Patents

Literature

33results about How to "Saving productivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of multifunctional yarn containing silver fibers

InactiveCN101985786ASignificant progressSolve the problem that it is easy to fall off and affect the subsequent production processYarnFiberYarn

The invention provides a preparation method of a multifunctional yarn containing silver fibers. The multifunctional yarn containing silver fibers is prepared by the following fiber materials by weight percent: 8-15% of nano silver fibers, 10-20% of nano carbon fiber and the balance of other fibers, wherein the other fibers refer to any one or more of Tencel fibers, modal fibers, outlast, moisture absorption fibers and fine denier fibers; the nano silver fiber is prepared by adding nano silver the weight ratio of which is 0.2-2% and the particle size of which is 18-150nm in a polypropylene solution and interlacing into a net structure through a multipoint high pressure jet mode, and the monofilament length of the nano silver fiber is 20-30mm; the monofilament length of the nano carbon fiber is 25-35mm, and the nano carbon content thereof is 1-3%; and the other fibers are discontinuous short fibers. By special treatment and collocation of raw materials as well as adjustment and improvement of the preparation method, the requirements of the existing production equipment for producing top grade textiles can be met.

Owner:山东昊龙集团有限公司

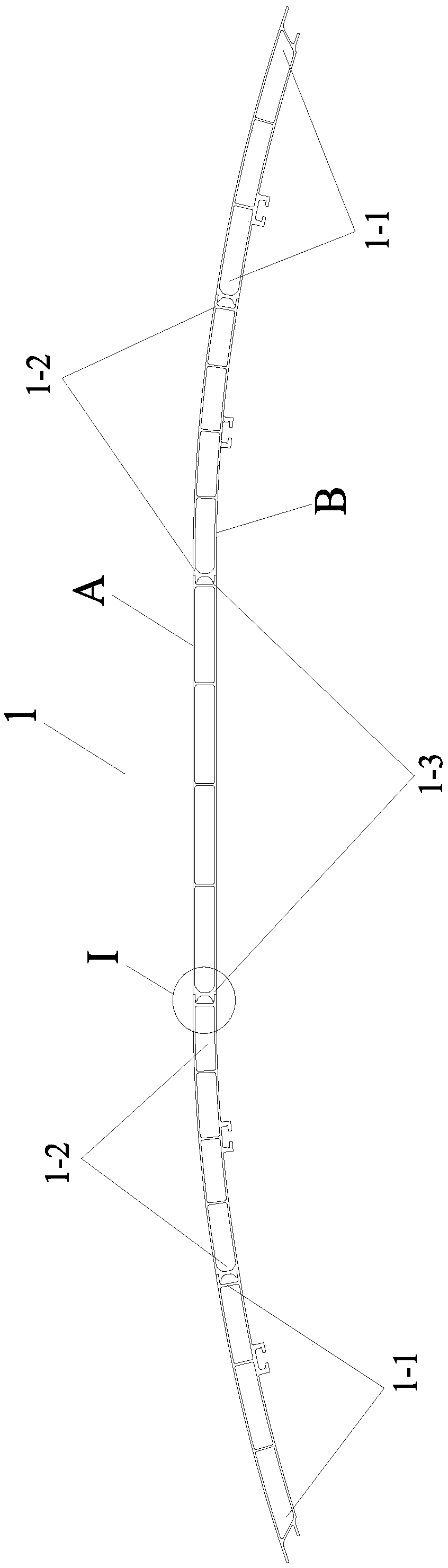

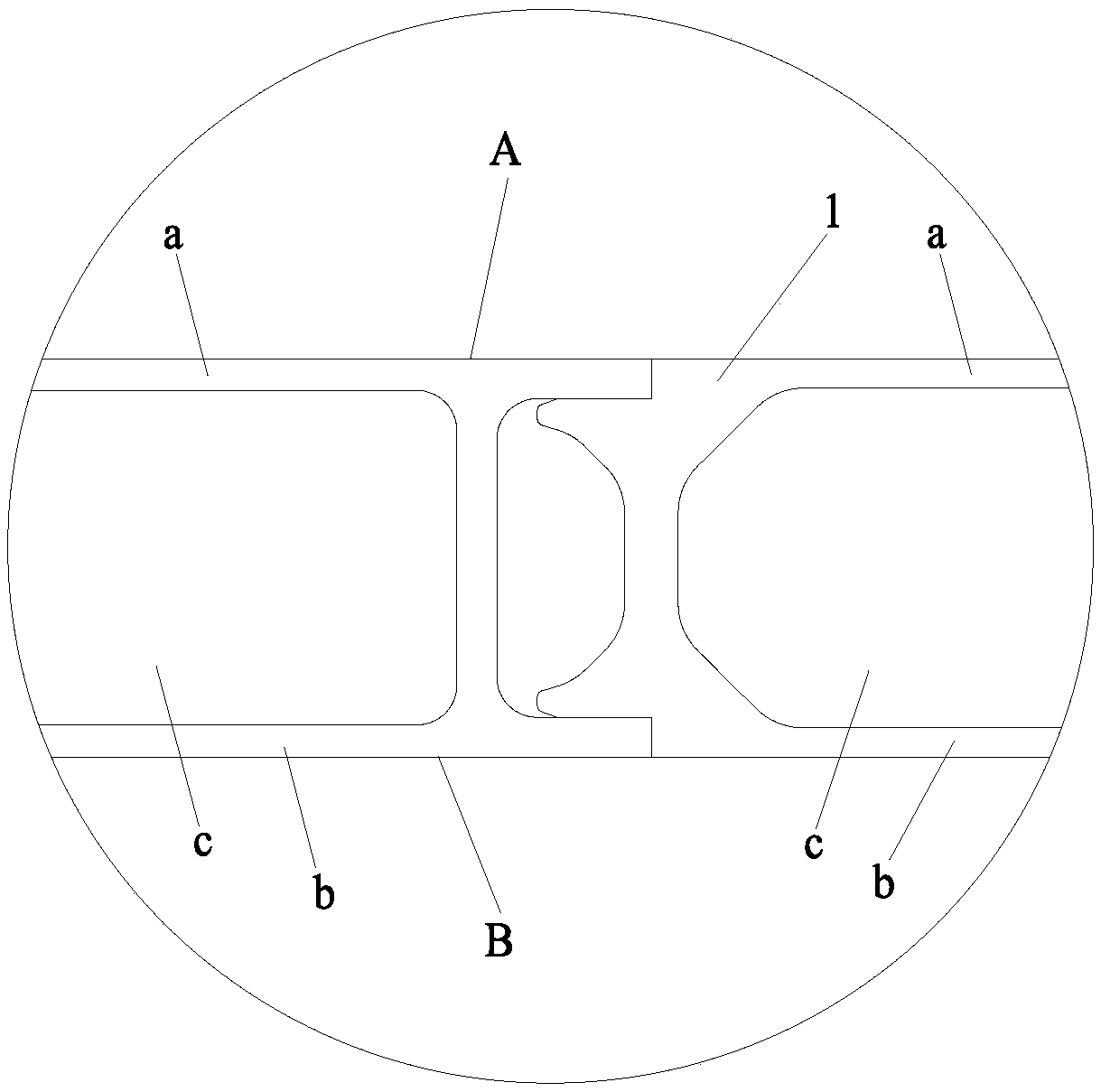

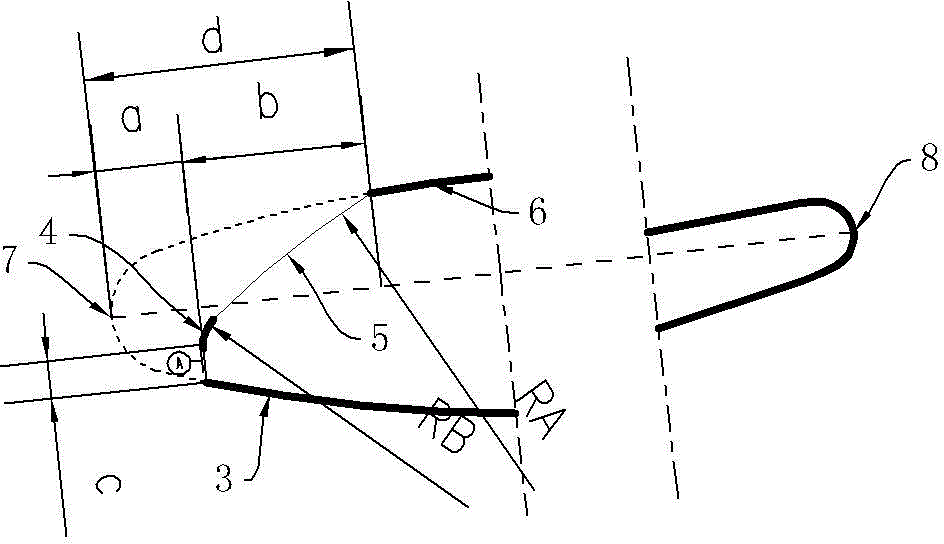

Stir friction welding method for hollow aluminum extruded section splicing arc plate

ActiveCN108723578AReduce incoming materialsLower requirementWorkpiece edge portionsNon-electric welding apparatusFriction weldingRailway passenger car

The invention discloses a stir friction welding method for a hollow aluminum extruded section splicing arc plate, and belongs to the field of welding method of a large arc roof plate component of an aluminum alloy car body of a railway passenger car. For stir friction welding of the aluminum alloy car body roof arc plate component of the railway passenger car, and a welding sequence of one-step reversed assembling and two-step forward assembling and a control method for weldment assembly interval values are proposed; a thickened protrusion is arranged on the position, adjacent to a weld seam,of the outer surface of the aluminum alloy hollow extruded section, the protrusion width and the diameter of the root of a stirring needle are maintained at a ratio of 95% to 105%, in order to ensurethe size of a post-weld workpiece, during the two-step forward assembling, when pre-fabrication reverse deformation friction stir welding is conducted, a thickened raised metal is filled in the gap generated at the weld seam of the outer surface of the pre-fabrication deformed curved section aluminum alloy hollow extruded section by the rotary extrusion of a stirring head, and the friction stir welding does not require additional raised metal grinding removal work; the method ensures the structural size requirement of aluminum alloy product components of the curved section hollow extruded section.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

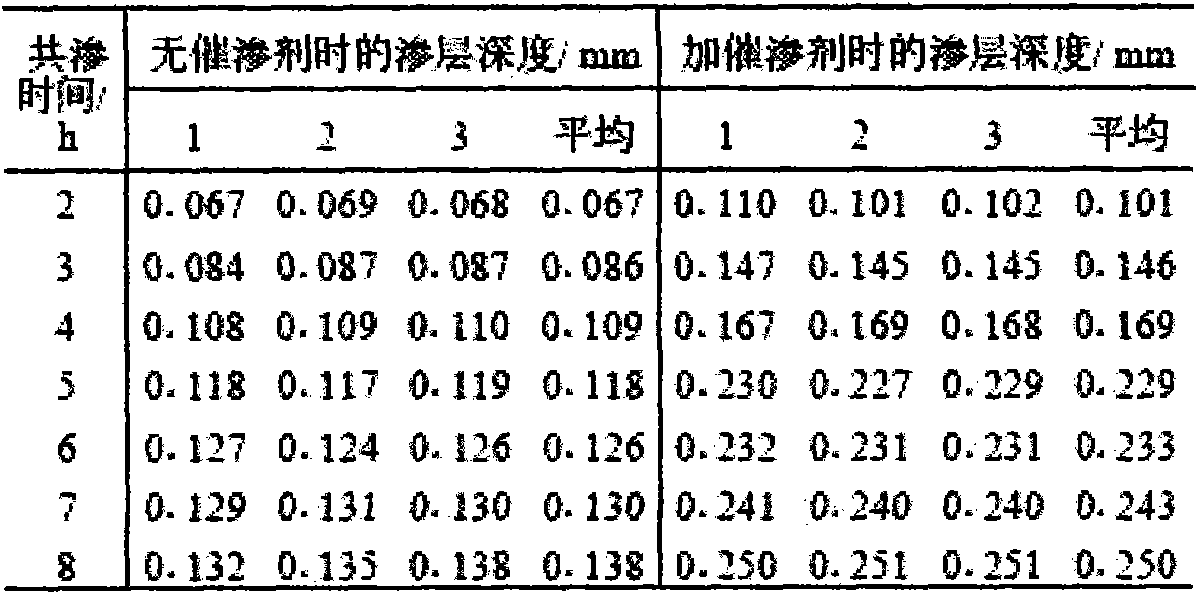

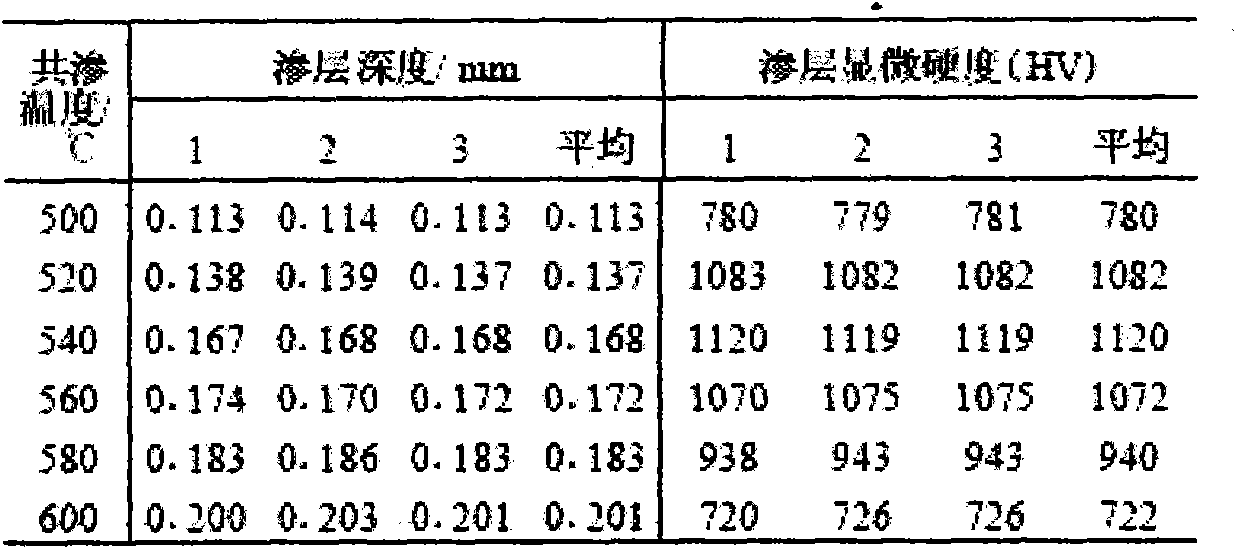

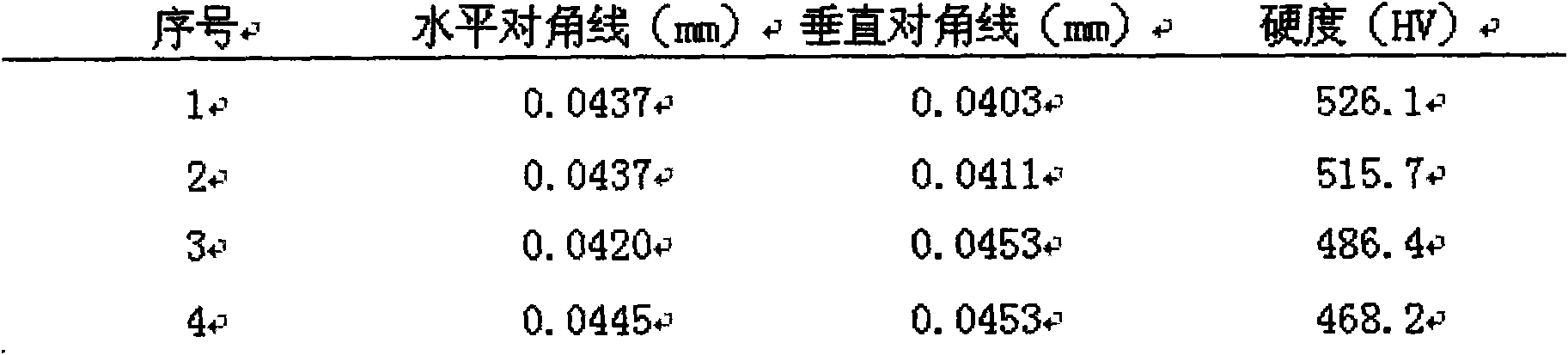

Low-temperature carbonitriding catalyst and carbonitriding method thereof

InactiveCN102125862AHigh surface hardnessImprove wear resistancePhysical/chemical process catalystsSolid state diffusion coatingRare earthTitanium

The invention provides a low-temperature catalyst and a carbonitriding method thereof. The catalyst comprises the following components in percent by weight: 10-15 percent of ammonium chloride, 1-5 percent of titanium sponge, 8-13 percent of rare earth, 0.1-2.5 percent of solid chromate, 0.01-1.5 percent of aluminum powder and the balance of quartz sand. The carbonitriding method comprises the following steps of: weighting the ammonium chloride, the titanium sponge, the rare earth, the solid chromate, the aluminum powder and the quartz sand as raw materials, grinding and mixing uniformly to form the catalyst; and mixing a cleaned workpiece with the catalyst uniformly and then charging into a furnace together for compound nitriding. The low-temperature catalyst and the carbonitriding method thereof are used for carrying out compound nitriding on a carbonitriding process by adopting the catalyst, and further improve surface hardness, wear resistance and corrosion resistance of a workpiece while reducing carbonitriding temperature and shortening carbonitriding time.

Owner:CENT SOUTH UNIV

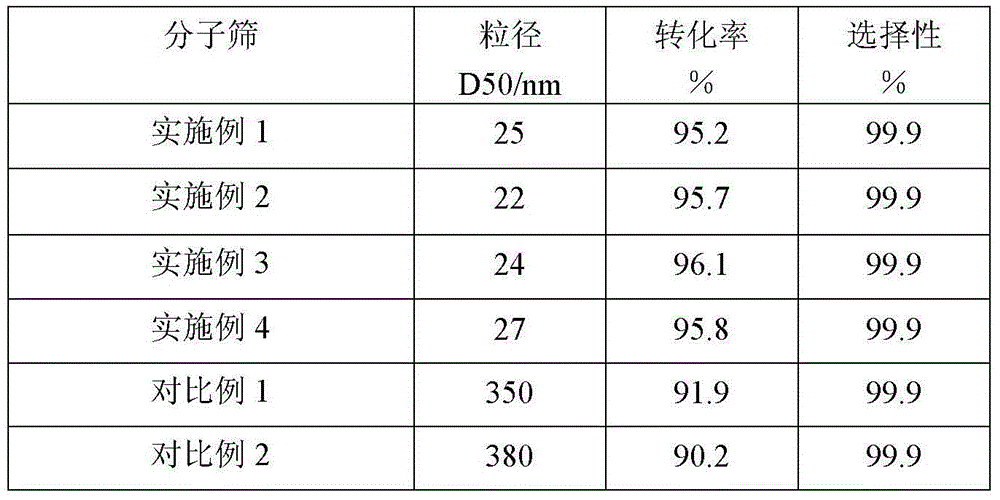

Preparation method of nanoscale titanium silicalite molecular sieve

ActiveCN104528760AMinimizes adverse effects of hydrolysis rate mismatchLarge specific surface areaMaterial nanotechnologyCrystalline aluminosilicate zeolitesMolecular sieveTitanium

The invention provides a preparation method of a nanoscale titanium silicalite molecular sieve. The preparation method comprises adding a proper amount of organic alkali to the molecular sieve after pre-crystallization and then continuously performing a hydrothermal crystallization process to obtain the molecular sieve product. The preparation method is capable of obtaining the molecular sieve product smaller in particle size, larger in specific surface area and more excellent in catalytic performance.

