Nailing cap

A technology for shooting nails and nail caps, which is applied in the direction of nails, U-shaped nails, connecting components, etc., which can solve problems such as laborious and time-consuming installation, and achieve the effect of saving production and installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

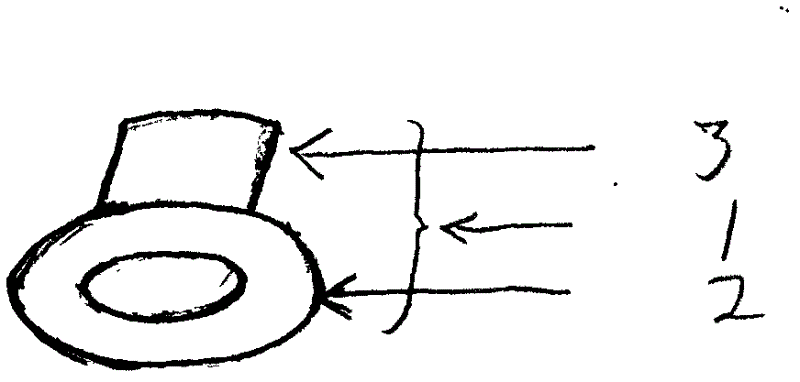

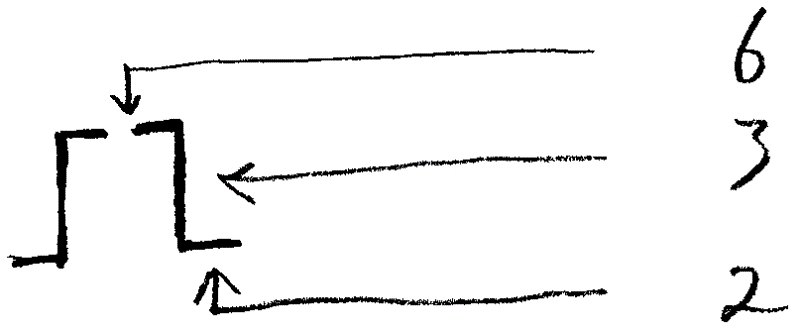

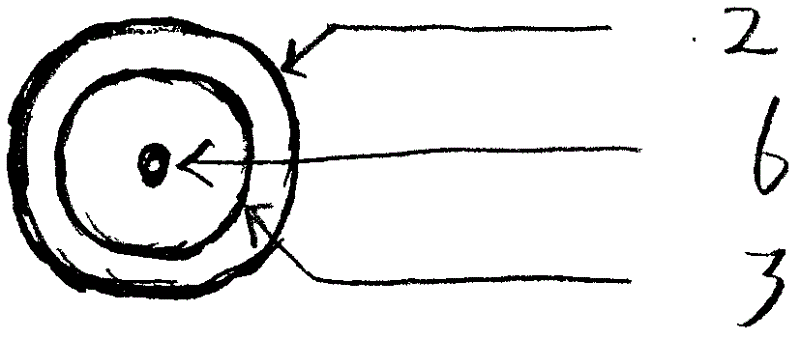

[0011] exist Figure 4 In the process, first stick the central round hole 4 (C) of the lamp panel 5 on the center position of the roof, then fasten the cap top 3 of the nail cap 1 on the central round hole 4 (C) of the lamp panel 5, and then use Nail the nail cap 1 on the roof with the nail gun, then straighten the lamp panel 5, and finally fix the remaining round holes 4 (A, B, D, E) in the same way.

[0012] Note: When we shoot nails, we should buckle the "discarded shells" upside down on the tip of the steel nail and nail the nail cap to the roof together. In this way, the gun jumping can be prevented to a certain extent. If you still use the original fixing parts for fixing, you can first drill a hole in the center of the roof with an electric hammer, then insert the expansion plug into the hole, and then stick the central round hole 4 (C) of the lamp panel 5 on the hole, Fasten the nail cap 1, use a self-tapping screw to pass through the nail hole 6 of the nail cap 1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com