Patents

Literature

101results about How to "Less powder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing Ni-Co-Mn ternary hydroxide

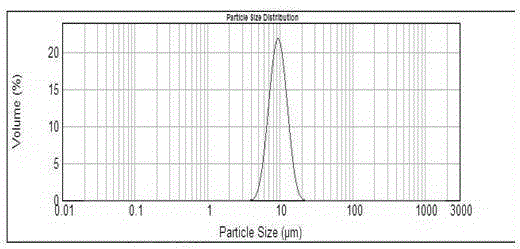

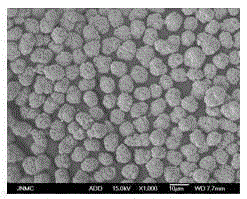

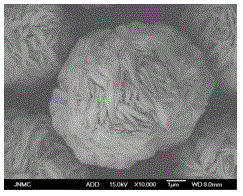

InactiveCN105399154AImprove performanceNarrow particle size distributionCell electrodesSecondary cellsSynthesis methodsFiltration

The invention discloses a method for producing a Ni-Co-Mn ternary hydroxide, and relates to a continuous synthesis method for a Ni-Co-Mn ternary hydroxide for a lithium ion battery. The method is characterized by comprising the following steps in a production process: first, adding a sodium hydroxide solution and an ammonia water solution into a Ni-Co-Mn metal salt solution, controlling the pH value of a reaction system to be 10.0-12.0, and carrying out a crystal nucleus creating reaction till the granularity of a created crystal nucleus reaches 3-5 [mu]m, so as to obtain a mixed solution containing the crystal nucleus; then, converging the mixed solution containing the crystal nucleus, the Ni-Co-Mn metal salt solution, the sodium hydroxide solution and the ammonia water solution, controlling the pH value of a system to be 9.5-11.5, carrying out a crystal nucleus growth reaction, and carrying out aging, filtration, washing and drying to obtain the Ni-Co-Mn ternary hydroxide. The Ni-Co-Mn ternary hydroxide produced according to the method is stable in product performance, narrow in granularity distribution, less in micro powder, and controllable in morphology.

Owner:LANZHOU JINCHUAN NEW MATERIAL SCI & TECH

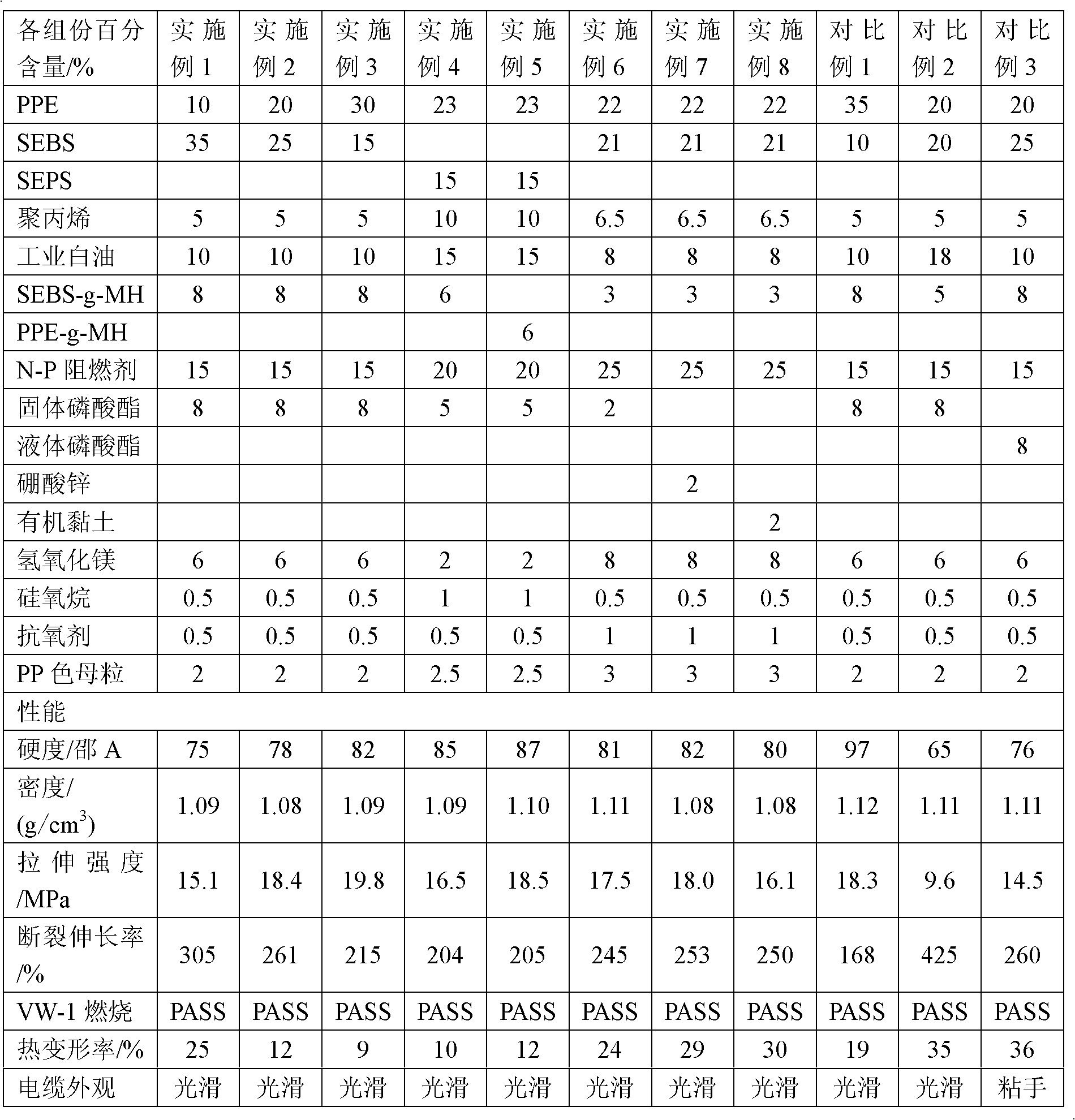

Flexible halogen-free flame-retardant polyphenyl ether electric wire cable shield material and preparation method thereof

InactiveCN102585428ANo migrationImprove flame retardant performancePlastic/resin/waxes insulatorsInsulated cablesElastomerPolyolefin

The invention relates to the field of halogen-free flame-retardant electric wire cable shield materials, in particular to a flexible halogen-free flame-retardant polyphenyl ether electric wire cable shield material and a preparation method thereof. The flexible halogen-free flame-retardant polyphenyl ether electric wire cable shield material is characterized by comprising the following raw materials in percentage: 10 to 30 percent of polyphenyl ether resin; 15 to 35 percent of styrene elastomer; 5 to 10 percent of polyolefin; 8 to 15 percent of plasticizing agent; 3 to 8 percent of compatilizer; 15 to 25 percent of main flame retardant; 2 to 8 percent of synergistic flame retardant; 2 to 8 percent of smoke suppressant; 0.5 to 1 percent of lubricant; 0.5 to 1 percent of antioxygen; and 2 to 3 percent of masterbatch. The flexible halogen-free flame-retardant polyphenyl ether electric wire cable shield material has favorable mechanical property, flexibleness, flame retardant property, heat resistance and processability.

Owner:浙江北化阻燃材料有限公司 +1

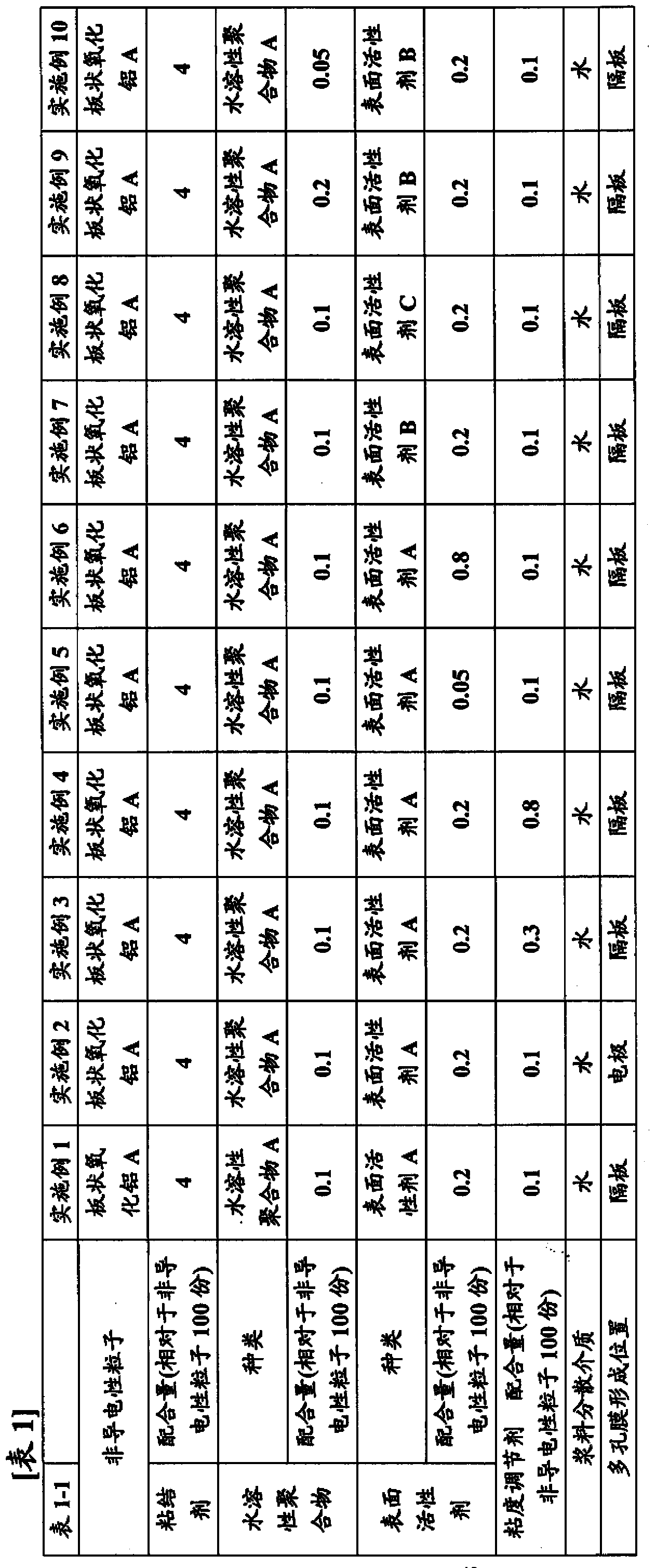

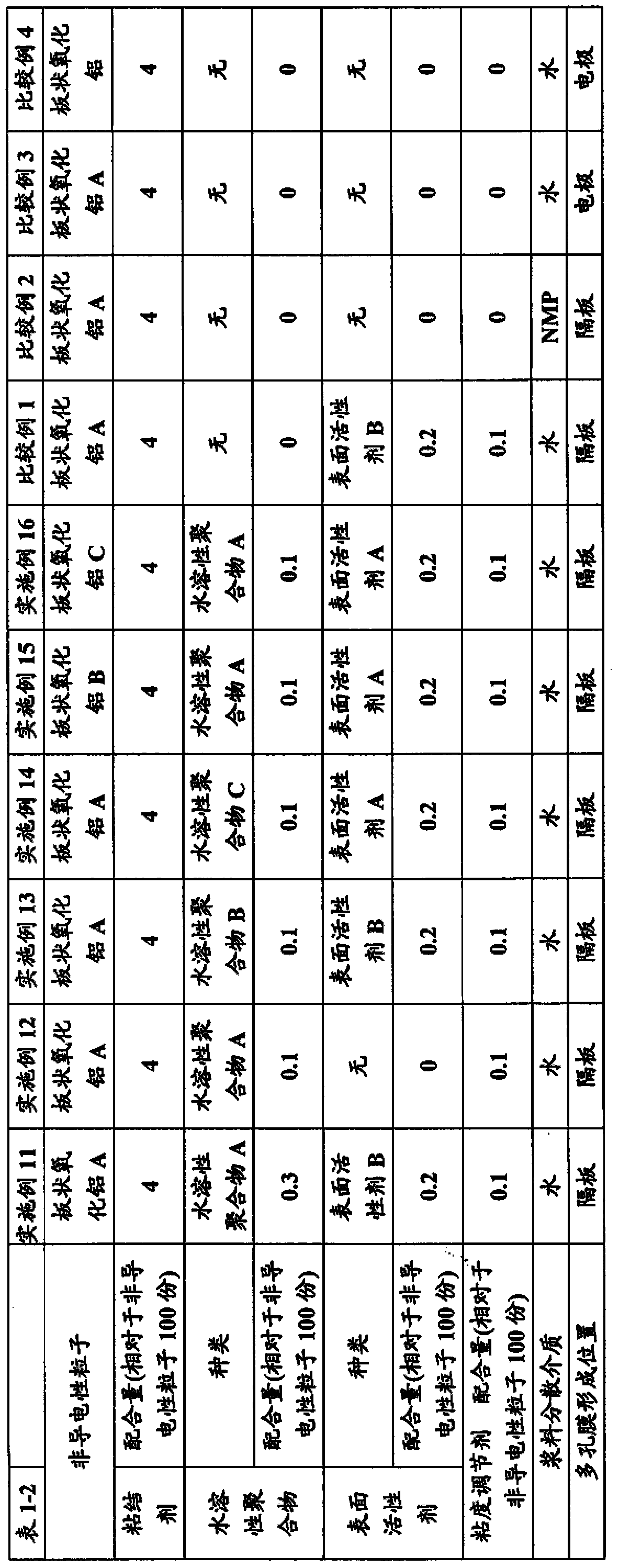

Porous membrane for secondary battery, slurry for secondary battery porous membrane and secondary battery

ActiveCN103403919AEvenly dispersedEasy to slideNon-aqueous electrolyte accumulator electrodesLi-accumulatorsAcrylonitrilePorous membrane

Owner:ZEON CORP

Lithium ion battery positive electrode material precursor nickel-cobalt-manganese hydroxide powder and preparation method thereof

The invention discloses lithium ion battery positive electrode material precursor nickel-cobalt-manganese hydroxide powder and a preparation method thereof. The lithium ion battery positive electrode material precursor nickel-cobalt-manganese hydroxide powder is represented by the general formula NixCoyMnz(OH)2. The preparation method comprises the steps that an alkali solution is added into a reaction device; a metal salt solution comprising nickel-cobalt-manganese and an alkali solution are continuously dropped on the liquid level of the alkali solution, such that a neutralization precipitation reaction is carried out; the produced nickel-cobalt-manganese hydroxide slurry is concentrated and is introduced into the reaction device, and a reaction is continued; final product nickel-cobalt-manganese hydroxide slurry is fetched, and is filtered and dried. The nickel-cobalt-manganese hydroxide provided by the invention has the advantages of uniform particle size, less micro-powder, high crystallinity, and large primary particles.

Owner:兰州金通储能动力新材料有限公司

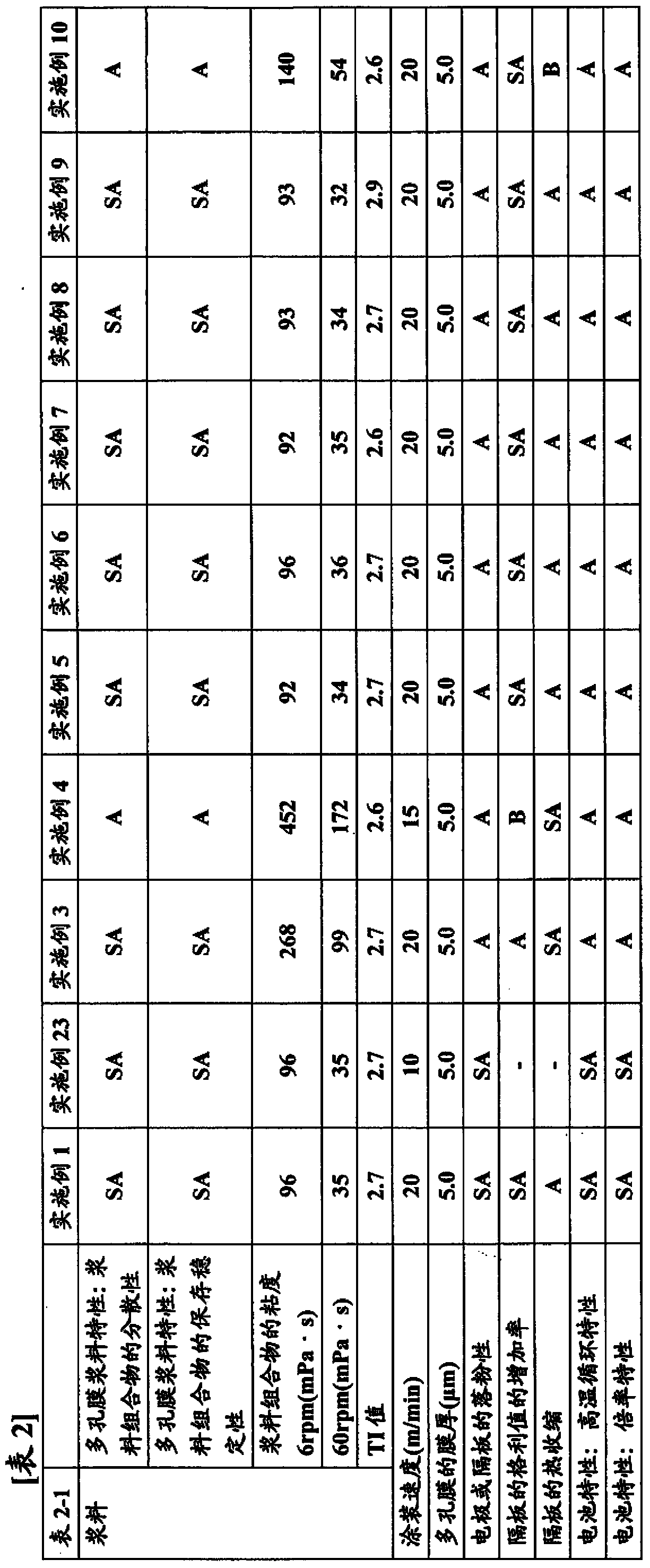

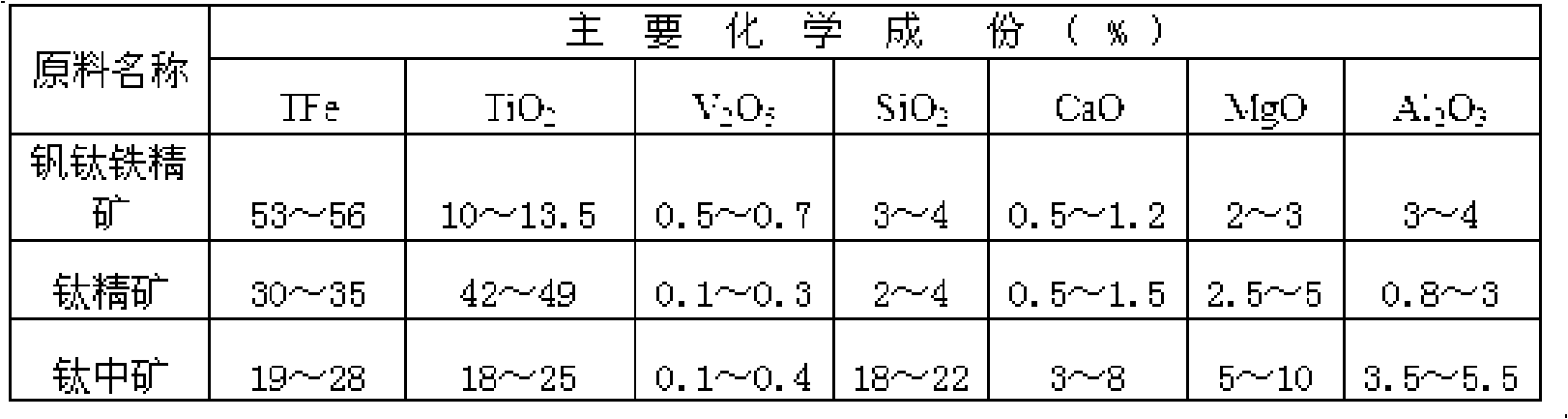

High-titanium protection stove pellet ore and preparation thereof

ActiveCN101343674AReduce shipping costsExtend your lifeBlast furnace detailsTitaniumTitanium dioxide

The invention relates to a high titanium furnace protecting pellet and the preparation method, which belongs to the metallurgical field. The invention solves the technical problem that a high titanium furnace protecting pellet with titanic oxide content of more than 15 percent and the preparation method thereof. The high purity titanium furnace protecting pellet of the invention comprises that, TiO2 content occupies 15 percent to 35 percent, TFe content occupies 35 percent to 50 percent, and the preparation method comprises the steps of raw materials mixing, pellet fabricating, roasting and cooling. When the high titanium furnace guarding pellet is used for high furnace ironmaking, the furnace protection effect is good, the service life of the high furnace can be effectively improved, and the application prospect is wide.