Owner:CHINA TIANCHEN ENG +1

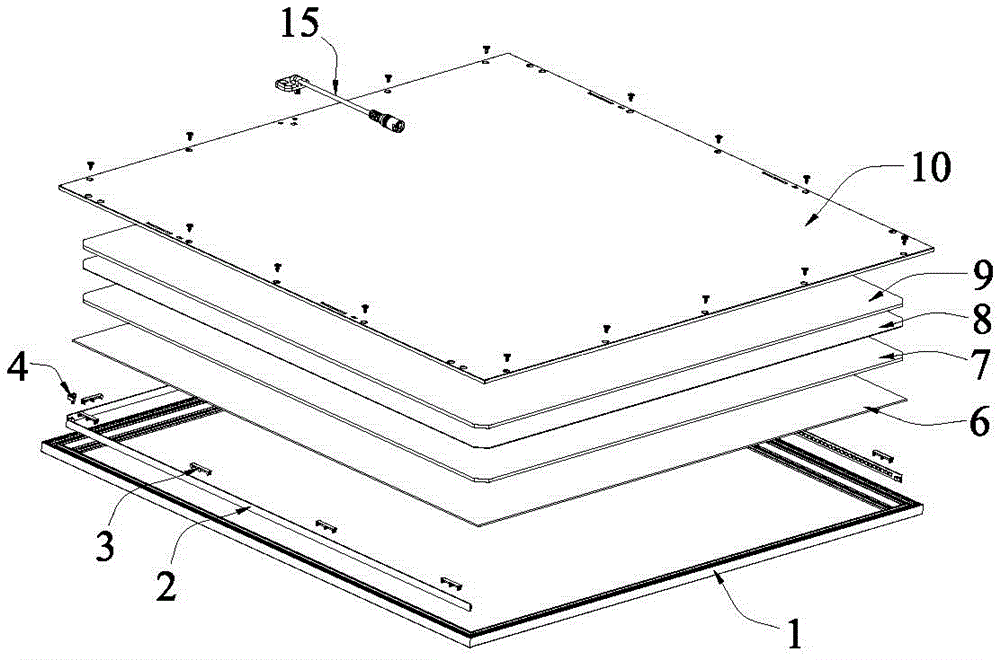

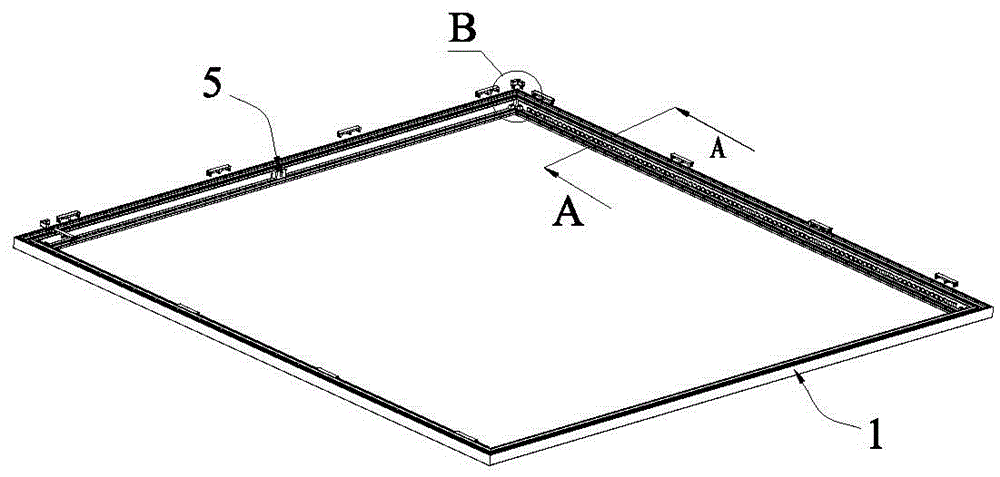

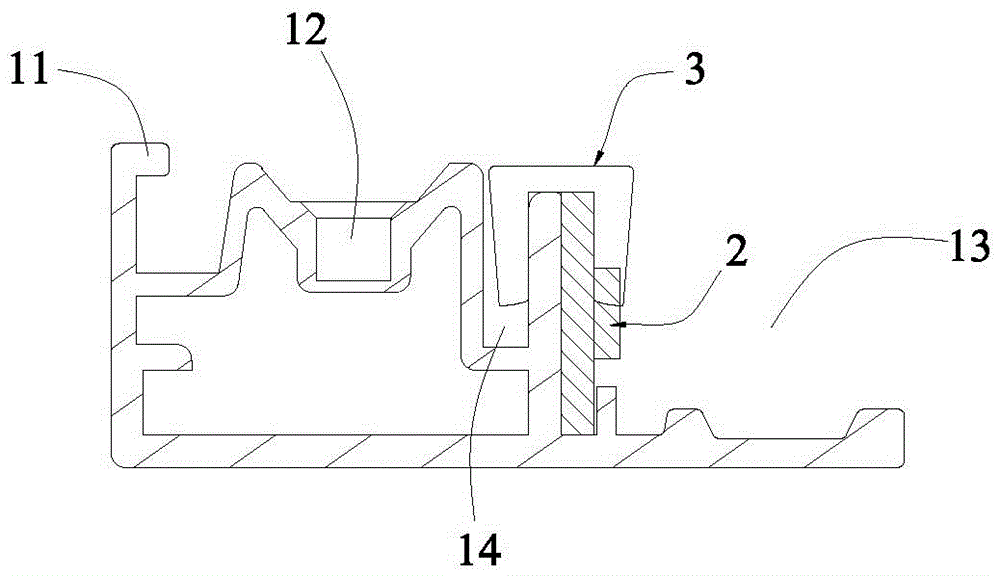

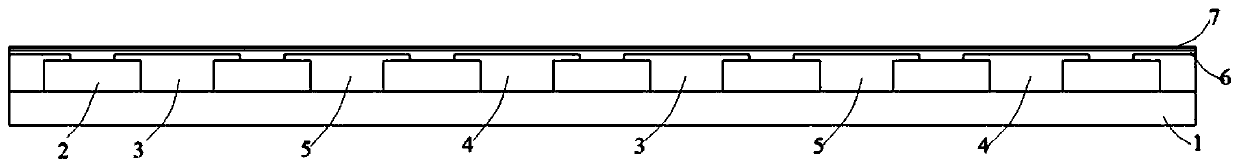

Automatic assembly LED side light-emitting panel lamp and assembly method thereof

InactiveCN106016017AQuick fixQuick connectionMechanical apparatusLighting support devicesLight guideEngineering

The invention discloses an automatically assembled LED side-emitting panel light and an assembly method thereof, which comprises a frame body with an inner cavity, a light bar, a light bar fastener, a light bar plug terminal, a power supply connection terminal, a diffusion plate, and a light guide plate , reflective paper, elastic body pressing plate and back plate; the structure design of the present invention is ingenious and reasonable, the light bar can be quickly fixed on the frame through the light bar fastener, and each The light bar realizes fast connection and conduction. By locking the screws, the diffuser plate, light guide plate, reflective paper and elastic compression plate can be quickly fixed on the frame through the back panel, effectively saving the traditional complicated glue and welding wires Wiring and other processes not only effectively simplify the traditional assembly process and improve production efficiency, but also help reduce production costs and enhance the overall competitiveness of enterprises. The process of the method provided by the invention is simple, and robots can be used to replace human hands to realize automatic assembly, which greatly improves product assembly efficiency and quality consistency.

Owner:DOANGUAN LEWEI ENERGY SAVING TECH CO LTD

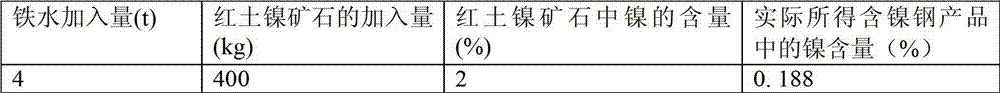

Nickel-containing steel production process

InactiveCN103045790ASimple production processSaving smeltingManufacturing convertersElectric furnaceAlloyIron alloys

The invention relates to a nickel-containing steel production process. The process comprises the following steps: preparing molten iron with the temperature of 1400-1520 DEG C in a blast furnace, transferring the molten iron into a converter or an electric furnace, and adding nickel-containing minerals into the converter or the electric furnace to enable the nickel-containing minerals to contact with the molten iron; and heating the nickel-containing minerals and the molten iron to 1400-1600 DEG C for smelting. The process provided by the invention fully optimizes a conventional nickel-containing steel production process, saves the smelting and production process of nickel-iron and metallic nickel, ensures nickel yield by using nickel ore to replace nickel-iron alloy and metallic nickel while significantly reducing the cost of production, improves the production efficiency, reduces economic investment, saves a great amount of raw materials, and is suitable for popularization and application in the fields of nickel-containing steel smelting.

Owner:河北节能耐火材料集团有限公司

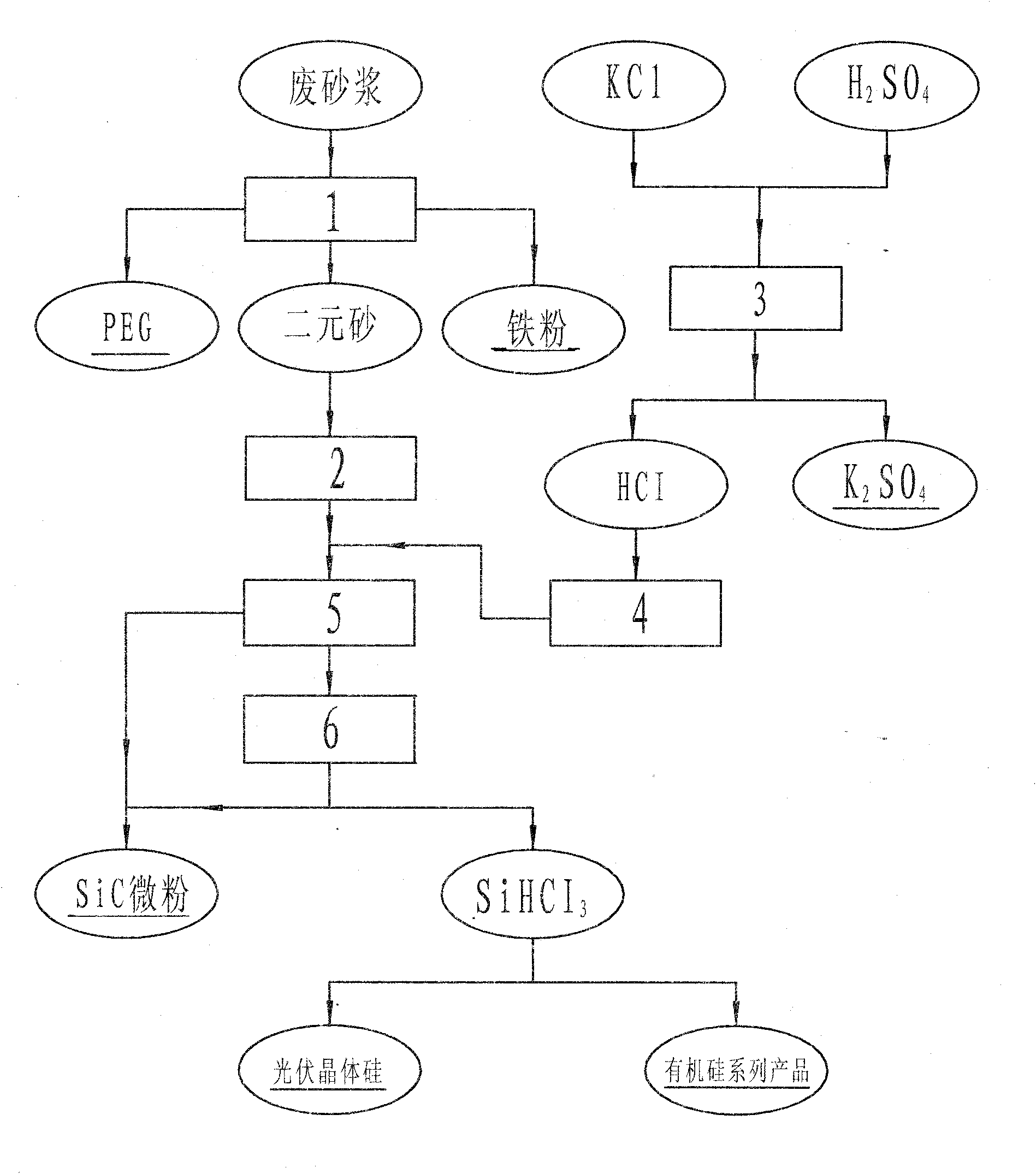

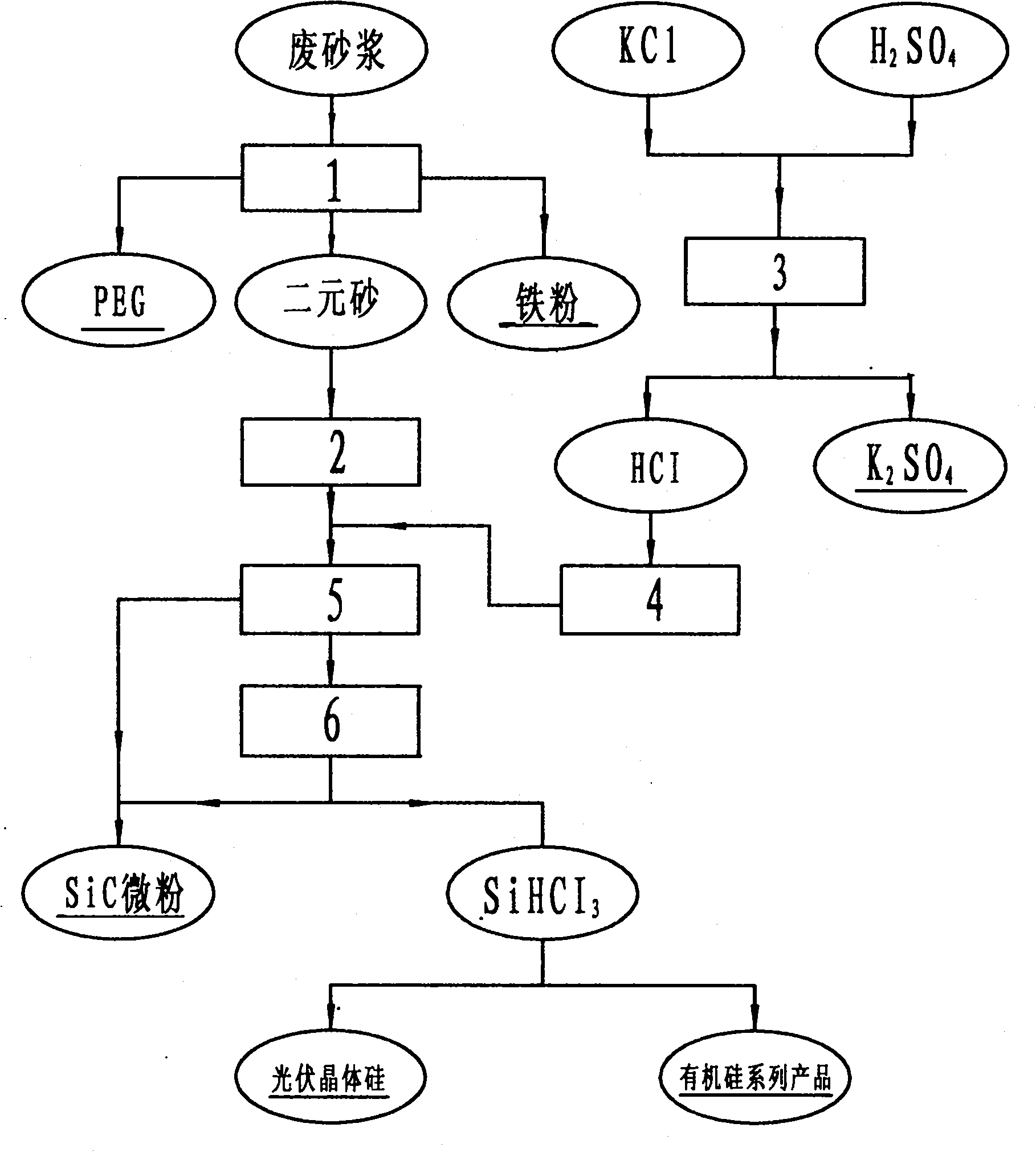

Method for producing trichlorosilane by utilizing photovoltaic crystalline silicon processing waste mortar

InactiveCN102408114ASimple processSolve the fluidization problemHalogenated silanesPolyethylene glycolRotational flow

The invention relates to a method for producing trichlorosilane by utilizing photovoltaic crystalline silicon processing waste mortar, which comprises the following steps of: separating the photovoltaic crystalline silicon processing waste mortar according to application number 201110101064.7<novel method of comprehensively treating photovoltaic crystalline silicon processing waste mortar>, and recovering PEG (polyethylene glycol) and iron to obtain binary sand containing Si and SiC; carrying out double replacement reaction to potassium chloride and sulfuric acid to obtain potassium sulfate; freezing, dehydrating and preheating byproduct HCl to obtain qualified HCl gas, using the HCl gas to carry the binary sand to an air stream bed reactor to form rotational flow, and separating and precipitating SiC favorable for reaction and non reaction of Si+3HCl=SiHCl3+H2; using the reaction product to carry the non reaction SiC micropowder to a separation purification system, and separating by a dust collection device to recover the SiC micropowder; and separating and purifying according to different physicochemical properties of Si chloride to obtain high-purity SiHCl3, which is used for preparing photovoltaic crystalline silicon materials and organosilane of series of products of organic silicon and alkyl, aryl and organic functional group chlorosilane and the like.

Owner:QINGHAI FUZHAO LITHIUM ANODE MATERIALS

Leak-proof patch of tubeless tire and production process thereof

InactiveCN103952092AOutstanding and Beneficial Technical EffectsSave moneyNon-macromolecular adhesive additivesFilm/foil adhesivesElastomerTubeless tire

The invention belongs to the technical field of tubeless tires and relates to a leak-proof patch of a tubeless tire and a production process thereof. The production process comprises the steps of weighing raw materials; heating a reaction kettle to 130-250 DEG C, then putting the weighed raw materials into the reaction kettle in batches or once, and stirring to obtain uniform liquid raw materials; laying a layer of release paper at the bottom of a box body, firstly injecting the liquid raw materials into the box body to form a layer of liquid raw materials, further laying a layer of release paper on the upper surface of the layer of liquid raw materials in the box body, then flattening the liquid raw material injected into the box body, and cooling to room temperature to form the leak-proof patch of the tubeless tire. The leak-proof patch of the tubeless tire is prepared from the following substances in parts by weight: 29-49 parts of elastomer, 41-52 parts of tackifier, 19-28 parts of rubber additive, 9-18 parts of leak-proof additive and 1-4 parts of dyeing agent. The production process provided by the invention has the advantages of simple production process, as well as convenience in use and convenience in storage and transportation of the produced leak-proof patch of the tubeless tire.

Owner:陶国华

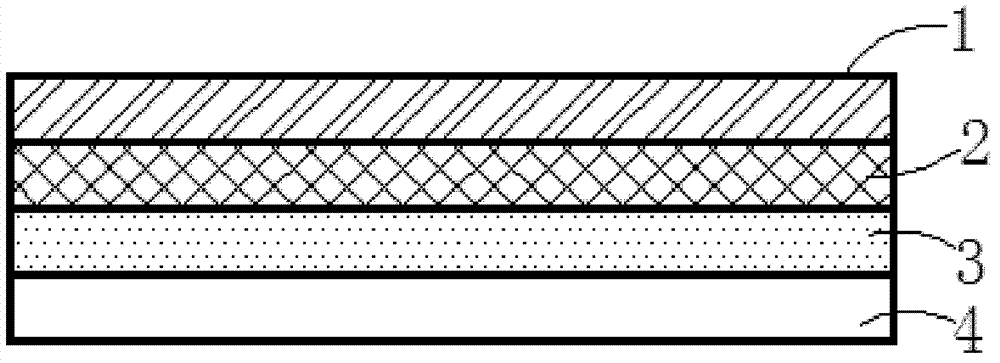

Non-glue single face copper clad laminate with bonding function and manufacturing method thereof

ActiveCN103200771AEasy to useSimplify fitCircuit susbtrate materialsMetal layered productsBonding processCopper

The invention discloses a non-glue single face copper clad laminate with a bonding function and a manufacturing method thereof. After an insulation bonding glue layer is formed on the copper clad laminate, the convenient and efficient non-glue single face copper clad laminate with the bonding function is provided, the non-glue single face copper clad laminate and the insulation bonding glue layer are integrally formed, the non-glue single face copper clad laminate can be used by a customer conveniently, bonding and other operation processes of the customer are simplified, production processes and working hours of the customer are saved, and size stability is good. The insulation bonding glue layer is integrally formed on the non-glue single face copper clad laminate through coating baking, easily produced bubbles or a poor appearance in a traditional pure glue bonding process is avoided, production yield is improved, and production cost is reduced. The non-glue single face copper clad laminate with the bonding function is suitable for a multi-layer production technique and other FPC laminates needing the combination of non-glue base materials and pure glue.

