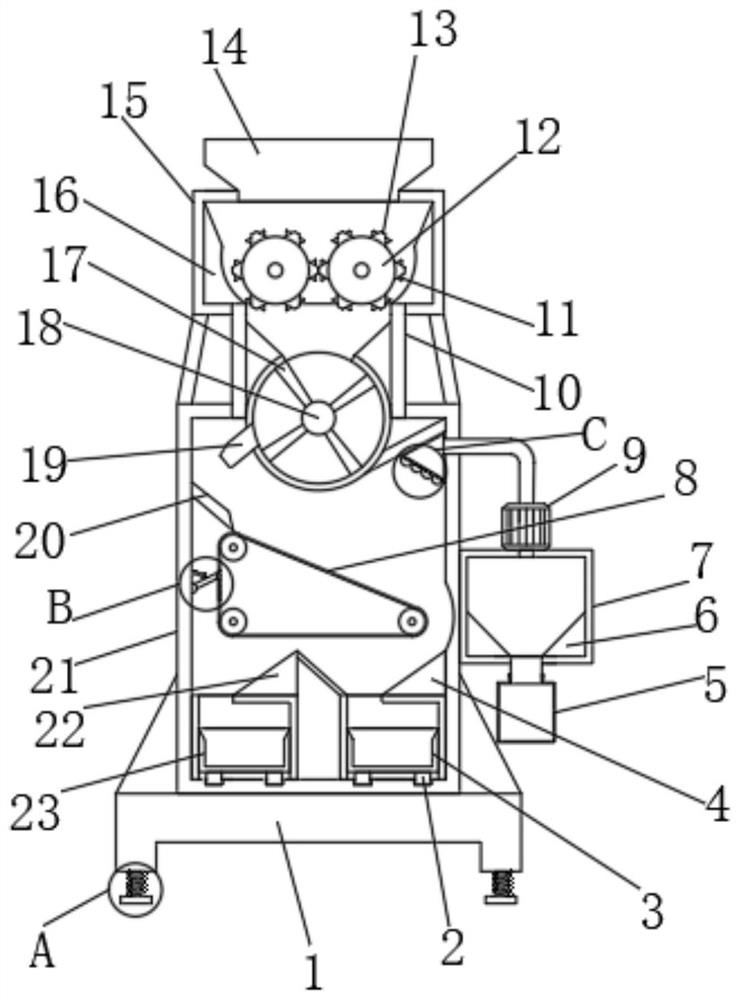

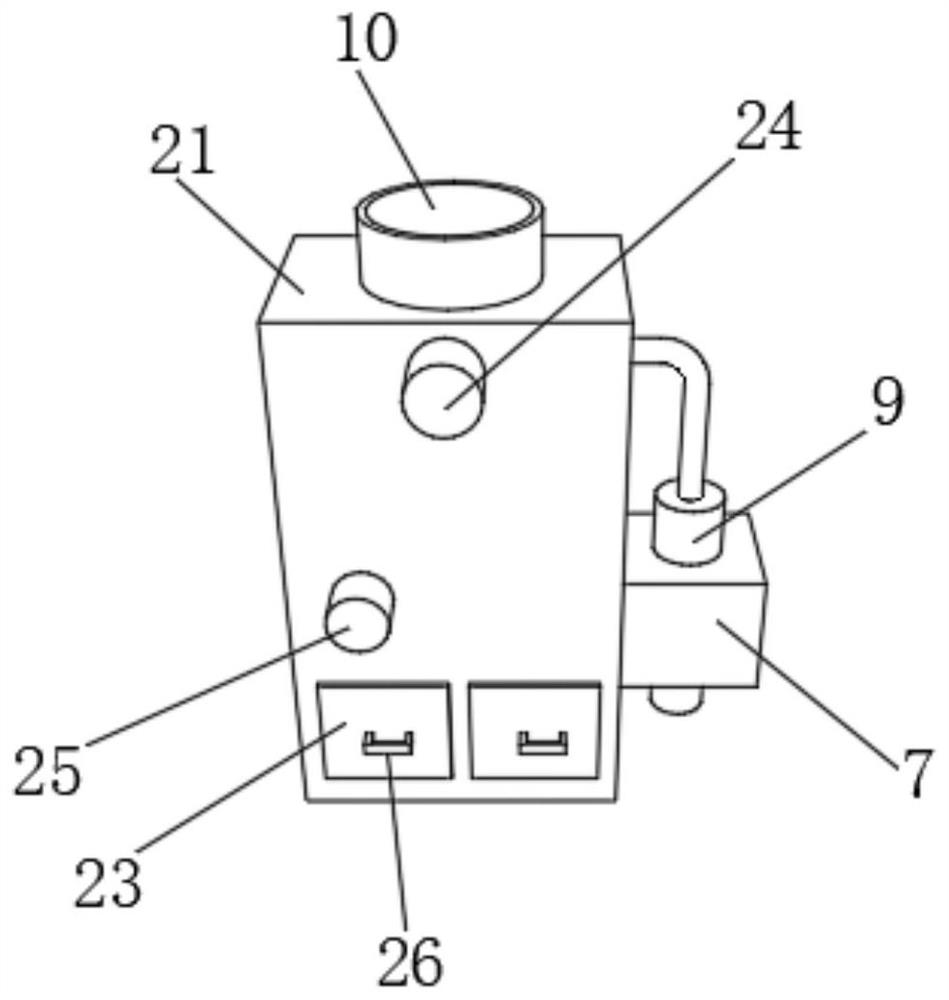

[0029] refer to Figure 1-5 , a device for recycling waste casings used in the production of electronic products, comprising a base 1, a sorting box 21 is fixed on the top outer wall of the base 1 by screws, and a servo motor 25 is fixed on one side of the outer wall of the sorting box 21 by screws, and the servo The output shaft of the motor 25 is connected with a transmission roller through a shaft coupling, and the outer wall of the transmission roller is sleeved with a conveyor belt mechanism. The conveyor belt mechanism includes a magnetic belt 8, and the two ends of the magnetic belt 8 are connected with the same non-magnetic belt. One side inner wall of selection box 21 is hinged with scraper 33, and the top outer wall of scraper 33 is provided with spring 31, and spring 31 is connected with the inner wall of sorting box 21 away from the end of scraper 33, and the top outer wall of sorting box 21 The support bar is fixed by screws, and the top outer wall of the support ...

Embodiment 2