Owner:攀枝花一立矿业股份有限公司

3D laser printing system and method based on robot

InactiveCN105499573AImprove processing efficiencyRealize processing and manufacturingAdditive manufacturing apparatusIncreasing energy efficiencyShielding gasEngineering

The invention relates to a 3D laser printing system and method based on a robot. A mechanical arm is utilized for driving a laser printing head unit for 3D printing, and comprises a machine base, a horizontal rotating disc, an arm joint, an upper arm, an elbow joint, a lower arm, a wrist joint, a robot wrist, a connecting disc, a protection gas supply pipeline, and a powder supply pipeline connected with a powder stock bin. The connecting disc is connected with the laser printing head unit, the connecting disc drives the laser printing head unit to rotate, and the protection gas supply pipeline and the powder supply pipeline are fixed to the upper arm and the lower arm through fixing rings. The end of the protection gas supply pipeline and the end of the powder supply pipeline are connected with the laser printing head unit. The 3D laser printing system and method have the advantages that metal parts, especially stainless steel alloy parts, in any shape can be directly machined and manufactured, and the machining and manufacturing efficiency of the metal parts, especially the stainless steel alloy parts, in the complex shapes is greatly improved. Adopted metal powder is directly sprayed according to the shapes of the parts, and little powder is left, and can be recycled and reused.

Owner:CANGZHOU DWAYA LASER TECH CO LTD

Method for producing fragrant and fruity persimmon leaf tea

The invention belongs to the field of comprehensive utilization of horticultural products and relates to a method for producing fragrant and fruity persimmon leaf tea. The method comprises the following steps: 1) picking the fresh tender emerald green leaves of the persimmon tree without diseases and insect pests; 2) placing the fresh leaves into a tea kneading and cutting machine to be kneaded and cut, and repeating kneading and cutting twice to prepare the leaves into grains, thus obtaining the kneaded and cut leaves; 3) placing the kneaded and cut leaves with thickness of 15-20cm into a fermenting tray to be fermented under the conditions of temperature of 30-35 DEG C, relative humidity of 50-70% and stacking fermentation time of 12h to obtain fermented leaves; and 4) placing the fermented leaves into a dryer to be dried twice to obtain the finished persimmon leaf tea, wherein the first drying temperature is 100-120 DEG C and the water content of the persimmon leaves is 10-15%; and the second drying temperature is 80-90 DEG C and the water content of the persimmon leaves is 3-5%. The persimmon leaf tea is characterized in that the tea is strongly fragrant and fruity, the liquor is orange red or orange yellow, the taste is mellow sweet, etc. The persimmon leaf tea is suitable for mechanized production.

Owner:HUAZHONG AGRI UNIV

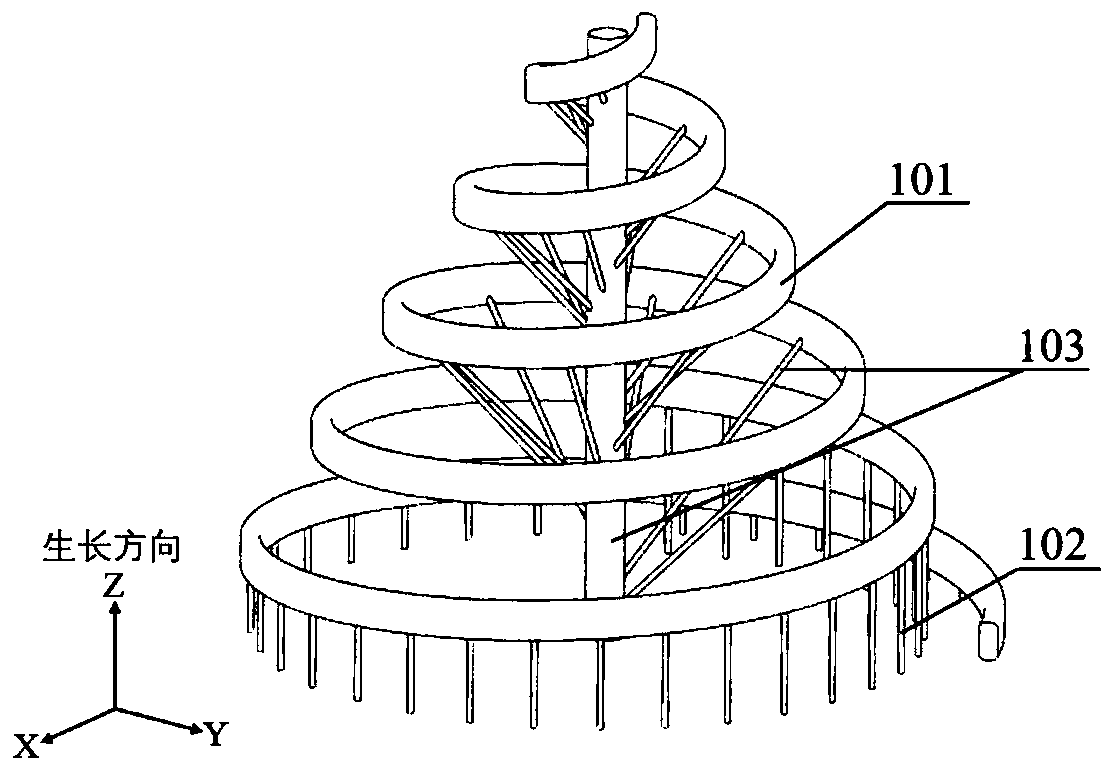

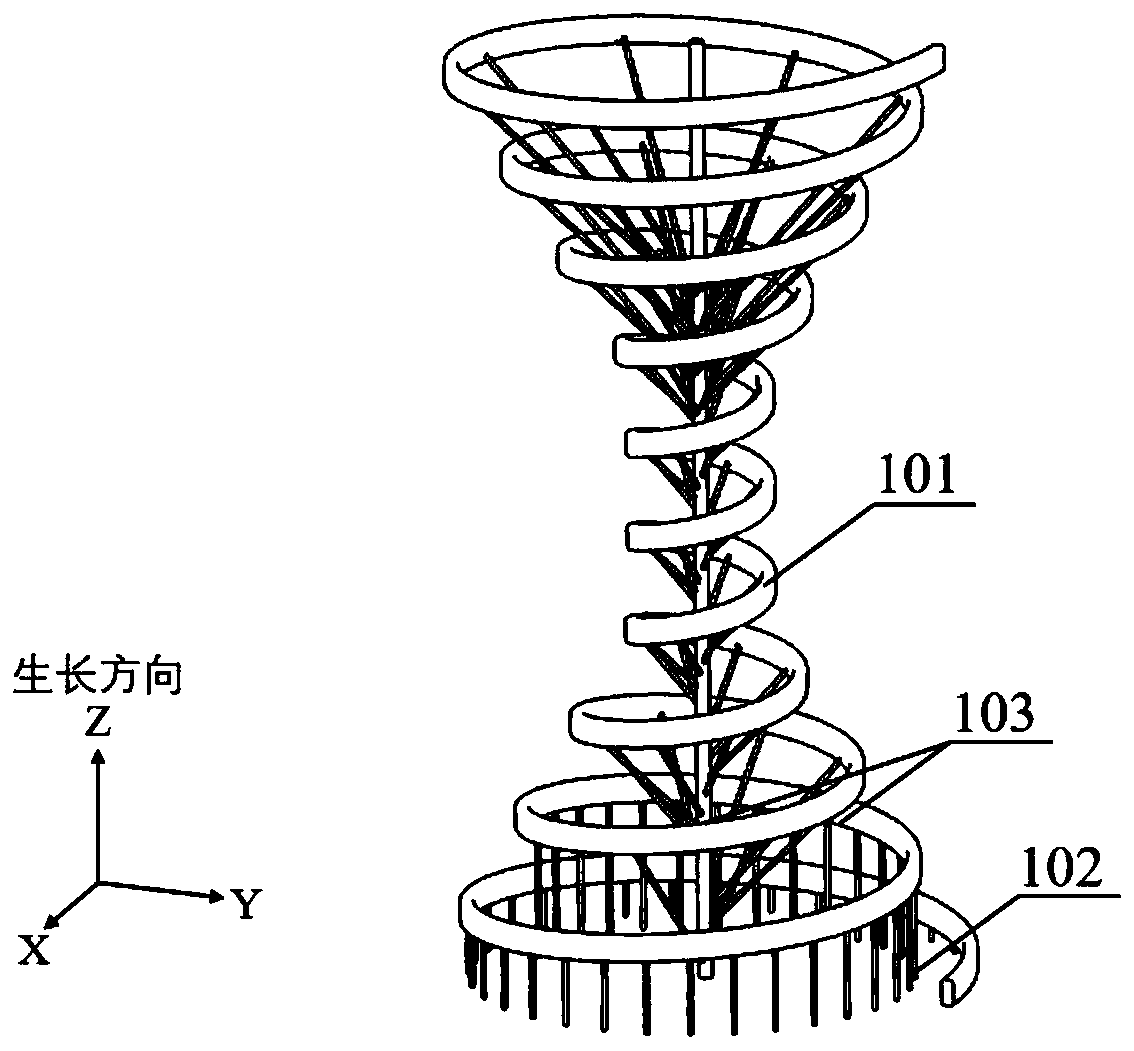

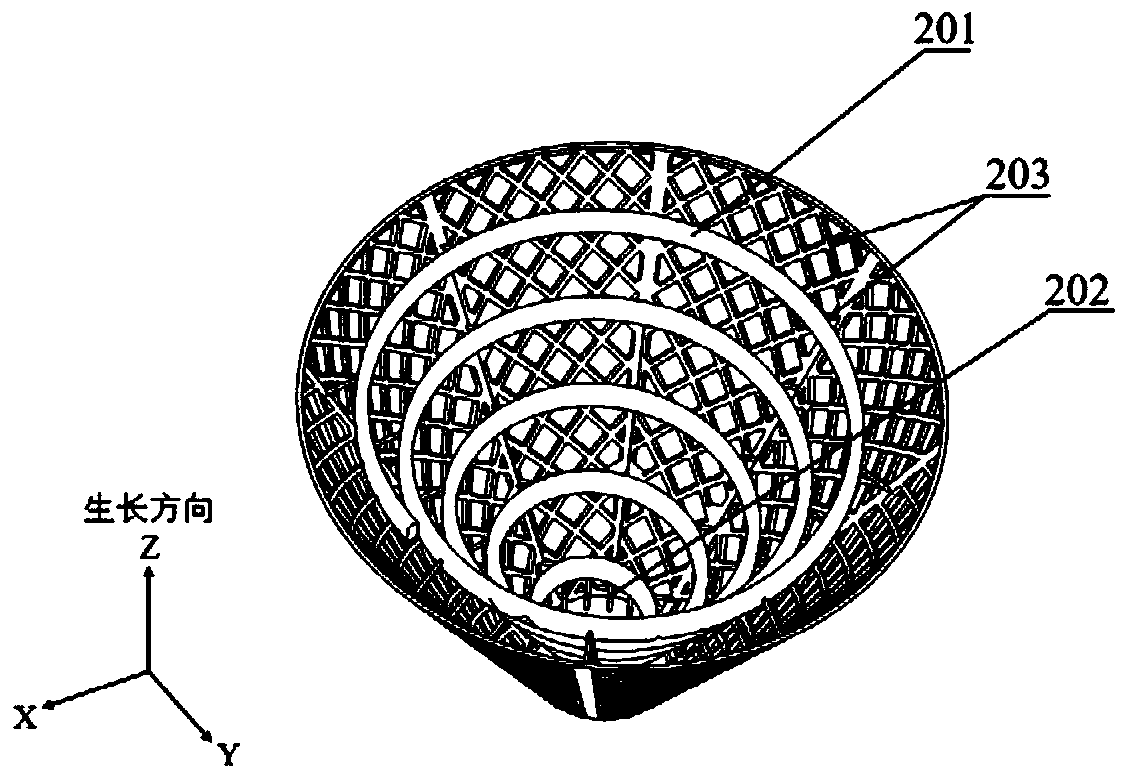

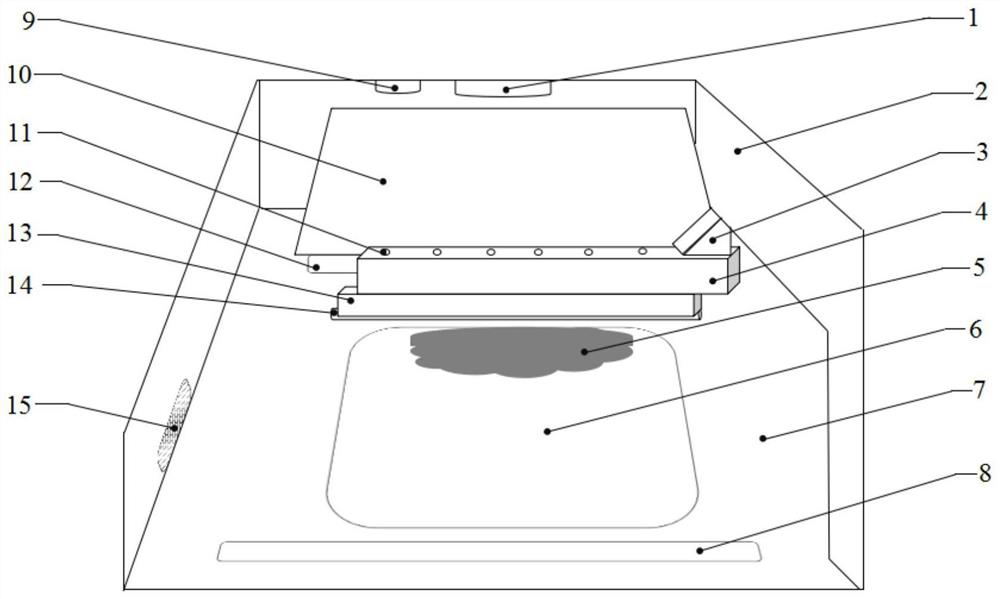

Material additive manufacturing device and method of high-degree-of-freedom complex structural part

ActiveCN109848410ANo stress deformationIncrease profitAdditive manufacturing apparatusIncreasing energy efficiencySpatial OrientationsThree-dimensional space

The invention belongs to the field of material additive manufacturing and provides a material additive manufacturing auxiliary method and device. The method comprises the steps of designing and optimizing the structure of a part to generate a corresponding three-dimensional entity model; establishing an appropriate three-dimensional special orientation supporting structure according to the part structure and shape of the part; machining raw material powder layer by layer to form a compact entity according to set machining parameters with the part and the three-dimensional spatial orientation supporting structure as objects to be machined and obtaining a combination composed of the three-dimensional spatial orientation supporting structure and the part; and removing the three-dimensional spatial orientation supporting structure on the combination to obtain the part. The invention further provides the three-dimensional spatial orientation supporting structure with the extensive applicability. Through the novel method and device provided for manufacturing the high-degree-of-freedom complex structural part at low cost, high efficiency and high quality, traditional material and processlimitation is broken through, and existing technical problems are solved.

Owner:HUAZHONG UNIV OF SCI & TECH

PEPSET resin moulding and sand cyclic utilization clean casting technology

ActiveCN103934411AFast and uniform curingLower regenerationFoundry mouldsMould handling/dressing devicesProcess engineeringRaw material

The invention relates to a PEPSET resin moulding and sand cyclic utilization clean casting technology. The technology comprises the following steps: using raw materials to carry out PEPSET resin sand moulding: putting a sand core into a mould cavity, closing the mould cavity by using an automatic mould closer, then casting with molten iron; shaking out the sands after the moulding of product; transferring the old sands into a waste sand regeneration processing system; wherein the regenerated sands can be applied to a cold box core blower to manufacture sand cores, thus the addition amount of new sands is reduced, and the cyclic utilization of old sands is achieved.

Owner:LAIZHOU XINZHONGYAO MACHINERY

Preparation method for nanometer tourmalinite powder

ActiveCN107096610ARegulate blood circulationShorten grinding timeGrain treatmentsFreeze-dryingSlurry

The invention relates to a preparation method for nanometer tourmalinite powder. The preparation method comprises the following steps: (1) wet-process high-speed coarse grinding: with micron-order tourmalinite powder as a raw material, adding micron-order tourmalinite powder and water into a ball milling tank for coarse grinding so as to obtain coarsely-ground tourmalinite slurry, wherein a coarse grinding medium is zirconia grinding beads with particle sizes of 1 to 5 mm; (2) wet-process high-speed fine grinding: separating the coarsely-ground tourmalinite slurry prepared in the step (1) from the coarse grinding medium, the mixing the coarsely-ground tourmalinite slurry with a fine grinding medium, adding water for dilution and carrying out fine grinding in a ball milling tank so as to obtain nanometer tourmalinite slurry, wherein the fine grinding medium is zirconia grinding beads with particle sizes of 0.1 to 0.5 mm; and (3) freeze drying: adding the nanometer tourmalinite slurry obtained in the step (2) into a container, putting the container in a freezing dryer and carrying out drying under the conditions of a vacuum degree of 5 to 50 Pa and a temperature of -60 to -80 DEG C so as to obtain the nanometer tourmalinite powder.