Owner:SONGYANG ELECTRONICS MATERIAL KUSN

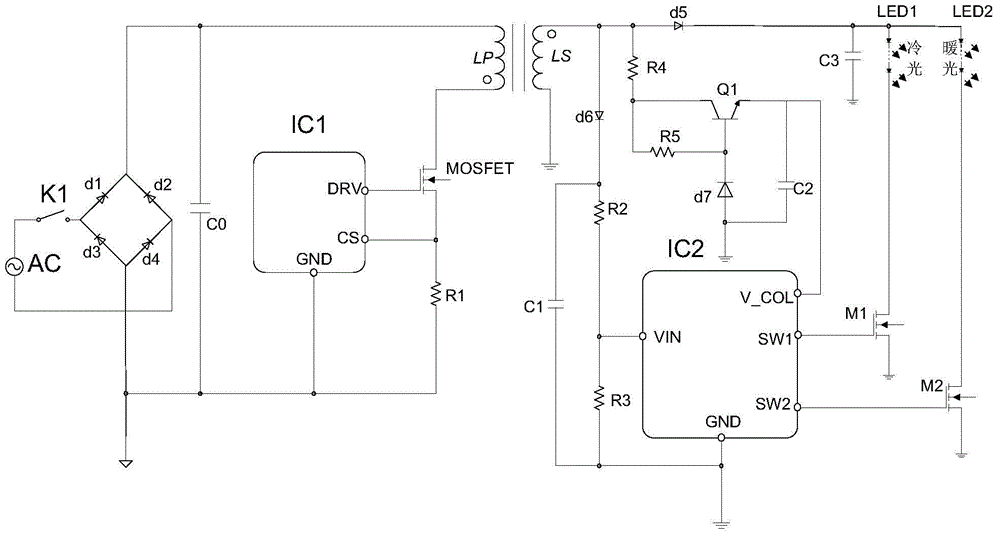

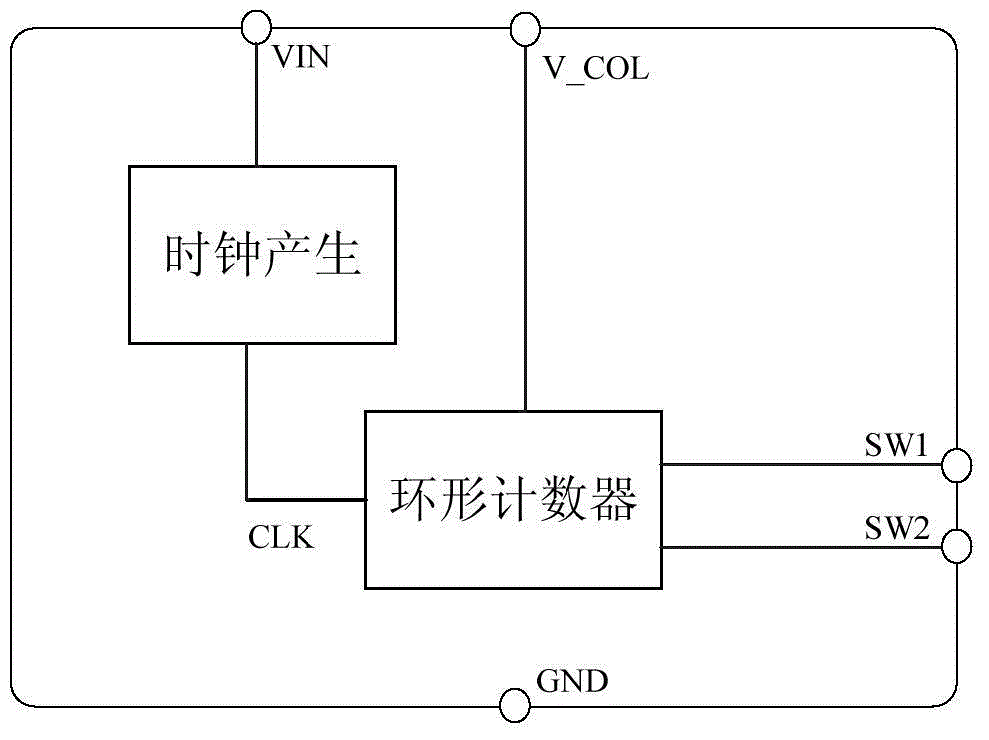

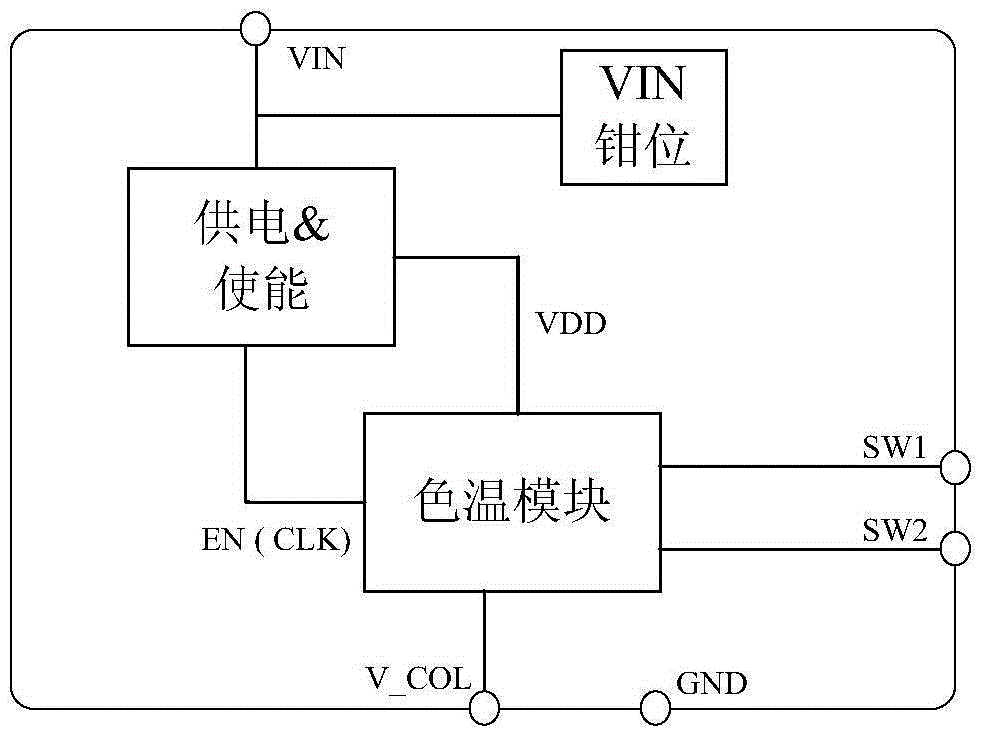

LED (Light Emitting Diode) color temperature regulating chip and application circuit thereof

ActiveCN104394632ASimple structureSaving productivityElectric light circuit arrangementColor temperatureLED circuit

The invention provides an LED (Light Emitting Diode) color temperature regulating chip. The LED color temperature regulating chip comprises a clamping module, a power supply and enabling module and a color temperature module; the clamping module is used for enabling the chip power supply end VIN to be maintained at the clamping voltage; an input end of the power supply and enabling module is connected with the chip power supply end VIN and used for generating clock namely enabling signals EN and providing a chip internal low voltage power supply VDD; the input of the color temperature module is the enabling signals EN; the power is supplied for the color temperature module through the chip internal low voltage power supply VDD; the color temperature module is connected with a second power supply end V_COL and two control ends SW1 and SW2 of the chip; the color temperature module is used for enabling the high level to be output from the two control ends SW1 and SW2 in turn. According to the LED color temperature regulating chip, the internal structure is simple and reasonable, only a few peripheral devices are required by the application scheme, the cost is low, the application range is wide, and the LED color temperature regulating chip can be applied to multiple structures of LED driving circuits.

Owner:WUXI SI POWER MICRO ELECTRONICS

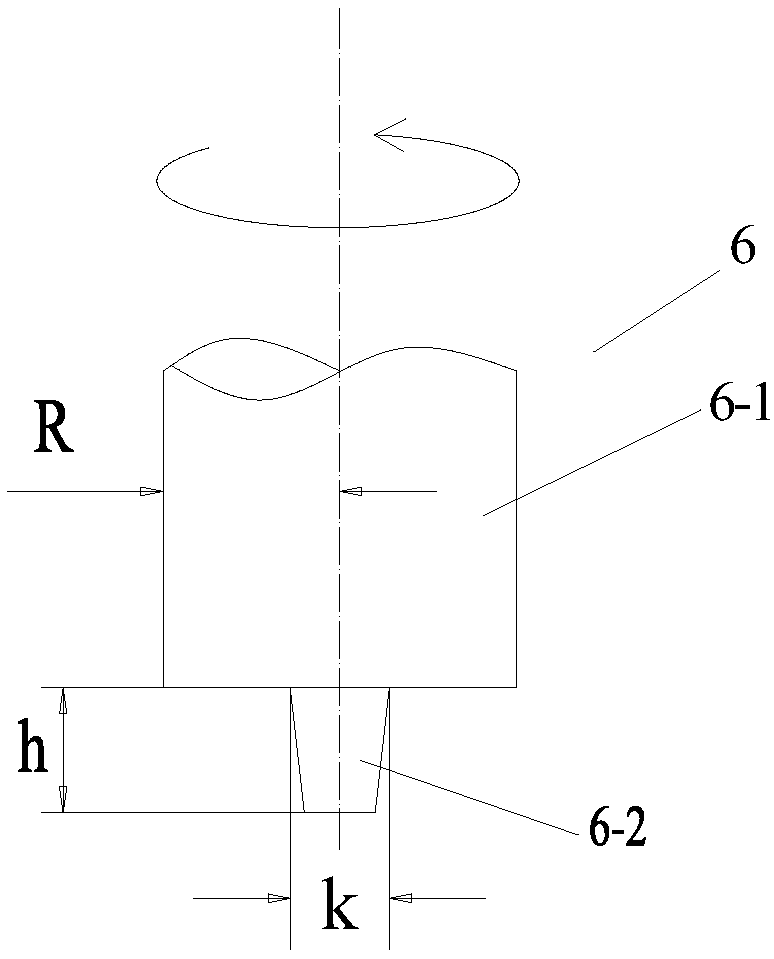

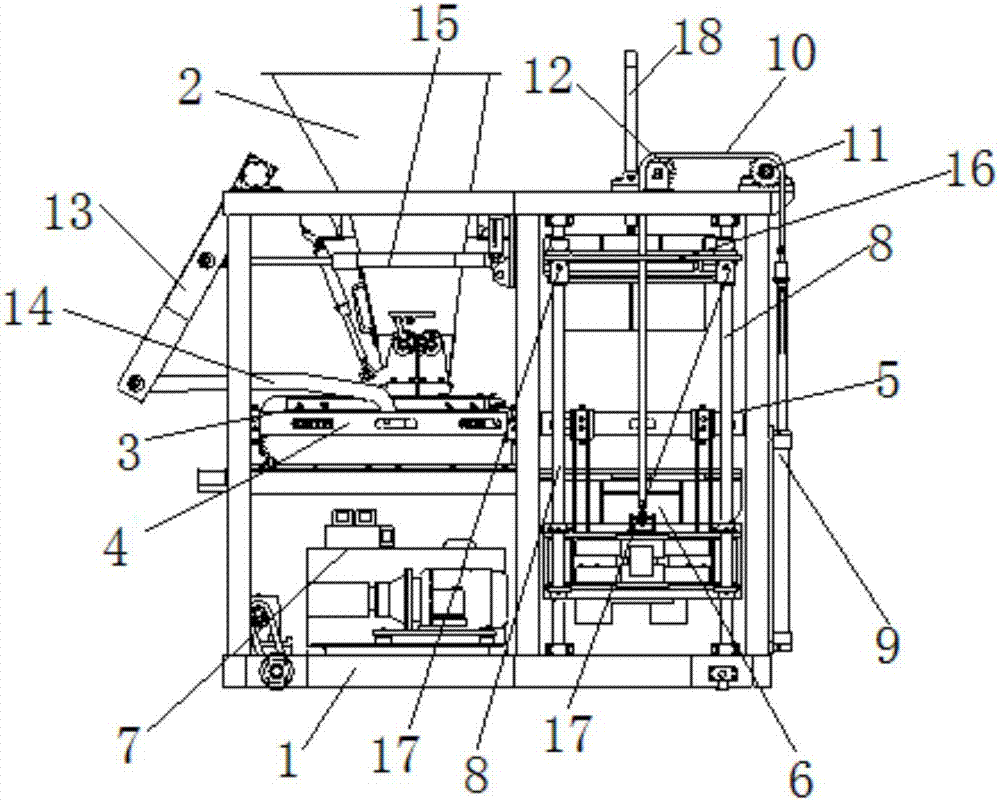

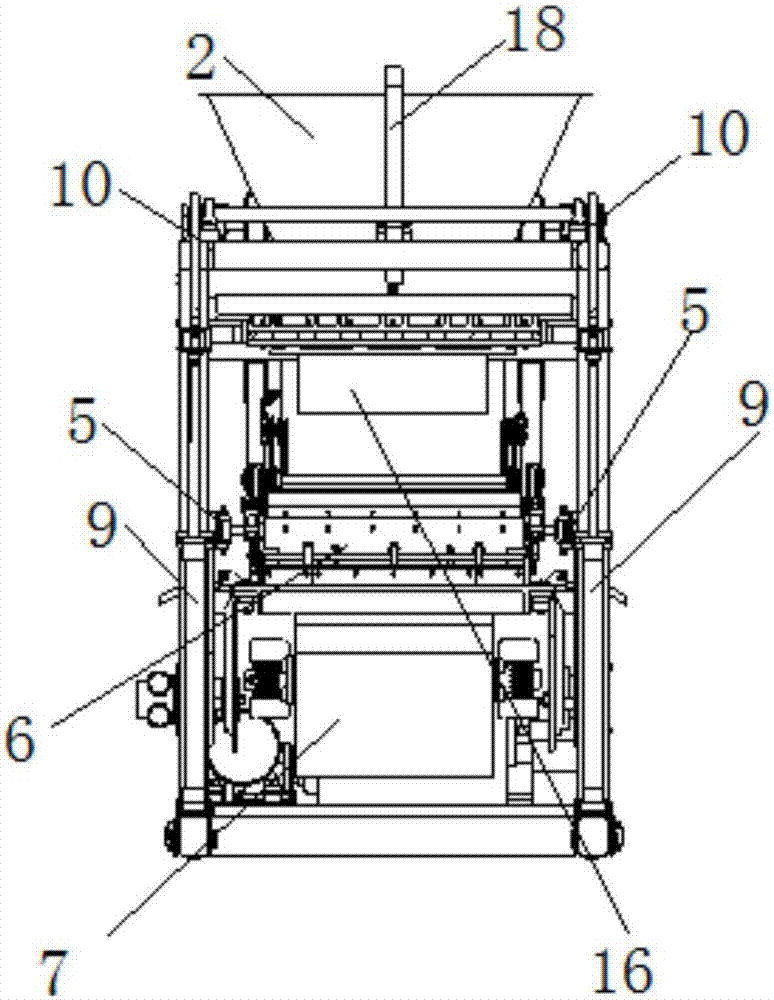

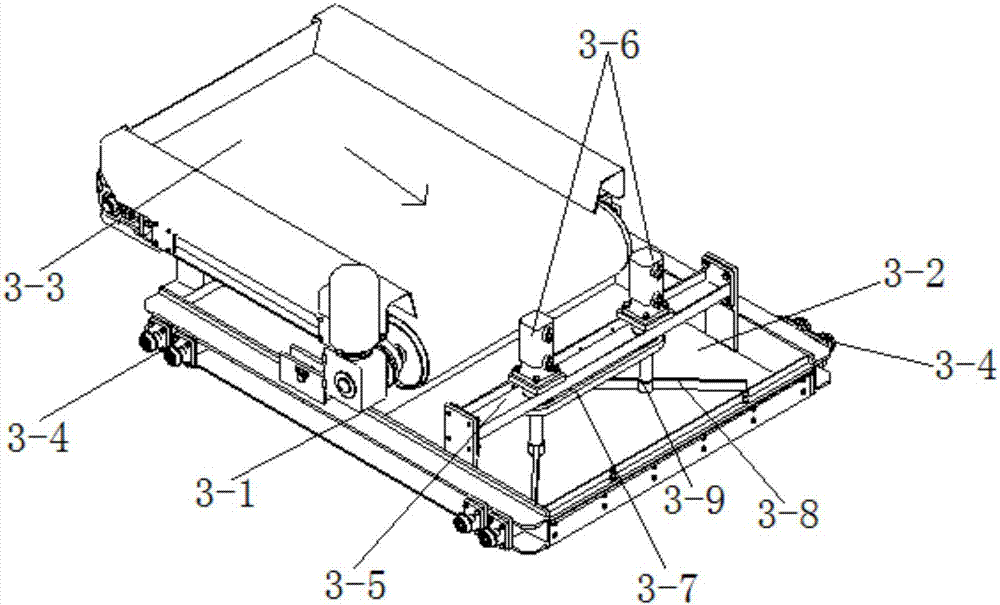

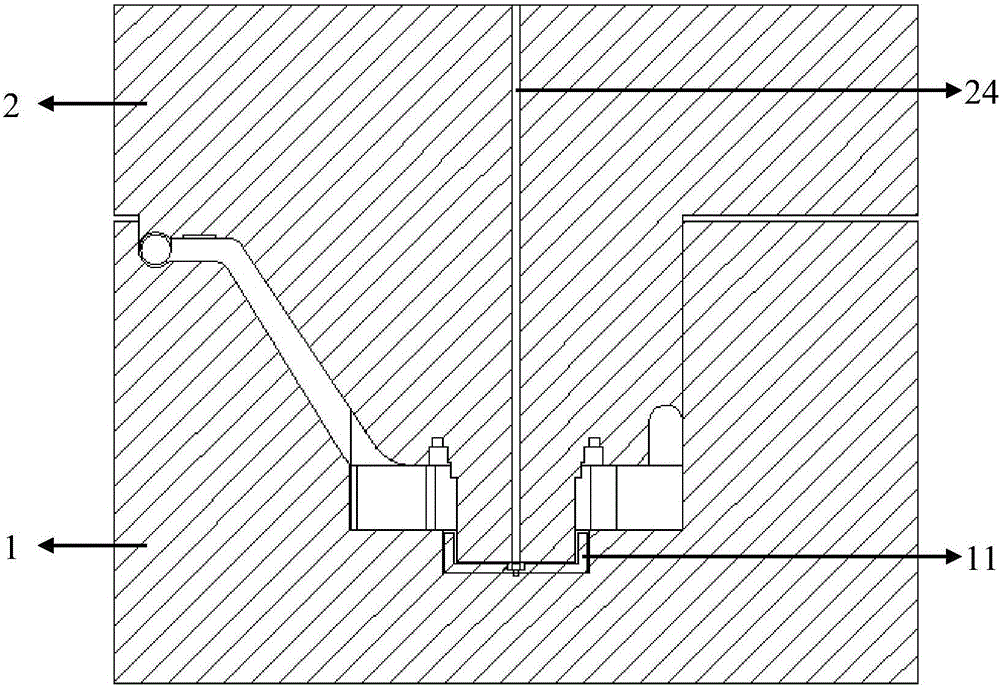

Rotary die type concrete product forming machine

ActiveCN107088950AImprove inner qualityRealize automatic mechanized productionDischarging arrangementFeeding arrangmentsEngineeringMaterial storage

The invention discloses a rotary die type concrete product forming machine. The rotary die type concrete product forming machine comprises a rack. A material storage hopper is arranged at the upper end of the rack. A material distributing trolley is arranged below the material storage hopper. Two parallel guide rails a and two parallel guide rails b located at the same height position with the guide rails a are arranged at the middle portion of the rack, and the guide rails a and the guide rails b are sequentially spliced and located on the same straight line. The two guide rails b are arranged on a rotary die vibration forming device. The rotary die vibration forming device is connected with a demoulding mechanism. A forming press head assembly is arranged above the rotary die vibration forming device. The rotary die vibration forming device is arranged on one side of the material distributing trolley. The material distributing trolley is connected with a material distributing driving device. The material distributing driving device and the demoulding mechanism are located at the two ends of the rack correspondingly. The rotary die vibration forming device, the demoulding mechanism, the forming press head assembly, the material distributing trolley and a hydraulic station providing power for the material distributing drive device are further arranged at the bottom of the rack. The problems that an existing forming machine cannot achieve uniform material distributing, and demoulding is difficult are solved.

