Method for improving abrasion resistance of crude terephthalic acid hydrofining palladium-carbon catalyst

A crude terephthalic acid, palladium carbon catalyst technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc., can solve the problem of poor wear resistance of catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

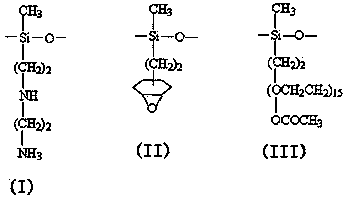

Method used

Image

Examples

Embodiment 1

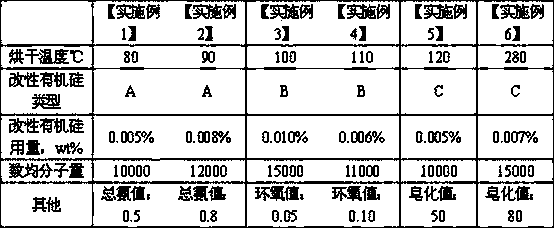

[0025] The fresh catalyst with a palladium mass percentage of 0.5% was dried at 80°C under nitrogen protection and cooled to room temperature; the ammonia-modified silicone with a number average molecular weight of 10000 and a mass percentage of 0.005% relative to the dry fresh catalyst was evenly sprayed on the On the freshly baked catalyst, the total ammonia value is 0.5, and then dried at 110°C under the protection of nitrogen. The analysis data of the catalyst are shown in Table 2.

Embodiment 2~6

[0027] Except the process condition change as shown in Table 1, other operation is as [Example 1]; The analysis data of catalyst is as Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com