Method for rapid preparation of metal composite molded parts by selective laser melting additive manufacturing

A technology for selective laser melting and metal composite materials, which is applied in the directions of additive manufacturing, additive processing, and process efficiency improvement. Powder, time saving, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following examples describe the present invention in more detail.

[0028] combine Image 6 The method for preparing metal and composite material moldings by the selective laser melting (SLM) additive manufacturing technology of the present invention is divided into the following five steps.

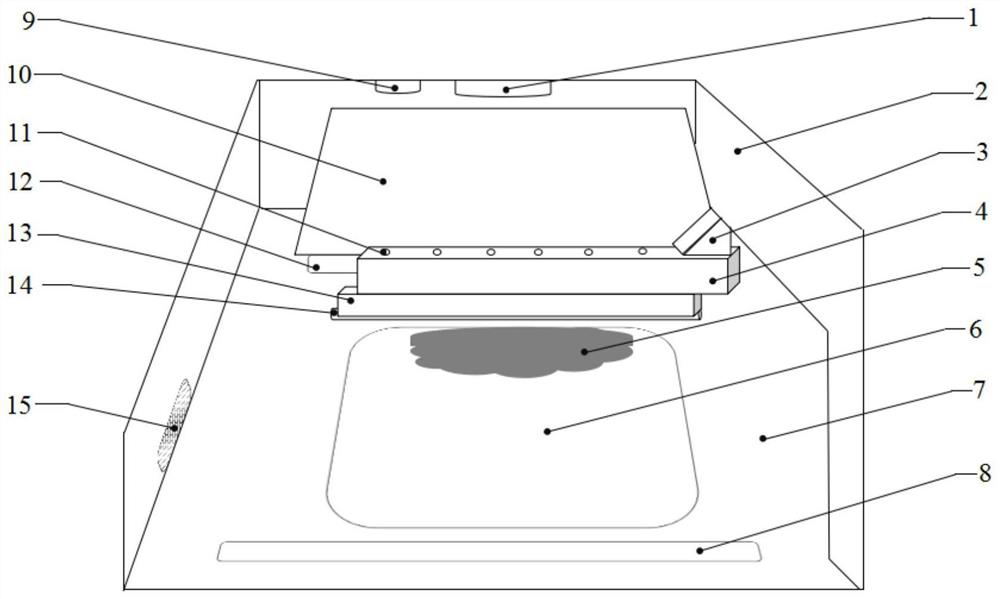

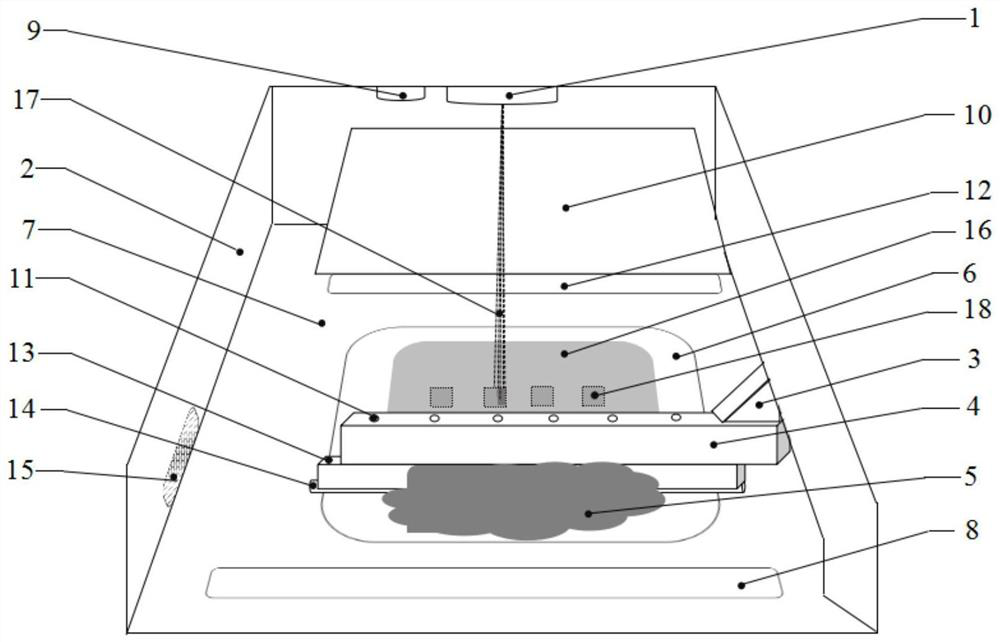

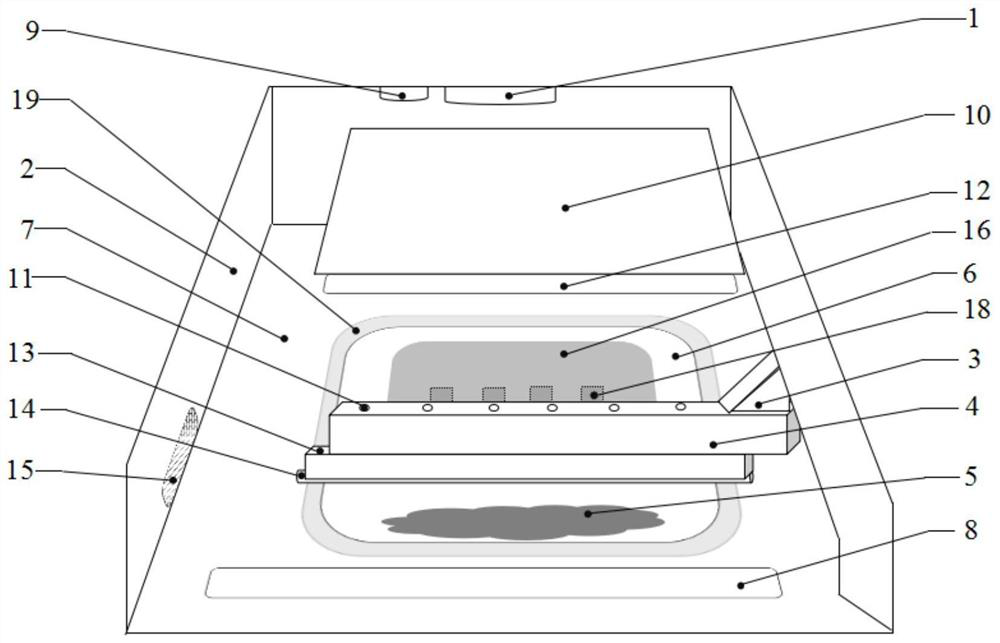

[0029] Step 1: Combine figure 1, in the schematic diagram of the position of each mechanical component and raw material powder in the part forming room in the processing preparation stage, the fixing device includes: laser 1, part forming room wall 2, part forming room bottom surface 7, material receiving port 8, laser galvanometer 9, powder storage room 10 , Powder outlet 12, air vent 15. The scraping strip 14 is fixed on the scraping strip fixing rod 13, the screw passes through the roller fixing rod screw hole 11 and is fixed on the roller fixing rod 4, and then is connected with the internal motor of the equipment through the roller linkage rod 3. The whole formed by s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com