Owner:HEBEI UNIV OF TECH

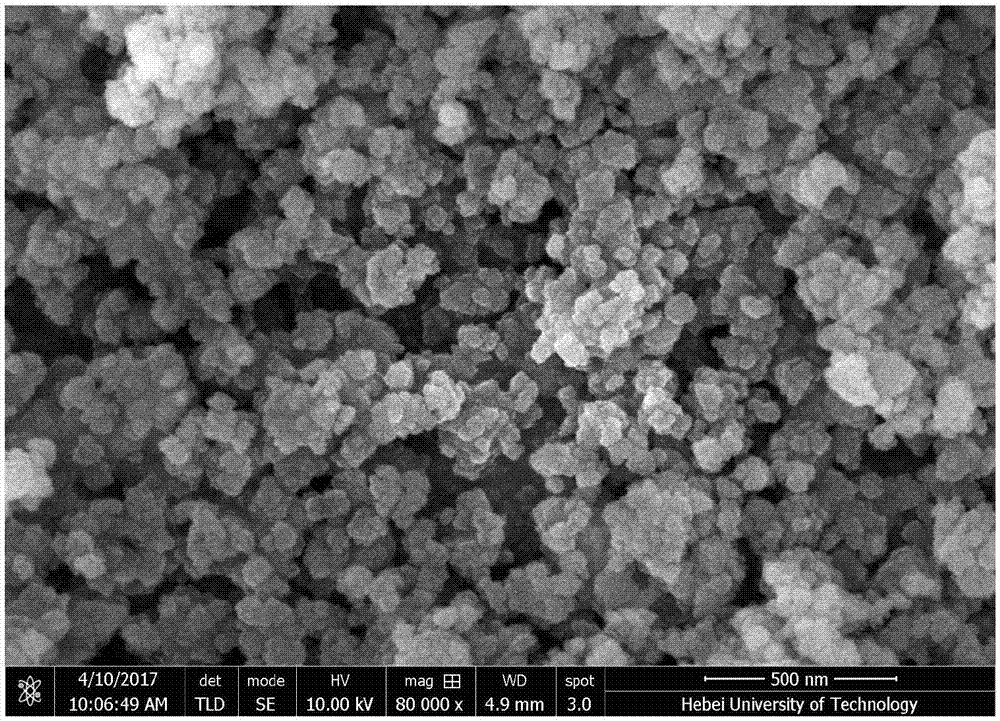

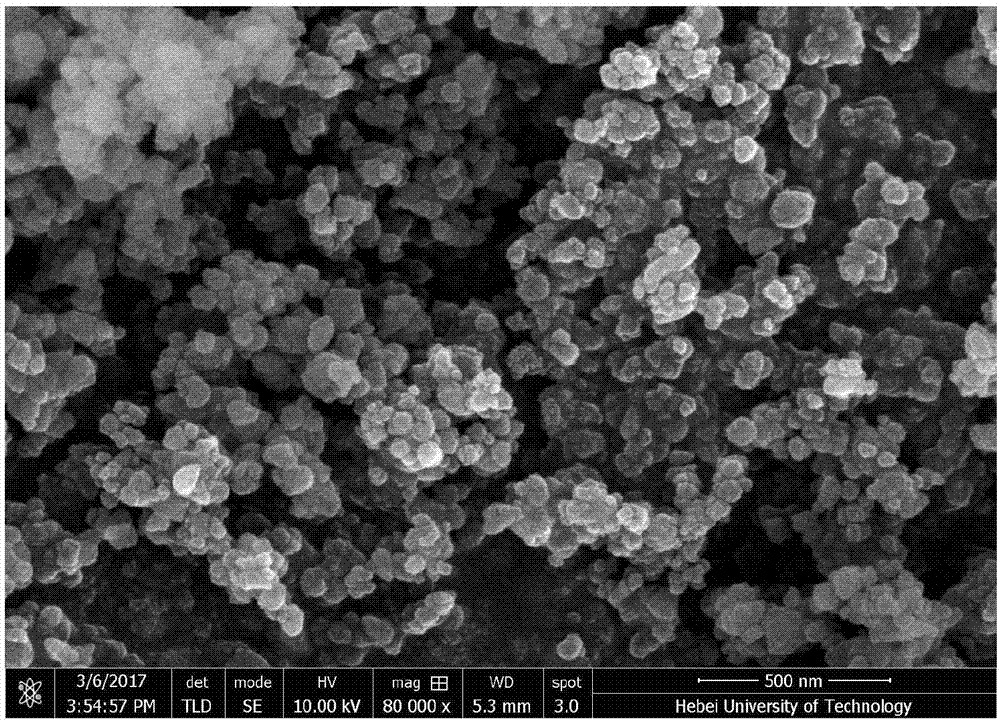

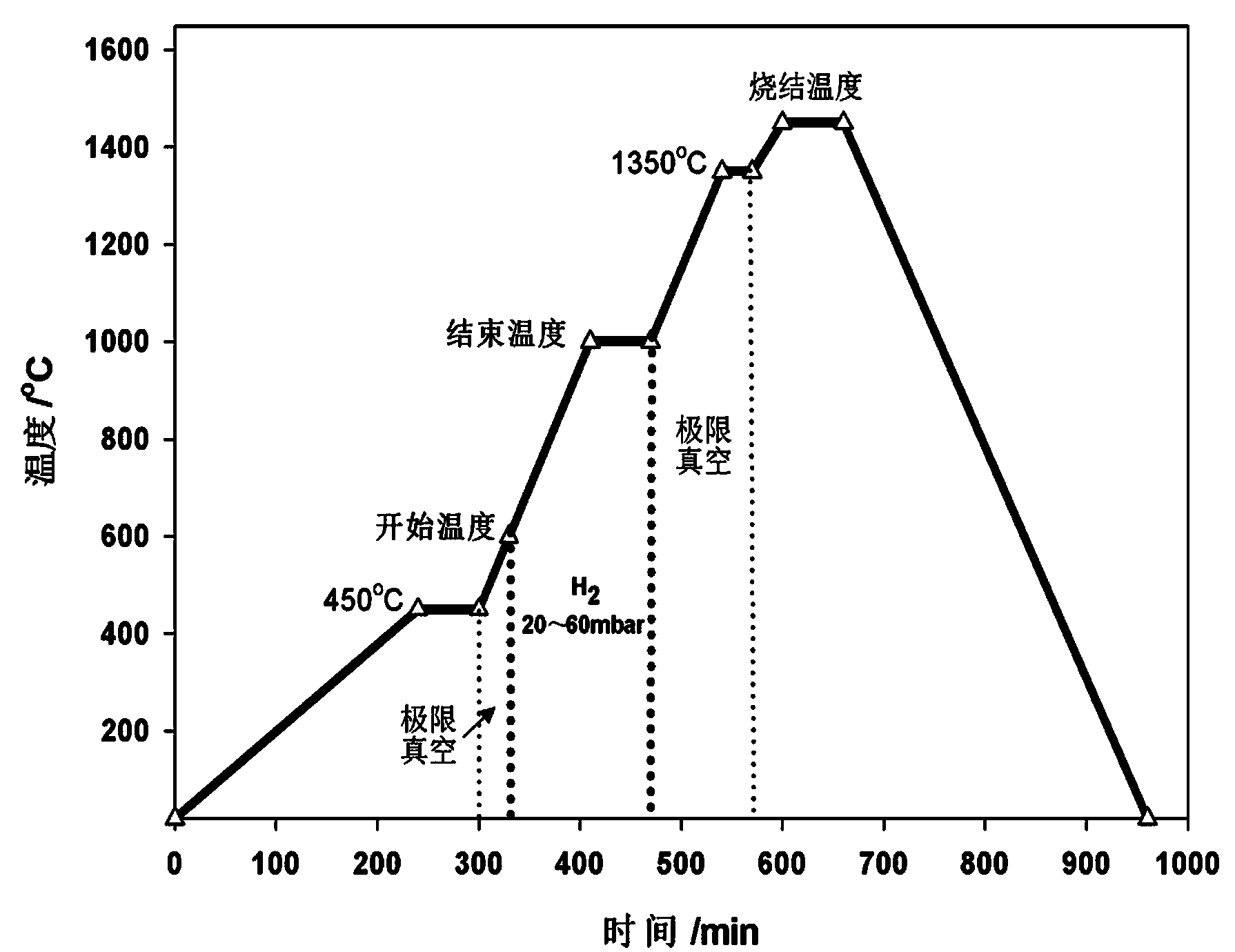

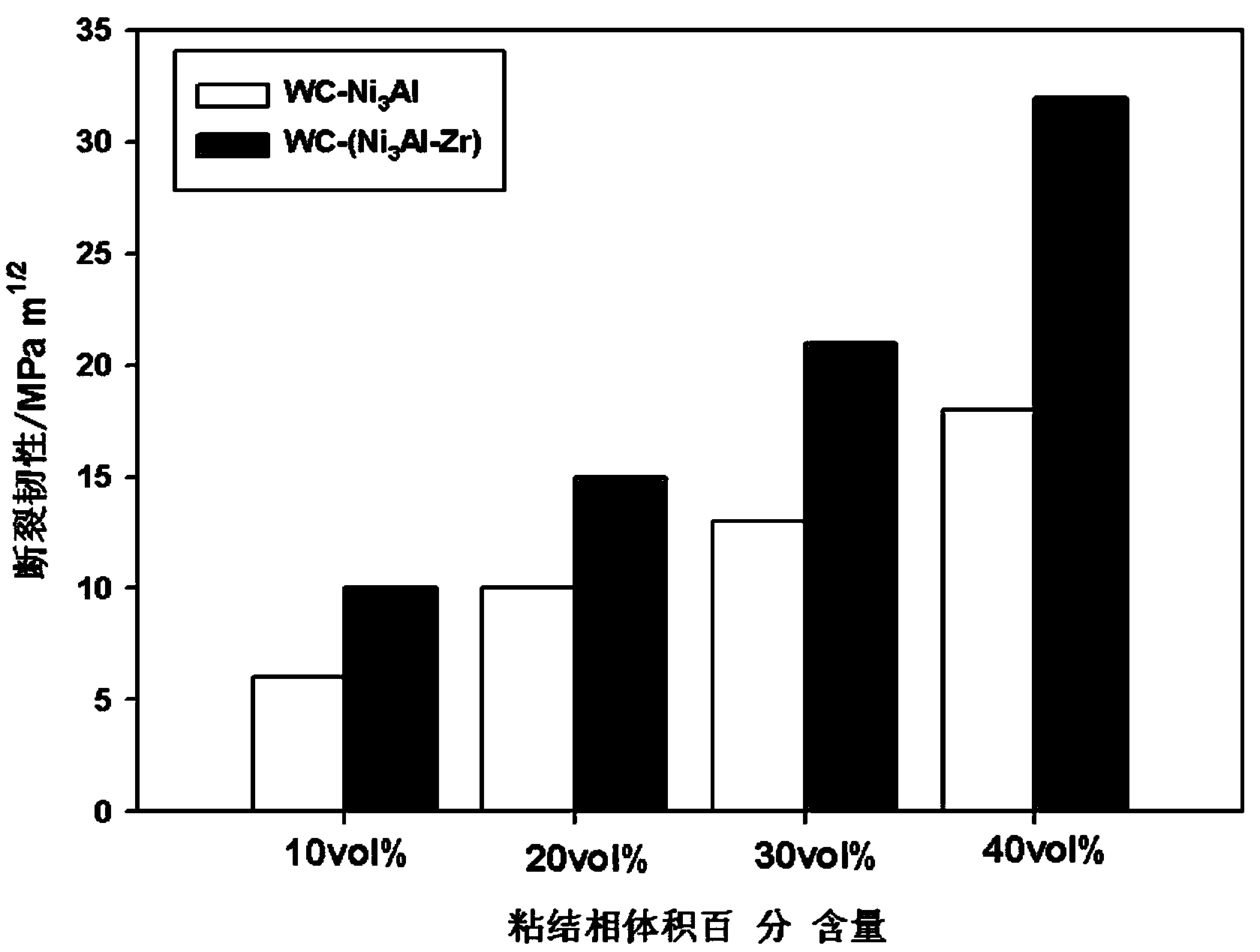

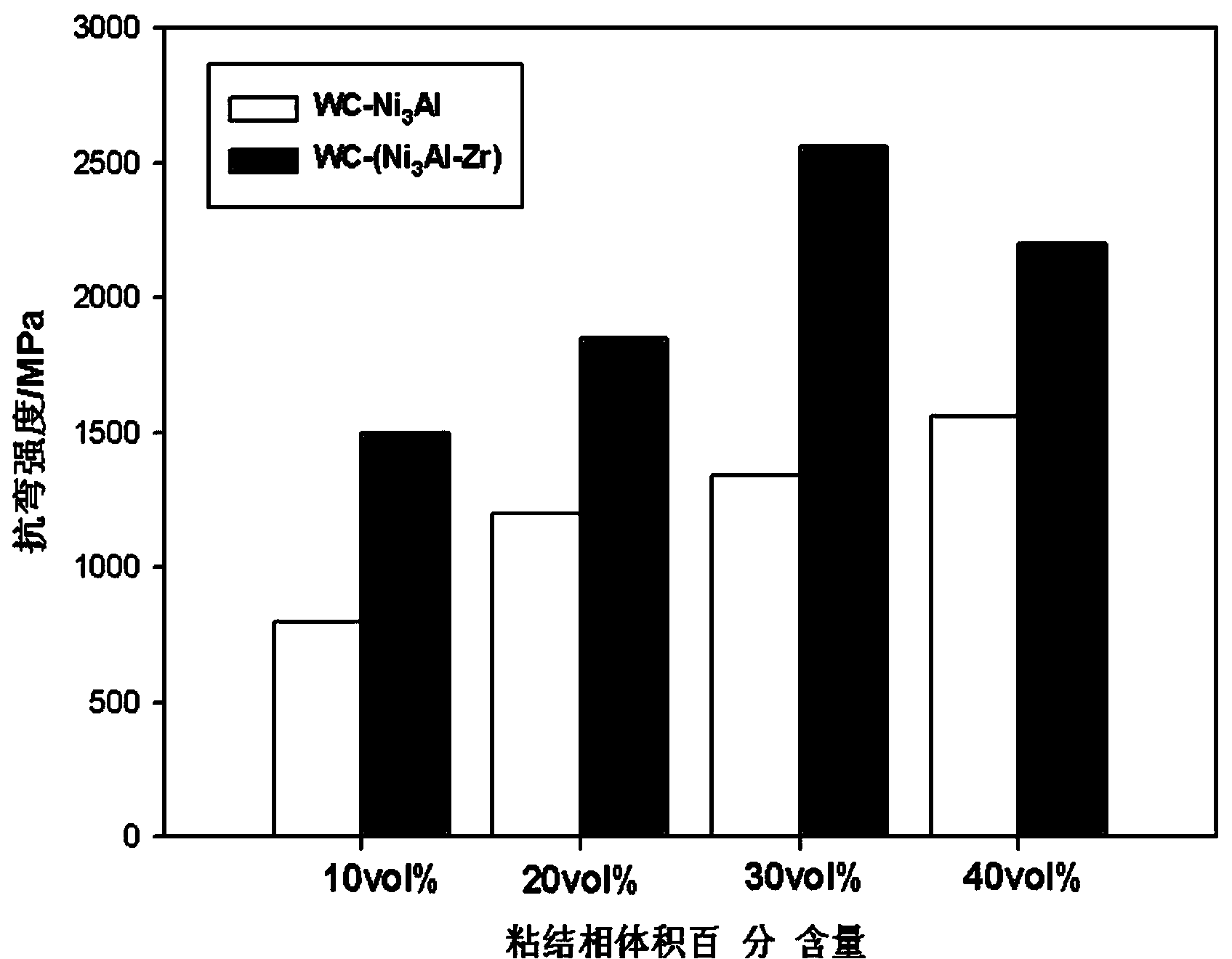

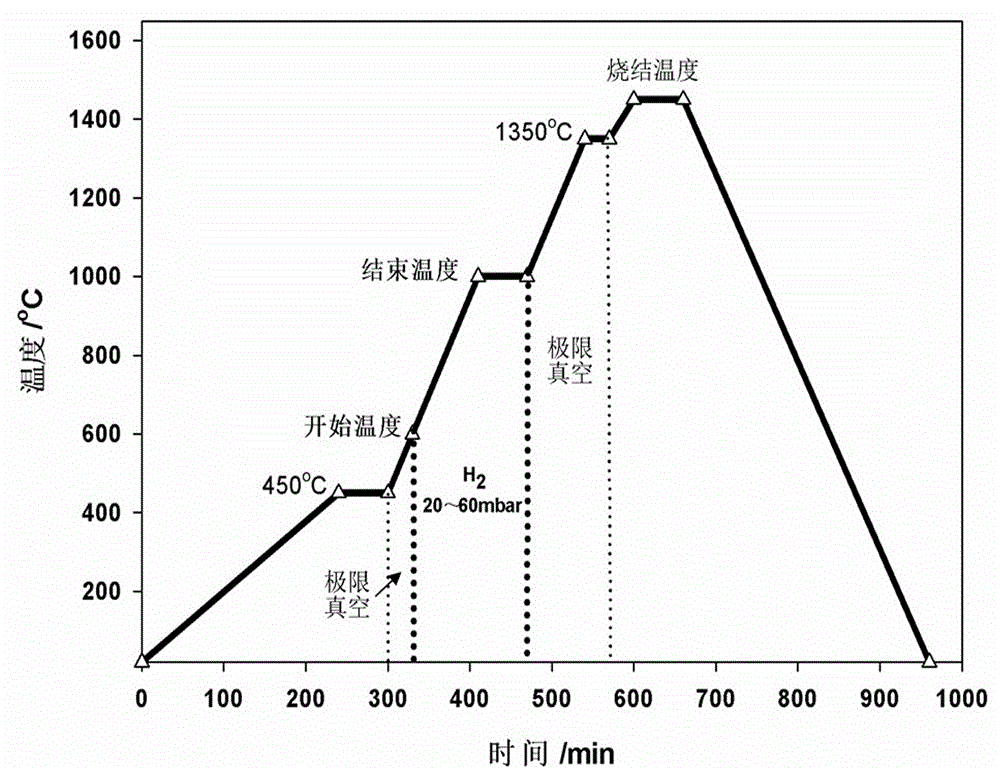

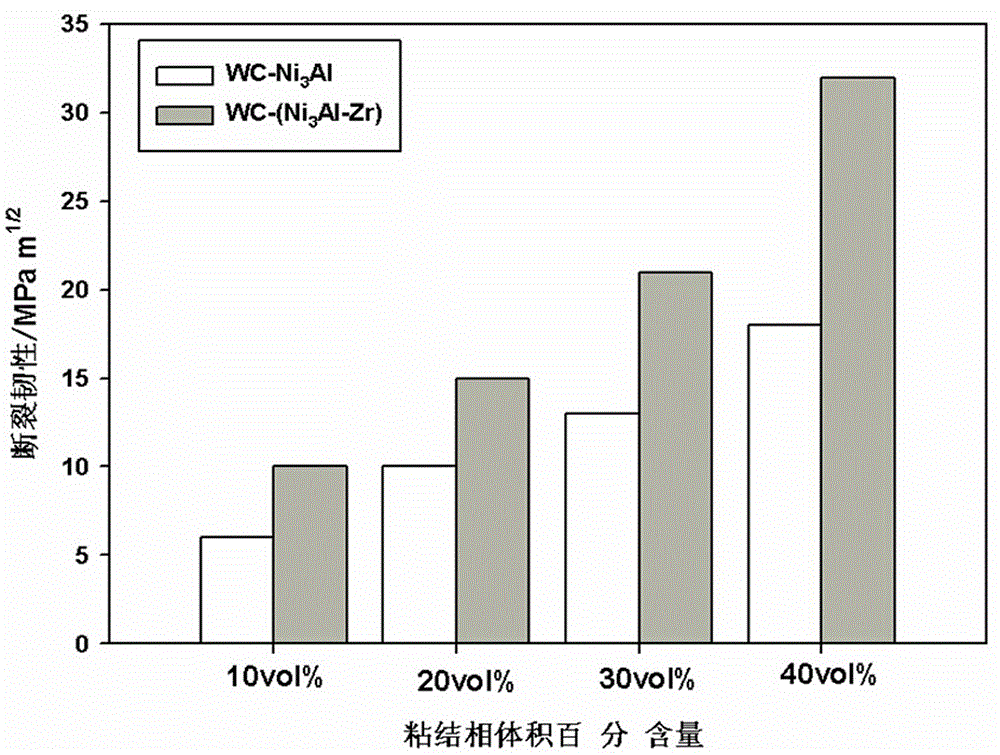

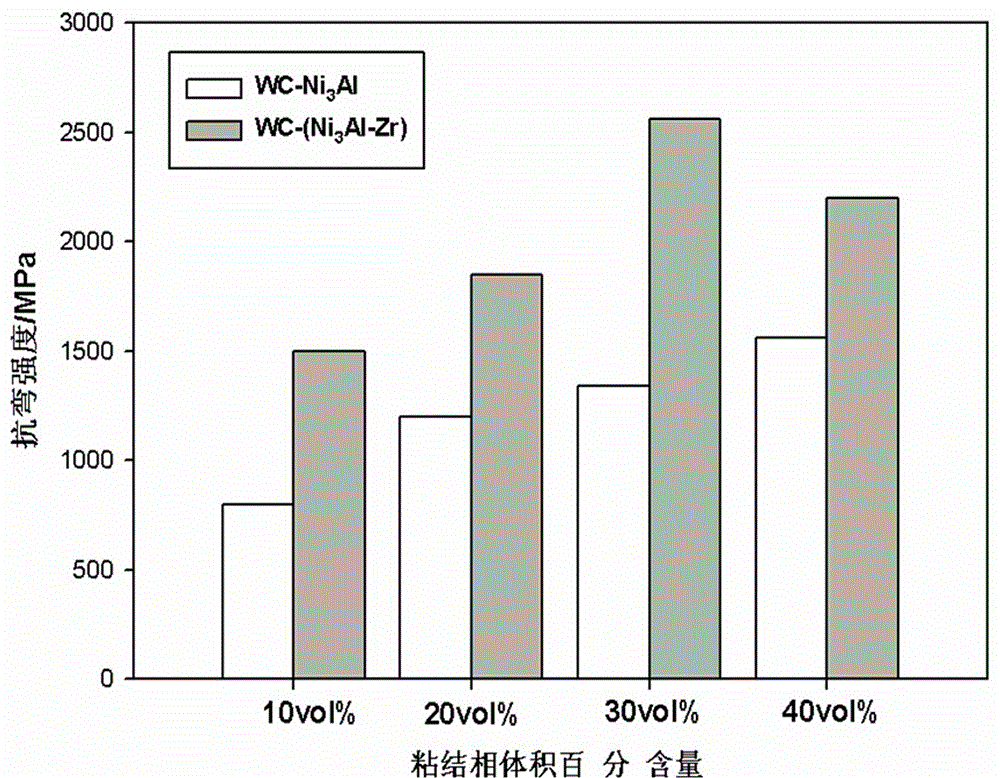

Zr element-toughened WC-Ni3Al hard alloy and preparation method thereof

The invention discloses a Zr element-toughened WC-Ni3Al hard alloy and a preparation method thereof. A hard phase is WC, and a binding phase is 10-40% of Ni3Al-Zr by volume. The preparation method comprises the following steps: performing pre-wet grinding on 0.005-0.246% of ZrH2 powder by mass for 1-2 hours, then adding the remaining WC and Ni3Al pre-alloyed powder, and performing wet grinding together to obtain a wet-grinding mixture; performing spray drying and compression moulding to obtain a compact; heating from normal temperature to 450 DEG C according to a conventional sintering curve, preserving heat for 1-2 hours, and exhausting to ultimate vacuum below 4*10<-3>Pa; introducing low-pressure hydrogen at 20-60mbar at a temperature of 450-1,200 DEG C, and heating at a speed of less than or equal to 5 DEG C per minute; after heating to the end temperature, vacuumizing again to below 4*10<-3>Pa, and preserving heat for 1-2 hours to finish the low-pressure hydrogen treatment on the compact; and heating to a sintering temperature of 1,350-1,550 DEG C according to the conventional sintering curve, and performing low-pressure liquid-phase sintering to obtain the Zr-toughened WC-Ni3Al hard alloy, wherein the toughness and bending resistance of the alloy are excellent, and the technology is simple and convenient.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

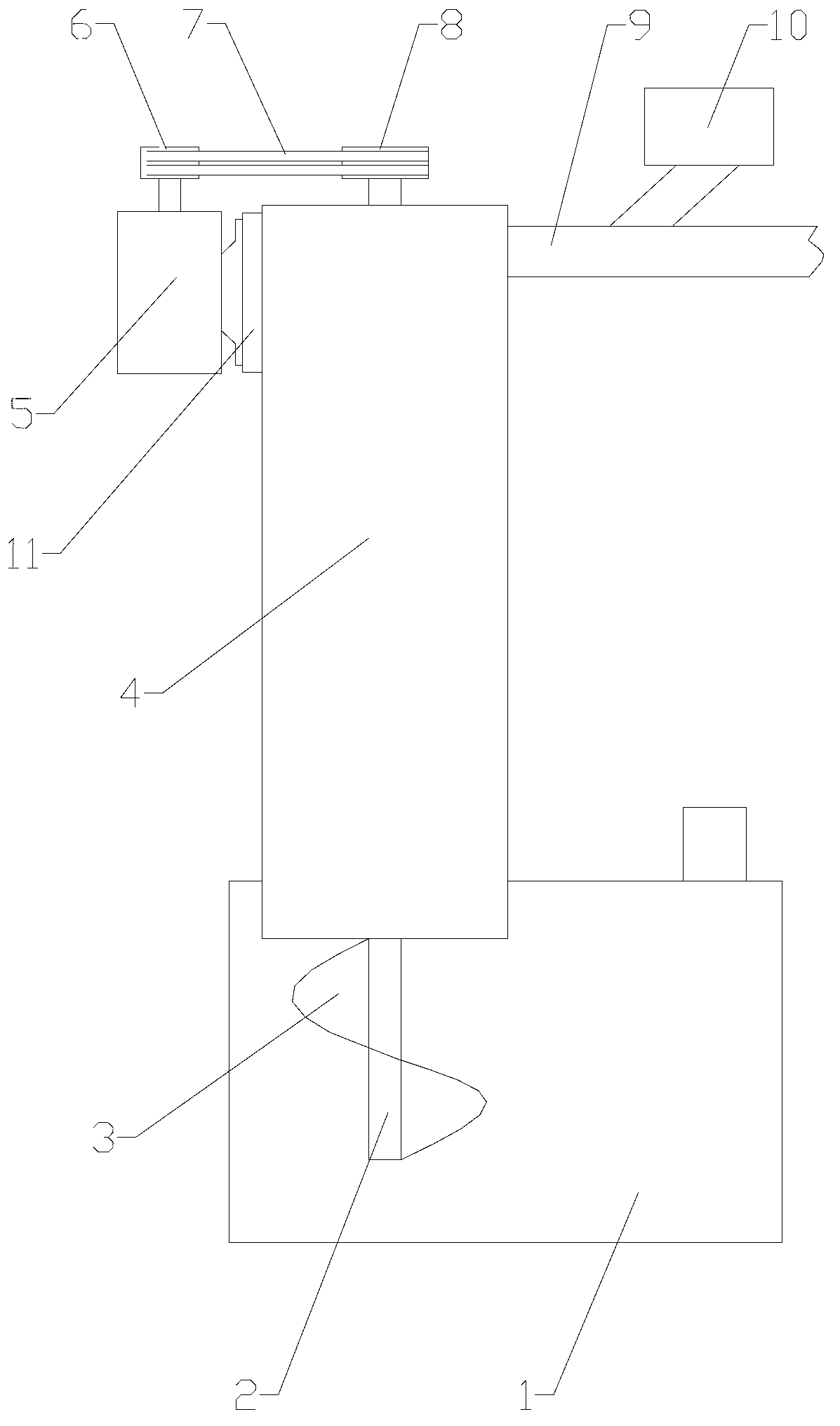

