Spraying system with vertical spraying chamber for aluminum profiles

A technology for aluminum profiles and spray booths, which is applied in coatings, spray booths, spray devices, etc., can solve the problems of affecting recovery efficiency and the decline of fine powder capacity, and improve the sanitation of the spray booth, improve the powder suction effect, and shorten the cleaning time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

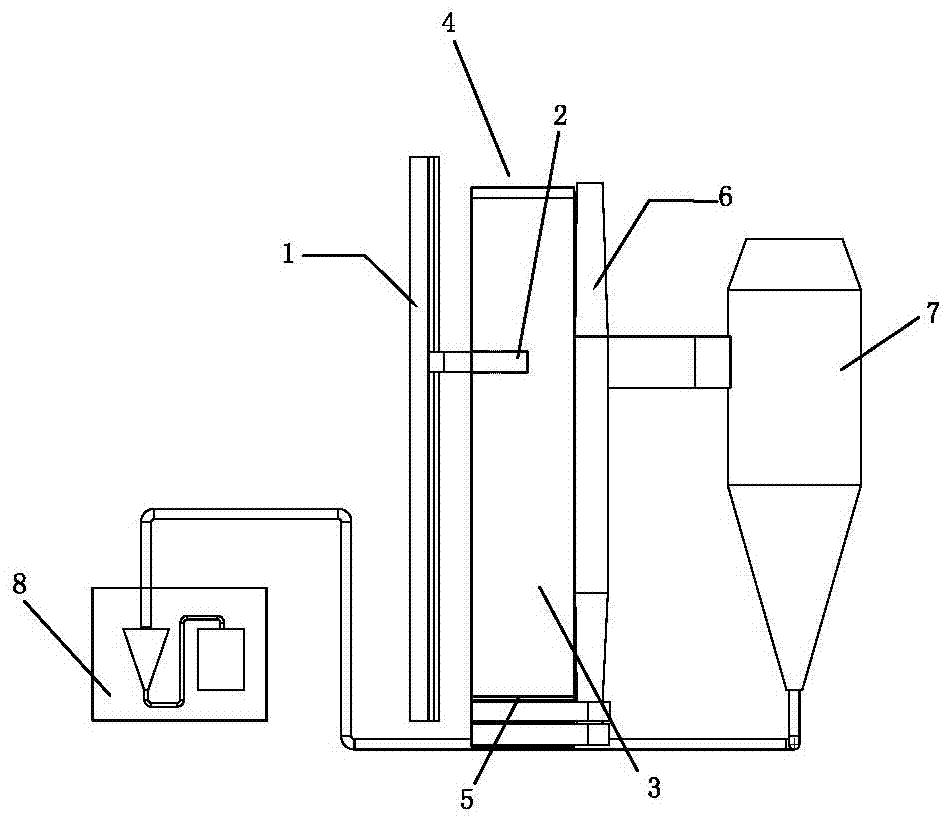

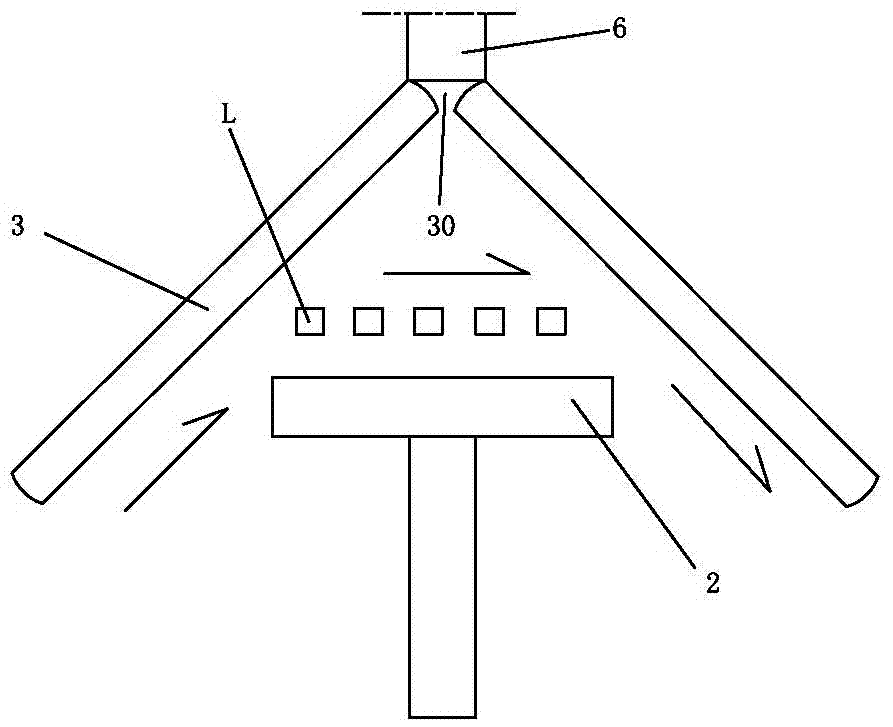

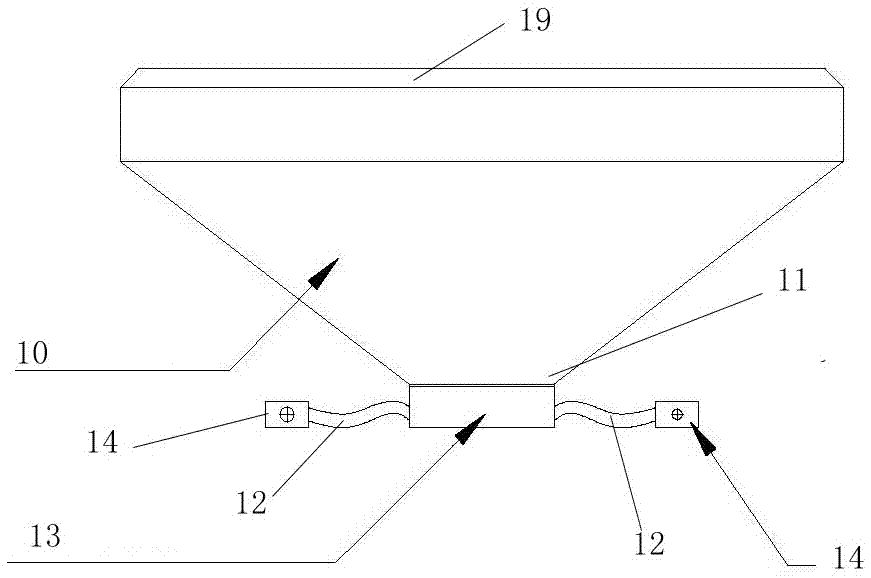

[0032] see Figure 3-10 As shown, a vertical spray booth spraying system for aluminum profiles, which includes a vertical spray booth 4 composed of cords 3, the key point is that the vertical spray booth 4 is composed of three cords 3, and adjacent cords 3 are vertically arranged , there is a gap 30 between adjacent curtains 3; the vertical spray booth 4 runs through up and down, and the lower end of the vertical spray booth 4 is connected to the recovery device 10.

[0033] It also includes a vertically arranged powder spraying column 1. The horizontally arranged nozzles 2 are connected to the powder spraying column 1 and can move up and down along the powder spraying column 1 to spray up and down the strip-shaped profiles. The nozzles 2 accommodate 4 in the vertical spray booth formed by cord 3; the moving structure here, and the nozzle, all are prior art, for example, utilize track to move up and down on the powder spraying column, a plurality of nozzle structures that are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com