Laser cladding structure of steam turbine blade air inlet side

A technology for steam turbine blades and laser cladding, which is applied to the supporting elements of blades, mechanical equipment, engine elements, etc., can solve the problems of easy water erosion and failure of the cladding layer, save production energy and production time, and save cladding metal powder. , Reduce the effect of blade deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

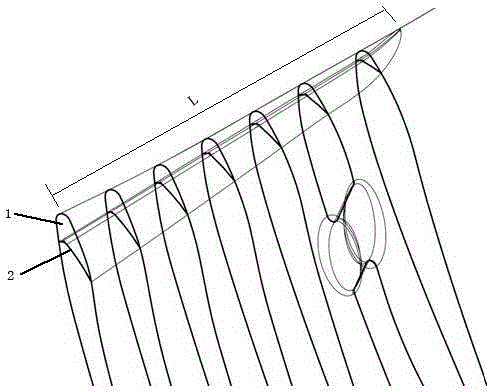

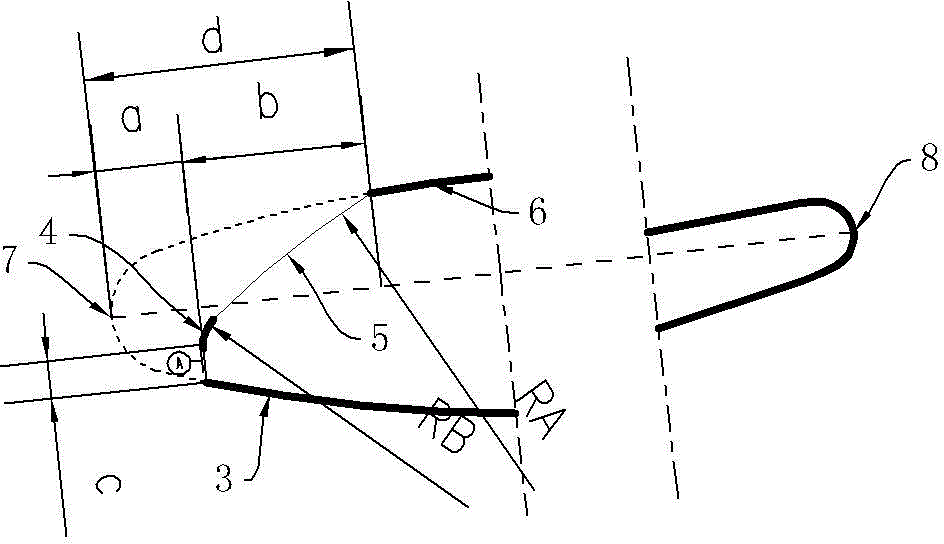

[0022] A steam turbine blade with a blade body length of 25 inches has a laser cladding area length of 200mm. Its groove shape is as follows:

[0023] The cross-sectional shape of the tip position is that the fillet RA is R40mm, the fillet RB is R1.5mm, the length a is 6mm, the length b is 13.4mm, and the length c is 2mm;

[0024] The cross-sectional shape at a distance of 50mm from the blade tip is R40mm for rounded corner RA, R1.5mm for rounded corner RB, length a is 5.1mm, length b is 12.5mm, and length c is 2mm;

[0025] The cross-sectional shape at a distance of 100mm from the blade top position is that the rounded corner RA is R40mm, the rounded corner RB is R1.5mm, the length a is 4.2mm, the length b is 11.2mm, and the length c is 2mm;

[0026] The section shape at a distance of 150mm from the tip of the blade is that the rounded corner RA is R40mm, the rounded corner RB is R1.5mm, the length a is 4.2mm, the length b is 11.2mm, and the length c is 2mm;

[0027] The cr...

Embodiment 2

[0032] A steam turbine blade with a blade body length of 67 inches has a laser cladding area length of 900mm. Its groove shape is as follows:

[0033] The cross-sectional shape of the blade tip position is that the fillet RA is R60mm, the fillet RB is R4mm, the length a is 8.0mm, the length b is 22mm, and the length c is 6mm;

[0034] The cross-sectional shape at a distance of 200mm from the tip of the blade is that the fillet RA is R60mm, the fillet RB is R4mm, the length a is 6.4mm, the length b is 18.4mm, and the length c is 6mm;

[0035] The cross-sectional shape at a distance of 400mm from the tip of the blade is that the rounded corner RA is R60mm, the rounded corner RB is R4mm, the length a is 4.7mm, the length b is 14.8mm, and the length c is 6mm;

[0036] The cross-sectional shape at a distance of 600mm from the tip of the blade is that the rounded corner RA is R60mm, the rounded corner RB is R4mm, the length a is 3.1mm, the length b is 11.2mm, and the length c is 6m...

Embodiment 3

[0042] A steam turbine blade with a blade body length of 75 inches has a laser cladding area length of 900mm. Its groove shape is as follows:

[0043] The cross-sectional shape of the blade tip position is that the fillet RA is R50mm, the fillet RB is R3mm, the length a is 8.0mm, the length b is 30mm, and the length c is 7mm;

[0044] The cross-sectional shape at a distance of 200mm from the tip of the blade is that the fillet RA is R50mm, the fillet RB is R3mm, the length a is 7.0mm, the length b is 24.7mm, and the length c is 7mm;

[0045] The cross-sectional shape at a distance of 400mm from the tip of the blade is that the rounded corner RA is R50mm, the rounded corner RB is R3mm, the length a is 6.0mm, the length b is 19.4mm, and the length c is 7mm;

[0046] The cross-sectional shape at a distance of 600mm from the blade tip is R50mm for rounded corner RA, R3mm for rounded corner RB, length a is 4.9mm, length b is 14.1mm, and length c is 7mm;

[0047] The cross-section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com