Interface material for dehydrating oilfield produced liquid as well as preparation method and application thereof

A technology of interface material and production fluid, which is applied in chemical dehydration/demulsification, hydrocarbon oil treatment, petroleum industry, etc., can solve the problems of low dehydration efficiency, environmental pollution of industrial waste gas fly ash, etc., and achieve dehydration effect Good, hard texture, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

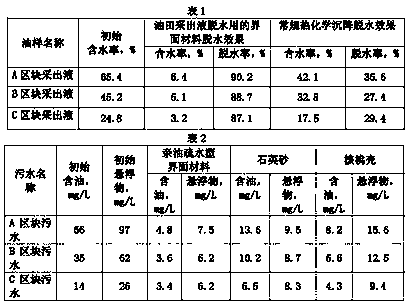

Image

Examples

Embodiment 1

[0020] Embodiment 1: The interface material used for the dehydration of the oilfield production fluid, raw materials include sludge, fly ash and cement produced by the oilfield sewage treatment system, and the interface material for the dehydration of the oilfield production fluid is obtained according to the following steps: the first step The sludge produced by the oilfield sewage treatment system is dried naturally or dried at 100°C to 105°C, ground and sieved to obtain the sludge produced by the dry oilfield sewage treatment system, and the required amount of powder Coal ash, cement and sludge produced by dry oilfield sewage treatment system are mixed, stirred and mixed to obtain mixed powder, wherein the mass-weight ratio of sludge produced by dry oilfield sewage treatment system, fly ash and cement is 85 to 92 : 5 to 11: 3 to 10; the second step is to granulate after spraying the required amount of mixed powder with a chemically active activator to obtain a primary spheri...

Embodiment 2

[0023] Embodiment 2: The interface material used for the dehydration of the oilfield production fluid, raw materials include sludge, fly ash and cement produced by the oilfield sewage treatment system, and the interface material for the dehydration of the oilfield production fluid is obtained according to the following steps: the first step The sludge produced by the oilfield sewage treatment system is dried naturally or dried at 100°C or 105°C, ground and sieved to obtain the sludge produced by the dry oilfield sewage treatment system, and the required amount of powder Coal ash, cement and sludge produced by dry oilfield sewage treatment system are mixed, stirred and mixed to obtain mixed powder, wherein, the mass-weight ratio of sludge produced by dry oilfield sewage treatment system, fly ash and cement is 85 or 92 :5 or 11:3 or 10; in the second step, granulate after spraying the required amount of mixed powder with a chemically active activator to obtain a primary spherical...

Embodiment 3

[0024] Embodiment 3: As an optimization of the above embodiment, the chemically active activator is a sodium silicate aqueous solution with a concentration of 2% by mass, and the added weight of the chemically active activator is 45% to 55% of the weight of the mixed powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com