Automatic assembly LED side light-emitting panel lamp and assembly method thereof

A panel light and side-emitting technology, which is applied to the light guides of lighting devices, semiconductor devices of light-emitting elements, optics, etc., can solve the problems of inability to automate assembly and production, troublesome assembly processes, and ingenious design, saving energy and production raw materials. , The assembly process is simple, and the effect of sticking glue and welding wire wiring is omitted.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

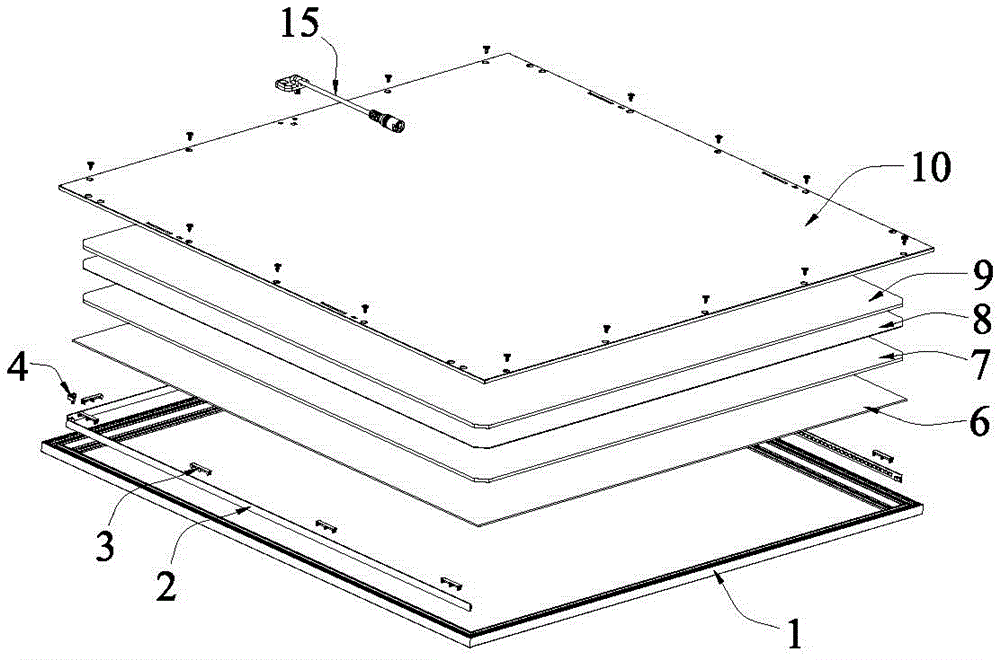

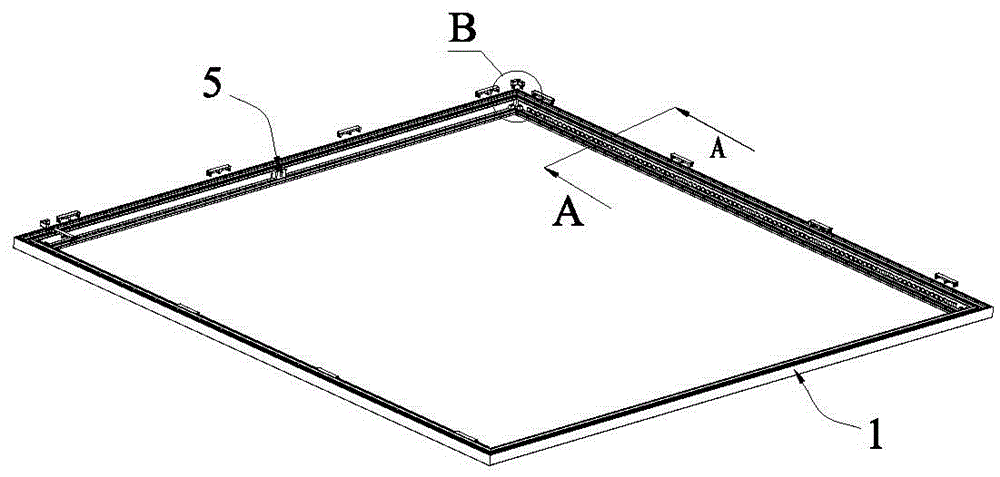

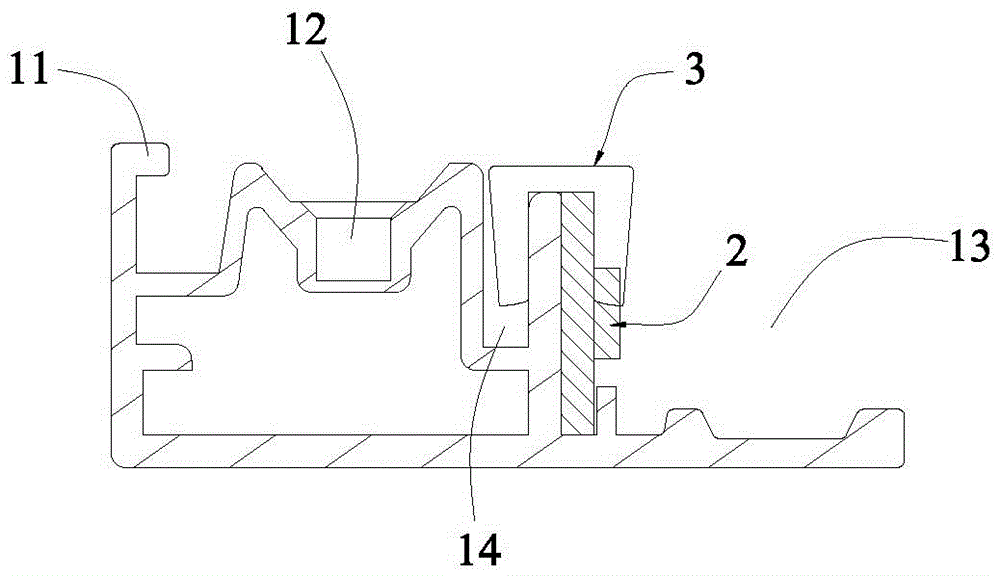

[0036] Examples, see Figure 1 to Figure 6 , an automatic assembly LED side-emitting panel light provided in this embodiment, which includes a frame body 1 with an inner cavity 13, a light bar 2, a light bar fastener 3, a light bar plug terminal 4, and a power connection terminal 5 , diffusion plate 6, light guide plate 7, reflective paper 8, elastic body pressing plate 9, back plate 10 and power cord 15, the light bar 2 is fixed on the inner cavity side wall of the frame body 1 through the light bar fastener 3 Each adjacent light bar 2 is sequentially connected through the light bar plug-in terminal 4, the power connection terminal 5 is arranged on one of the light bar 2, the diffusion plate 6, the light guide plate 7, the reflective paper 8 and the elastomer pressure The tightening plates 9 are stacked and placed in the inner cavity of the frame body 1 sequentially from the outside to the inside, the back plate 10 is fixed on the frame body 1 by screws, and the elastic body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com