Casting mold for steering knuckle

A casting mold and steering knuckle technology, which is applied in the direction of casting molds, casting mold components, casting molding equipment, etc., can solve the problems of wasting maintenance resources and delaying production, so as to improve production efficiency, avoid production delays, and save production processes and costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

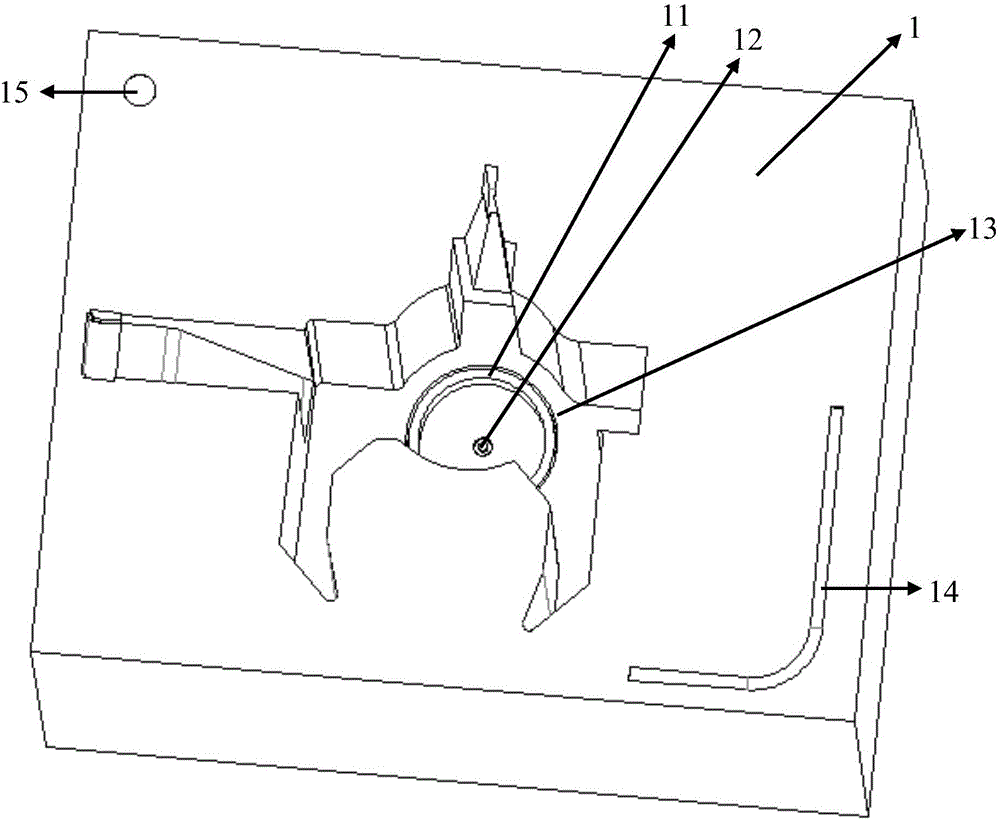

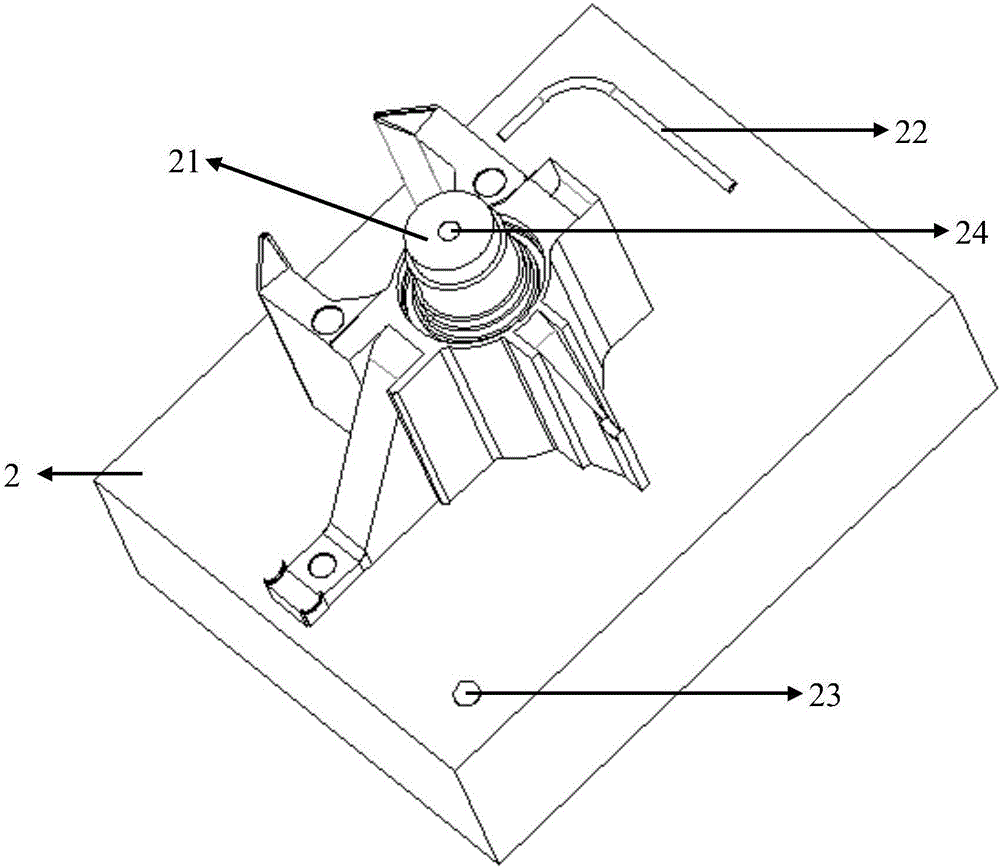

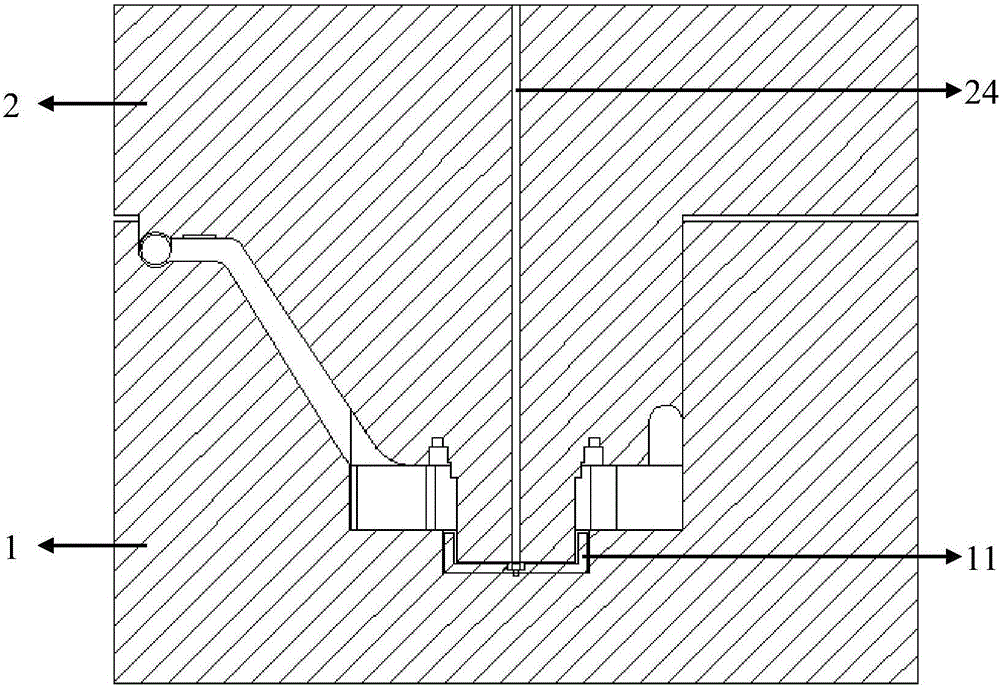

[0017] One embodiment of the structure of the present invention is as Figure 1-4 As shown, it includes a matched die 1 and a punch 2, the die 1 and punch 2 can form the molding space of the steering knuckle of the automobile after the mold is closed, and the riser forming part in the die 1 is detachable An insert 11 is provided, and the outer surface of the insert 11 is in sealing fit with the inner surface of the die 1, and the convex mold 2 is provided with a boss 21 that can cooperate with the insert 11. The table 21 can cooperate with the insert 1 after the mold is closed to form the riser structure of the automobile steering knuckle.

[0018] Wherein, the bottom surface of the insert 11 is detachably fixed in the molding groove 13 formed on the inner surface of the die 1 by bolts 12 .

[0019] Wherein, the outer surface of the insert 11 is in sealing fit with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com