Protective film for fuel cell membrane electrode and preparation method of protective film

A fuel cell membrane and protective film technology, which can be used in fuel cells, film/sheet adhesives, circuits, etc., can solve the problems of increased peel strength, increased production process and cost, and difficult to directly remove the protective film. , to achieve the effect of saving production processes and costs, and reducing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

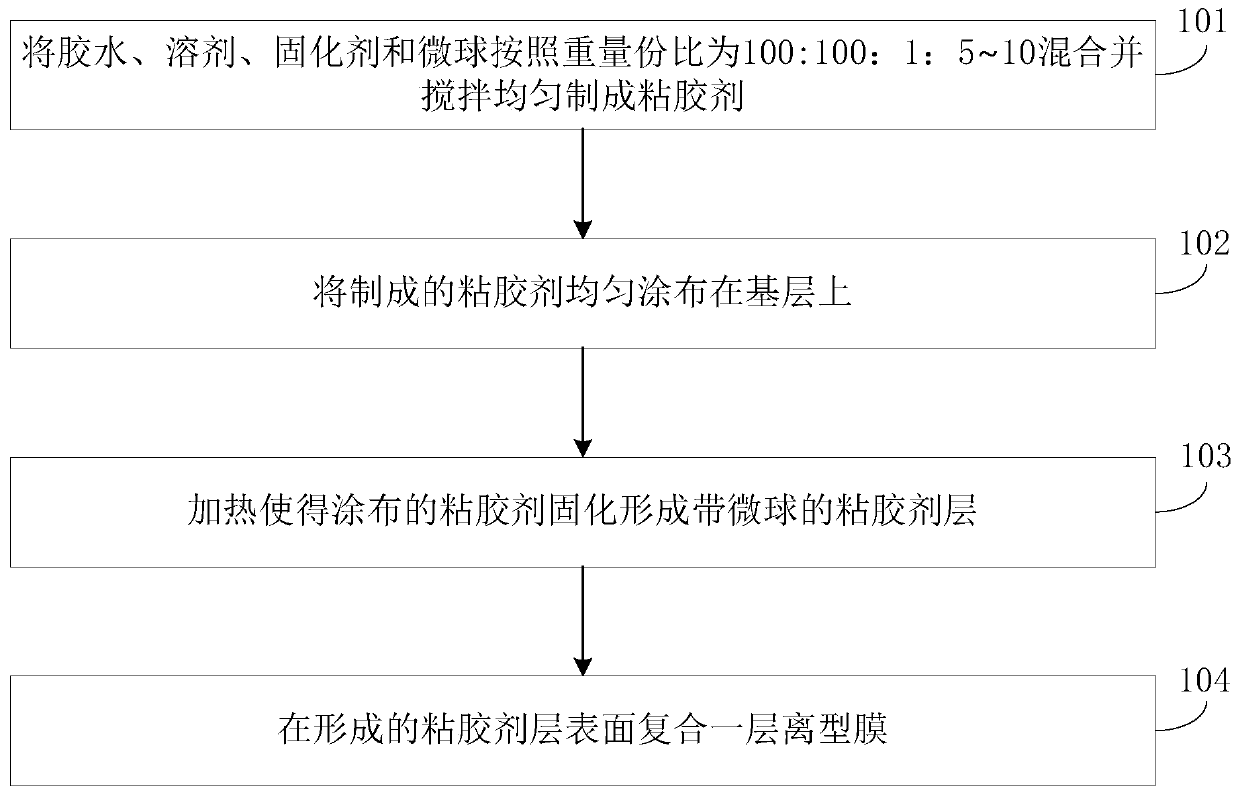

[0032] Please refer to figure 1 , the present embodiment provides a method for preparing a protective film for a fuel cell membrane electrode, the method comprising the following steps:

[0033] Step 101: mixing glue, solvent, curing agent and microspheres in a weight ratio of 100:100:1:5-10 and stirring evenly to make an adhesive;