Owner:BEIJING REIT TECH DEV

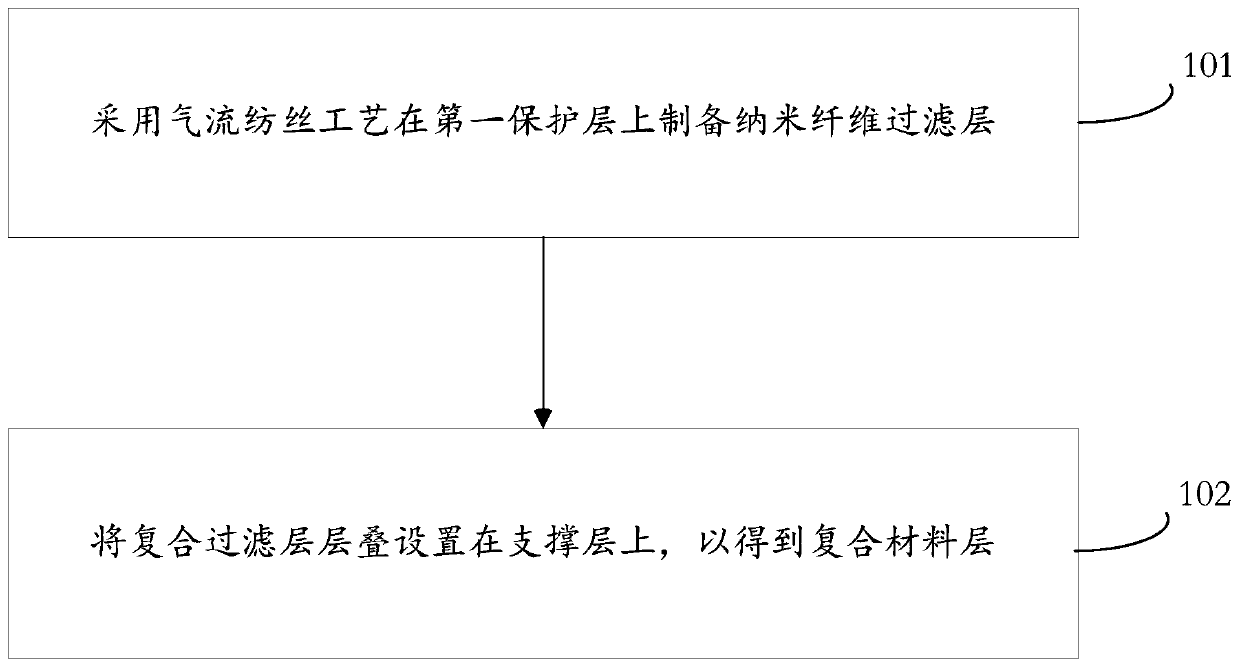

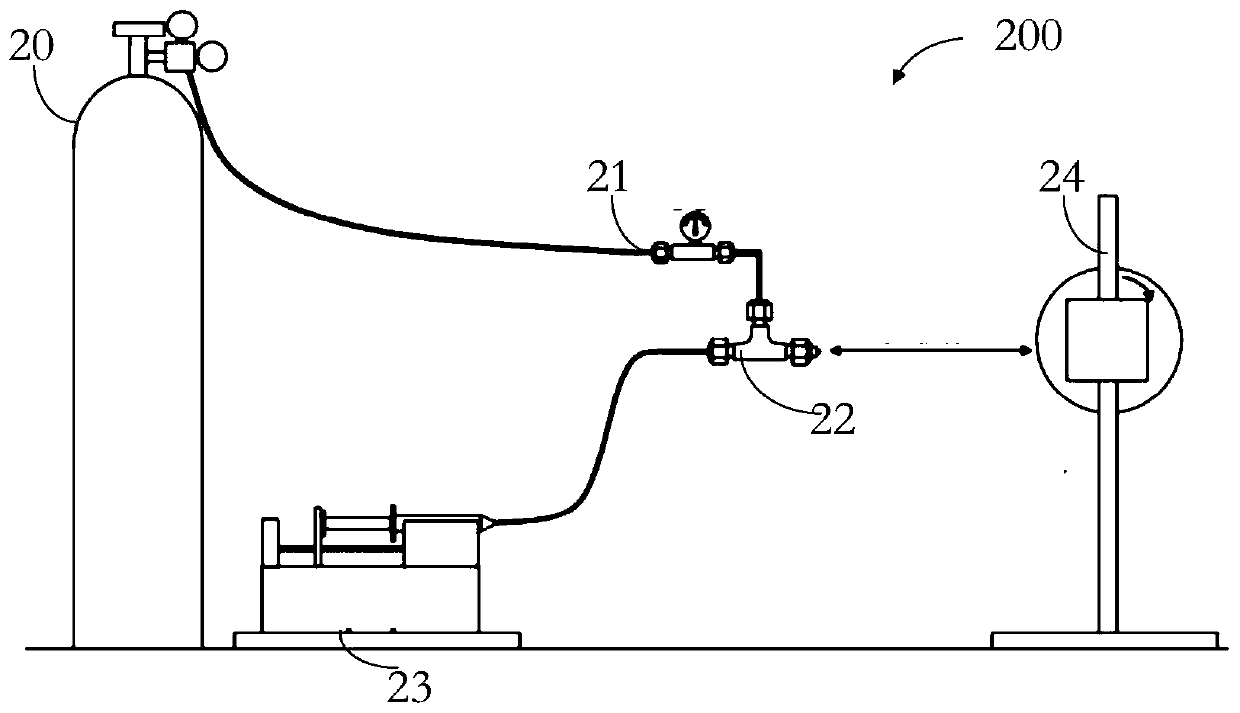

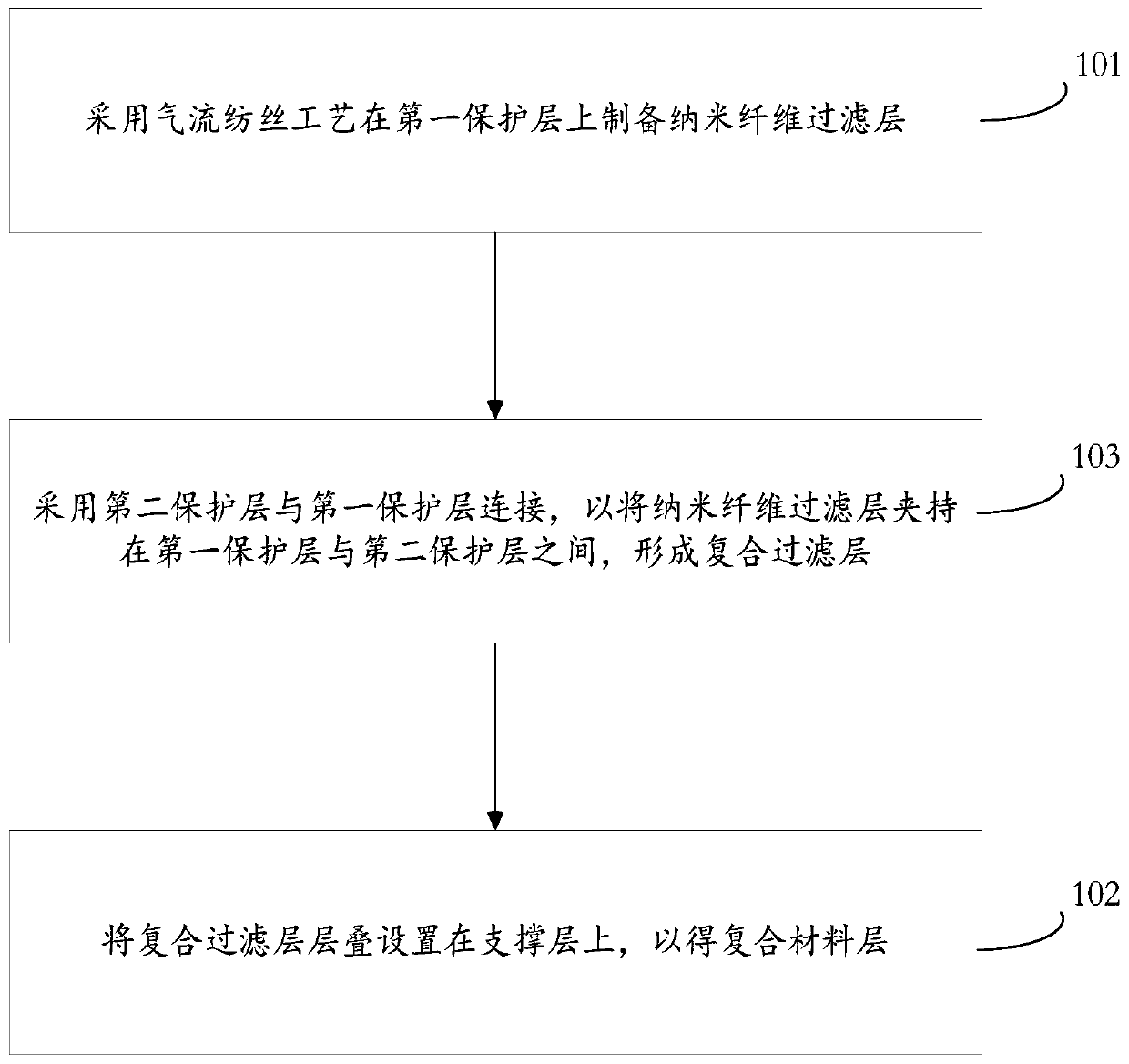

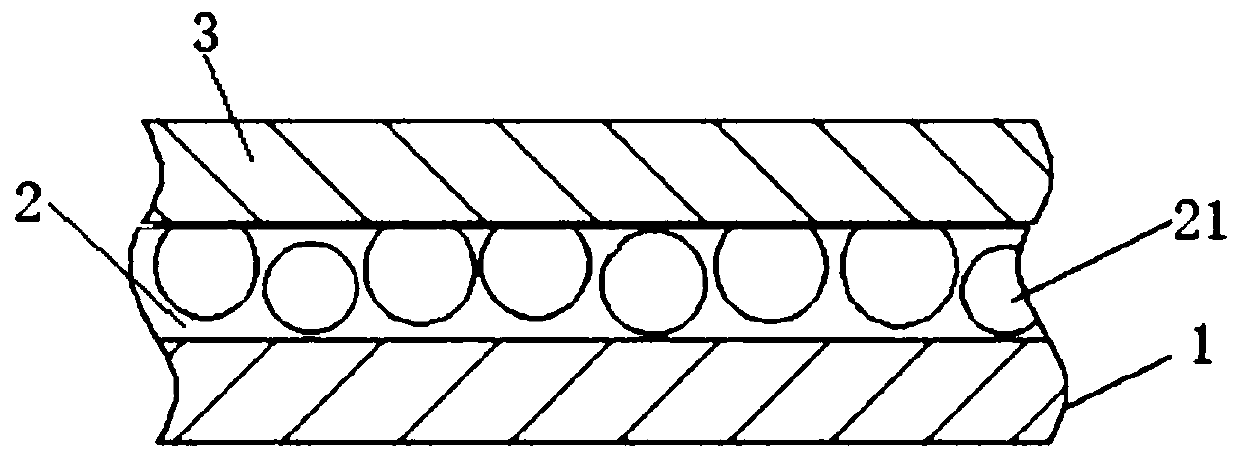

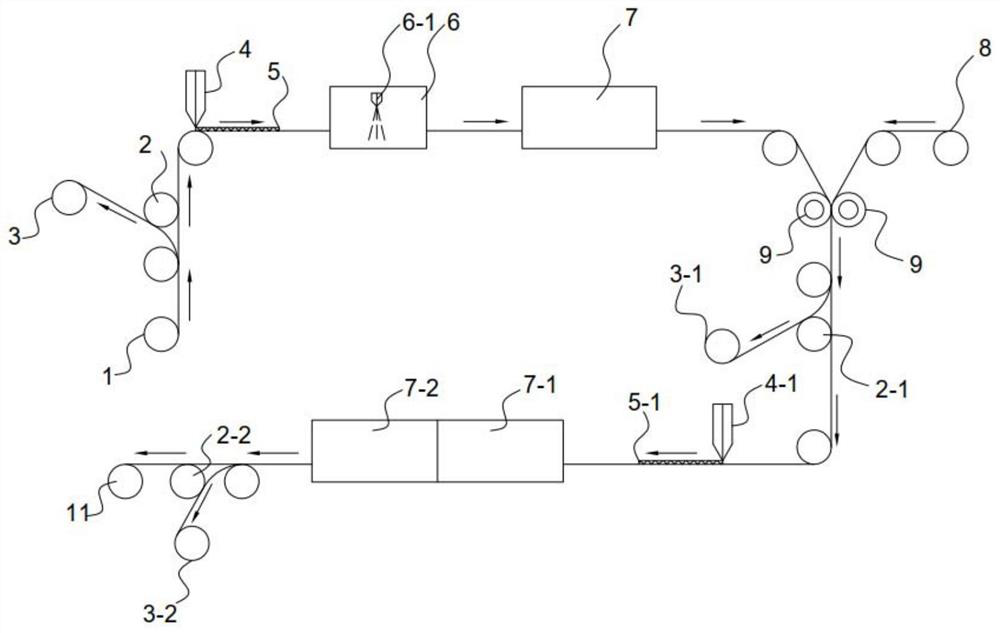

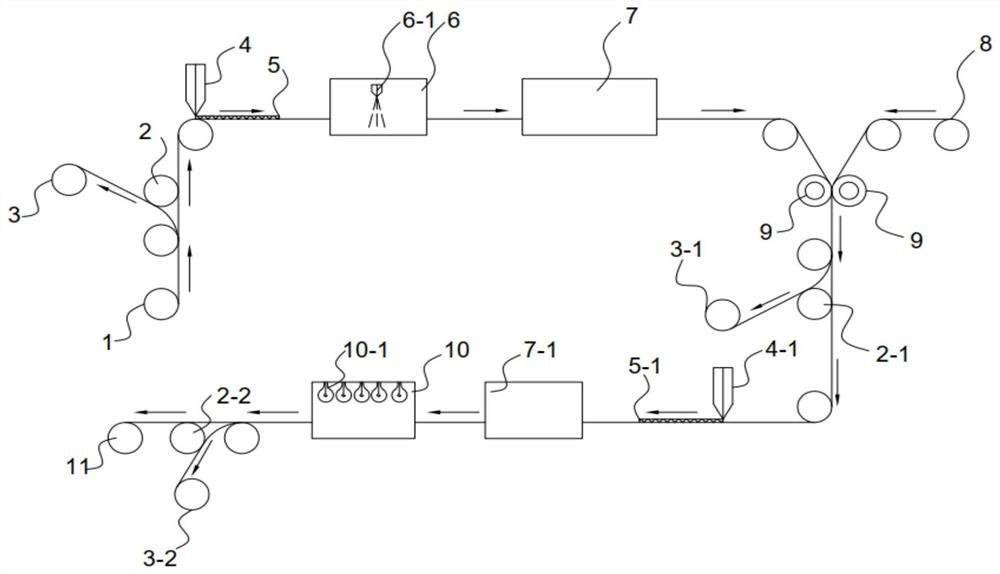

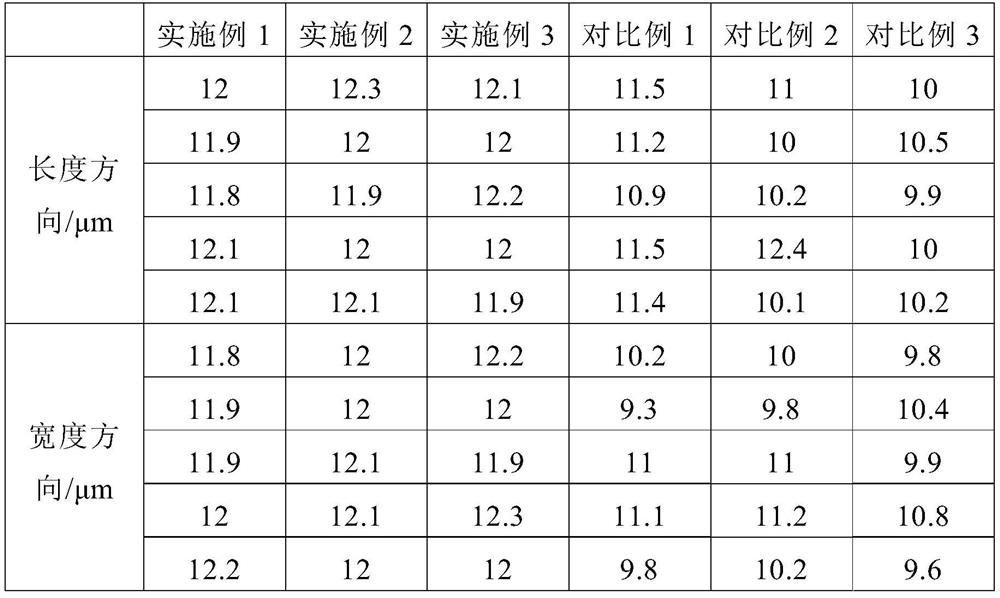

Preparation method of composite material layer, composite material layer and mask

InactiveCN111298520ASaving productivitySave costBreathing filtersSynthetic resin layered productsComposite filterFiber

The embodiment of the invention provides a preparation method of a composite material layer, the composite material layer and a mask. The preparation method comprises the following steps: preparing ananofiber filter layer on a first protective layer by adopting an airflow spinning process, connecting the second protective layer with the first protective layer, so that the nanofiber filter layer is clamped between the first protective layer and the second protective layer and a composite filter layer is formed, and laminating the composite filter layer on the support layer to obtain the composite material layer. The embodiment of the invention provides the preparation method of the composite material layer, the composite material layer and the mask. The nanofiber filter layer on the firstprotective layer is prepared by adopting an airflow spinning process, and the composite material layer is used as the core filter layer of the mask, so that the mask can be used for many times after being effectively disinfected and sterilized by alcohol, high temperature, ultraviolet rays, fumigation, boiling and the like, the productivity and the use cost are greatly saved, and the waste and thepost-treatment pollution are reduced.