Feeding device

The invention discloses a feeding device. The feeding device comprises a material storage tank, wherein the material storage tank is connected with a conveying device; the conveying device comprises a feeding tube; a rotating shaft is arranged in the feeding tube; a spiral blade is arranged on the rotating shaft; a discharging tube is arranged on the feeding tube; and the discharging tube is connected with an induced draft fan. The discharging tube is arranged on the feeding tube, and the discharging tube is connected with the induced draft fan, so that a material is conveyed by performing air draft by the induced draft fan; the moisture of the material can be reduced effectively; dust is reduced; the radiating effect is good; blockage is not caused easily; the production efficiency is greatly improved; and the production cost is reduced. The feeding device is small in structure; the product quality can be improved effectively; and the effective control over the cost is realized.

Owner:JIANGSU BOILN PLASTICS CO LTD

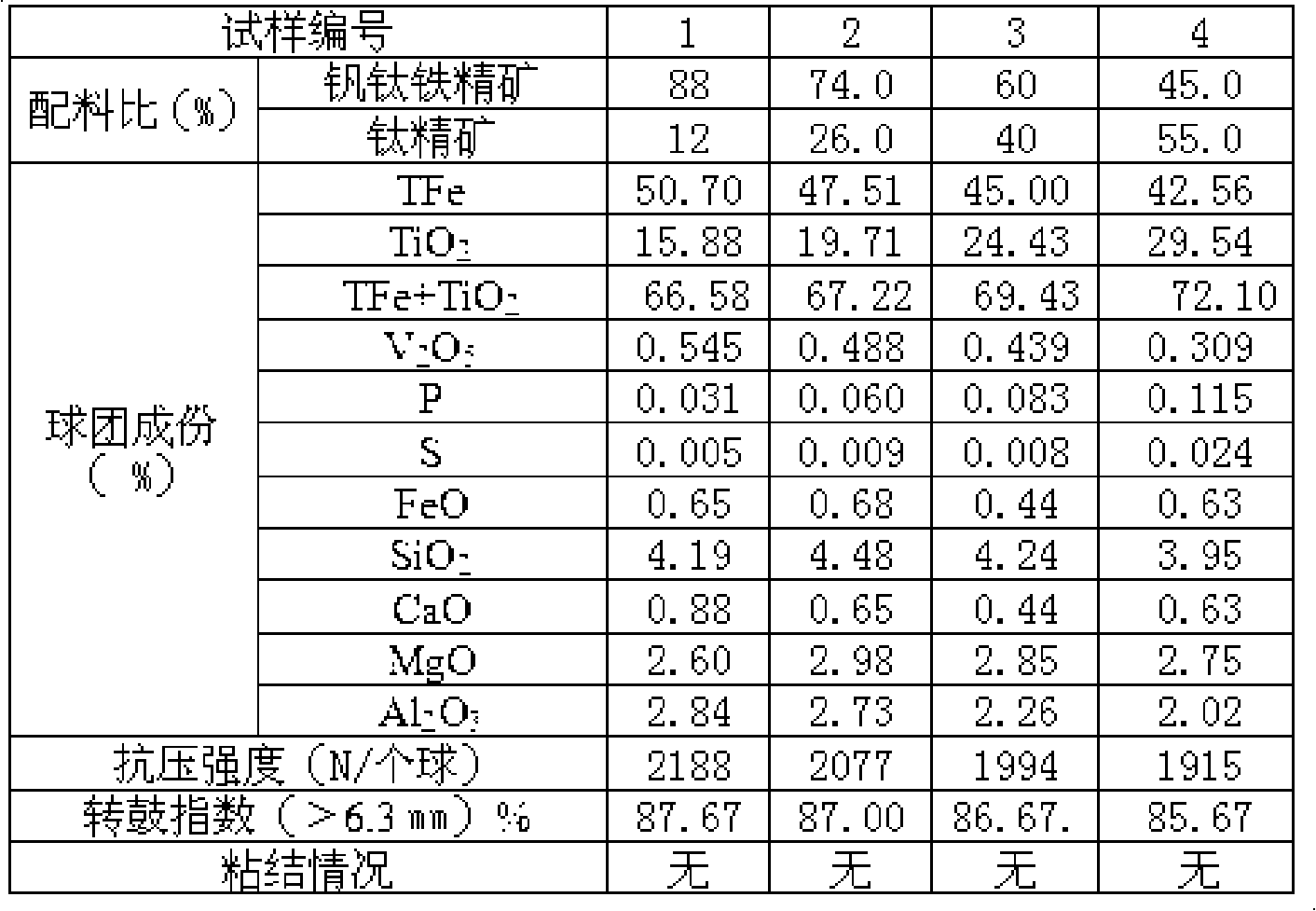

Titanium-rich pellet and production method thereof

The invention belongs to the field of steel and iron smelting, and in particular relates to a titanium-rich pellet and a production method thereof. The titanium-rich pellet contains 10-15% of TiO2 and 40-55% of TFe. Furthermore, the invention provides a production method of the titanium-rich pellet, and the production method comprises the steps of preparing materials, pelletizing, drying, pre-heating, baking and cooling to obtain a finished product. The titanium-rich pellet prepared by the method disclosed by the invention not only can serve as a raw material when making steel in a blast furnace, but also can protect furnace bottom of the blast furnace used for making steel, and the titanium-rich pellet is good in effect.

