Environment-friendly waste battery recovery and treatment device

A waste battery, recycling and processing technology, applied in grain processing, cleaning methods and utensils, filtration and separation, etc., can solve the problems of inability to meet the needs of use, insufficient battery crushing, and poor grinding effect of recycling processing devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

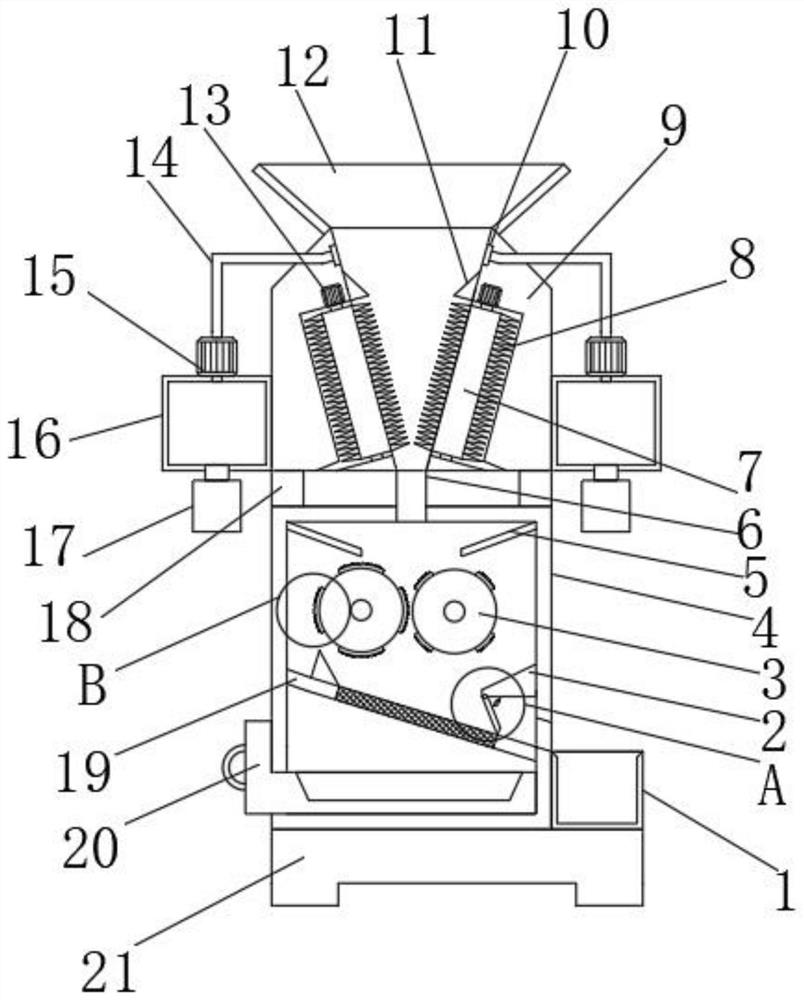

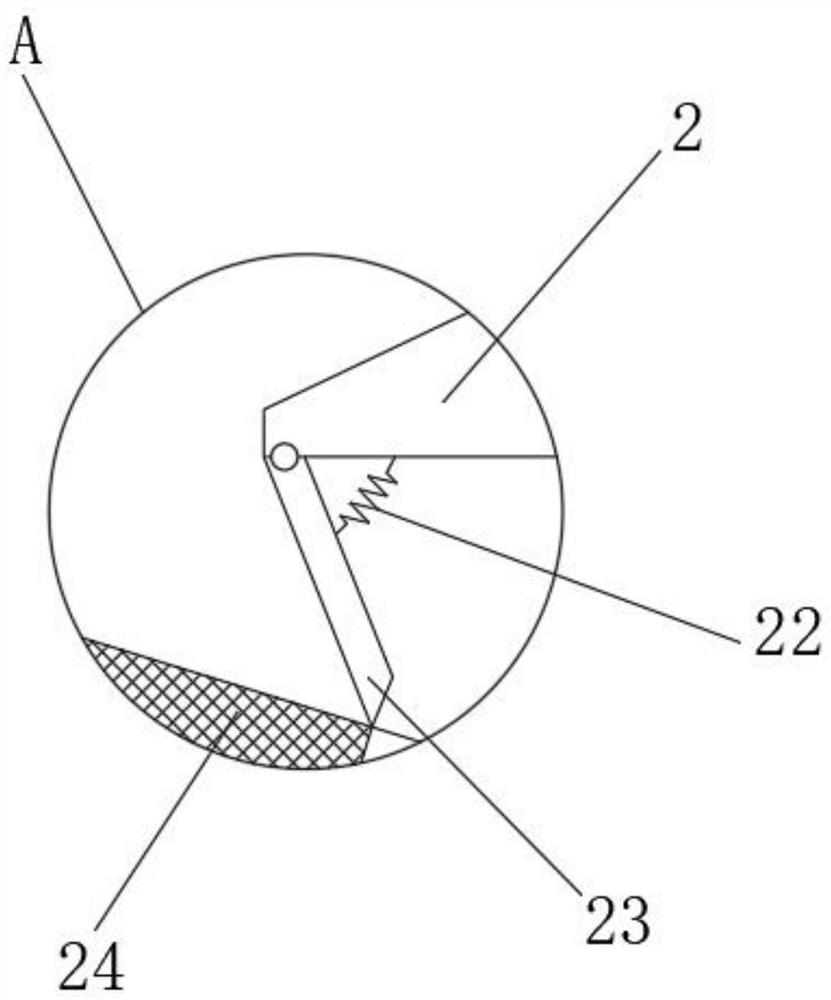

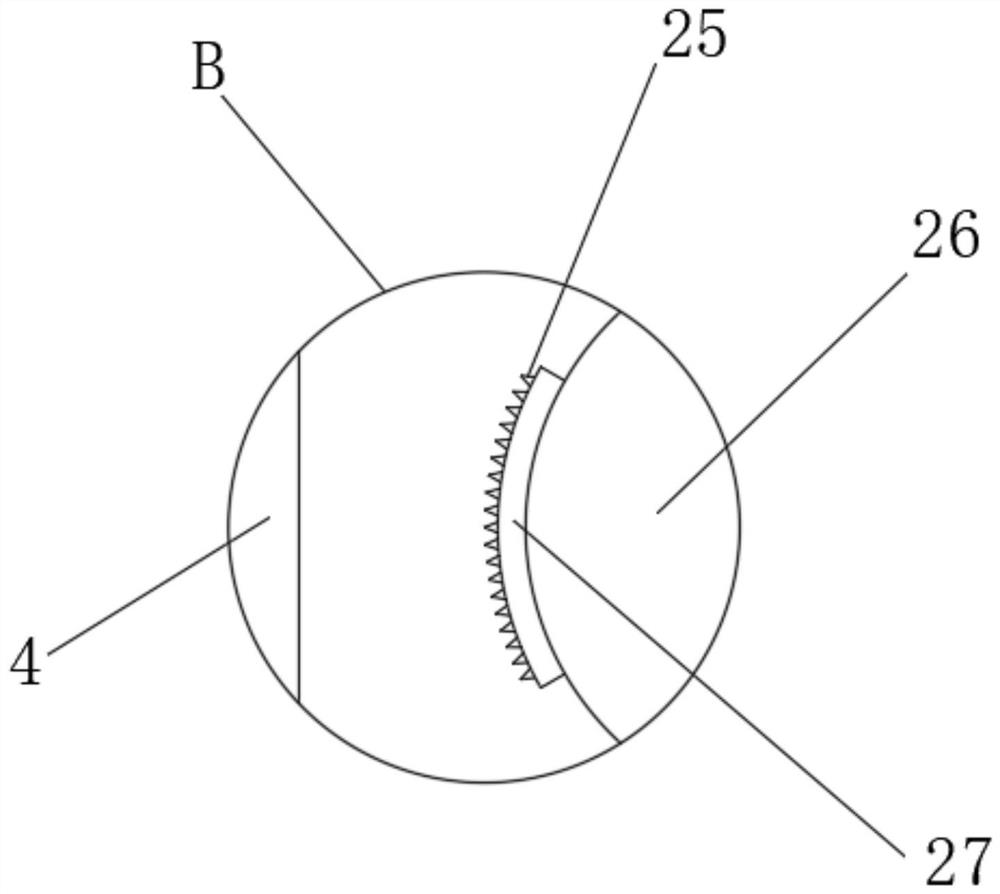

[0030] refer to Figure 1-5 , an environment-friendly waste battery recovery treatment device, including a base 21, one side of the outer wall of the top of the base 21 is fixed with a second crushing box 4 by screws, and one side of the outer wall of the second crushing box 4 is fixed with two motors 29, the output shafts of the two motors 29 are respectively connected to the first crushing roller 3 and the second crushing roller 26 through couplings, and the outer walls of the first crushing roller 3 and the second crushing roller 26 are provided with arc-shaped plates 27, and The outer wall of the arc-shaped plate 27 is provided with crushing teeth 25, the top outer wall of the second crushing box 4 is fixed with a support block 18 by screws, and the top outer wall of the support block 18 is fixed with a first crushing box 9 by screws, the first crushing box 9 Both sides of the inner wall are provided with inclined grooves, and the top inner wall of the groove is fixed with...

Embodiment 2

[0040] refer to figure 1 , a waste battery recycling device for environmental protection. Compared with Embodiment 1, this embodiment also includes that the outer walls on both sides of the first crushing box 9 are fixed with dust collection boxes 16 by screws, and the top outer wall of the dust collection box 16 is The dust suction pump 15 is fixed by screws, the output end of the dust suction pump 15 is connected with the dust collection box 16, the input end of the dust suction pump 15 is sleeved with a dust suction pipe 14, and the end of the dust suction pipe 14 is far away from the dust suction pump 15 The dust suction head 10 is sleeved, and the outer wall of the bottom of the dust box 16 is provided with a threaded hole, and the inner wall of the threaded hole is connected with a dust bag 17 by threads.

[0041] Waste batteries will generate flying dust during the crushing process, and the dust suction pump 15 can suck the dust into the dust collection box 16 through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com