Owner:昆山柔维环境科技有限公司

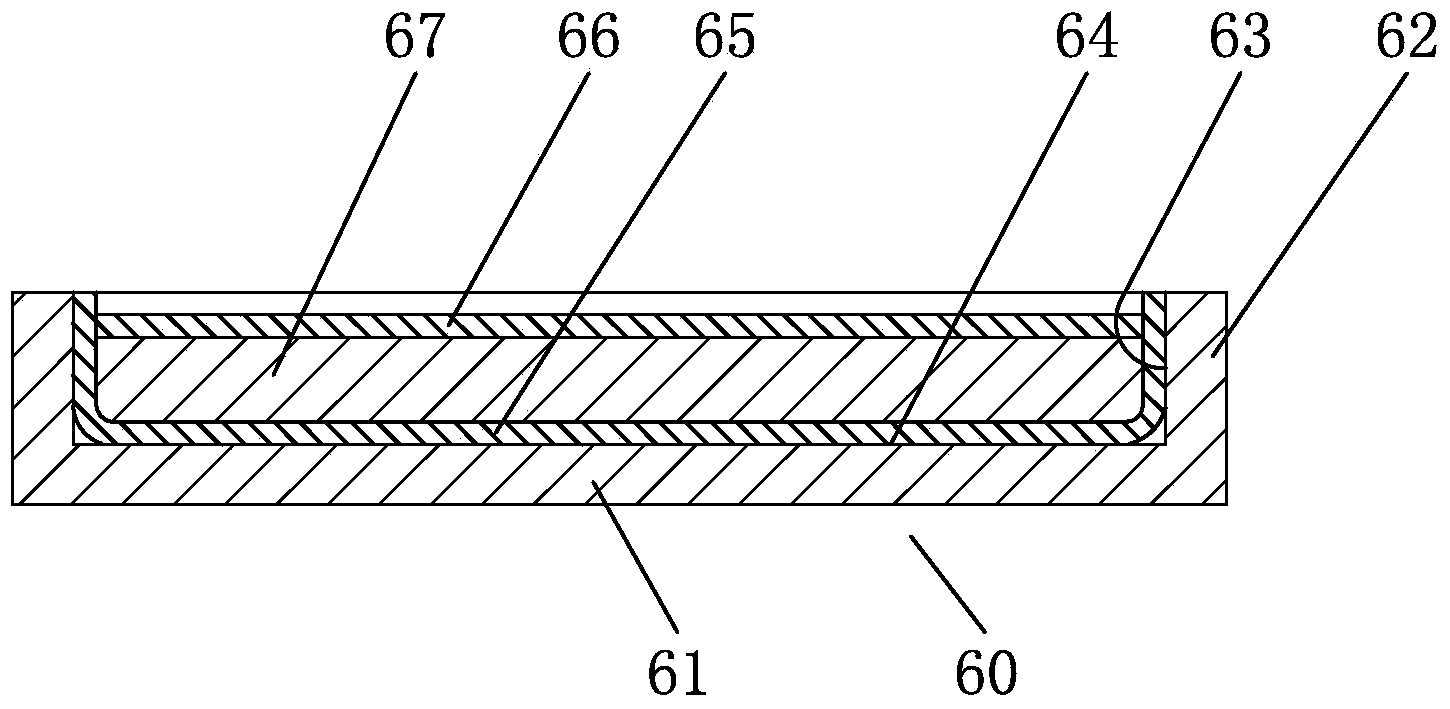

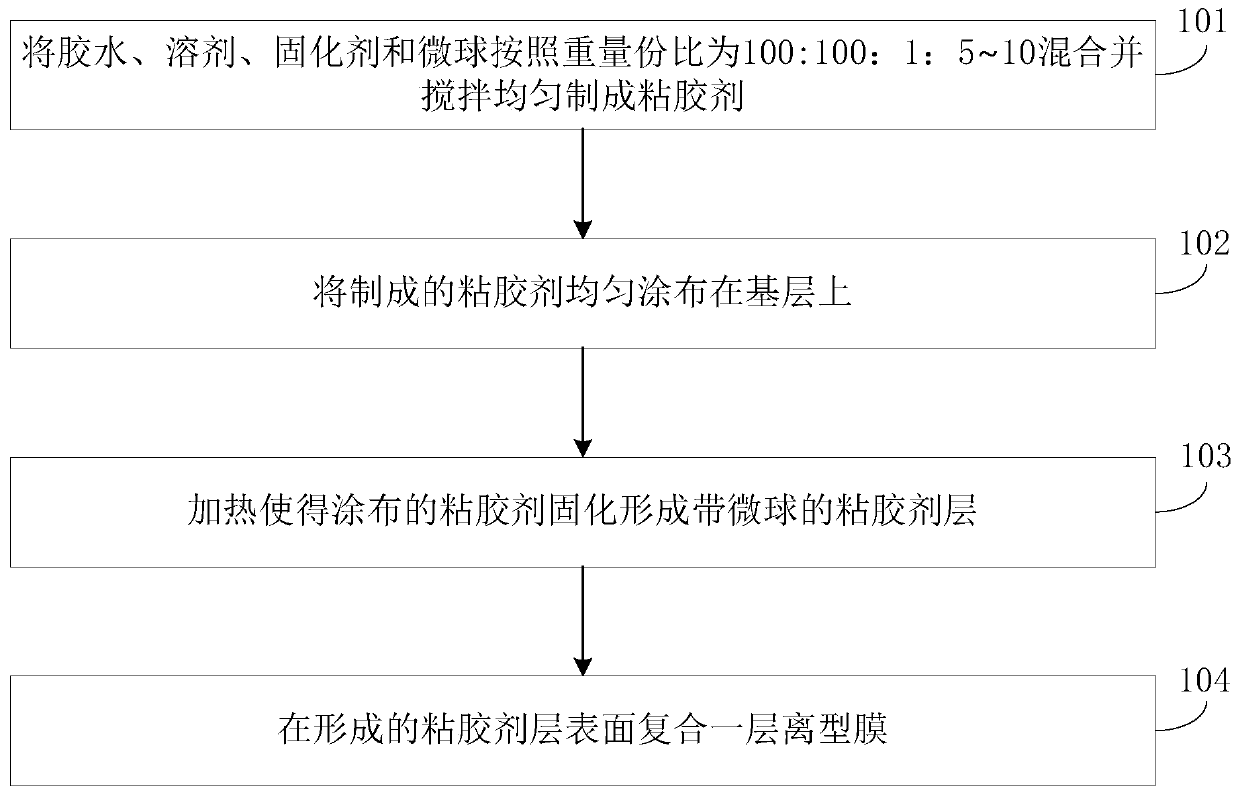

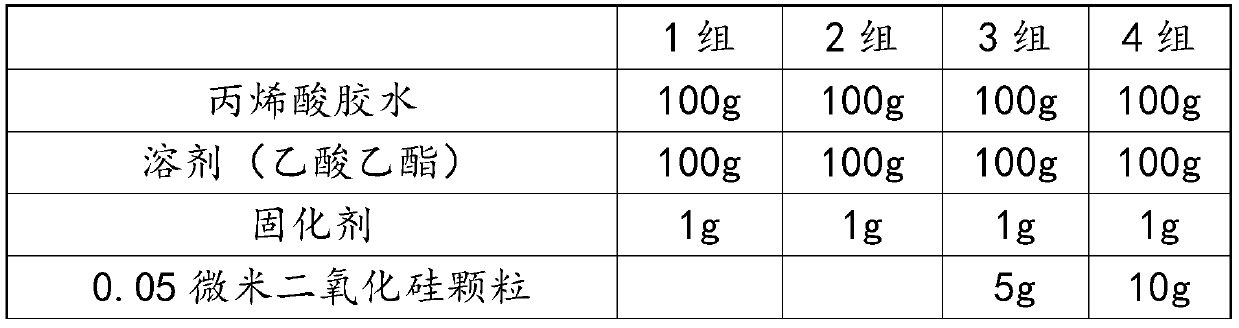

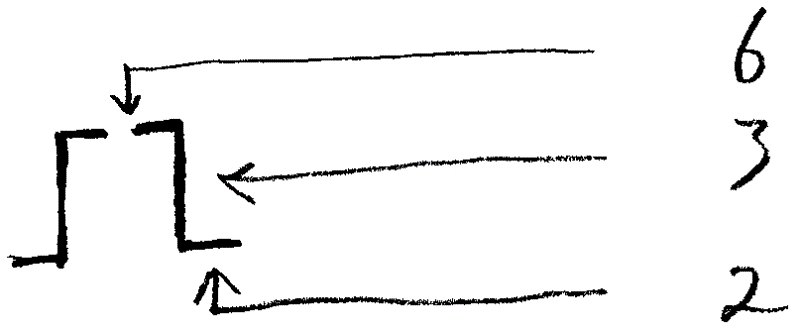

Protective film for fuel cell membrane electrode and preparation method of protective film

ActiveCN110117469AReduce contact areaReduce viscosityNon-macromolecular adhesive additivesFinal product manufactureTectorial membraneReduction treatment

The invention relates to the technical field of fuel cells, in particular to a preparation method of a protective film for a fuel cell membrane electrode. The preparation method comprises the steps ofmixing glue, a solvent, a curing agent and microspheres according to a weight ratio of 100:100:1:(5-10), and uniformly stirring the mixture to prepare an adhesive; uniformly coating a base layer withthe prepared adhesive; heating the base layer to solidify the adhesive used for coating in order to form an adhesive layer with the microspheres; compounding a release film layer on the surface of the formed adhesive layer. The provided protective film is provided with the microspheres attached to the surface of the adhesive layer, and the microspheres form uneven contact points; when the membrane electrode is prepared, the protective film and a proton exchange membrane are in point contact with each other, so that the technical problem is effectively avoided that after baking, the protectivefilm is difficult to peel off or a catalyst with which the proton exchange membrane is coated is taken away when the protective film is peeled off. When the protective film is peeled off, there is noneed to perform viscosity reduction treatment in advance, so that the production processes are simplified and the cost is reduced.

Owner:SHENZHEN SHINING AUTOMATION CO LTD

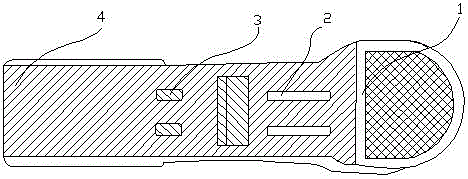

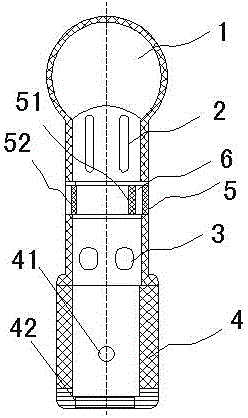

Nailing cap

Owner:胡长存

Laser cladding structure of steam turbine blade air inlet side

InactiveCN104533539AExtended service lifeReduce distortionBlade accessoriesMachines/enginesSteam turbine bladeEngineering

The invention provides a laser cladding structure of a steam turbine blade air inlet side. The problem that according to an existing steam turbine blade steam inlet side laser cladding slope structure, longitudinal sections are the same, so that cladding layers close to the blade tops on the blade longitudinal sections can be subjected to water erosion easily and lose efficacy can be solved. Accordingly, the anti-water-erosion capacity of a blade steam outlet side laser cladding layer is improved, and the service life of a steam turbine blade is prolonged. The structure comprises a laser cladding layer. A cladding slope which extends from the blade top to the blade root is formed in one side of the air inlet side of the steam turbine blade, and the laser cladding layer is arranged in the cladding slope in a cladding mode. The laser cladding structure is characterized in that the width and the thickness of the longitudinal section of the laser cladding layer are reduced gradually to zero from the blade top to the blade root, the length L of the laser cladding layer is 200 mm-900 mm, and the width and the thickness of the longitudinal section of the laser cladding layer are determined by the cladding slope structure.

Owner:WUXI TURBINE BLADE

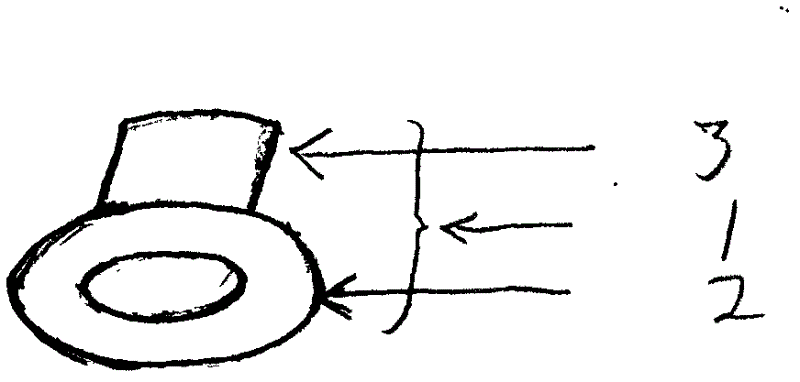

CCM coating process for realizing swelling resistance by using protective back film

ActiveCN112599793AEasy to makeReduce productionMaterial nanotechnologyCell electrodesPtru catalystPhysical chemistry

The invention discloses a CCM coating process for realizing swelling resistance by using a protective back film. The process comprises the following steps: coating a first surface of a proton exchangemembrane with a catalyst slurry, and performing drying to form a first catalyst layer; preparing a protective film with a flexible carrier layer, laminating a layer of protective film with the flexible carrier layer on the first surface of the proton exchange membrane containing the first catalyst layer, and laminating the protective film with the proton exchange membrane; coating the second surface of the proton exchange membrane with the catalyst slurry, and performing drying to form a second catalyst layer, so as to obtain a membrane electrode with a temporary protective membrane; finally,carrying out heat treatment or ultraviolet (UV) irradiation on the membrane electrode with the temporary protective film, and stripping the temporary protective layer to obtain the membrane electrode; and if heat treatment is selected, spraying a nano oxide solution on the surface of the first catalyst layer before the first catalyst layer is dried. In the membrane electrode preparation process,the swelling of the proton exchange membrane is effectively avoided, the preparation process is simple, the production efficiency is high, and the battery performance is excellent.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