Owner:攀枝花钢企米易白马球团有限公司

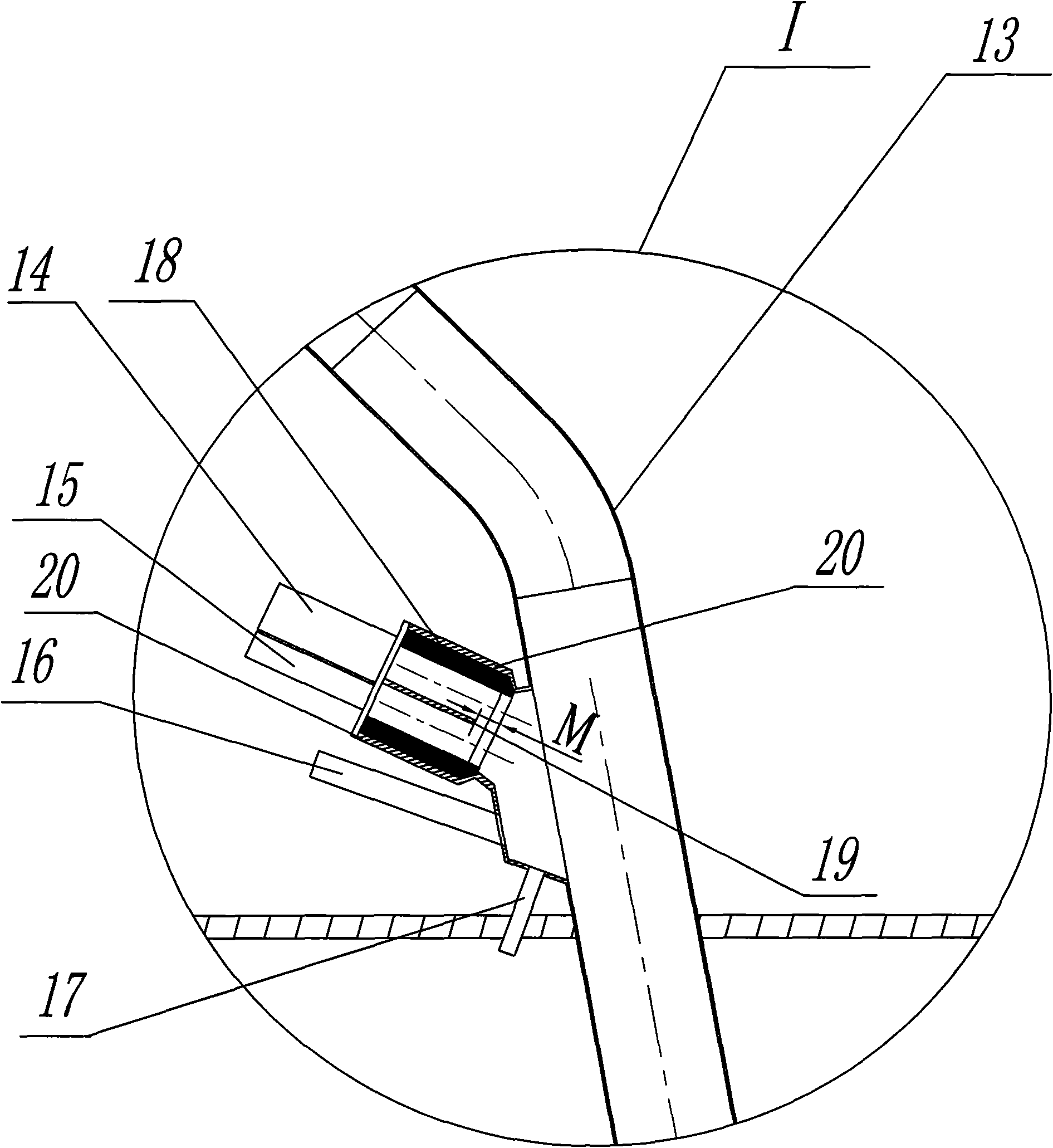

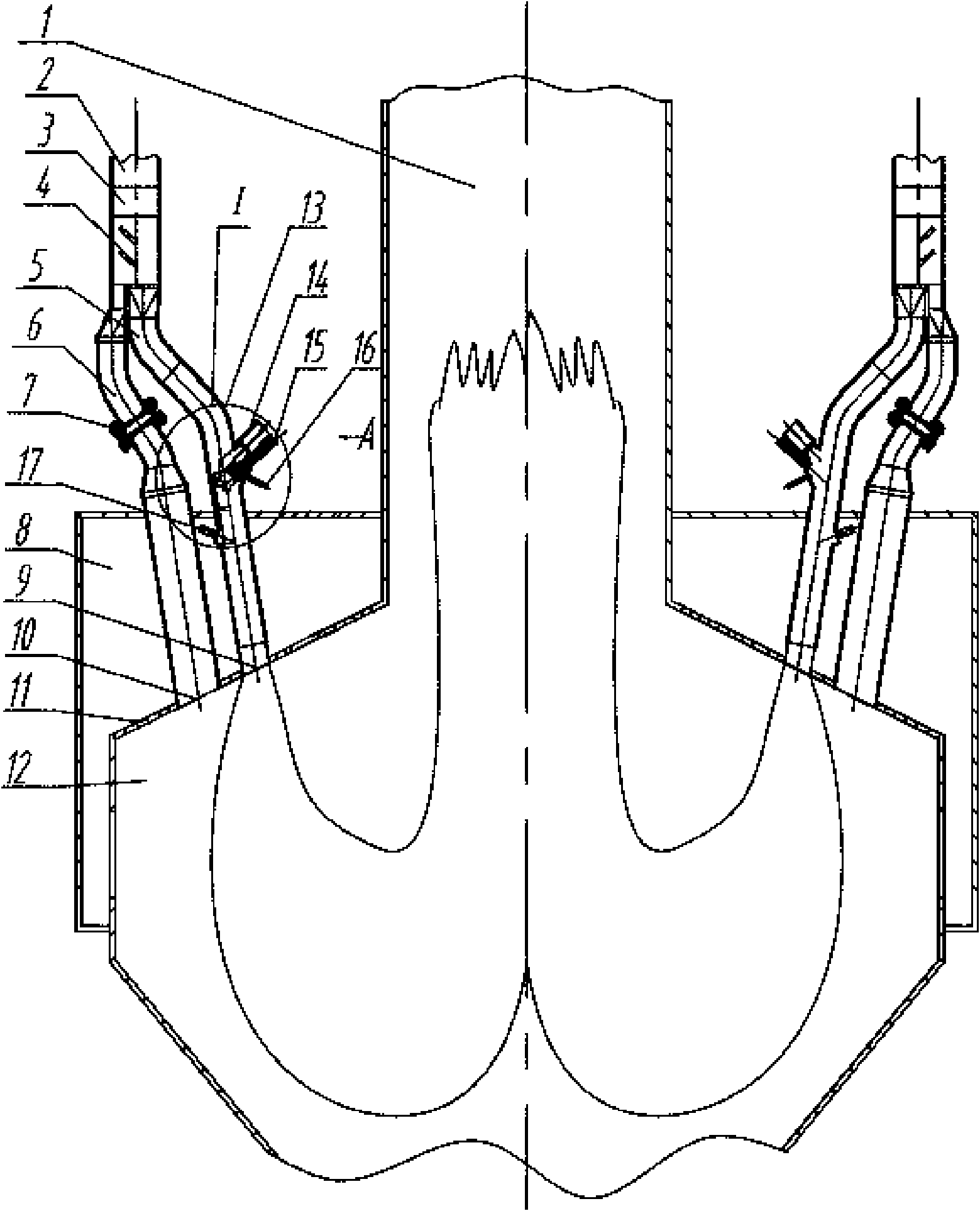

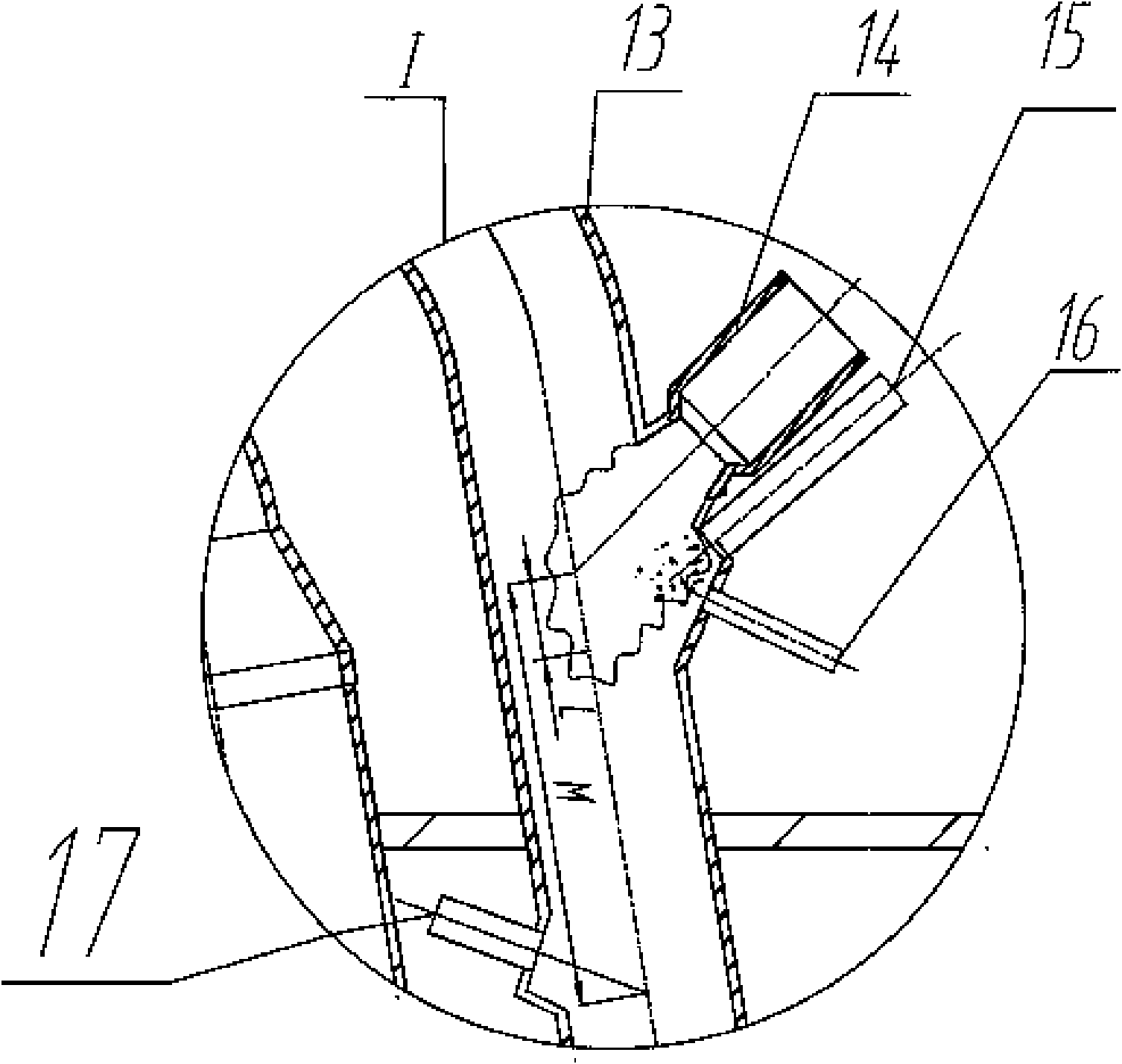

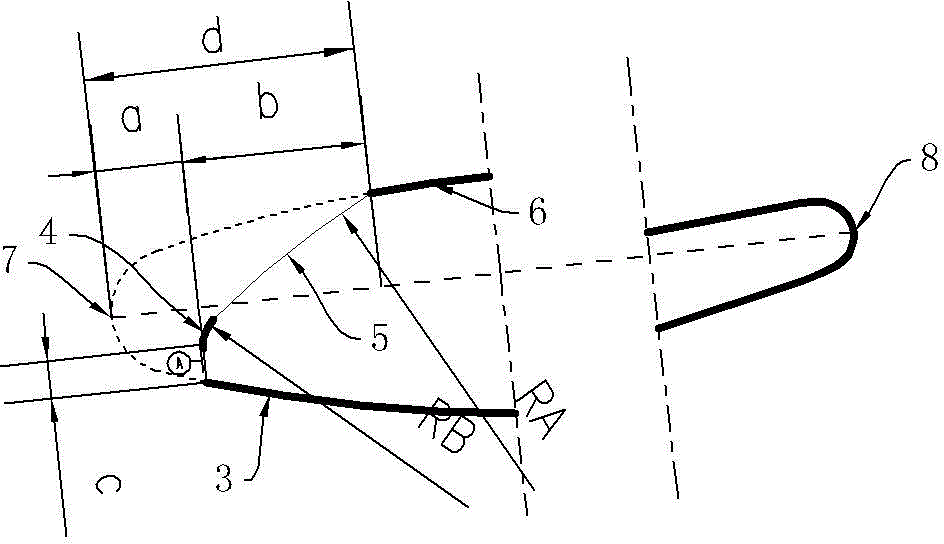

Micro oil content ignition coal powder burner capable of improving initial ignition heat

ActiveCN101806452AReduce outputNot easy to ignitePulverulent fuel combustion burnersCoalPetroleum engineering

The invention provides a micro oil content ignition coal powder burner capable of improving initial ignition heat, which relates to a burner. The invention solves the problems of difficult ignition of coal powder and unstable burning of the existing burner. The invention has the technical scheme that the micro oil content ignition coal powder burner capable of improving the initial ignition heat of the invention comprises a No.1 main oil gun, a No.2 main oil gun, an oil gun installing branch pipe and a heat insulation burning sleeve barrel, wherein the heat insulation burning sleeve barrel is arranged in the inlet end of the oil gun installing branch pipe, the No.1 main oil gun and the No.2 main oil gun are arranged in the inlet end of the oil gun installing branch pipe from top to bottom, and both of the No.1 main oil gun and the No.2 main oil gun are communicated with an inner cavity of the heat insulation burning sleeve barrel. The invention is mainly applied to W flame boilers, the burnt and used coal types belong to lean coal and blind coal with the characteristics of low volatilization constituent content, high ignition temperature and difficult ignition.

Owner:HARBIN INST OF TECH

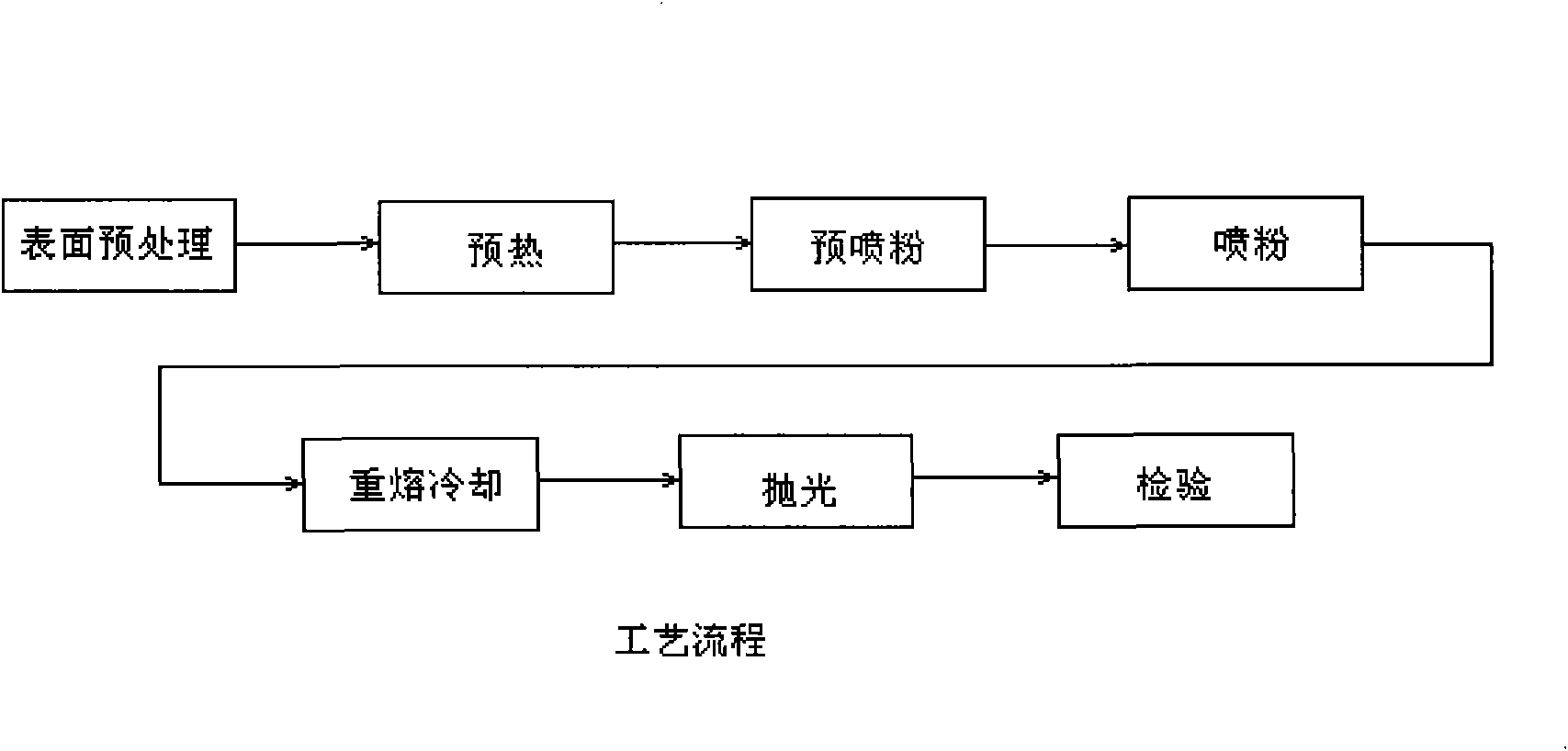

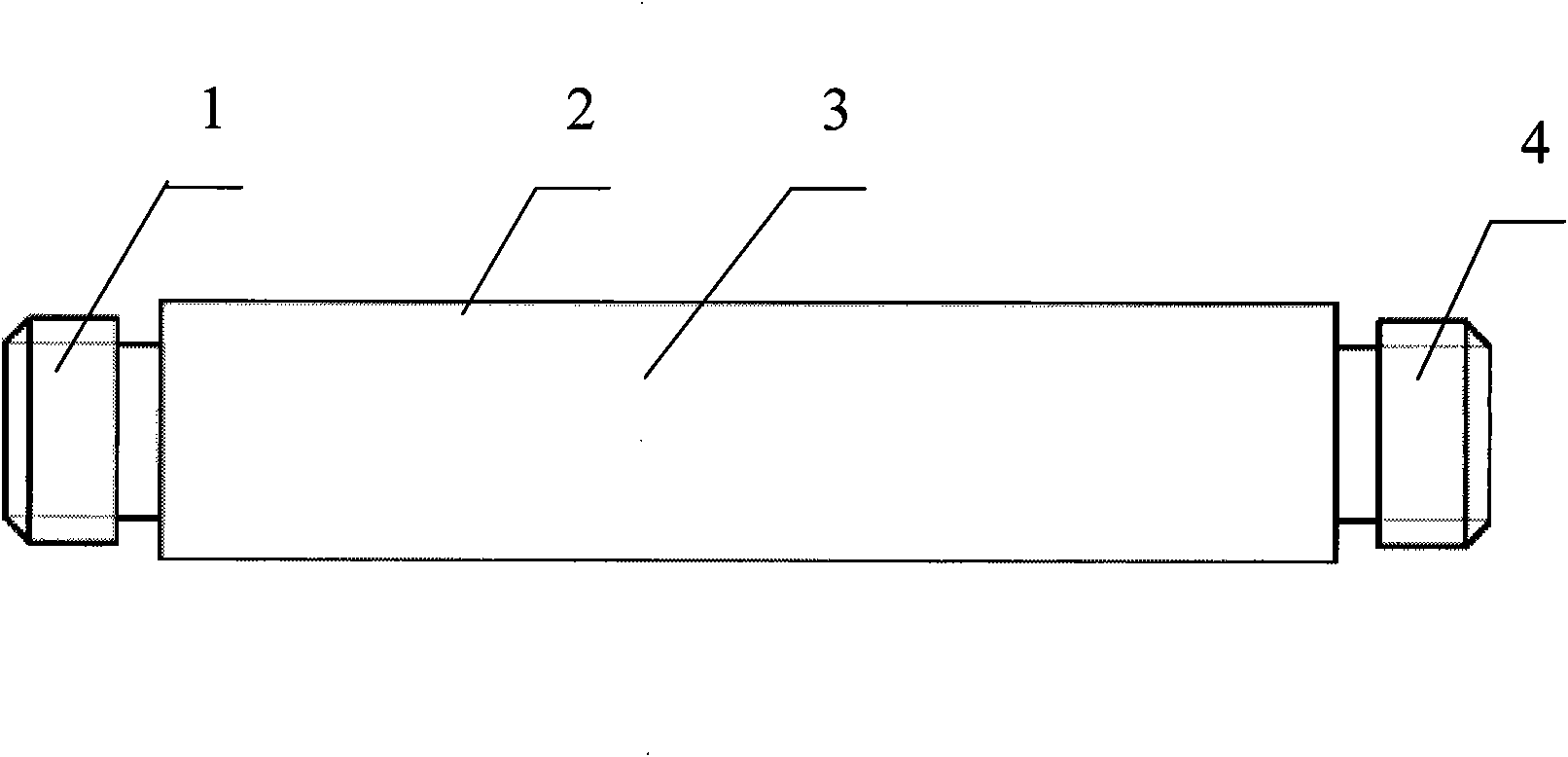

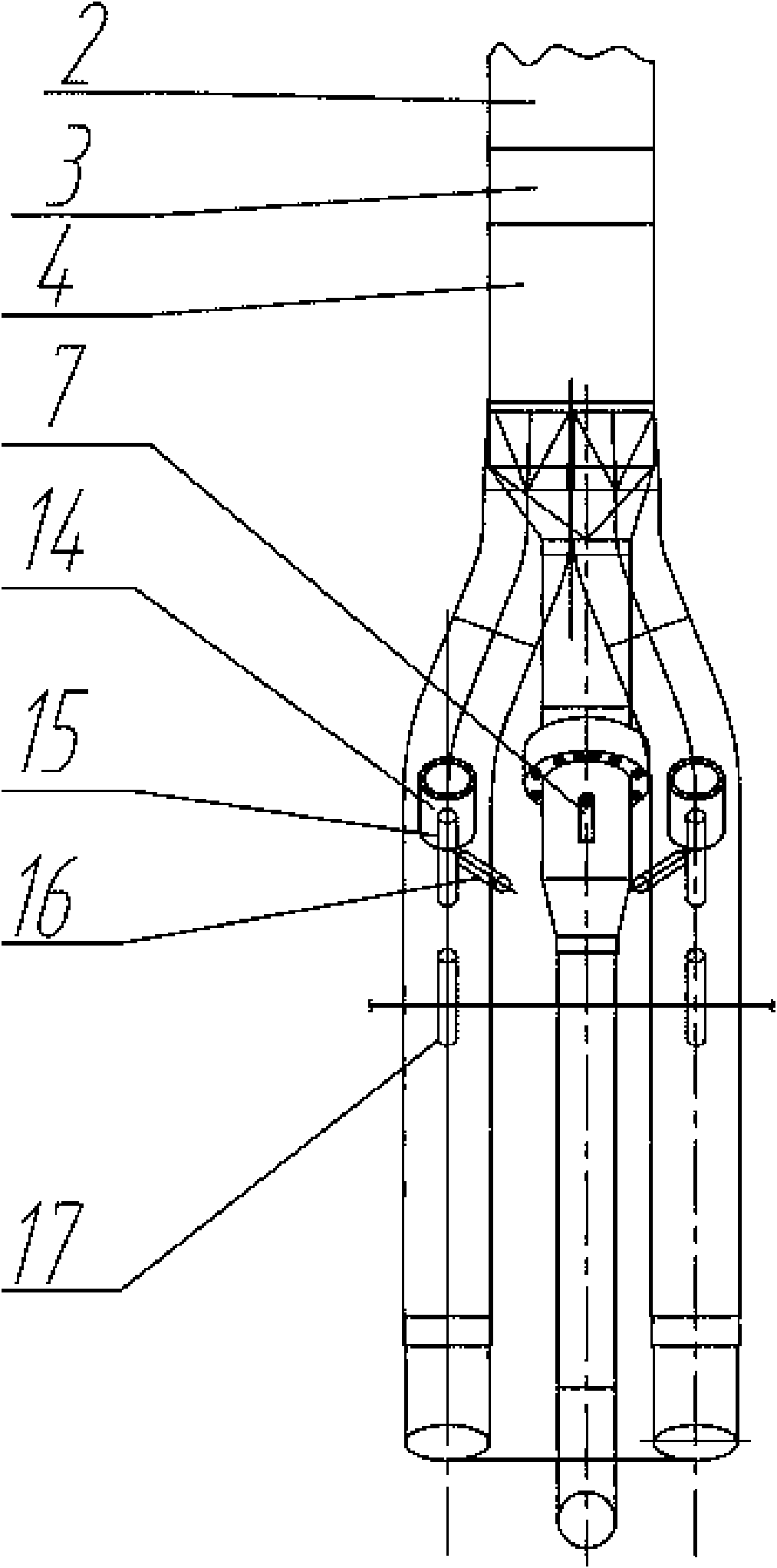

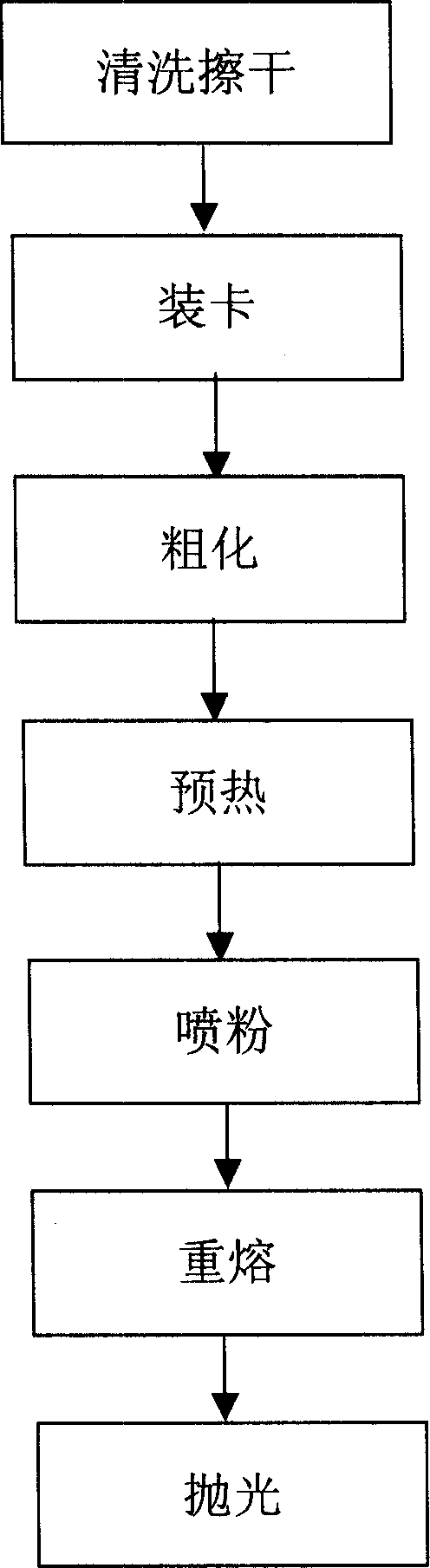

Bidirectional protecting oil pump plunger and hot spray processing technique for alloy coating of same

InactiveCN101586558ALess powderTightly boundMolten spray coatingPositive displacement pump componentsWear resistantAlloy coating

The invention relates to a bidirectional protecting oil pump plunger and a hot spray processing technique for an alloy coating of the same. The protecting oil pump plunger comprises a long cylinder, wherein two ends of the cylinder are provided with external threads and are connected with a valve cover; and the surface of the plunger is sprayed with a corrosion-resistant and wear-resistant AOC alloy coating; the thickness of the alloy coating is more than 0.25mm; the alloy coating comprises the following components: 14 to 17 percent of chromium, less than 8 percent of iron, 3.5 to 5 percent of silicon, 2.8 to 3.8 percent of boron, 0.5 to 1 percent of carbon and 65.2 to 78.9 percent of nickel; and after the working procedures of surface roughening activating treatment, spraying, remelting and polishing, a wear-resistant and corrosion-resistant coating is formed on the surface of the plunger. The process has simple and convenient operation; the coating is combined closely after spraying; the performance of a basal body of the plunger is not influenced during spraying; and the thickness of the coating is more than 0.25 mm, and the coating can resist outside wearing and corrosion, and reduce the wearing to the inner surface of a pump cylinder of an oil well pump.

