CCM coating process for realizing swelling resistance by using protective back film

A coating process and protective film technology, which is applied in the field of CCM coating process, can solve the problems of catalytic layer falling and catalyst layer falling off, and achieve the effects of avoiding falling off, reducing adhesion and good peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

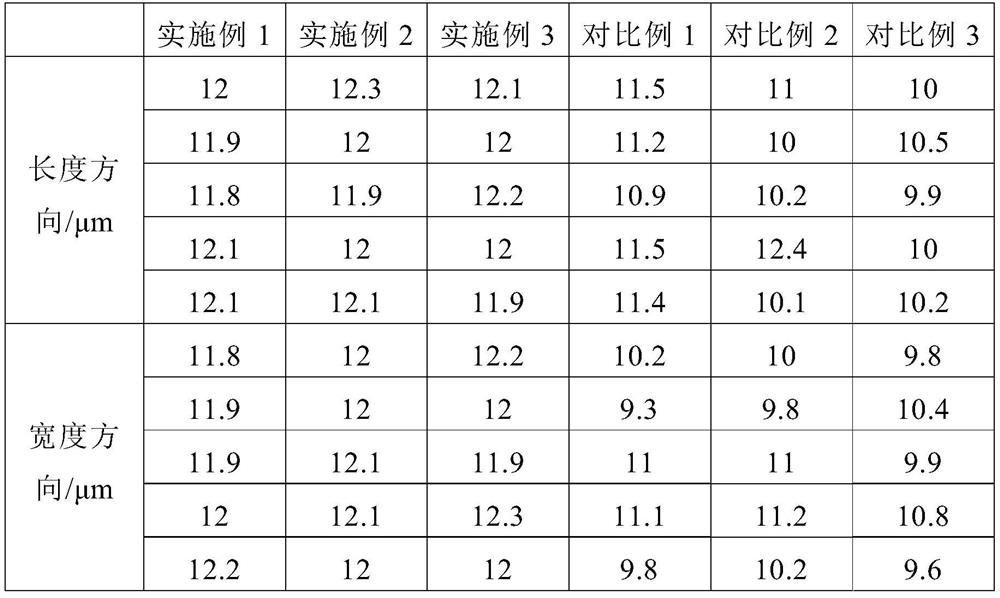

Embodiment 1

[0046] (1) Take 20g ethylene glycol phthalate and dissolve it in 113g ethanol to obtain a solution of 15wt% ethylene glycol phthalate, and apply it evenly with a coating speed of 4m / min and a coating thickness of 80 μm. Spread it on a polyethylene naphthalate film with a thickness of 10 μm, and dry it at 40°C to obtain a temporary protective film of a flexible carrier layer with thermal degradation function, which is ready for use;

[0047] (2) Weigh 15g of Pt / C catalyst particles with a Pt content of 10wt%, 30g of 5wt% perfluorosulfonic acid resin solution and 600g of isopropanol and mix them, stir and disperse at 25°C for 60min at high speed, and use ultrasonic vibration for 10min, Defoaming bubbles to obtain catalyst slurry;

[0048] (3) Weigh 0.5g nano-TiO 2 Place in a glass container, add 455g deionized water and 45.5g isopropanol, stir evenly by magnetic force, and make 0.1wt% nano-TiO 2 Solution, pass into spraying chamber 6, standby;

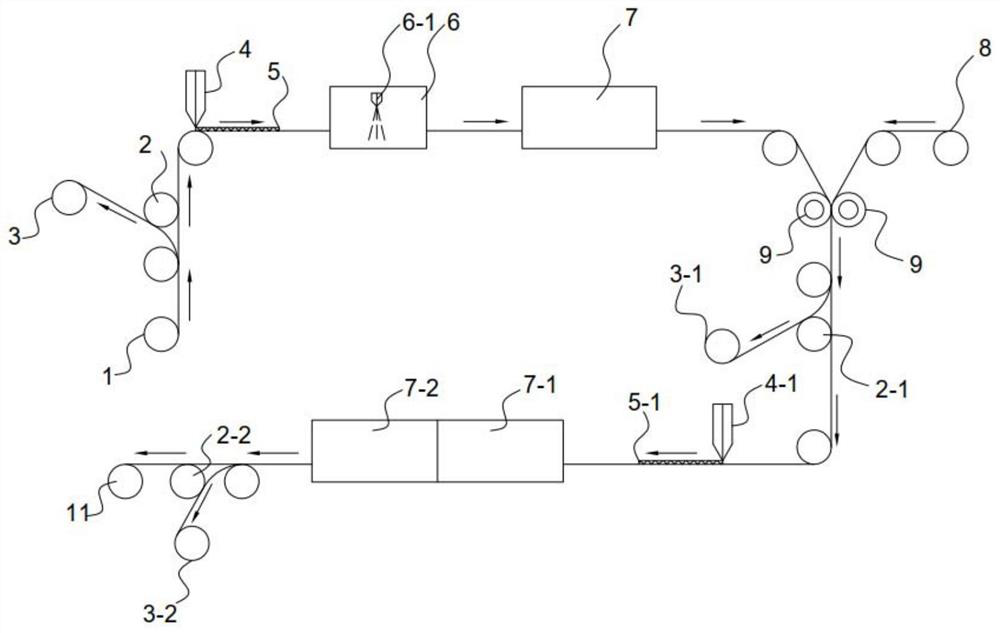

[0049] (4) if figure 1 As sho...

