Support-free 3D printing method

A 3D printing, unsupported technology, applied in the field of 3D printing, can solve the problems of increased powder consumption, low manufacturing efficiency, inability to add supports, etc., to shorten the forming time, save powder, and improve the efficiency of 3D printing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] In this embodiment, the unsupported 3D printing method can refer to the following steps:

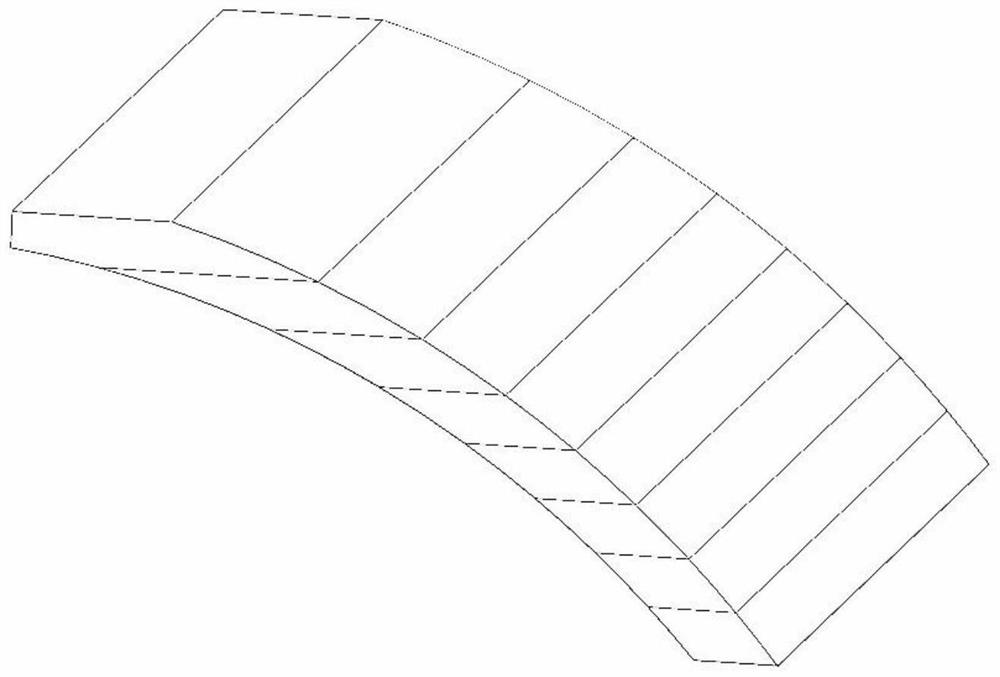

[0051] Step 1, see figure 1 , the present invention is explained by taking a small-angle arc structure as an example, which is defined as: arc body;

[0052] Step 2, define the area where the angle between the inscribed surface of the arc structure and the horizontal direction is less than 45° as the small angle area D;

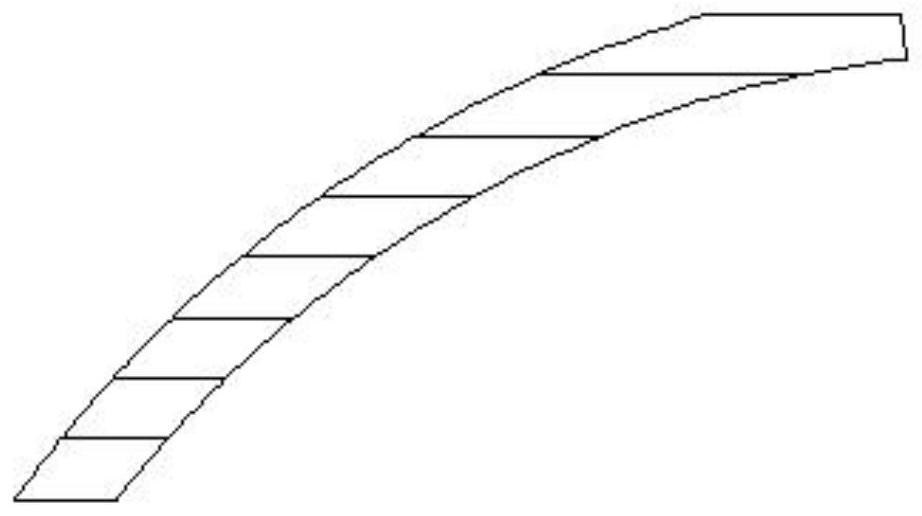

[0053] Step 3, according to the principle of laser selective melting forming, the parts are formed in a layer-by-layer manner. The layered thickness of each part is defined as d, and d is generally 0.02 to 5 mm. The structure of the arc body after layering is as follows figure 1 , 2 shown;

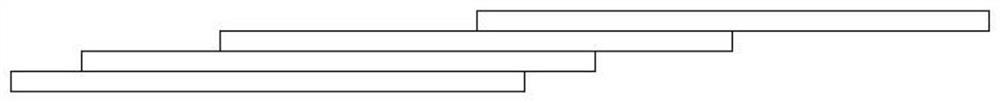

[0054] Step 4. After the arc body is directly layered, each layer will have sharp edges. Because the part is actually composed of a series of triangular faces, when the layering software recognizes it, the sharp edges will be blunted and form right-angled edges. , so th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com