Forward osmosis concentration method of ionic liquid water solution

An ionic liquid and aqueous solution technology, applied in reverse osmosis, chemical instruments and methods, semi-permeable membrane separation, etc., can solve the problem of limited concentration and achieve the effect of wide selection, universality and good recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

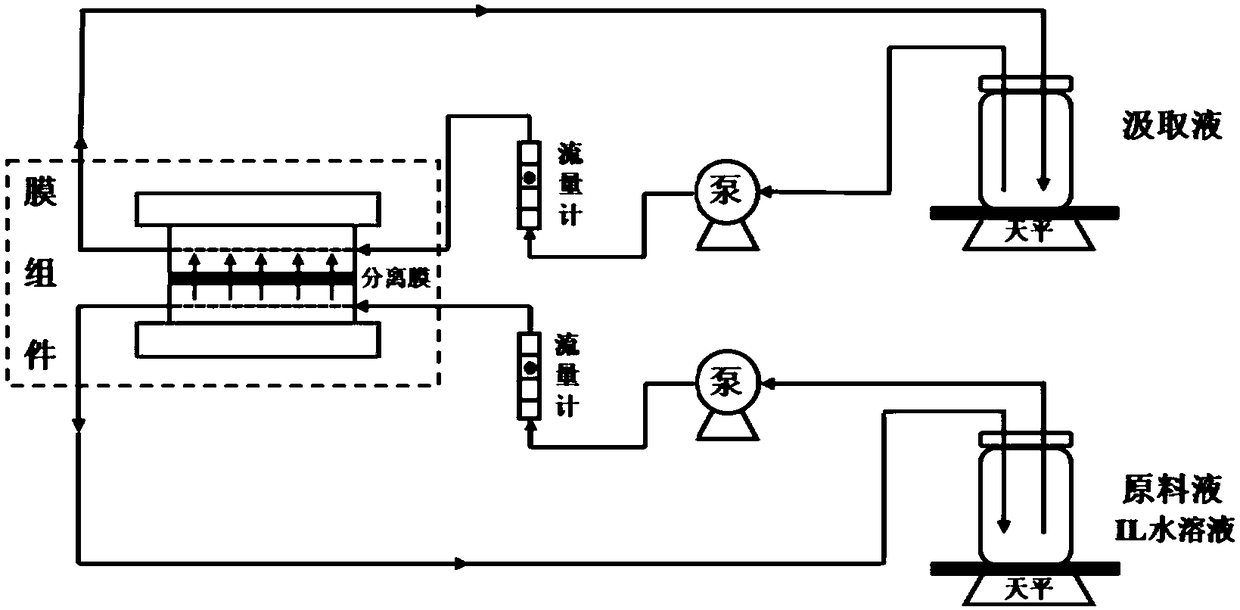

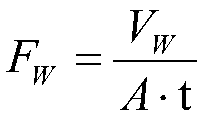

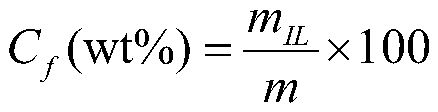

Method used

Image

Examples

Embodiment 1

[0050]Prepare 1L of sodium chloride aqueous solution with a concentration of 6mol / L as the drawing solution, prepare 0.5L of 0.5mol / L aqueous solution of 1-butyl-3-methylimidazole chloride (M4) as the raw material solution, and transfer the two solutions to the corresponding raw material liquid storage tank. The separation membrane adopts commercial reverse osmosis membrane FilmTec BW30-4040 (DOW), the pump adopts peristaltic pump Masterflex L / S (Cole-Parmer), the cross-flow flow rate is set at 30L / h, the concentration time is 96h, and the circulation of the draw liquid and the raw material liquid are controlled. The cycle temperature was 30°C. Forward osmosis concentration performance is shown in Table 1.

Embodiment 2~5

[0052] The 1-butyl-3-methylimidazole chloride in embodiment 1 is replaced by 1-hexyl-3-methylimidazole chloride (M6), 1-octyl-3-methylimidazole chloride (M8 ), 1-decyl-3-methylimidazole chloride (M10), 1-dodecyl-3-methylimidazole chloride (M12), pyridinium chloride, and all the other conditions are the same as in Example 1. Forward osmosis concentration performance is shown in Table 1.

[0053] The forward osmosis concentration performance of table 1 embodiment 1~5

[0054]

Embodiment 6~9

[0056] In embodiment 1, 1-butyl-3-methylimidazole chloride is replaced by N-butylpyridine chloride (P4), M-hexylpyridine chloride (P6), N-octylpyridine chloride (P8) , N-decylpyridine chloride (P10), N-dodecylpyridine chloride (P12), and all the other conditions are the same as in Example 1. Forward osmosis concentration performance is shown in Table 2.

[0057] The forward osmosis concentration performance of table 2 embodiment 6~9

[0058]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com