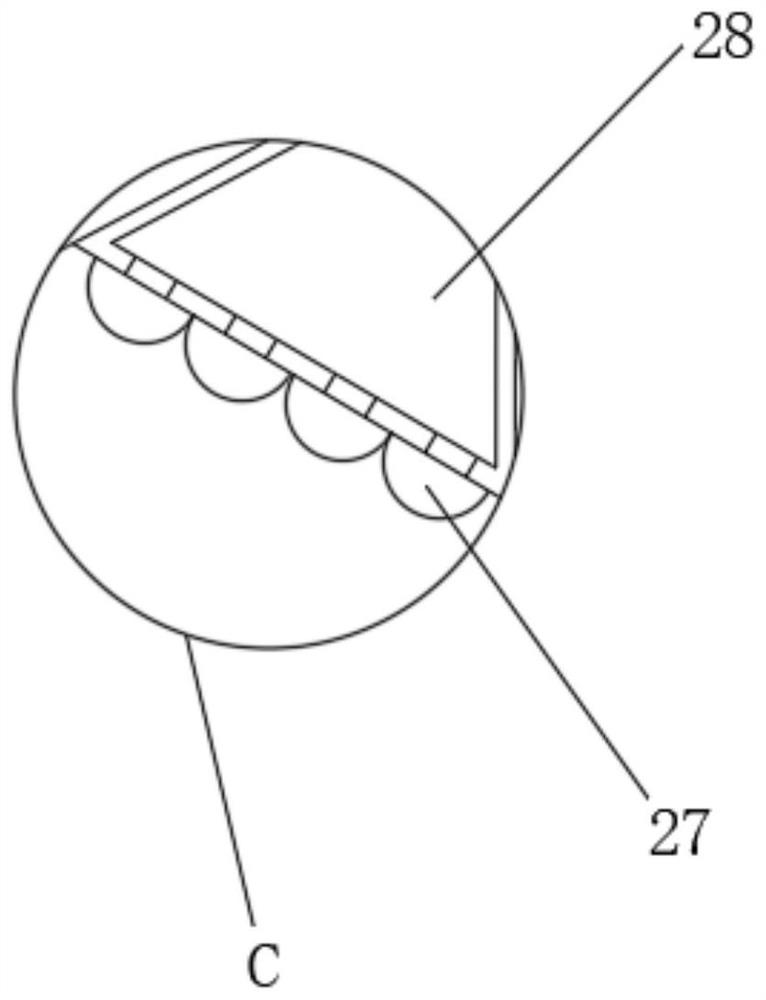

[0038] refer to figure 1 , a device for recovering waste casings used in the production of electronic products. Compared with Embodiment 1, this embodiment also includes a dust collection box 7 fixed on one side of the outer wall of the sorting box 21 by screws, and the top outer wall of the dust collection box 7 The dust suction pump 9 is fixed by screws, the input end of the dust suction pump 9 is sleeved with a triangular dust suction pan 28, the outer wall of the triangular dust suction pan 28 is provided with a dust suction hole, and the inner wall of the dust suction hole is inserted with a dust suction head 27 , both sides inner walls of the dust box 7 are fixed with a material guide plate 6 by screws, and the bottom outer wall of the dust box 7 is provided with a threaded hole, and the inner wall of the threaded hole is threadedly connected with a dust bag 5.

[0039] After the casing is crushed, a large amount of flying dust will definitely be produced in the sorting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com