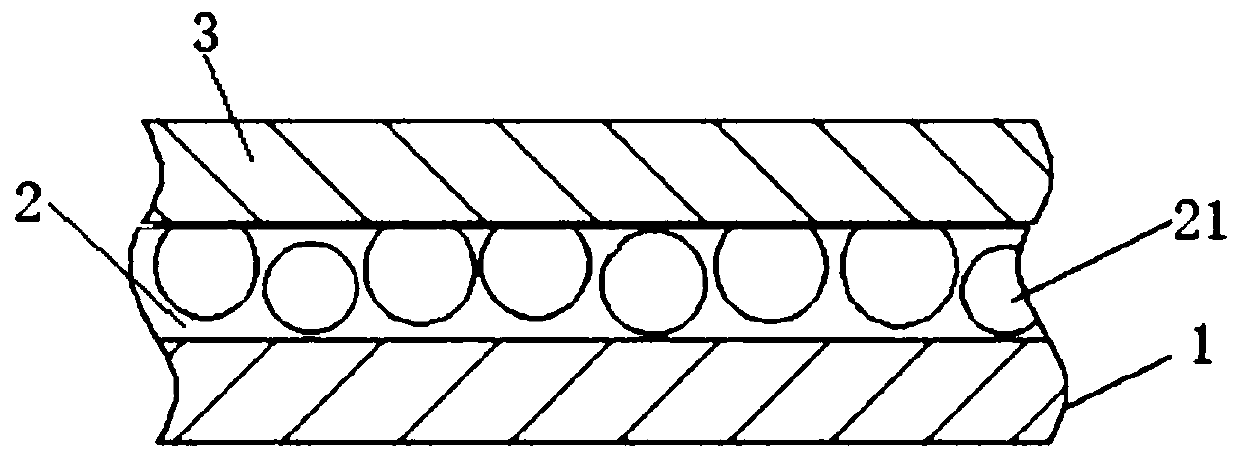

[0034] Step 102: evenly coating the prepared adhesive on the base layer 1;

[0035] Step 103: heating to cure the applied adhesive to form an adhesive layer 2 with microspheres 21;

[0036] Step 104: compound a release film 3 on the surface of the adhesive layer 2 formed.

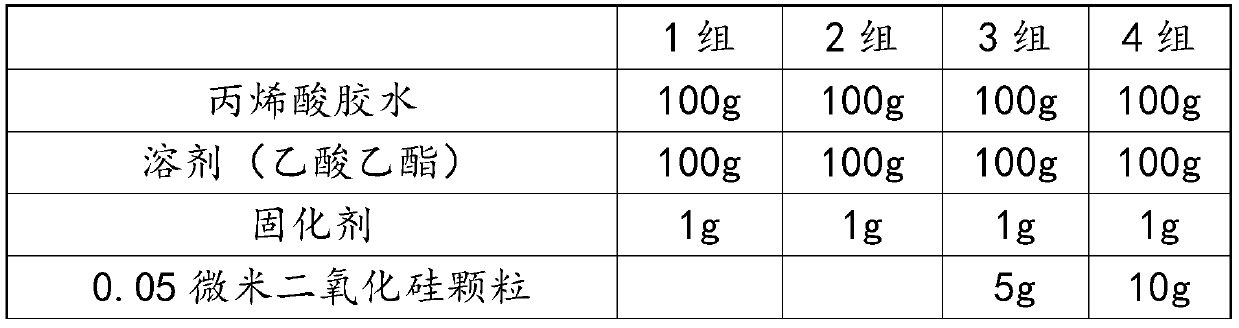

[0037] Among them, in step 101 of this embodiment, the solvent is ethyl acetate, the glue is acrylic glue, and the microspheres 21 are respectively made of silicon dioxide particles and polymethyl methacrylate materials with a diameter of 3 μm, and are respectively set as shown in Table 1 below. Four sets of examples.

[0038] Table 1

[0039]

[0040]

[0041] Prepa...

Embodiment 2

[0047] In this example, four sets of protective films were prepared using the same preparation method as in Example 1, wherein ethyl acetate was used as the solvent, and polyurethane glue was used as the glue, and the weight ratios of glue, solvent, curing agent, and microspheres in each set of protective films were as follows table 3:

[0048] table 3

[0049] 5 groups 6 groups 7 groups 8 groups polyurethane glue 100g 100g 100g 100g Solvent (ethyl acetate) 100g 100g 100g 100g Hardener 1g 1g 1g 1g 3 micron silica particles 5g 10g 3 Micron PMMA 5g 10g

[0050] Prepare four kinds of adhesives according to the ratio of 5 groups, 6 groups, 7 groups and 8 groups respectively, apply the four groups of adhesives evenly on the base layer 1, and then heat the coated adhesives to cure to form a tape The adhesive layer 2 of the microsphere 21 is compounded with a layer of release film 3 on the surface of the formed a...

Embodiment 3

[0056] In this example, four sets of protective films were prepared using the same preparation method as in Example 1, wherein ethyl acetate was used as the solvent, and acrylic glue was used as the glue, and the weight ratios of glue, solvent, curing agent, and microspheres in each set of protective films were as follows table 5:

[0057] table 5

[0058] 9 groups 10 groups 11 groups 12 groups acrylic glue 100g 100g 100g 100g Solvent (ethyl acetate) 100g 100g 100g 100g Hardener 1g 1g 1g 1g 5 micron silica particles 5g 10g 5 Micron PMMA 5g 10g

[0059] Prepare four kinds of adhesives according to the ratio of 5 groups, 6 groups, 7 groups and 8 groups respectively, apply the four groups of adhesives evenly on the base layer 1, and then heat the coated adhesives to cure to form a tape The adhesive layer 2 of the microsphere 21 is compounded with a release film 3 on the surface of the formed adhesive layer 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com