Preparation method of composite material layer, composite material layer and mask

A composite material layer and mask technology, applied in separation methods, chemical instruments and methods, synthetic resin layered products, etc., can solve problems such as resource waste, and achieve the goal of reducing waste, saving productivity and use costs, and reducing post-processing pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

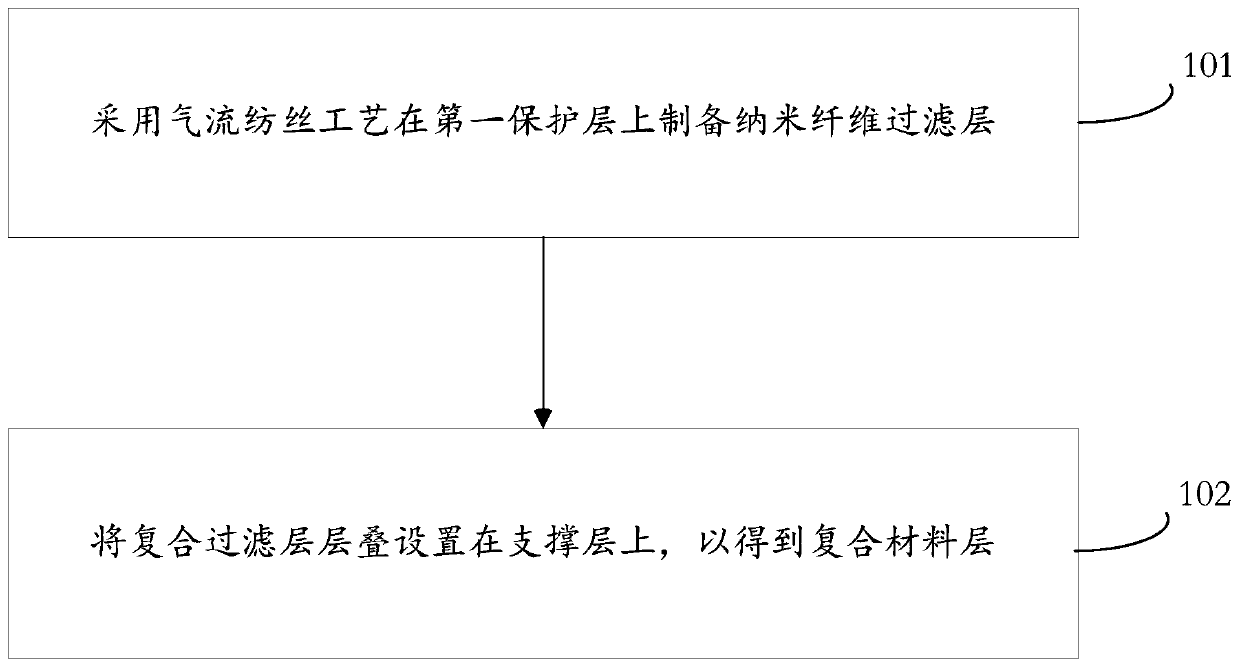

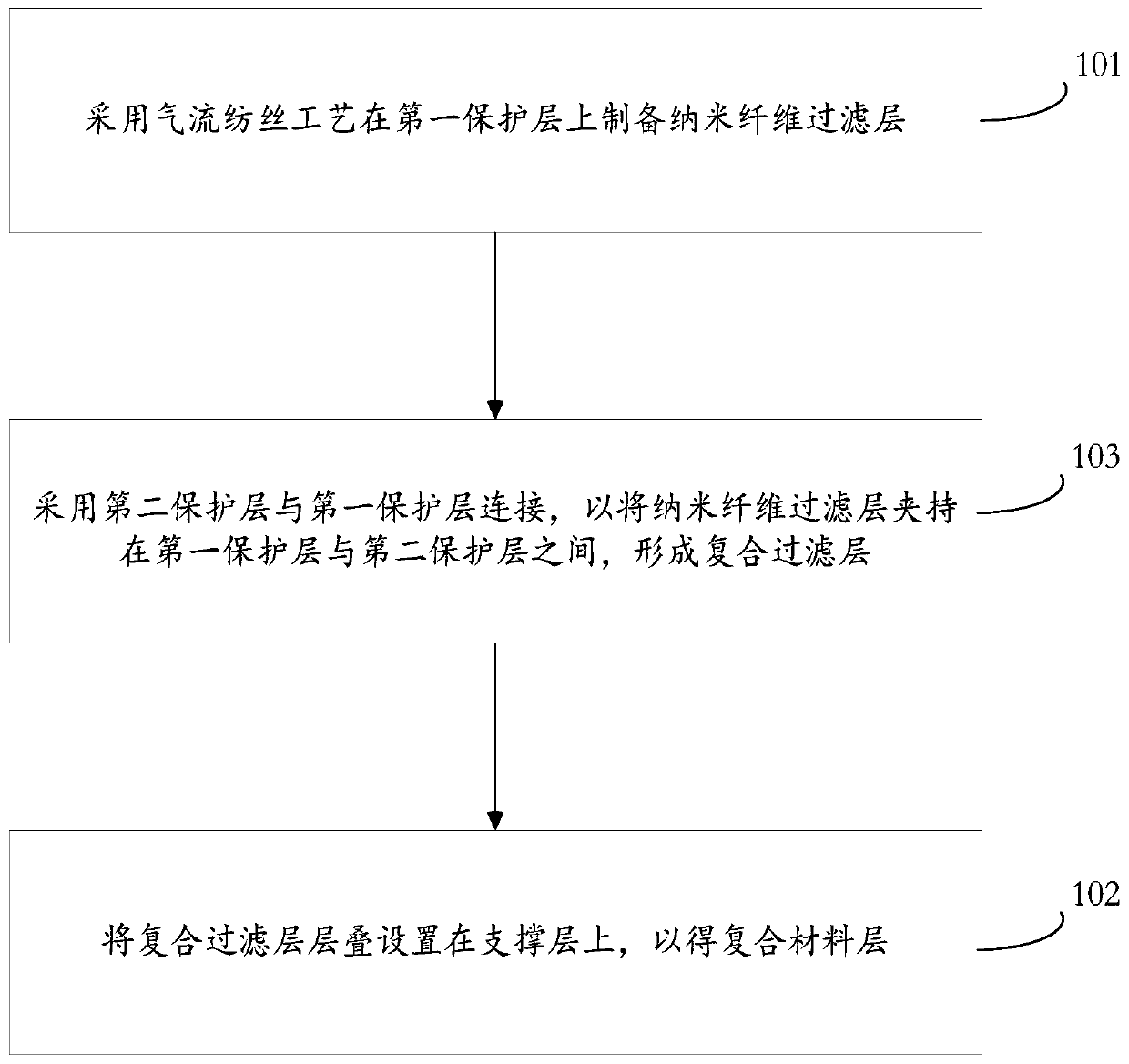

[0055] Also, see image 3 , image 3 Another schematic flowchart of the preparation method of the composite material layer provided in the embodiment of the present application. like image 3 As shown, the composite filter layer is laminated and arranged on the support layer, so that before the step of obtaining the composite material layer, it also includes:

[0056] 103. Connect the second protective layer to the first protective layer, so as to clamp the nanofiber filter layer between the first protective layer and the second protective layer, to form a composite filter layer.

[0057] Wherein, the second protective layer is cotton woven fabric or polypropylene spun-bonded non-woven fabric. The areal density of the polypropylene spunbonded nonwoven fabric ranges from 10 grams per square meter (g / m2) to 30 grams per square meter (g / m2). It should be noted that the second protective layer may be a hydrophobic polypropylene spunbonded nonwoven fabric or a hydrophilic polyp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com