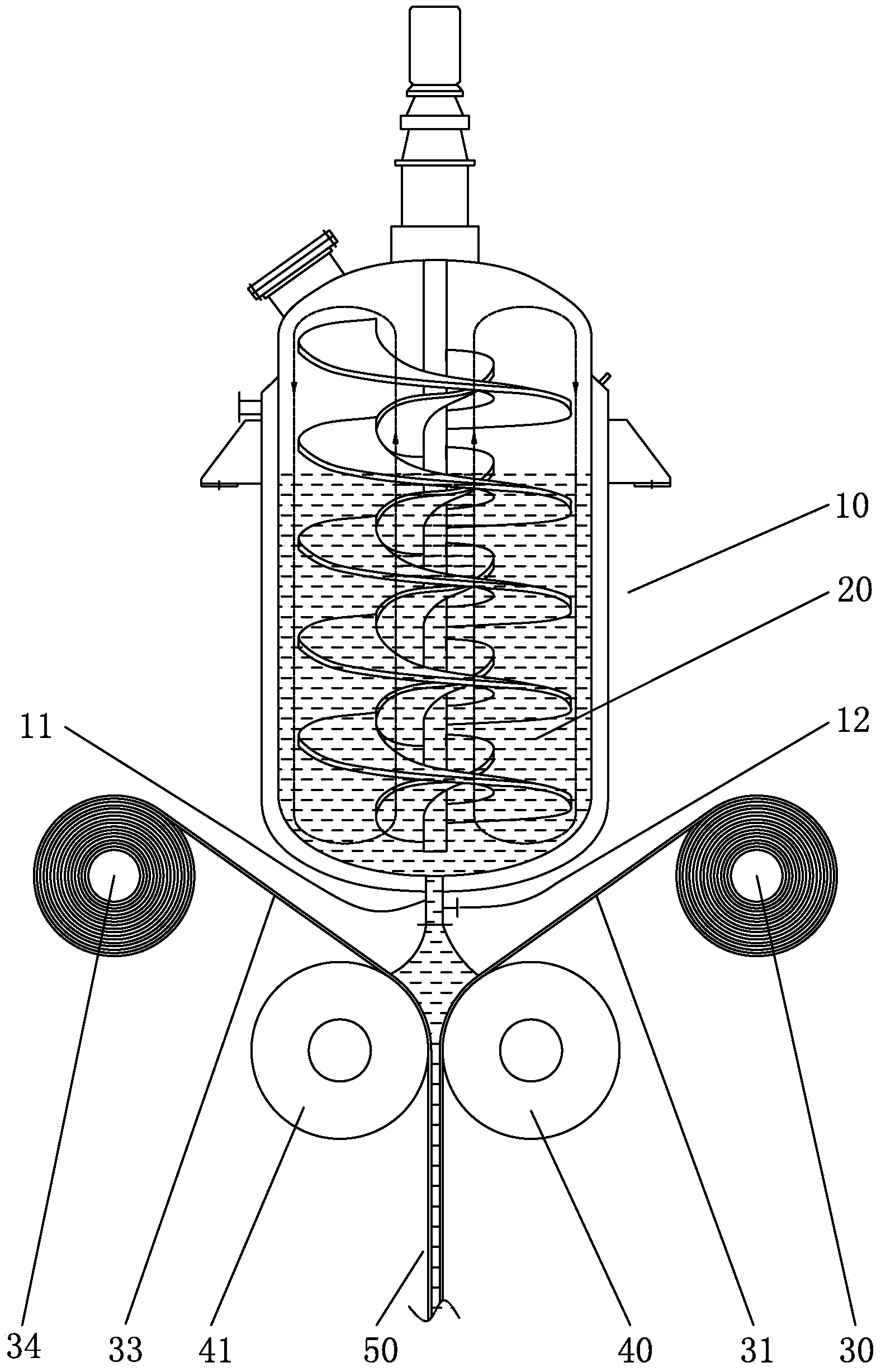

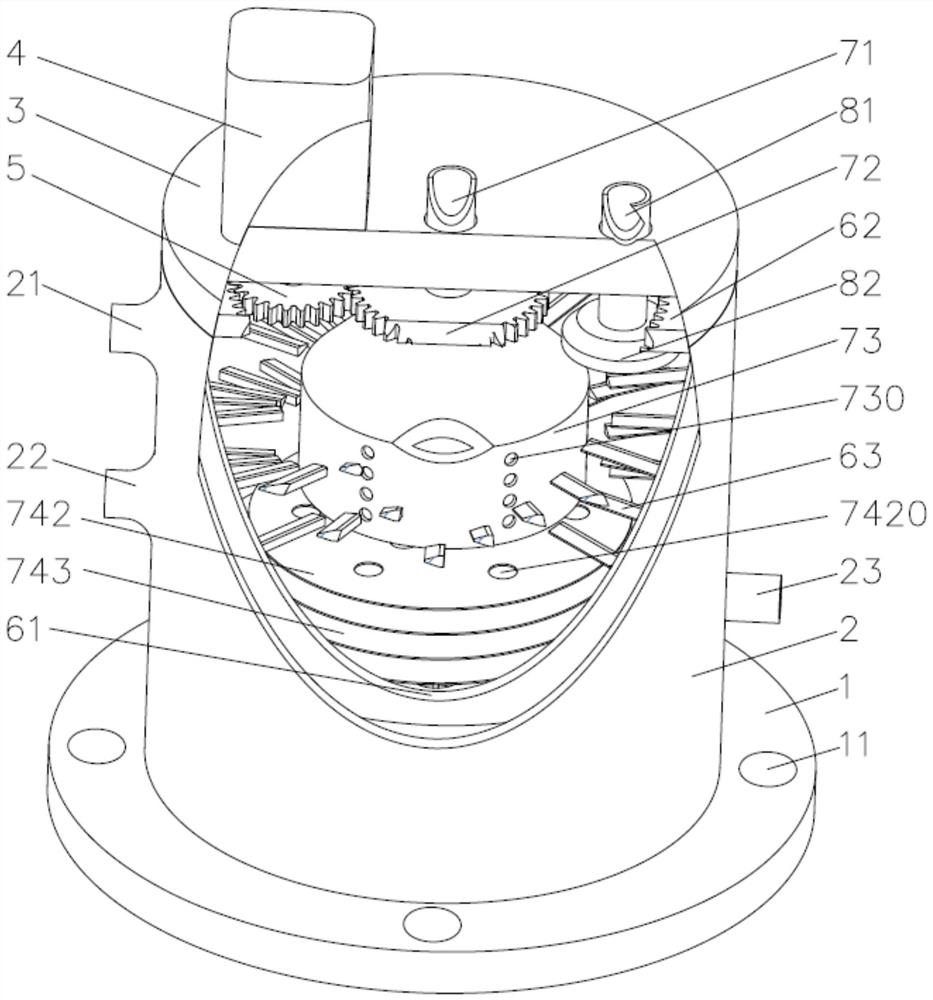

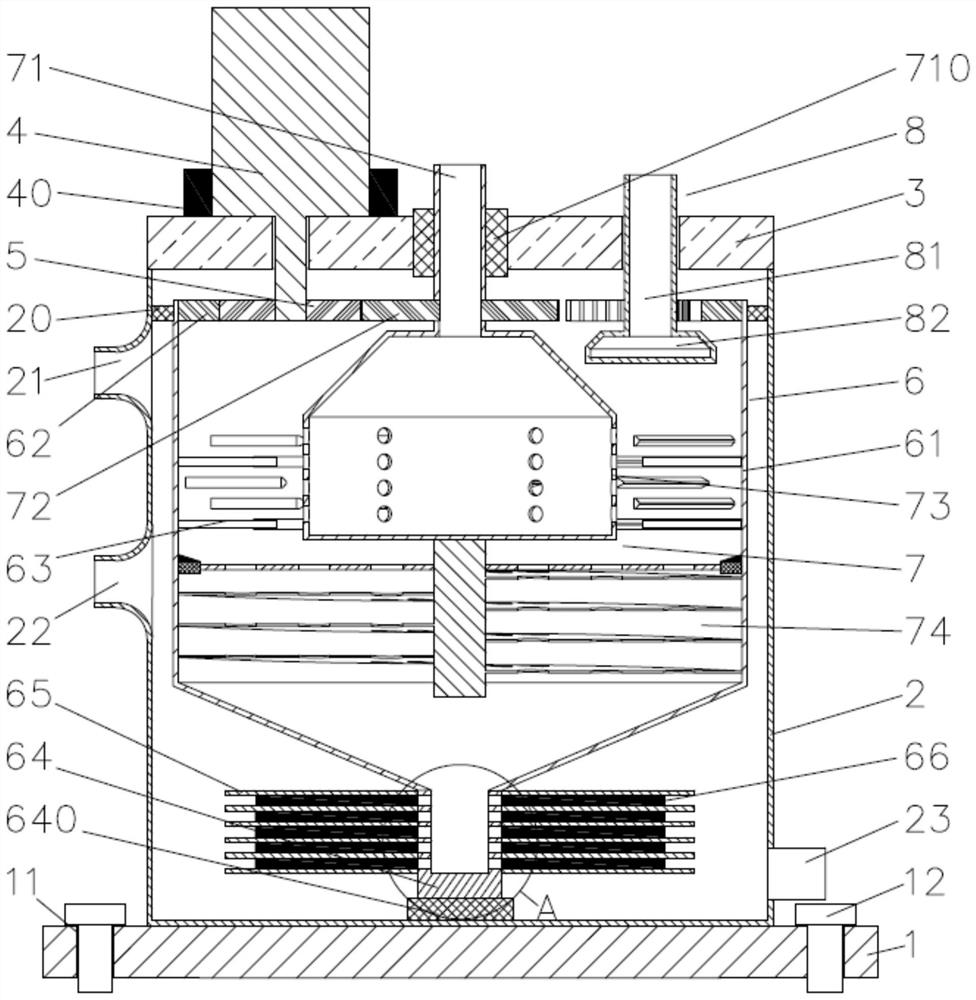

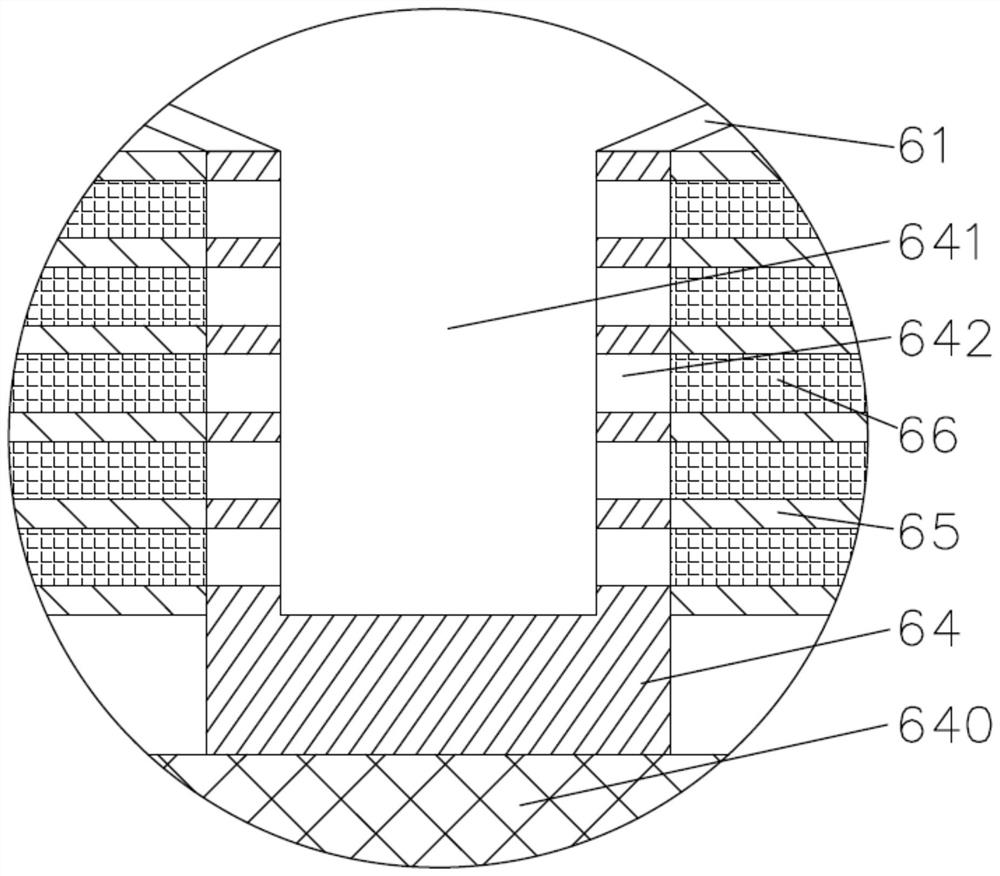

Oily sludge treatment equipment

ActiveCN113354233ARespond effectively to processing needsCompact structureSludge treatment by thermal conditioningWater contaminantsSludgeResource recovery

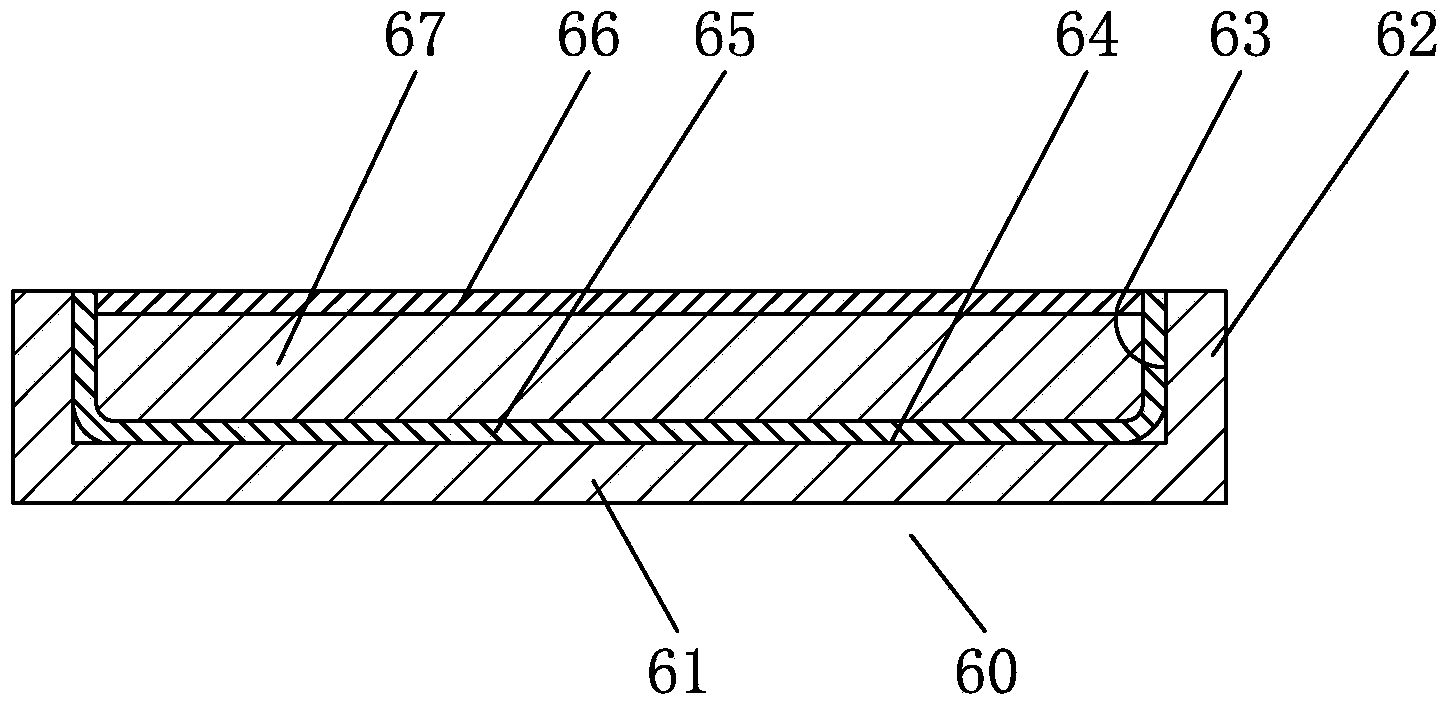

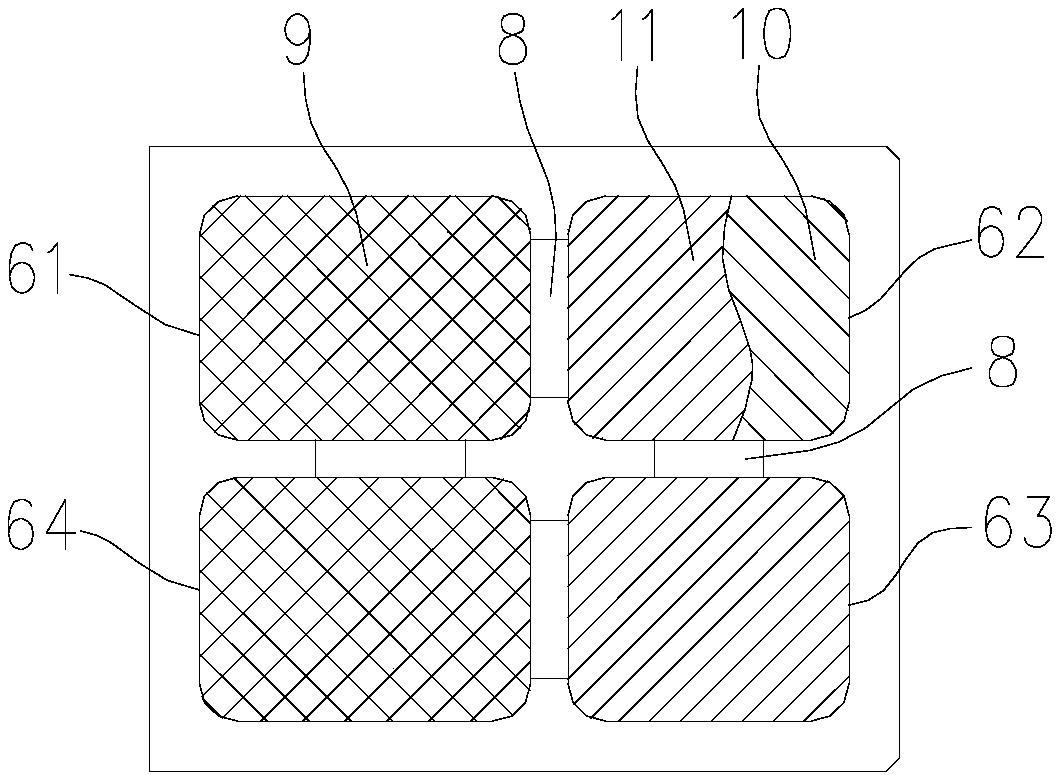

The invention provides oily sludge treatment equipment. The oily sludge treatment equipment comprises a base (1), an oil stain separation main body (2), an end cover (3), a driving motor (4), a driving gear (5), a separation part (6) and a dispersion part (7), wherein the separation part (6) is arranged in the oil stain separation main body (2) and comprises a separation cavity (61), a gear ring (62), wedge-shaped teeth (63), a supporting separation shaft (64), a separation disc (65) and fins (66); the dispersing part (7) is arranged in the separating part (6) and comprises a feeding pipe (71), a driven gear (72), a dispersing cavity (73) and a spiral blade assembly (74), and the spiral blade assembly (74) comprises a connecting mandrel (741), a partition plate (742) and a spiral blade (743). The equipment is convenient to move, suitable for treating a small amount or a large amount of oily sludge, high in oily sludge treatment efficiency, low in energy consumption, free of environmental pollution in the treatment process and high in resource recovery rate.

Owner:CHONGQING WATER RESOURCES & ELECTRIC ENG COLLEGE

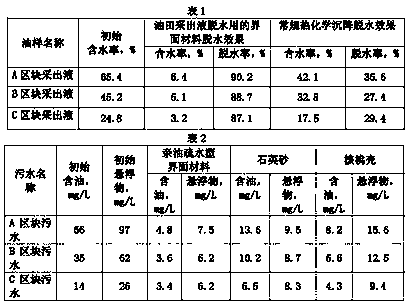

Interface material for dehydrating oilfield produced liquid as well as preparation method and application thereof

ActiveCN108821668AStable chemical propertiesHard textureDewatering/demulsification with chemical meansHydrocarbon oils treatmentSludgeResource utilization

The invention relates to the technical field of resource utilization of oilfield solid wastes, provides an interface material for dehydrating oilfield produced liquid as well as a preparation method and application thereof and further provides a lipophilic and hydrophobic type interface material which takes the interface material for dehydrating the oilfield produced liquid as a raw material. Theinterface material for dehydrating the oilfield produced liquid is prepared from sludge produced by an oilfield sewage treatment system, fly ash and cement. The interface material for dehydrating theoilfield produced liquid, provided by the invention, has the advantages of sable chemical performance, firm texture, low abrasion rate, strong lipophilic and hydrophobic performance and good dehydration effect; a preparation technology is simple and the interface material is applied to the field of rapid agglomeration and dehydration of the oilfield produced liquid; the environment pollution problem caused by the sludge produced by the oilfield sewage treatment system in an oilfield development process and industrial waste fly ash is solved, and produced wastes also can be circularly utilized;the interface material for dehydrating the oilfield produced liquid has the advantages of cost reduction, energy source saving and environment-friendly protection; meanwhile, the lipophilic and hydrophobic interface material can be used for the field of deep purification of oilfield sewage.

Owner:XINJIANG KELI NEW TECH DEV

Environment-protecting low-noise adhesive tape production method

InactiveCN104003239AImprove wettabilityWind evenlyArticle deliveryWebs handlingEnvironmental resistanceLow noise

The invention discloses an environment-protecting low-noise adhesive tape production method which comprises the following steps that (1) a corona processor and a take-up roller pressing wheel are arranged; (2) an adhesive tape with coated glue is arranged into a striping machine; (3) corona processing is carried out; and (4) pressing taking up is carried out through the take-up roller pressing wheel. The production processes are simple, efficiency is high, a corona processing step is added before the striping step of the striping machine, so that the surface of the adhesive tape becomes rough, the wettability on polar solvents is improved, and release force is increased. During taking up, the take-up roller pressing wheel can carry out full pressing and squeeze out gas between adhesive tape layers, the adhesive tape is wound on a take-up roller evenly and tightly, during using and tearing, noise is small, zero noise is basically achieved, the working environment is protected, using is convenient, a traditional coating procedures and the like are effectively reduced, traditional adhesive tape production procedures are greatly simplified, production efficiency is improved, energy is saved, production raw materials are saved, production cost is lowered, and enterprise competitiveness can be well improved.

Owner:DONGGUAN KAIDI ADHESIVE TECHNOLOGY CO LTD

A clothes peg

PendingCN106120260ASave manufacturing costSaving productivityTextiles and paperClothes-pegsEngineeringMechanical engineering

A clothes peg comprises wire springs and two single-sheet plastic peg bodies. Each single-sheet plastic peg body comprises a peg head, a retaining rib, a magnetic object, spring fixing grooves, spring through holes, a handle end, an arc-shaped outer wall rib, an arc-shaped built-in rib, and an arc-shaped rib, wherein the magnetic object is embedded in an outer end opening edge of the peg head, and the retaining rib is arranged in the middle of the an inner cavity of the peg head. The two single-sheet plastic peg bodies match each other left and right; the arc-shaped ribs are embedded in middle groove cavities between the arc-shaped outer wall ribs and the arc-shaped built-in ribs of the corresponding plastic peg bodies. The wire springs penetrate the spring through holes of the plastic peg bodies and the two ends of the wire springs are located in the spring fixing grooves, so that the clothes peg is formed.