Embodiment 2

[0052] (1) Take 20g of polyimide and dissolve it in 113g of ethanol to obtain a solution of 15wt% polyimide, and uniformly coat the polyimide with a thickness of 80 μm with a coating speed of 4m / min and a coating thickness of 200 μm. On the ethylene terephthalate film, dry at 40°C to obtain a temporary protective film for the flexible carrier layer with thermal degradation function, and set aside;

[0053] (2) Weigh 10g of Pt / C catalyst particles with a Pt content of 90wt%, 100g of 5wt% perfluorosulfonic acid resin solution and 600g of isopropanol and mix them with high-speed stirring at 25°C for 60min, and use ultrasonic vibration for 10min, Defoaming bubbles to obtain catalyst slurry;

[0054] (3) Weigh 0.5g nano-SiO 2 Place in a glass container, add 249.5g deionized water and 249.5g isopropanol, stir evenly by magnetic force, and prepare 0.1wt% nano-SiO 2 Solution, stored in spray booth 6, for subsequent use;

[0055] (4) if figure 1 As shown, protective films are provi...

Embodiment 3

[0058] (1) Take by weighing 20g epoxy acrylate and dissolve in 113g ethanol, obtain the solution of the epoxy acrylate of 15wt%, be that 4m / min, coating thickness 150 μm process are evenly coated on the thickness of 20 μm poly On the vinyl film, dry at 40°C to obtain a temporary protective film with a flexible carrier layer with UV function, and set aside;

[0059] (2) Weigh 10g of Pt / C catalyst particles with a Pt content of 40wt%, 20g of 5wt% perfluorosulfonic acid resin solution and 500g of isopropanol and mix them with high-speed stirring at 25°C for 60min, and use ultrasonic vibration for 10min, Defoaming bubbles to obtain catalyst slurry;

[0060] (3) Weigh 0.5g nano-Al 2 o 3 Place in a glass container, add 416.25g of deionized water and 83.25g of isopropanol, stir evenly with a magnetic force, and prepare 0.1wt% nano-Al 2 o 3 Solution, stored in spray booth 6, for subsequent use;

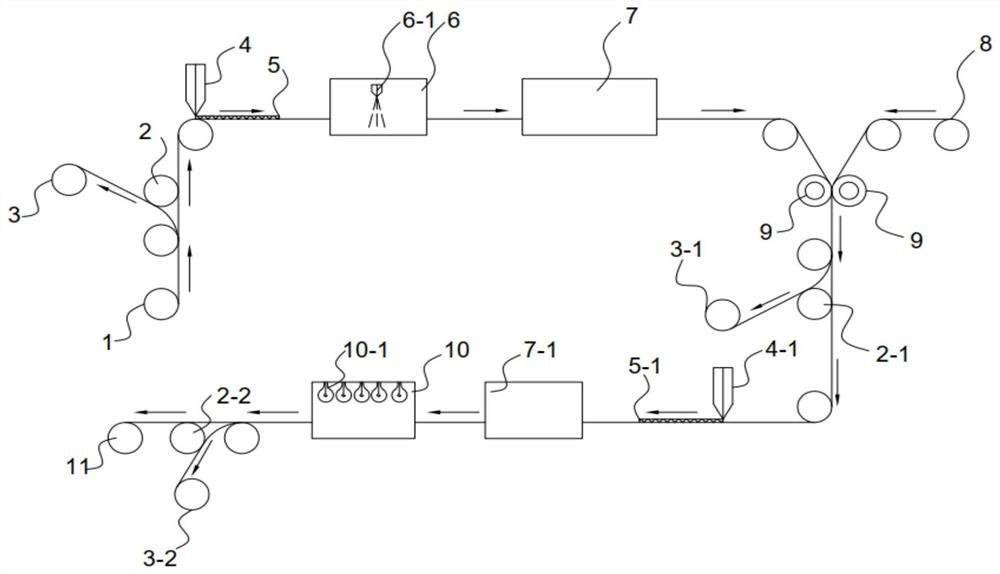

[0061] (4) if figure 2 As shown, protective films are provided on both sides of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com