Owner:ANTON OILFIELD SERVICES (GRP) LTD

Spraying system for spraying room workpiece height automatic identification

The invention discloses a spraying system for spraying room workpiece height automatic identification. The spraying system comprises a conveying device, a first encoder, a measuring grating, a reciprocating machine, a limiting mechanism and a main control module; the main control module is electrically connected with the first encoder, the measuring grating, the reciprocating machine and a spraying gun for receiving conveying speed information detected by the first encoder, workpiece height information detected by the measuring grating and height information of the spraying gun detected by thereciprocating machine and controlling if the spraying gun performs the spraying operation according to the same; when some workpieces reach the position of the spraying gun, the heights of the workpieces are compared with the height of the spraying gun; when the heights of the workpieces are in a maximum operation range of the spraying gun, the spraying gun is started to spray powder; and when the heights of the workpieces are beyond the maximum operation range of the spraying gun, the spraying gun dose not work without spraying the powder, so that the powder is saved, the rework rate can bereduced, the workpiece scrap rate is reduced, and the production cost is reduced.

Owner:ZHONGSHAN JUNHE ELECTRO MECHANICAL APP

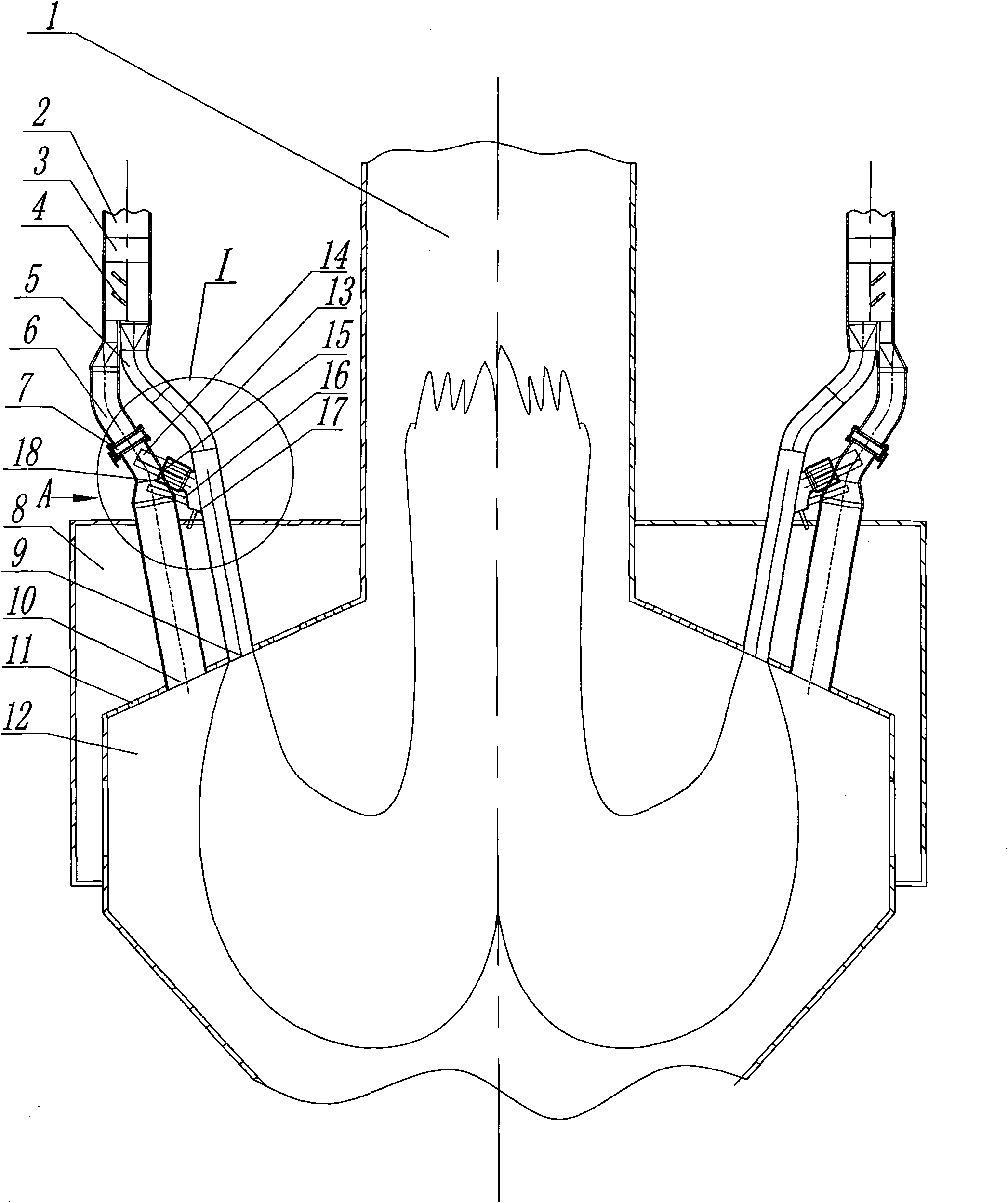

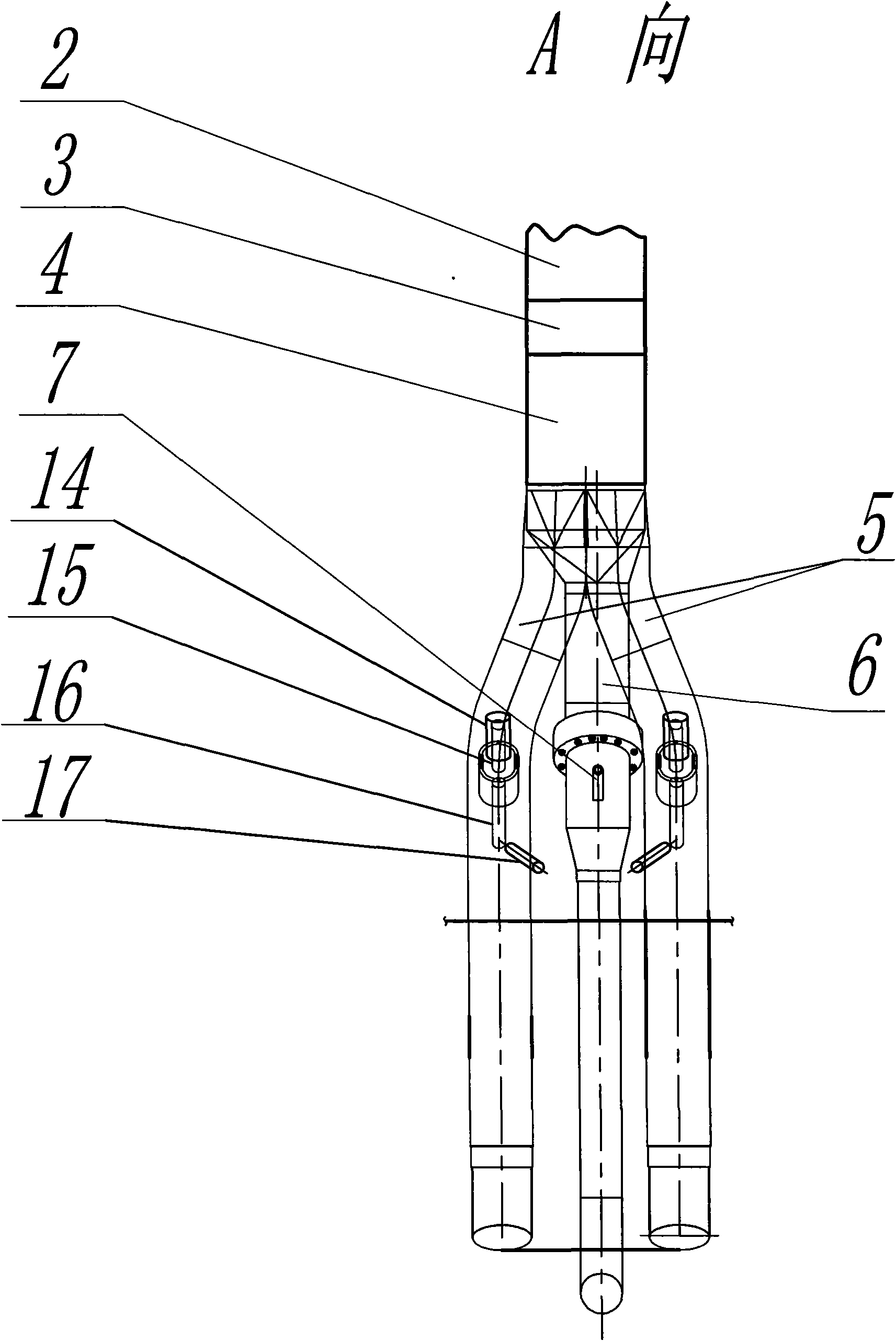

Trace oil igniting coal dust firing device for multiple oil guns

InactiveCN101603684AEasy to igniteNot easy to ignitePilot flame ignitersPulverulent fuel combustion burnersCoal dustHigh heat

The invention provides a trace oil igniting coal dust firing device for multiple oil guns, relates to a firing device, and solves the problem of easily failed ignition due to the fact that distance between a main oil gun and an auxiliary oil gun on the same side is large, and the main oil gun and an auxiliary oil gun on the opposite side are not alternately arranged in the prior firing device. The main oil gun and the auxiliary oil gun on the opposite side are alternately and oppositely arranged on side walls of a concentrated coal dust pipeline; distances of crossing points among the central line of the main oil gun, the central line of the auxiliary oil gun on the same side and the central line of the concentrated coal dust pipeline are between 80 and 100mm; and distances of the crossing points of the central line of the main oil gun, the central line of the auxiliary oil gun on the opposite side and the central line of the concentrated coal dust pipeline are between 500 and 700mm. The distance between the main oil gun and the auxiliary oil gun on the same side is close so as to ensure that fuel which is sprayed from the auxiliary oil gun and has excellent atomization can be directly sprayed into high temperature flame generated by ignition of the main oil gun for fierce firing, and the flame generated after fuel sprayed from the main oil gun and the auxiliary oil gun is fired can support each other to form whole flame which has large length and roughness and good rigidity and can ignite high concentrated coal dust.

Owner:HARBIN INST OF TECH

Hot spray process to form alloy coating on the surface of oil pumping polished AOC alloy rod

InactiveCN1811005ATightly boundProtection Bi-directional protection functionMolten spray coatingAlloy coatingGrinding wheel

The hot spray process to form AOC alloy coating on the surface of polished oil pumping rod includes the following steps: surface deoiling the rod; roughening with grinding wheel; pre-heating to activate surface, spraying AOC alloy powder at 0.5-0.8 MPa gas pressure, spraying distance 200-1000 mm and spraying angle 0-90 deg.c; heating in a MF inducing furnace to smelt the alloy coating at 1000 deg.c for 5-10 min; and final polishing with grinding belt. The technological process is simple and can form one coating of 0.25-0.6 mm thickness to resist wear and corrosion.

Owner:ANTON OILFIELD SERVICES (GRP) LTD

Low-temperature pulverization inhibitor for sintered ore

InactiveCN102605176AReduce the problem of continuous cycle enrichmentReduce the pulverization rate of low temperature reductionKirchhoff's circuit lawsCarboxymethyl starch

The invention relates to a smelting assistant for steel works, namely a low-temperature pulverization inhibitor for sintered ore. The low-temperature pulverization inhibitor is prepared by mixing carboxymethyl starch, boric acid, silicon micropowder and a permeate agent in designated proportion; compared with CaCl, Cl ion drag-in quantity is reduced more than 50%, the low-temperature pulverization inhibitor can not generate a replacement reaction with K and Na alkali metals in a furnace charge, therefore, the problem of continuous and circulating enrichment of KCl (kirchhoff's circuit laws) and NaCl in a blast furnace is solved, the reactivity of coke is restrained, the melting loss reaction is reduced, the heat intensity of the coke is ensured, low temperature reduction pulverization rate of the sintered ore is reduced, the destructive effect of the alkali metal on the coke and the blast furnace is basically solved, the furnace condition is smooth, and the output is increased.

Owner:通化耐博新材料股份有限公司

Method of separating feldspar and quartz from granite materials

The invention relates to a method of separating feldspar and quartz from granite materials, and belongs to the technical field of separation and mineral beneficiation. The method comprises the steps of an ore breakage working procedure, an ore grinding working procedure, a screening working procedure, a photoelectric color sorting working procedure, a powder milling working procedure and a magnetic separation working procedure. The feldspar, the quartz and magnetic materials in granite are thoroughly separated by use of the physical technology, no any waste gas or waste water or other substances which pollute the environment are generated in the process of operation, and the damage caused by the floatation technology in the prior art to the environment is effectively avoided. In addition,the feldspar which is separated and purified by use of the method and the quartz which is separated and purified by use of the method can be applied to the ceramic industry instead of natural feldsparand natural quartz, the source of raw materials in the method is sufficient, and the method is suitable for large-scale industrial production.

Owner:内蒙古华宸再生资源科技有限公司

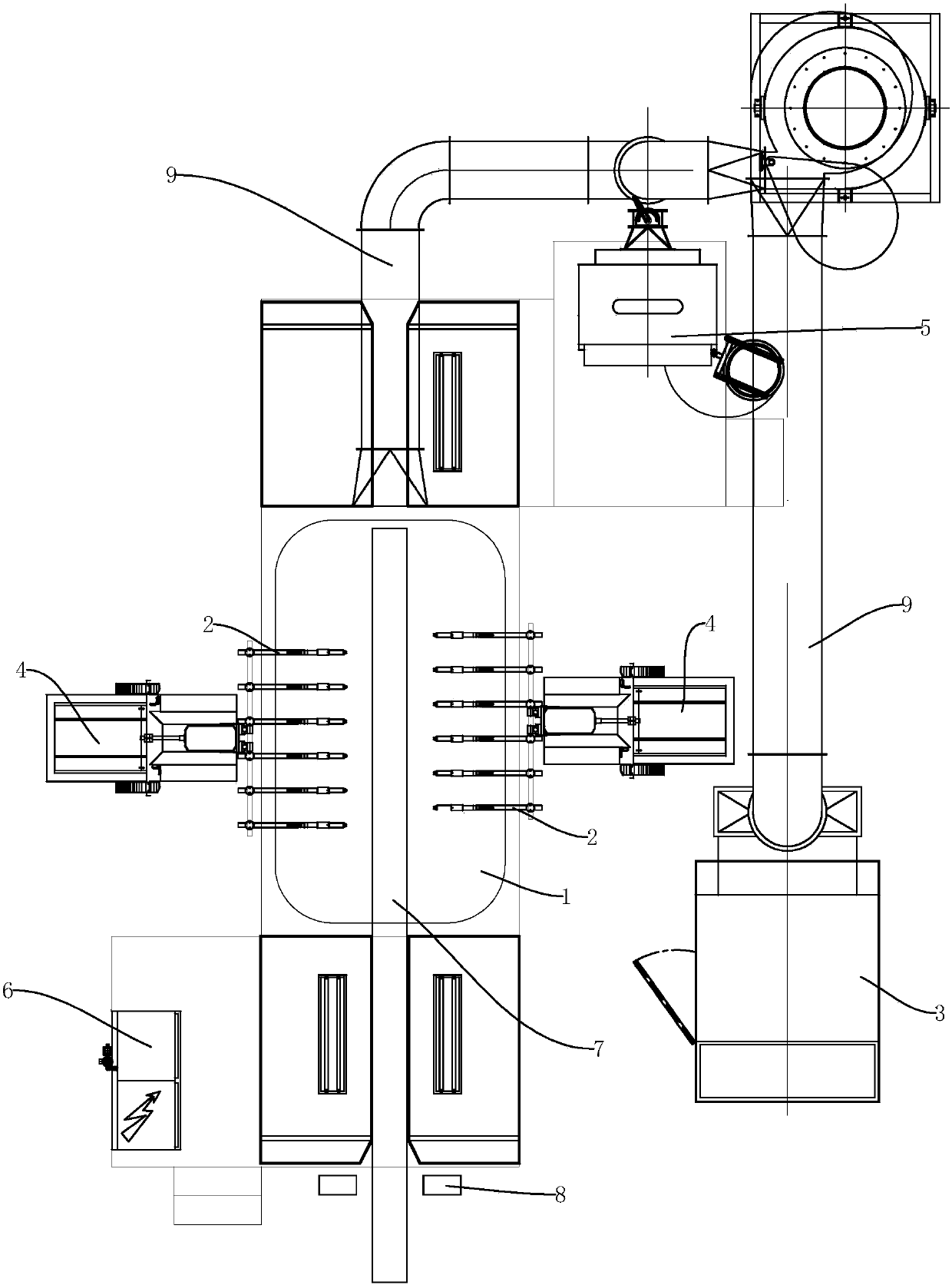

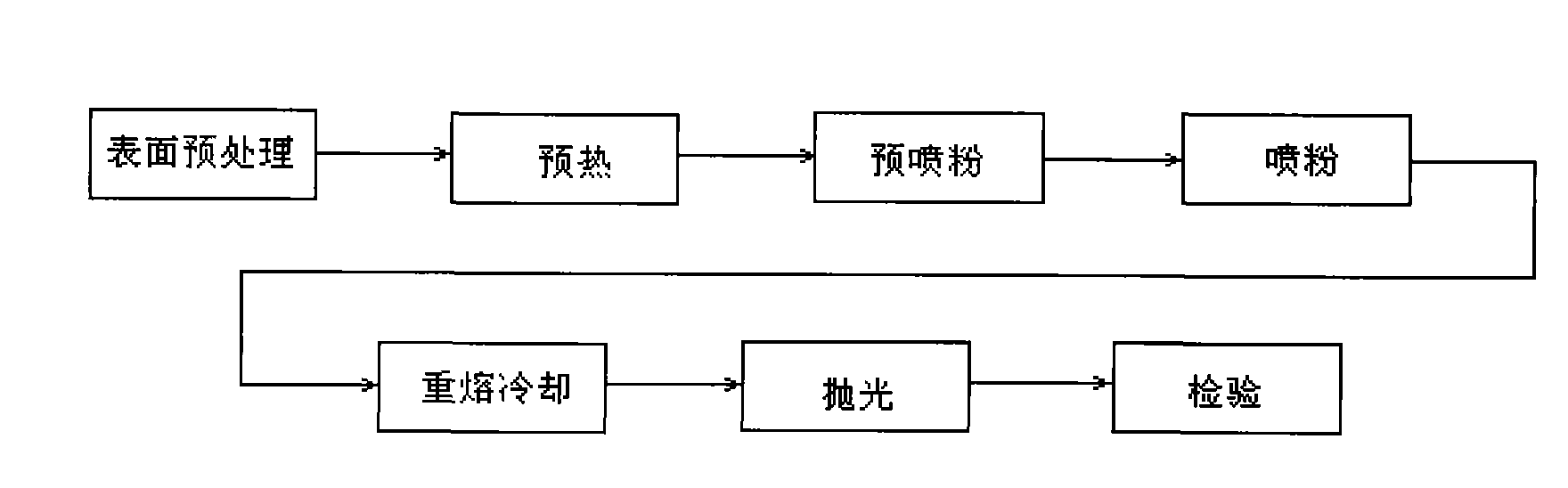

Hot spray processing technique for alloy coating of AOF bidirectional protecting oil pump plunger