Owner:石雪丽

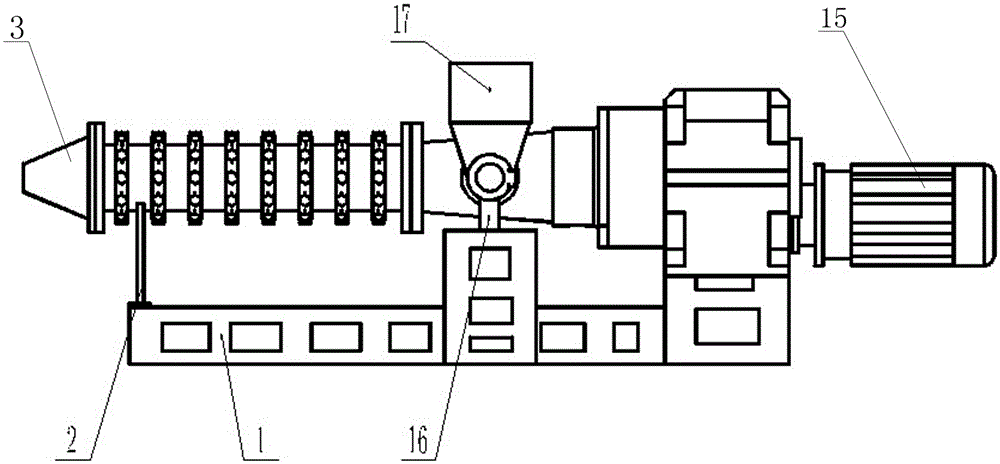

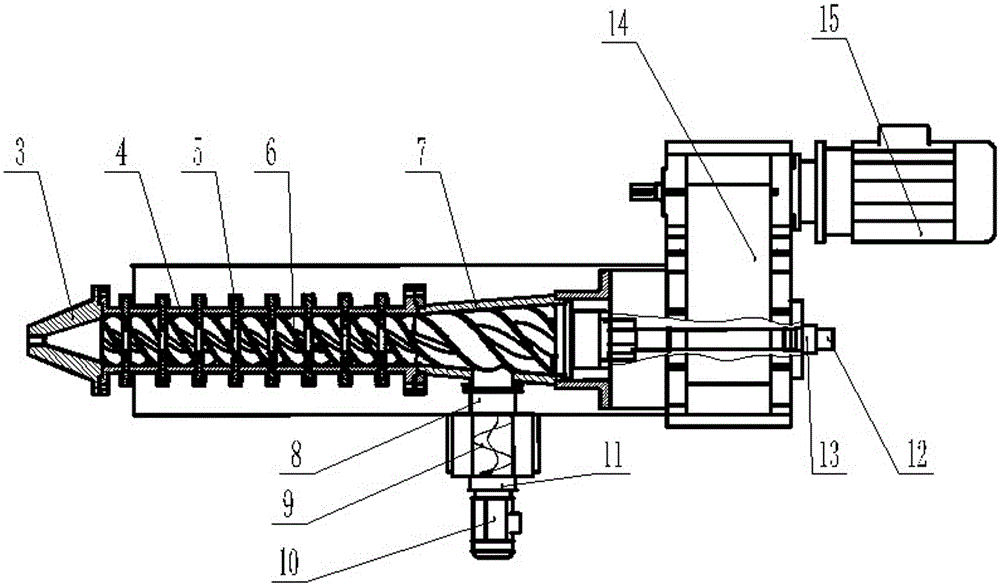

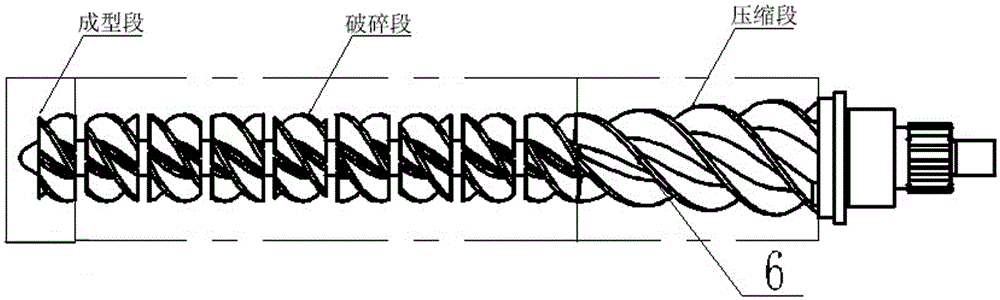

Waste rubber crushing and forming integration machine

InactiveCN106553286AFine particle sizeEasy to shapePlastic recyclingMechanical material recoveryWaste rubberEngineering

The invention discloses a waste rubber crushing and forming integration machine. The waste rubber crushing and forming integration machine comprises a frame, and a feeding mechanism, a speed reducer and a crushing mechanism which are arranged on the frame, the end portion of the crushing mechanism is connected with a forming machine head, and the speed reducer is connected with a motor; the crushing and forming screw of the crushing mechanism traverses through the hollow shaft of the speed reducer, and the other end of the hollow shaft is locked by a locking screw to form a cantilever structure, and torque transmitted from the motor and the speed reducer is applied to the crushing and forming screw depended on a spline structure; and a compression cylinder is provided with a feed inlet, and the feed inlet is abutted to the feeding cylinder of the feeding mechanism in a flange connection form. The waste rubber crushing and forming integration machine has the following advantages: the granularity of a crushed material is very fine, and basically approaches that of powder; no heating is needed in the forming process; crushing and forming are integrated, the process is reduced, and energy and the production place are saved; and the forming machine head and a pin knife can be rapidly replaced, so the machine is convenient to maintain.

Owner:GUILIN JUNWIN MECHANICAL & ELECTRICAL TECH CO LTD

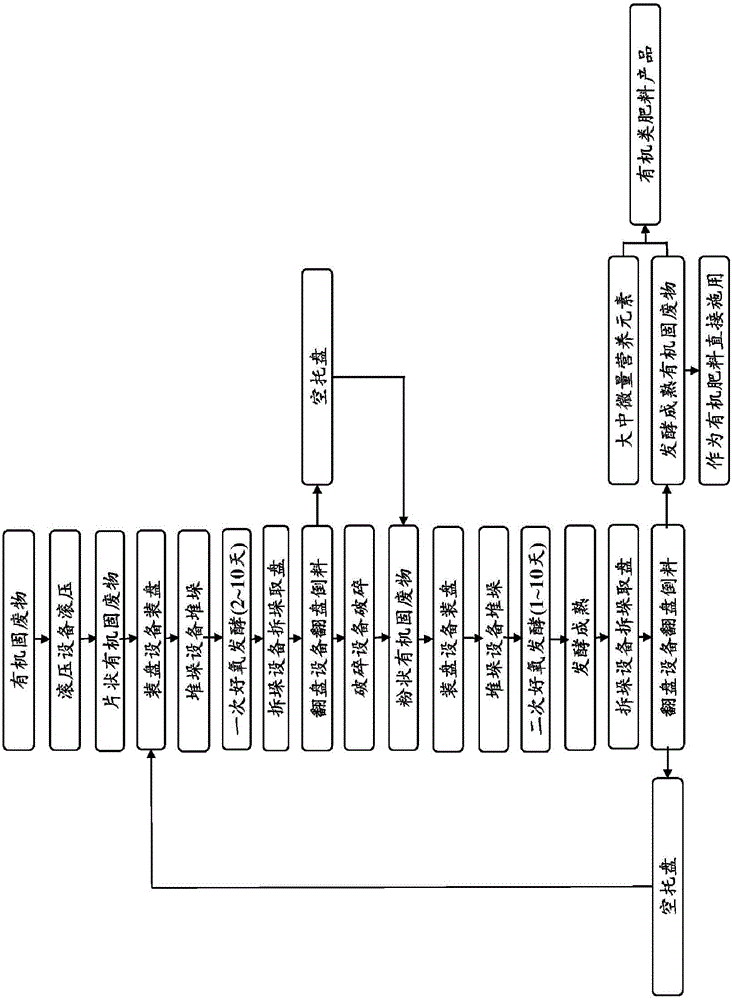

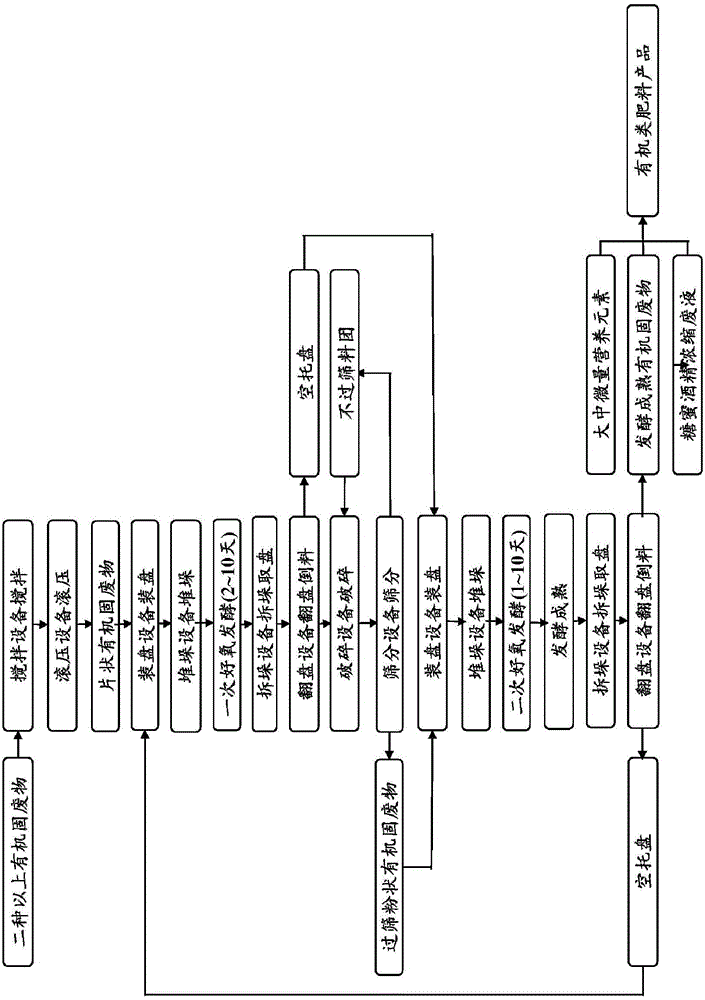

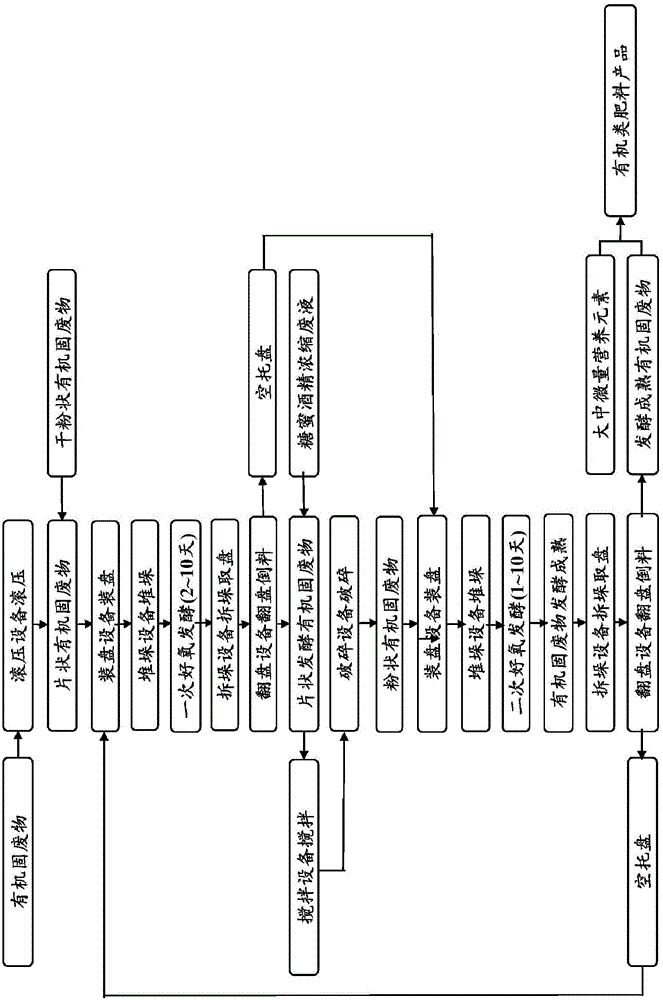

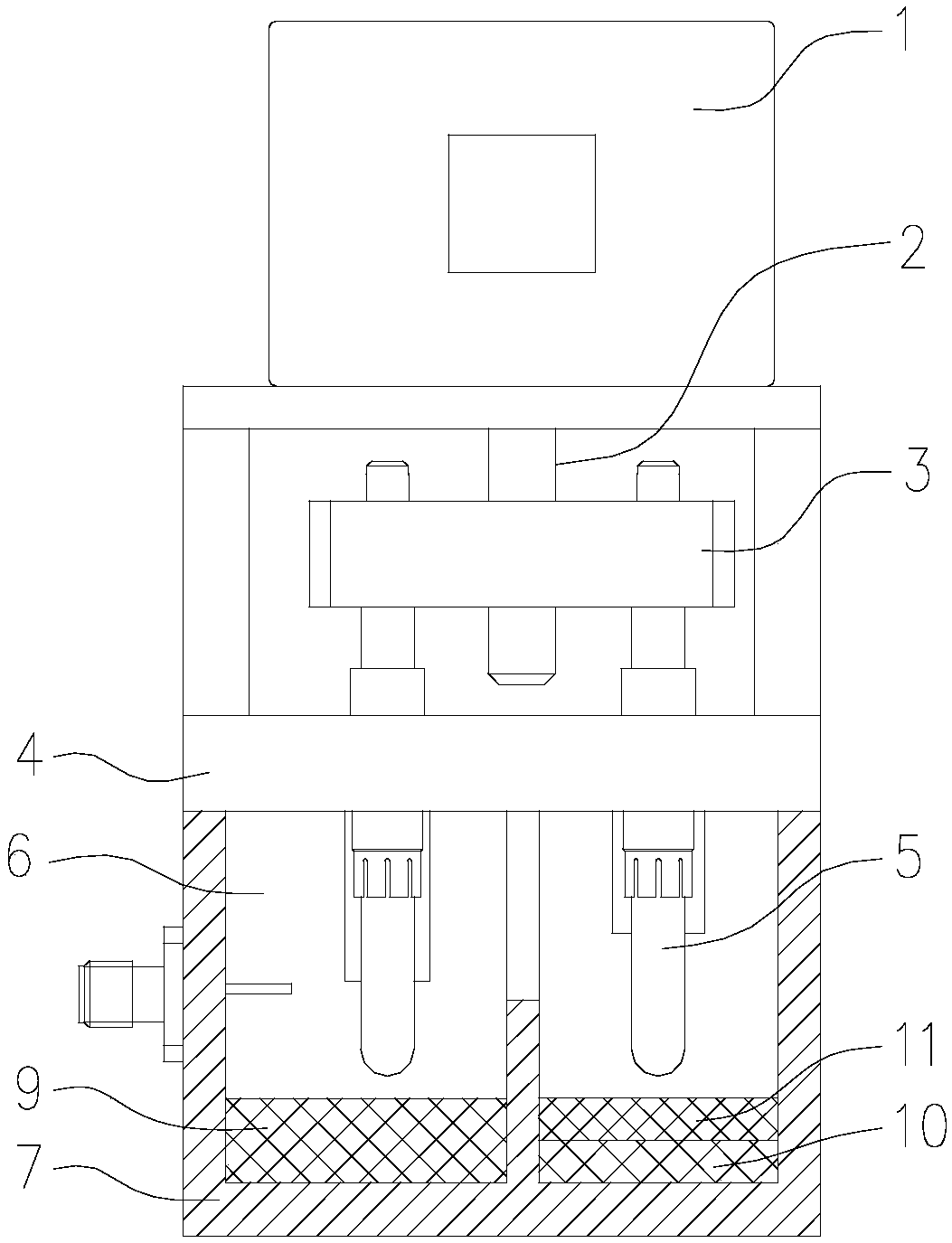

Method for preparing fertilizer by using organic solid waste

InactiveCN105060957AImprove breathabilityInhibitionBio-organic fraction processingOrganic fertiliser preparationOrganic fertilizerOxygen

The invention relates to a method for preparing fertilizer by using organic solid waste. According to the method, the organic solid waste with 75%-50% of water content is crushed and / or rolled and is loaded in ventilated fermentation trays, then the fermentation trays filled with the organic solid waste are stacked for aerobic fermentation for 3-20 days, the organic solid waste is composted and dried into a composted organic material with lower than 40% of water content, and the composted organic material is applied directly as organic fertilizer or is matched with macronutrients and secondary and trace nutrient elements required by plants for production of fertilizer products. With adoption of the method, the fertilizer can be prepared from the organic solid waste in more environment-friendly, efficient and low-cost manners.

Owner:GUANGXI LIYUANBAO SCI & TECH

Adjustable mechanical filter

InactiveCN108091966AStable frequency band amplitude-frequency characteristicsSmall frequency driftWaveguide type devicesResonant cavityFrequency compensation

The invention discloses an adjustable mechanical filter, which comprises a DC motor, a transmission device and a resonance device, wherein the DC motor is arranged above the transmission device, the resonance device is arranged below the transmission device, and the transmission device and the resonance device are isolated by means of a cover plate; the transmission device comprises a transmissionshaft and a bracket, the transmission shaft is fixedly connected with the DC motor, the transmission shaft and the bracket are movably connected by means of a lead screw structure, vertically downward tuning rods are evenly fixed on the bracket, and the lower ends of the tuning rods extend into resonant cavities; the resonance device comprises a filter cavity body, the cover plate, the resonant cavities and the tuning rods; the filter cavity body is of an enclosed cuboid structure, and four resonant cavities are distributed in the filter cavity body in front-rear symmetry, and the adjacent resonant cavities are connected by means of a coupling groove. The adjustable mechanical filter utilizes differential frequency compensation inside the resonant cavities, and achieves the consistency oftuning rod displacement and resonant frequency variation, thereby realizing the stability of amplitude-frequency features of the filter.

Owner:南京乾波通信技术有限公司

Preparation technology of rayon cationic polyester wrap yarn irregular-stripe cloth

InactiveCN108103645AReduce processingSimple production processWeft knittingHeating/cooling textile fabricsYarnPolyester

The invention discloses a preparation technology of rayon cationic polyester wrap yarn irregular-stripe cloth. The technology includes the following steps that firstly, 50% of rayon, 25% of cationic yarn and 25% of polyester fiber are subjected to crossed blending to form multi-fiber two-sided jersey, and the weaving tension is adjusted in the weaving process to make the polyester yarn only exposed to the surface of the two-sided jersey and interwoven with the cationic yarn; then, gray cloth is subjected to presetting before dyeing under 198 DEG C*26 y to guarantee that the cloth surface is flat without creases in the dyeing process, and the gray cloth is subjected to deoiling under 90 DEG C*20' with a 1% multifunctional emulgator to guarantee the dyeing uniformity; finally, the rayon andthe cationic yarn are subjected to one-bath dyeing (active and acidic), a kam cotton dyeing one-bath agent is added in dyeing, sufficient washing is carried out under 60 DEG C*60' and then under 98 DEG C*30' with 4.2% HAC added, then finishing is carried out, and the white-stripe polyester yarn emerges on the cloth surface to form an irregular-stripe cloth surface. The preparation technology of the rayon cationic polyester wrap yarn irregular-stripe cloth is environmentally friendly, saves energy and consumes little time.

Owner:浙江雅雪纺织科技有限公司

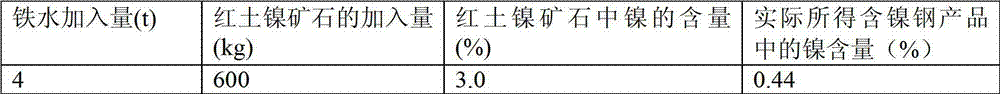

Nickel-containing steel production process

InactiveCN106282474ASimple production processSaving smeltingManufacturing convertersProcess efficiency improvementNickel alloyMetal

The invention relates to a nickel-containing steel production process which comprises the following steps: preparing liquid iron at the temperature of 1,400 to 1,520 DEG C in a blast furnace, transferring the liquid iron into a converter or an electric furnace, adding a nickel-containing mineral into the converter or the electric furnace to enable the nickel-containing mineral to be in contact with the liquid iron, and heating the nickel-containing mineral and the liquid iron to 1,400 to 1,600 DEG C for smelting. According to the nickel-containing steel production process, the conventional nickel-containing steel production process is fully optimized, and the smelting and production procedures for ferro-nickel and metal nickel are eliminated; the nickel-containing mineral replaces a ferro-nickel alloy and the metal nickel, so that the nickel yield is guaranteed, and the production cost is substantially reduced; therefore, the production efficiency is improved, the economical investment is reduced, and a large quantity of raw materials are saved; and the nickel-containing steel production process is suitable for being popularized and applied to the relevant field of nickel-containing steel smelting.

