Nickel-containing steel production process

A production process and technology for nickel steel, applied in the field of nickel-containing steel production process, can solve the problems of not being optimized well and the degree of cost reduction is limited, so as to optimize the production process, save the smelting and production process, and reduce the production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

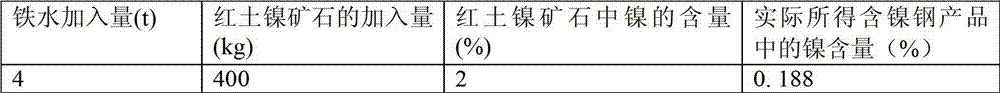

Embodiment 1

[0026] Taking the preparation of nickel-containing steel with a nickel content of 0.2% as an example, the production process of such nickel-containing steel includes the following steps:

[0027] (1) Preparation of molten iron

[0028] Obtain 4t molten iron with a temperature of 1470℃ in the blast furnace;

[0029] (2) Transfer of molten iron

[0030] Put the molten iron ladle obtained in step (1) into the electric furnace;

[0031] (3) Add laterite nickel ore

[0032] Add 400 kg of laterite nickel ore with a nickel content of 2% to the electric furnace described in step (2) to fully contact the molten iron;

[0033] (4) Smelting

[0034] The molten iron and laterite nickel ore of step (3) are heated, the temperature is increased to 1550°C, and the temperature is maintained at 1550°C for 10 minutes.

[0035] In the above embodiment:

[0036] In the step (1), the mass percentage of the components of the obtained molten iron is: 2.7% Si, 4.1% C, and the balance is Fe;

[0037] In the step (3), ...

Embodiment 2

[0045] Taking the preparation of nickel-containing steel with a nickel content of 0.2% as an example, the production process of this kind of nickel-containing steel is the same as in Example 1, except that in the step (3), the laterite nickel ore is pre-reduced The nickel-containing minerals; the step of pre-reduction treatment of laterite nickel ore is:

[0046] (3.1) After crushing the laterite nickel ore and mixing it with a reducing agent, the particle size of the mixture is 20mm-150mm;

[0047] (3.2) Roast the resulting mixture at 650℃ for 3h;

[0048] Wherein, the reducing agent is carbon powder, and the mass of carbon in the reducing agent is 5% of the mass of nickel in the nickel-containing mineral.

[0049] In the above embodiment, through the pre-reduction treatment of laterite nickel ore, the nickel oxide contained in it is partially reduced and some chemical bonds are in a different degree of activation state, so that it will be contacted with high temperature molten iron ...

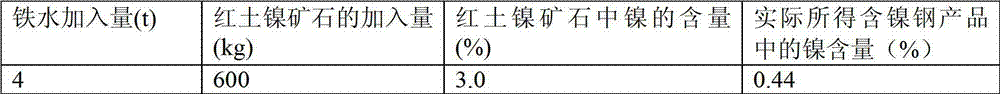

Embodiment 3

[0052] Taking the preparation of nickel-containing steel with a nickel content of 0.2% as an example, the production process steps of this nickel-containing steel are the same as those in Example 1, except that:

[0053] In step (1), obtain 4t molten iron with a temperature of 1400°C in a blast furnace;

[0054] In step (4), the laterite nickel ore and molten iron in step (3) are heated, the temperature is increased to 1400°C, and the temperature is maintained at 1400°C for 8 minutes.

[0055] In the above embodiment:

[0056] In the step (1), the mass percentage of the components of the obtained molten iron is: 2.0% Si, 3.6% C, and the balance is Fe;

[0057] In the step (3), the laterite nickel ore has a particle size of 40mm-60mm;

[0058] In the step (4), the heating rate for heating the mixture of nickel-containing minerals and molten iron is 10°C / min.

[0059] The nickel-containing steel obtained by the above-mentioned nickel-containing steel production process has a nickel content ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com