InactiveCN101586237AReduce coating stressHigh bonding strengthHeat inorganic powder coatingOil wellAlloy coating

The invention relates to a hot spray processing technique for an alloy coating of an AOF bidirectional protecting oil pump plunger. The processing technique comprises the following steps: carrying out surface oil removal treatment on an oil pump plunger blank; burnishing and roughening the blank by an abrasive band; preheating the treated blank to 300 DEG C for surface activation; then pre-spraying alloy powder with the thickness about 0.2 mm to protect the surface of the plunger from contacting air indirectly; continuously spraying till the ultimate thickness of the coating reaches 0.4 mm; heating the plunger blank by an intermediate induction heating device after spraying is completed for remelting of the alloy coating, wherein the remelting temperature is about 1,000 DEG C; and finally burnishing and polishing to prepare the AOF bidirectional protecting oil pump plunger by using No.100 and No.200 abrasive bands. The processing technique has simple and convenient operation, the coating is combined closely after spraying; the performance of a basal body of the plunger is not influenced during coating; and the thickness of the coating is more than 0.25 mm, and the coating can resist outside wearing and corrosion, and reduce the wearing to the inner surface of a pump cylinder of an oil well pump.

Owner:ANTON OILFIELD SERVICES (GRP) LTD

Breeding method of easy-dry type self-incompatible line of Chinese cabbage anther

InactiveCN102172208AOvercoming self-incompatibilityLoose powder time is shortPlant genotype modificationRelease timePollen

The invention discloses a breeding method of an easy-dry type self-incompatible line of Chinese cabbage anther. The method comprises the following steps: (1) selecting the easy-dry type self-incompatible line of anther as breeding protospecies to plant; (2) collecting the anther of the self-incompatible line blossoming in the day and not releasing pollen at 8-10 a.m.; (3) processing the anther so that the anther is loosened and releases pollen until the pollen can be dipped; (4); manually opening the bud to blossom in 3-5 days on the self-incompatible line, and exposing the stigma; (5) manually dipping the pollen obtained in the step (3) with a finger or a rubber, and smearing the pollen on the stigma obtained in the step (4); and (6) collecting the self-pollinated seeds after hulling. As easy-dry type self-incompatible line of Chinese cabbage anther has short pollen releasing time and small pollen quantity, the method disclosed by the invention adopts a mode of in vitro pollen collection and artificial pollination, improves the pollen quantity, overcomes the self-incompatibility of Chinese cabbage, can increase the seed collection quantity by 100-200 times, and realizes high breeding efficiency and yield.

Owner:山东春秋大白菜育种研究中心

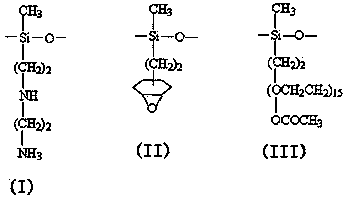

Method for improving abrasion resistance of crude terephthalic acid hydrofining palladium-carbon catalyst

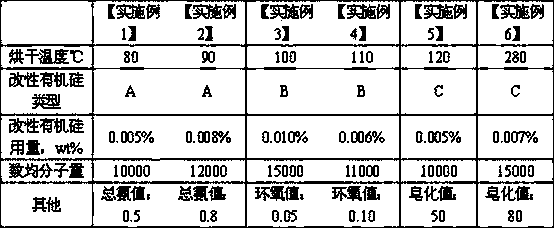

ActiveCN103769210ALess powderReduce wearOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsEpoxyPtru catalyst

The invention relates to a method for improving abrasion resistance of a crude terephthalic acid hydrofining palladium-carbon catalyst, and mainly solves the problem of easy abrasion of the catalyst in use in the prior art. The method for improving the abrasion resistance of the crude terephthalic acid hydrofining palladium-carbon catalyst comprises the following steps: (A) a fresh commercial palladium-carbon catalyst is dried under the protection of inert gas of 80-120 DEG C; (B) modified organosilicon, being 0.005-1.0% of the mass of the dried fresh catalyst and using polydimethylsiloxane as matrix, is sprayed on the dried fresh catalyst, and is dried under the protection of the inert gas; the modified organosilicon is at least one of ammonia-modified organosilicon, epoxy-modified organosilicon or polyether-modified organosilicon. The method preferably solves the problem, and can be applied to the industrial production of crude terephthalic acid hydrofining.

Owner:CHINA PETROLEUM & CHEM CORP +1

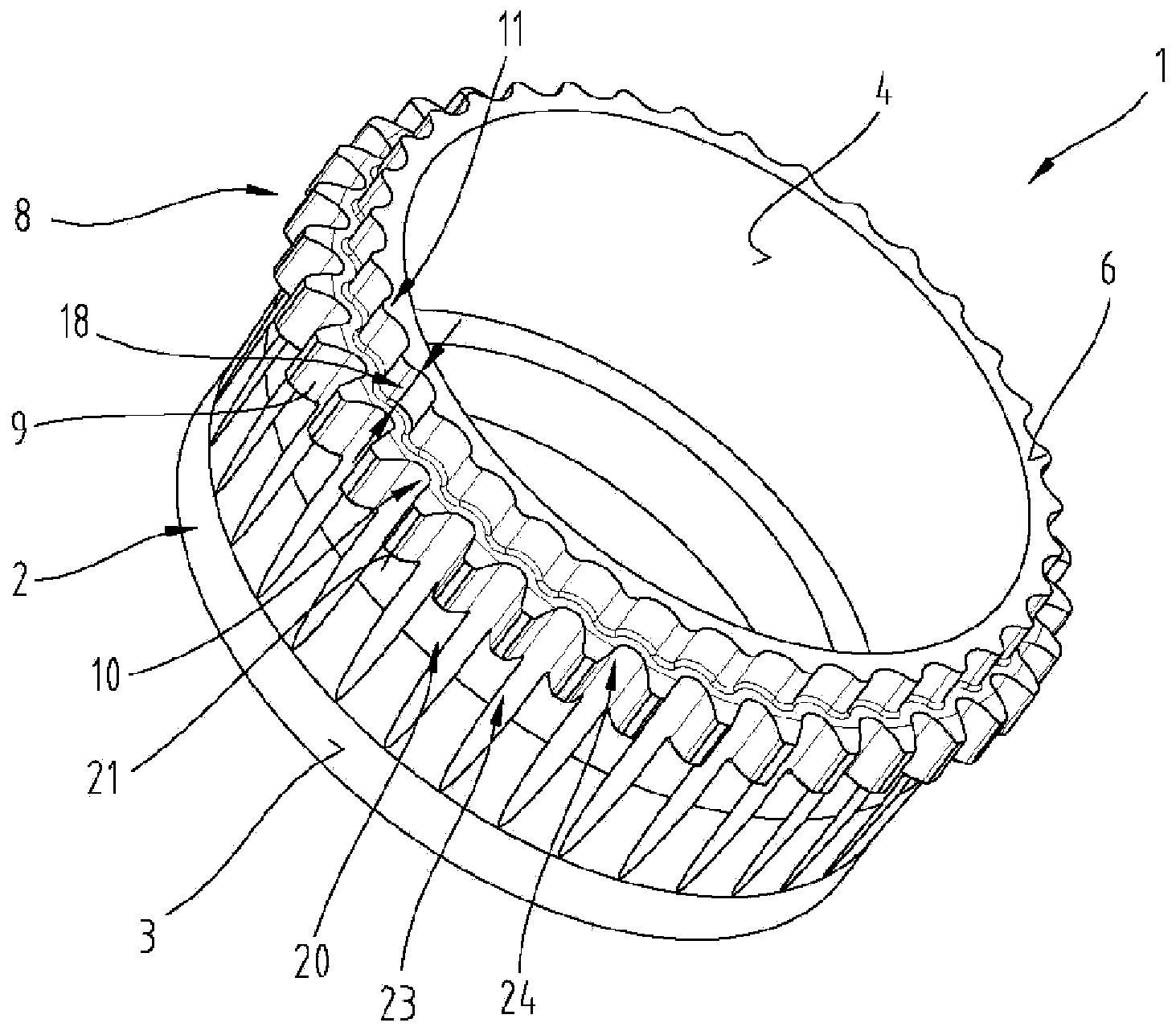

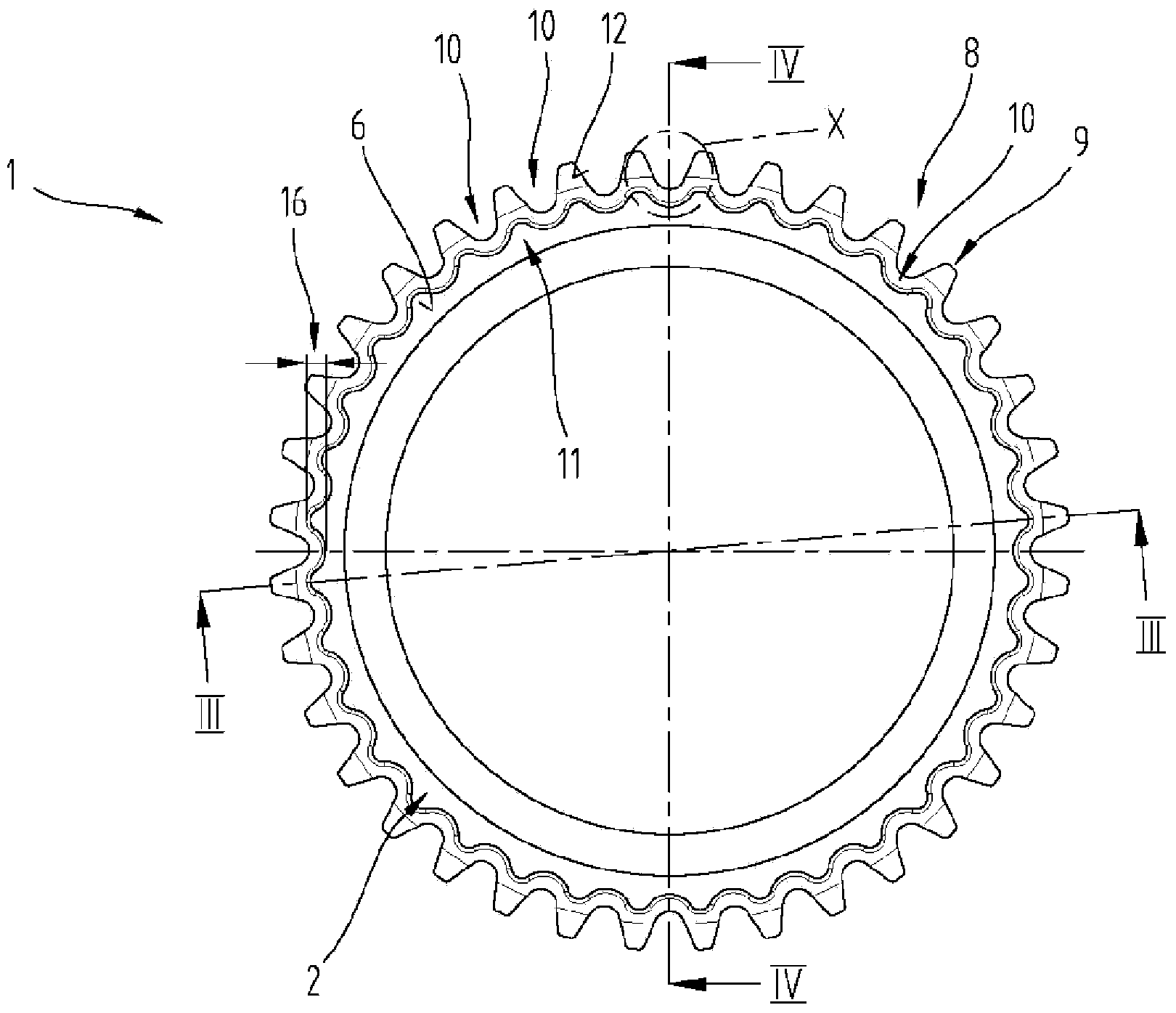

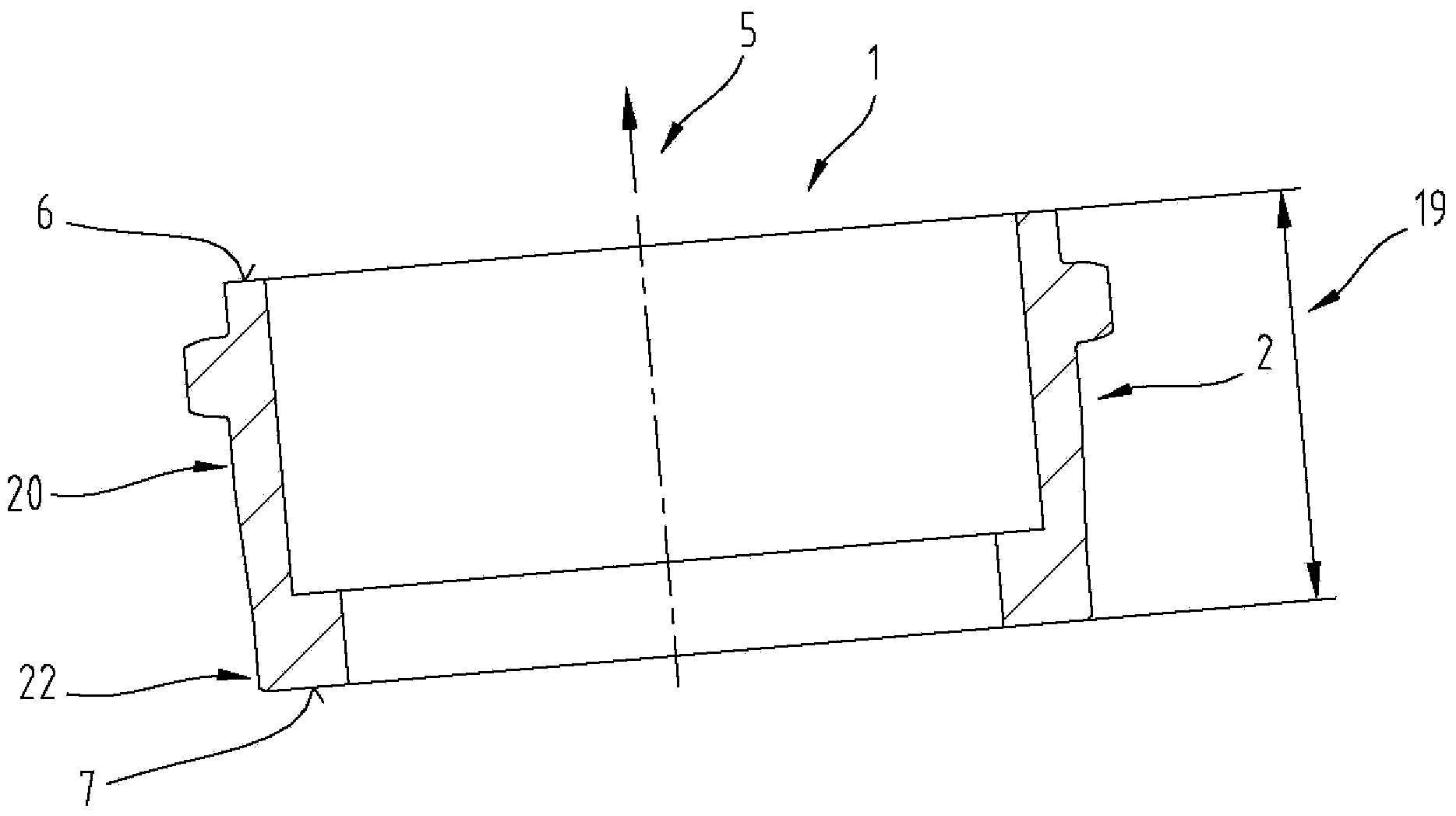

Toothed wheel

ActiveCN103807409AGood releasabilityGood compactabilityValve arrangementsPortable liftingSprocketNear net shape

The invention relates to a method for producing a toothed wheel (1) in net shape or near-net shape quality, in particular a chain wheel, for a VVT system from a powder, with the toothed wheel (1) having an at least approximately cylindrically shaped housing (2) which is delimited in axial direction by one respective end face (6, 7) and which has an outside surface (3), and at the outside surface (3), a toothing (8) having teeth (9) and tooth roots (10) between the teeth (9) is embodied at a distance to both of the end faces (6, 7), and the toothing (8) has a tooth root circle (25) having a tooth root circle diameter, and the powder is filled into a mold (28) and pressed by means of at least one punch, and protrusions (11, 20) are embodied at least in the region of the teeth (9) at the outside surface (3) of the housing (2) and projecting over the latter in radial direction. The invention also relates to a gear, especially a chain.