Owner:姜蕾

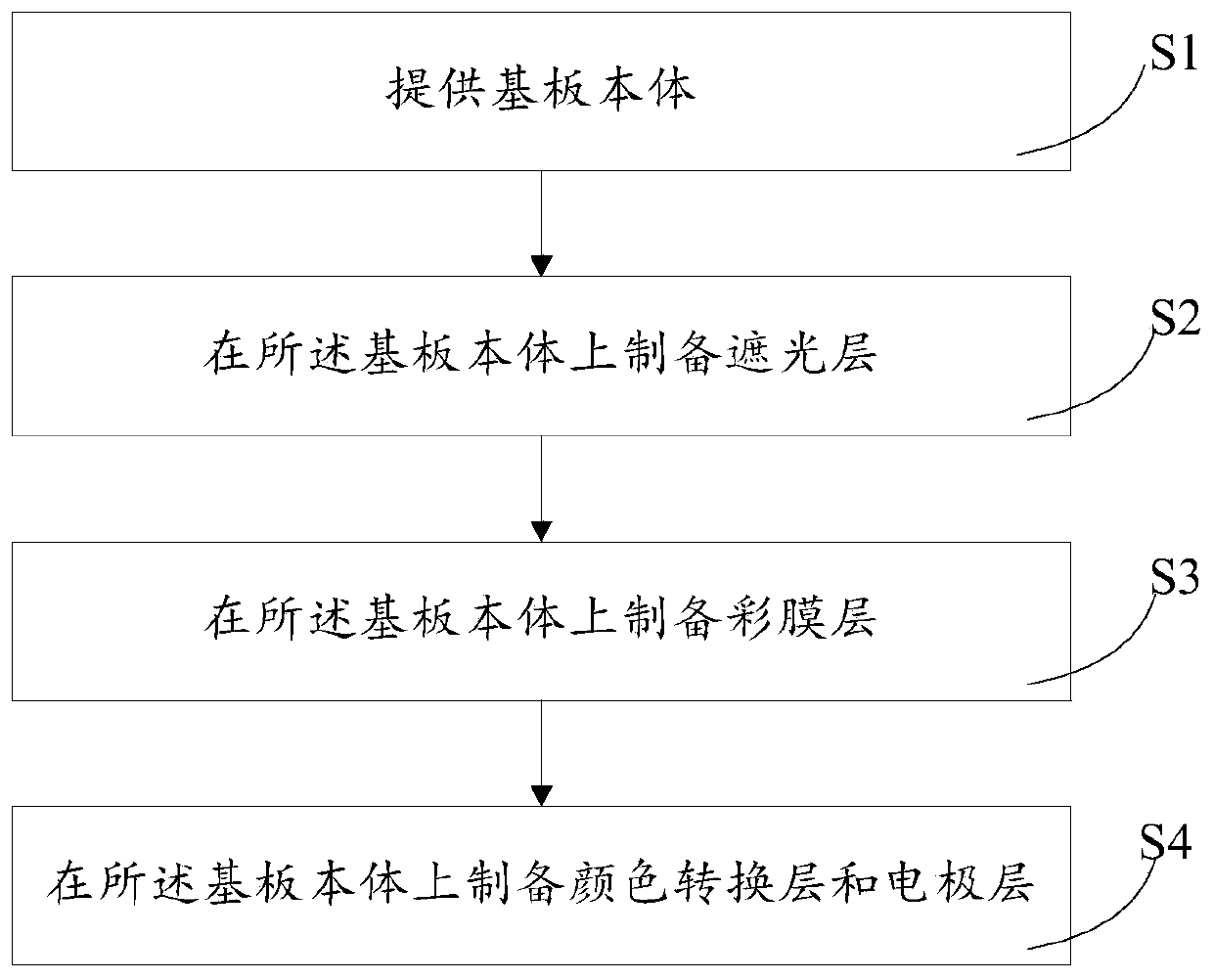

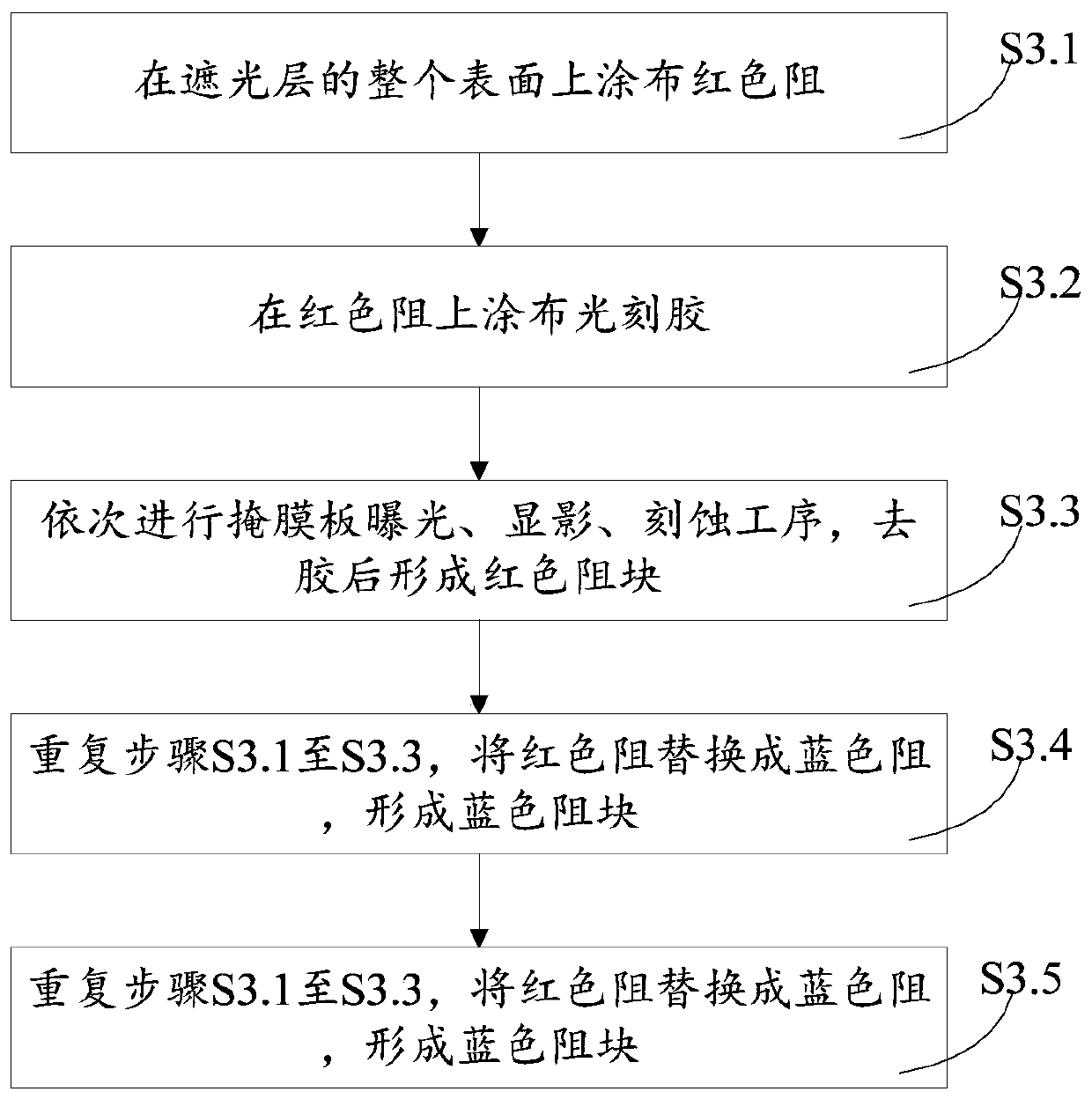

Color film substrate, preparation method of color film substrate and application of color film substrate in liquid crystal display

ActiveCN111323959AOther production processes remain unchangedThe production process remains unchangedNon-linear opticsLiquid-crystal displayPhysical chemistry

The invention discloses a color film substrate which comprises a substrate body, a shading layer, a color film layer, a color conversion layer and an electrode layer, by arranging the color conversionlayer, a liquid crystal display panel comprising the color film substrate can be matched with backlight plates of different specifications, and therefore the same optical performance and display effect are achieved. The invention further discloses a preparation method of the color film substrate and application of the color film substrate in liquid crystal display.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

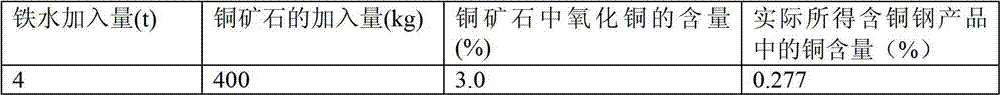

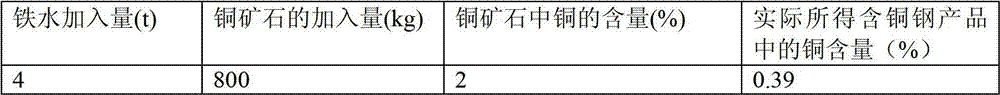

Copper bearing steel production process

The invention relates to a copper bearing steel production process. The copper bearing steel production process comprises the steps that molten iron with the temperature being 1400 DEG C-1520 DEG C isprepared in a blast furnace, the molten iron is transferred into a converter or an electric furnace, and copper bearing mineral is added into the converter or the electric furnace to make contact with the molten iron; and the copper bearing mineral and the molten iron are heated to 1400 DEG C-1600 DEG C to be smelted. According to the copper bearing steel production process, a traditional copperbearing steel production process is sufficiently optimized, the smelting and production processes of copper and iron are saved, a copper and iron alloy is replaced by copper ore, while the yield of copper is guaranteed, the production cost is greatly reduced, the production efficiency is improved, the economic input is reduced, a great number of raw materials are saved, and the copper bearing steel production process is suitable for being applied and popularized in the related field of copper bearing steel smelting.

Owner:青岛金越隆机械有限公司

Production process of copper-containing steel

The invention relates to a production process of copper-containing steel. The production process comprises the following steps: preparing molten iron at the temperature of 1400 DEG C-1520 DEG C in a blast furnace, transferring the molten iron into a converter or an electric furnace, and adding copper-containing minerals into the converter or the electric furnace to enable the copper-containing minerals to be in contact with the molten iron; and heating the copper-containing minerals and the molten iron to 1400 DEG C-1600 DEG C for smelting. According to the production process disclosed by the invention, the traditional production process of the copper-containing steel can be fully optimized, the smelting and the production processes can be saved, copper-containing ores are used for replacing a copper-iron alloy, the yield of copper can be ensured, the production cost is greatly reduced, the production efficiency is improved, the economic input is reduced, a large number of raw materials can be saved, and the production process is suitable for popularization and application in the field of related smelting of the copper-containing steel.

Owner:河北节能耐火材料集团有限公司

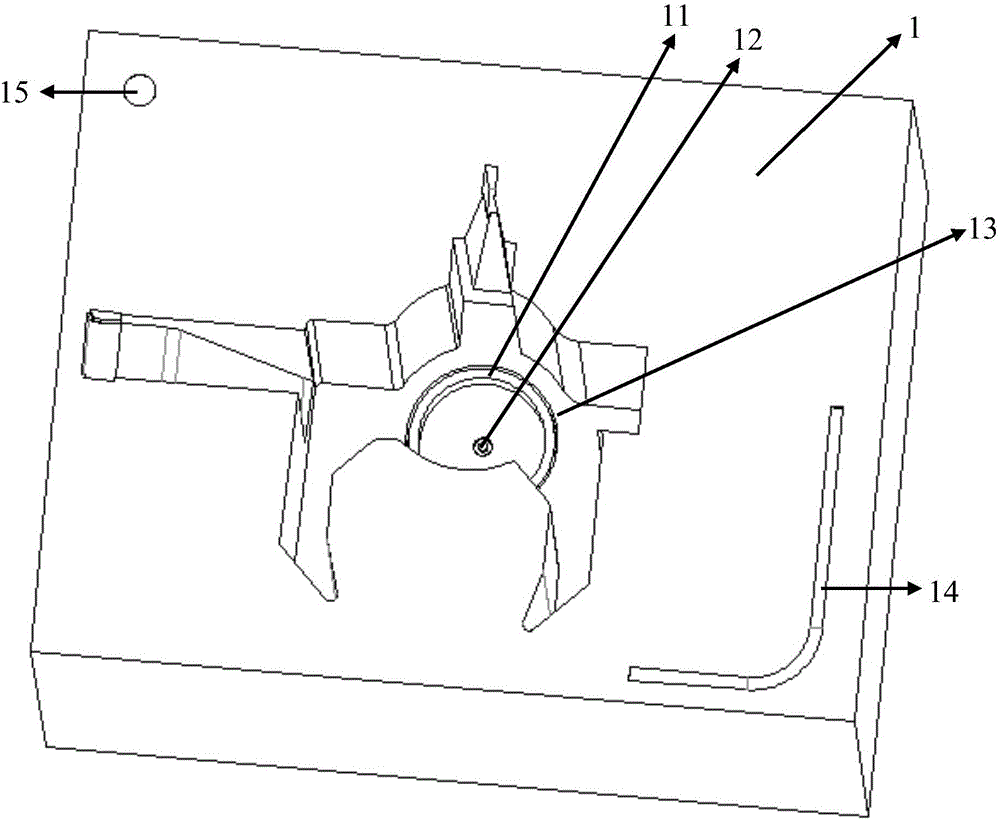

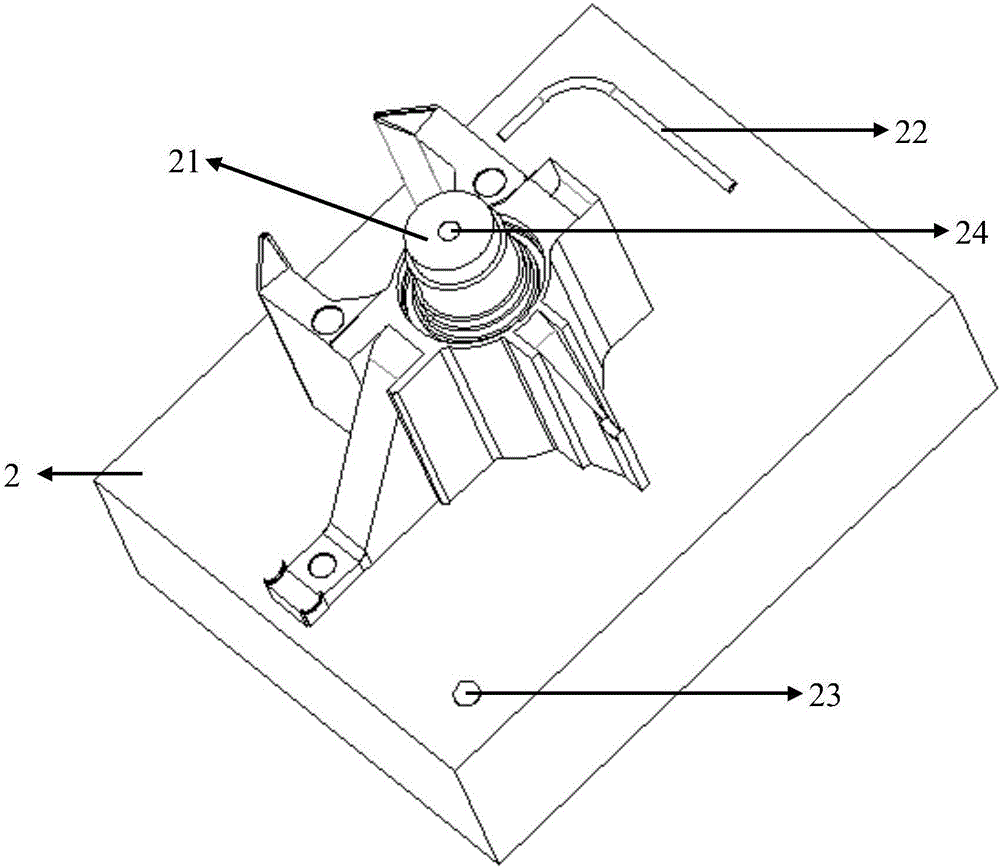

Casting mold for steering knuckle

InactiveCN105945236ASolve sheddingSaving productivityFoundry mouldsFoundry coresCasting moldEngineering

The invention provides a casting mold for a steering knuckle. The casting mold for the steering knuckle comprises a concave mold and a convex mold, wherein the concave mold and the convex mold can form a forming space of the steering knuckle of a vehicle after being clamped; an insert bushing is detachably arranged at a riser forming position in the concave mold; and a boss which can be matched with the insert bushing is formed on the convex mold and can be matched with the insert bushing after mold clamping, so that a riser structure of the steering knuckle of the vehicle is formed. According to the casting mold, local maintenance can be carried out on the mold, and frequent mold lowering is prevented.

Owner:中联精工(天津)有限公司

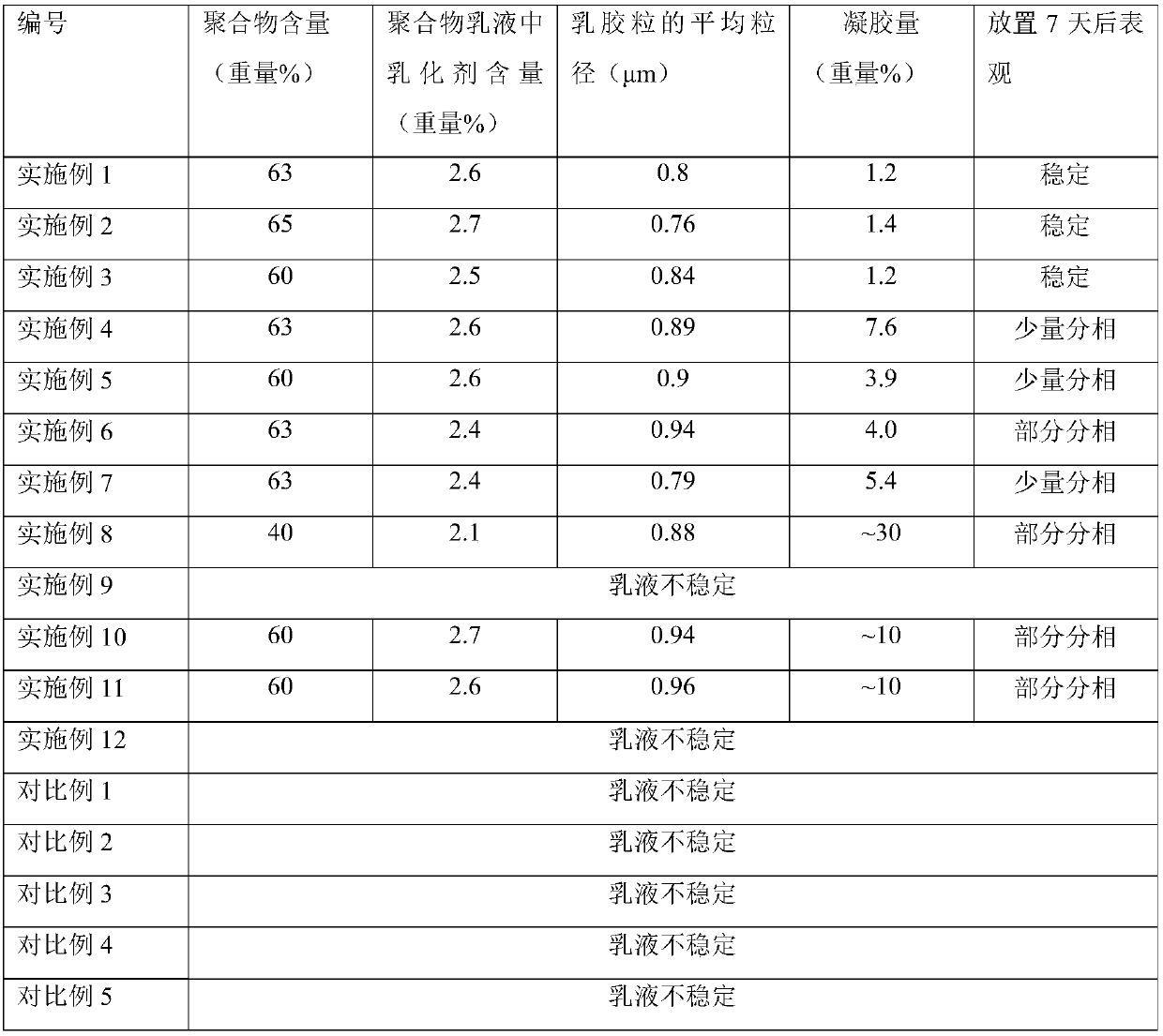

Polymer emulsion and preparation method thereof

The present invention relates to the field of polymer emulsions, and discloses a polymer emulsion and a preparation method thereof, wherein the preparation method comprises: emulsifying, and at leastcarrying out one emulsifying liquid separation and concentration. According to the method, in the emulsifying step, a polymer solution containing an olefin polymer and an organic solvent and an aqueous solution containing an emulsifying agent are mixed, and the mixed solution is emulsified; the emulsifying liquid separation and concentration step sequentially comprises: an organic solvent removalsub-step and a centrifugal separation sub-step; the emulsifying liquid is subjected to at least one distillation, and the diluted emulsion is subjected to at least one centrifugation; and the emulsifying agent is an anion type emulsifying agent. According to the present invention, with the method, the high polymer content polymer emulsion is obtained, and the product has good stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com