Owner:MIBA SINTER AUSTRIA

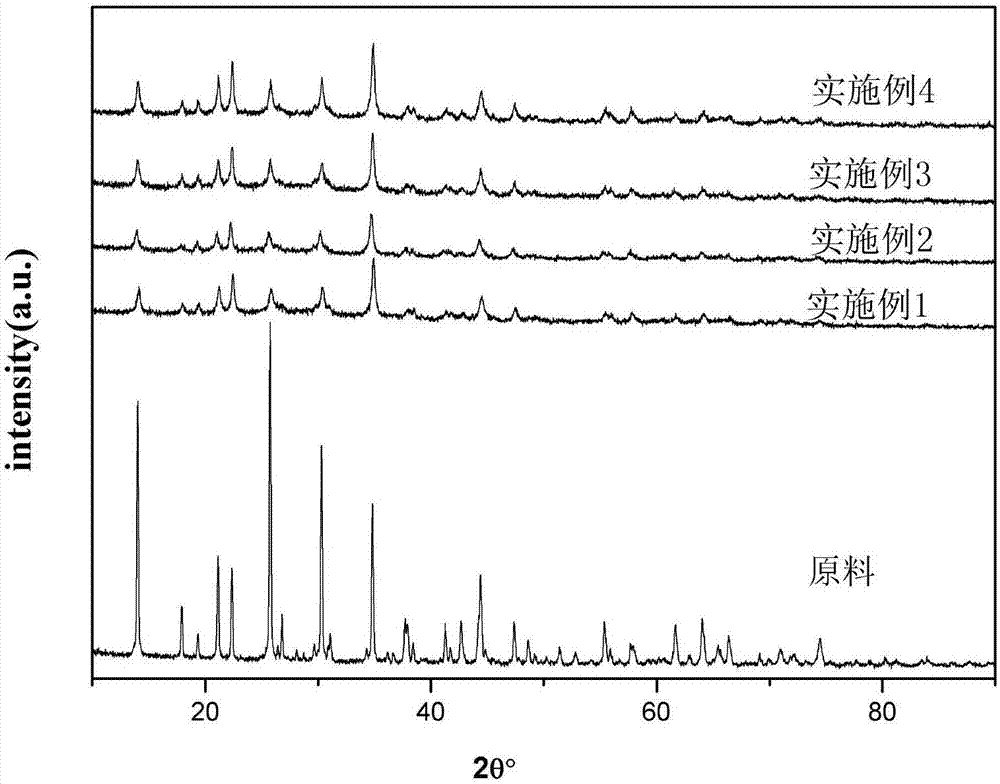

A kind of WC-Ni3Al cemented carbide toughened by Zr element and preparation method thereof

The invention discloses a WC-Ni3Al cemented carbide toughened by Zr element and a preparation method thereof. The hard phase is WC, and the binder phase is Ni3Al-Zr with a volume percentage of 10% to 40%. The preparation steps include: Pre-wet mill the ZrH2 powder with a mass percentage of 0.005% to 0.246% for 1 to 2 hours, and then add the remaining WC+Ni3Al pre-alloyed powder to wet mill together to obtain a wet mill mixture; after spray drying and compression molding Make a compact; first follow the conventional sintering curve, raise from normal temperature to 450°C, keep warm for 1 to 2 hours, pump to a limit vacuum below 4×10-3Pa, and then pass 20mbar to 60mbar between 450°C and 1200°C Low-pressure hydrogen, heating rate ≤ 5°C / min, after reaching the end temperature, vacuum again to below 4×10-3Pa, and keep warm for 1 to 2 hours to complete the low-pressure hydrogen treatment of the compact; then follow the conventional sintering curve, heat up The Zr-toughened WC-Ni3Al cemented carbide is obtained after low-pressure liquid-phase sintering at a sintering temperature of 1350°C to 1550°C, which has excellent toughness and flexural strength and is simple in process.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

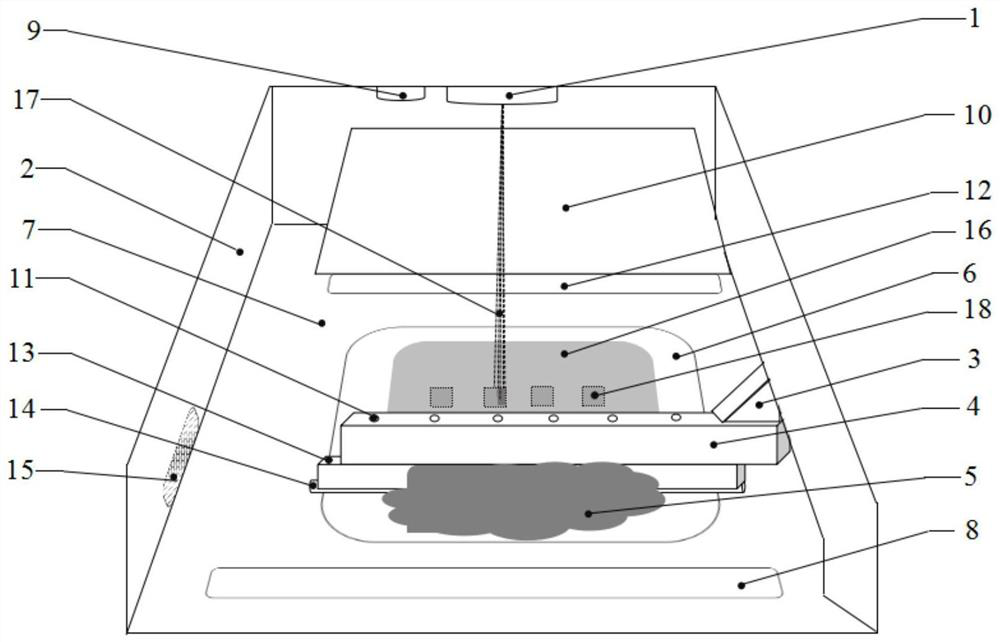

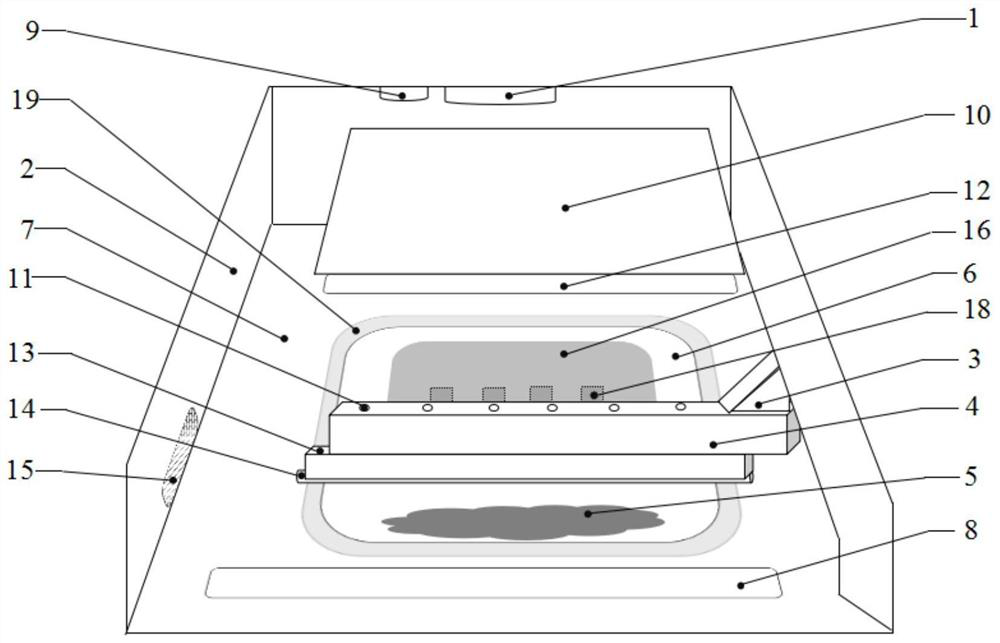

Support-free 3D printing method

ActiveCN114131050AImprove printing efficiencyLess powderAdditive manufacturing apparatusIncreasing energy efficiencyLaser scanningEngineering

The invention discloses a support-free 3D printing method, which is characterized in that a currently printed part layer is set as an Nth layer, a next layer to be printed is set as an (N + 1) th layer, in a small-angle area, a part of area of the (N + 1) th layer can exceed a boundary line of the Nth layer, the part of area exceeding the boundary is defined as a suspended area, the suspended width of the suspended area is defined as W, and defining an included angle between a connecting line from the (N + 1) th layer of bottom edge to the Nth layer of bottom edge and the horizontal direction as alpha. The ratio of the laser power P to the laser scanning speed V is adjusted in time in the laser scanning process of the inner side and the outer side of the boundary and the suspension area, when the laser beam scans the (N + 1) th layer of overlapping area, the spot diameter phi of the laser beam is controlled to be kept unchanged or amplified, and after the laser beam scans the (N + 1) th layer of small-angle suspension area and the overlapping area, the laser beam is controlled to be not changed. And the spot diameter phi of the laser beam is controlled to be reduced, and based on the principle, the suspended area and the overlapped area of each part layer can be printed and formed under the condition of not depending on a supporting body.

Owner:深圳市华阳新材料科技有限公司

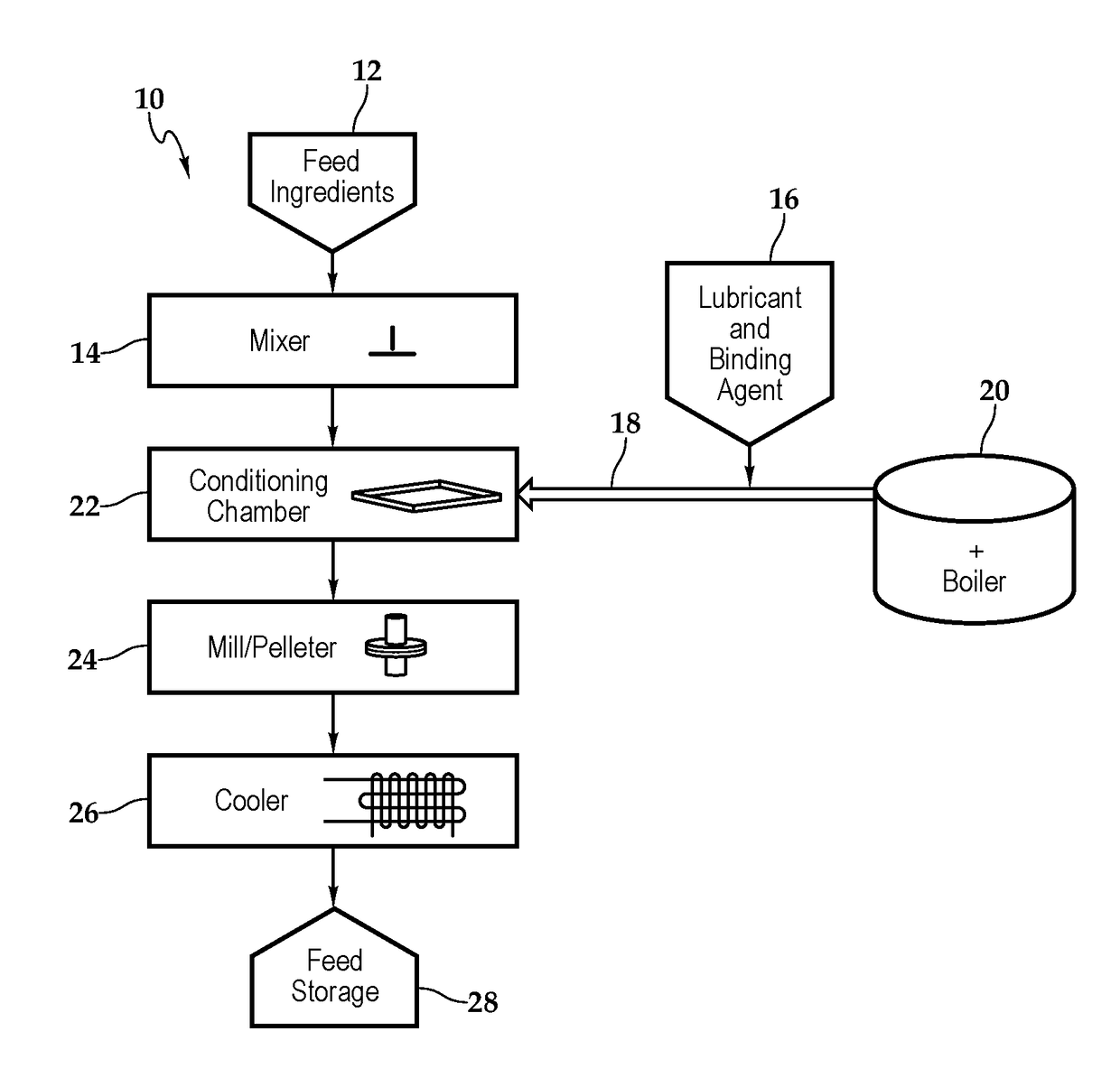

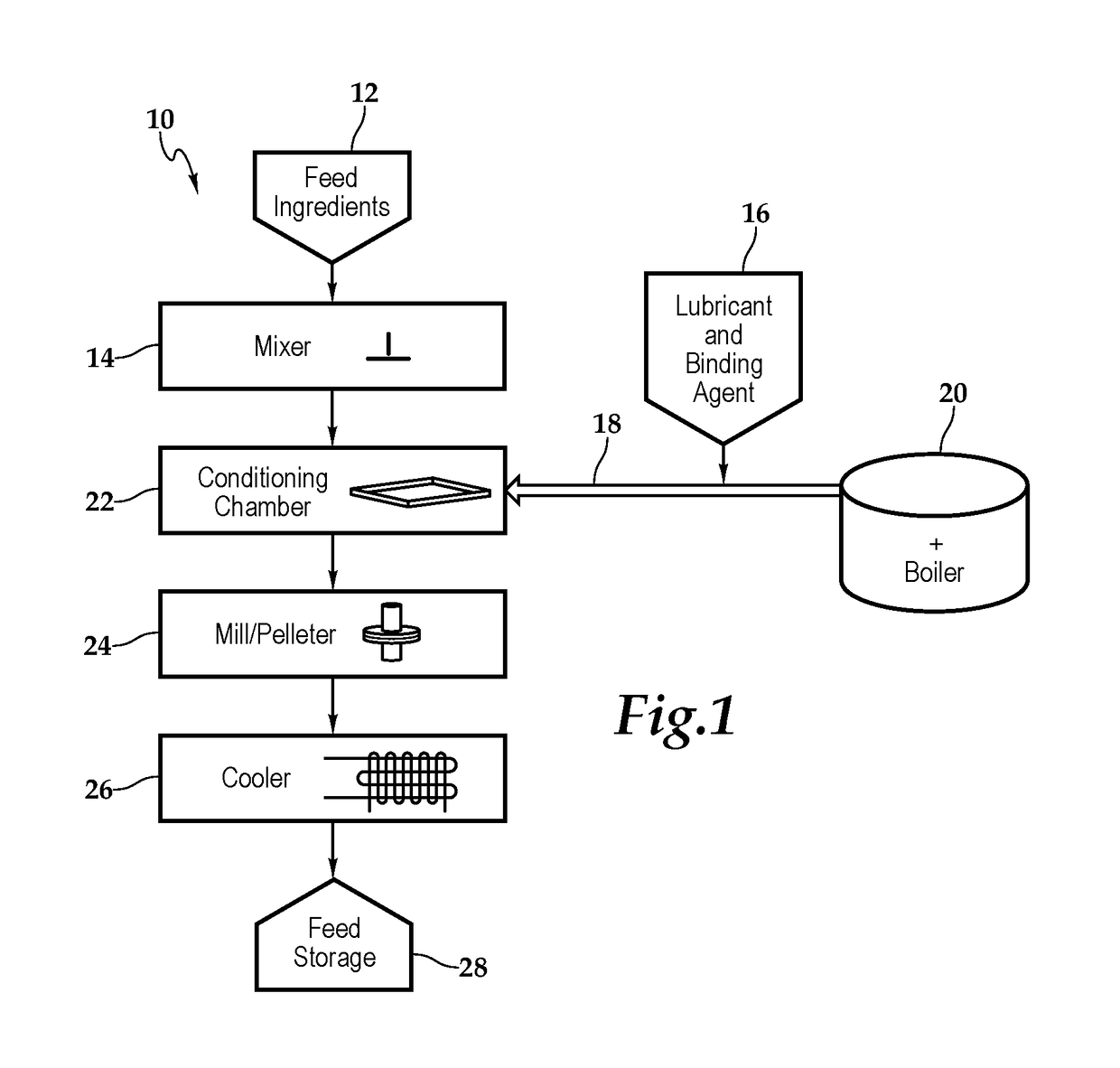

Lubricant and binding agent for the production of feedstuff and the like and system and method for use of same

A lubricant and binding agent for the production of feedstuff and the like and a system and method for use of the same are disclosed. In one embodiment of the method, an organic-based ingredient and a lubricant and binding agent are combined and subjected to a pellet-mill production process. The lubricant and binding agent includes about 15% to about 40% by weight of glycerin, about 0.005% to about 0.017% by weight of guar gum, about 0.009% to about 0.028% by weight of gum arabic, about 0.005% to about 0.017% by weight of aloe vera, and a balance by weight of water. The lubricant and binding agent increases production efficiency and pellet durability.

Owner:VINOKUR ARON

Process for producing aggregated latex particle

A novel method of particle formation by which aggregated latex particles extremely reduced in the content of fine particles and coarse particles and satisfactory in powder properties including blocking resistance and powder flowability can be recovered from a polymer latex without deteriorating the original quality possessed by the polymer itself. The process for producing aggregated latex particles is characterized in that a polymer latex containing a water-soluble polymer having the property of forming a physical gel is atomized or dropped in a gas phase containing an inorganic salt and / or an acid in an aerosol state and the droplets of the polymer latex are caused to fall or come into an aqueous phase.

Owner:KANEKA CORP

Method for rapid preparation of metal composite molded parts by selective laser melting additive manufacturing

ActiveCN109249024BLess powderShort manufacturing cycleAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingManufactured material

The invention provides a method for rapid preparation of metal composite material molded parts by selective laser melting additive manufacturing. Place a small amount of metal or metal composite material powder on the molding substrate instead of the powder storage chamber; operate the selected area laser melting equipment externally without opening the door of the part molding chamber. The software controls the powder rollers in the part molding chamber to move the powder and the molding cylinder It drives the lifting of the substrate; without opening the door of the part molding chamber, the software of the externally operated selective laser melting equipment controls the laser to selectively melt the powder. The invention improves the operation method of the traditional selective laser melting additive manufacturing equipment. By modifying the software of the selective laser melting additive manufacturing equipment, the powder roller in the part forming room is controlled to move and spread powder, the forming cylinder drives the lifting of the substrate and laser selective melting Powder layers, shaped test pieces, small-sized workpieces or complex structures. The invention can shorten the manufacturing cycle, save raw material powder and ensure the quality of molded parts.

Owner:HARBIN ENG UNIV

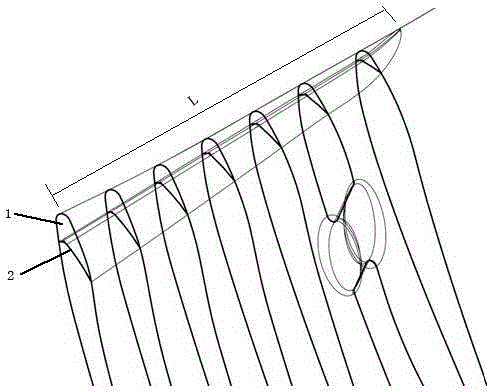

Laser cladding structure of steam turbine blade air inlet side

InactiveCN104533539AExtended service lifeReduce distortionBlade accessoriesMachines/enginesSteam turbine bladeEngineering

The invention provides a laser cladding structure of a steam turbine blade air inlet side. The problem that according to an existing steam turbine blade steam inlet side laser cladding slope structure, longitudinal sections are the same, so that cladding layers close to the blade tops on the blade longitudinal sections can be subjected to water erosion easily and lose efficacy can be solved. Accordingly, the anti-water-erosion capacity of a blade steam outlet side laser cladding layer is improved, and the service life of a steam turbine blade is prolonged. The structure comprises a laser cladding layer. A cladding slope which extends from the blade top to the blade root is formed in one side of the air inlet side of the steam turbine blade, and the laser cladding layer is arranged in the cladding slope in a cladding mode. The laser cladding structure is characterized in that the width and the thickness of the longitudinal section of the laser cladding layer are reduced gradually to zero from the blade top to the blade root, the length L of the laser cladding layer is 200 mm-900 mm, and the width and the thickness of the longitudinal section of the laser cladding layer are determined by the cladding slope structure.

Owner:WUXI TURBINE BLADE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com