Adjustable mechanical filter

A filter and mechanical technology, applied in waveguide devices, electrical components, circuits, etc., can solve the problems of poor frequency consistency of resonant cavity, large filter frequency drift, and difficulty in achieving amplitude-frequency response, etc., and achieve small and stable frequency drift Good performance and improve debugging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

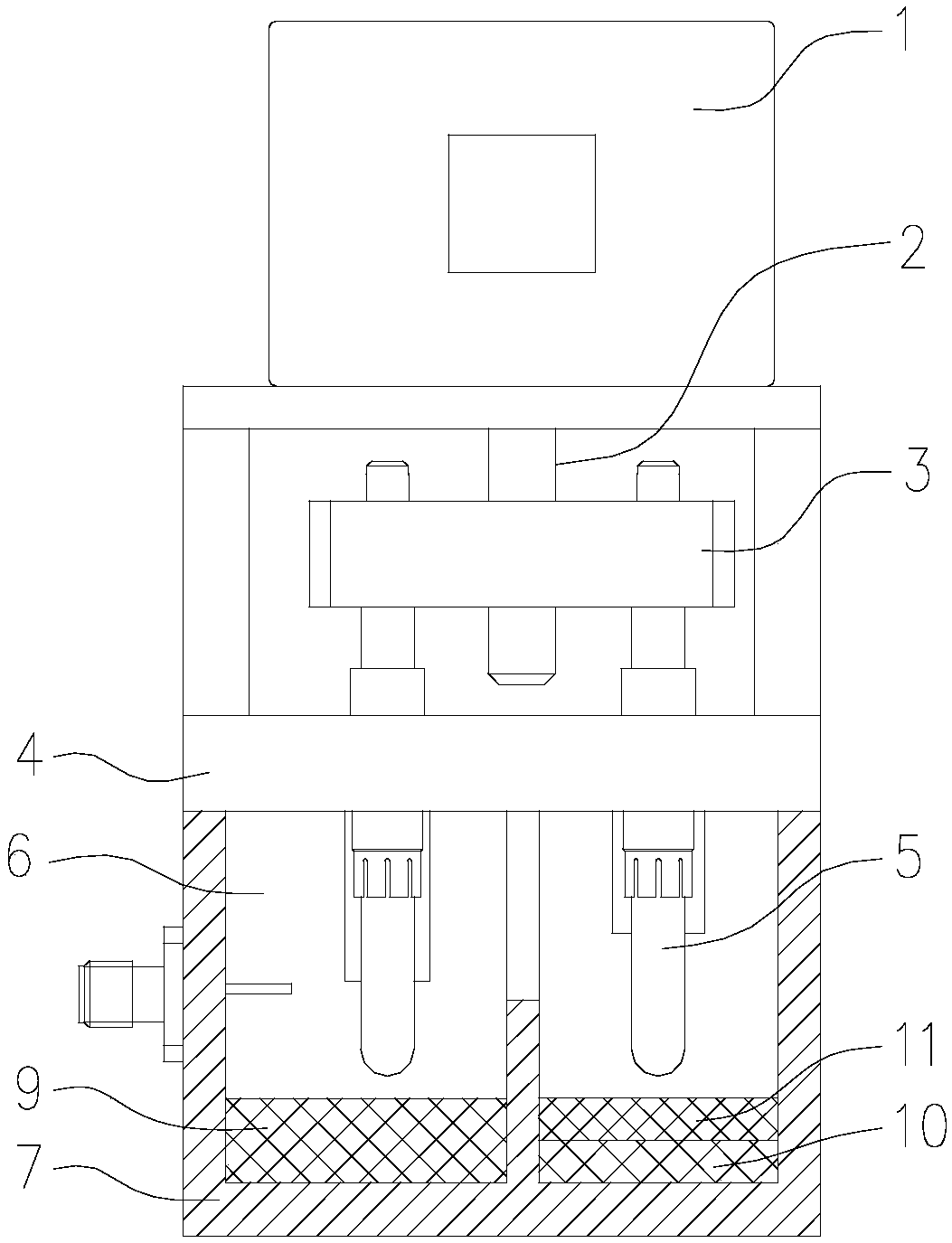

[0020] Embodiment 1: A kind of tunable mechanical filter, such as figure 1 As shown, it includes a DC motor 1, a transmission device and a tuning device.

[0021] The DC motor 1 is arranged above the transmission device, the resonant device is arranged below the transmission device, and the transmission device and the resonant device are isolated by a cover plate 4 .

[0022] The transmission device includes a transmission shaft 2 and a support 3, the transmission shaft 2 is fixedly connected to the DC motor 1, the transmission shaft 2 and the support 3 are flexibly connected through a screw structure, and the support 3 is evenly fixed with a vertical downward tuning Rod 5, the lower end of the tuning rod 5 extends into the resonant cavity 6. The up and down movement of the bracket 3 is controlled by the DC motor 1 , thereby controlling the up and down movement of the tuning rod 5 .

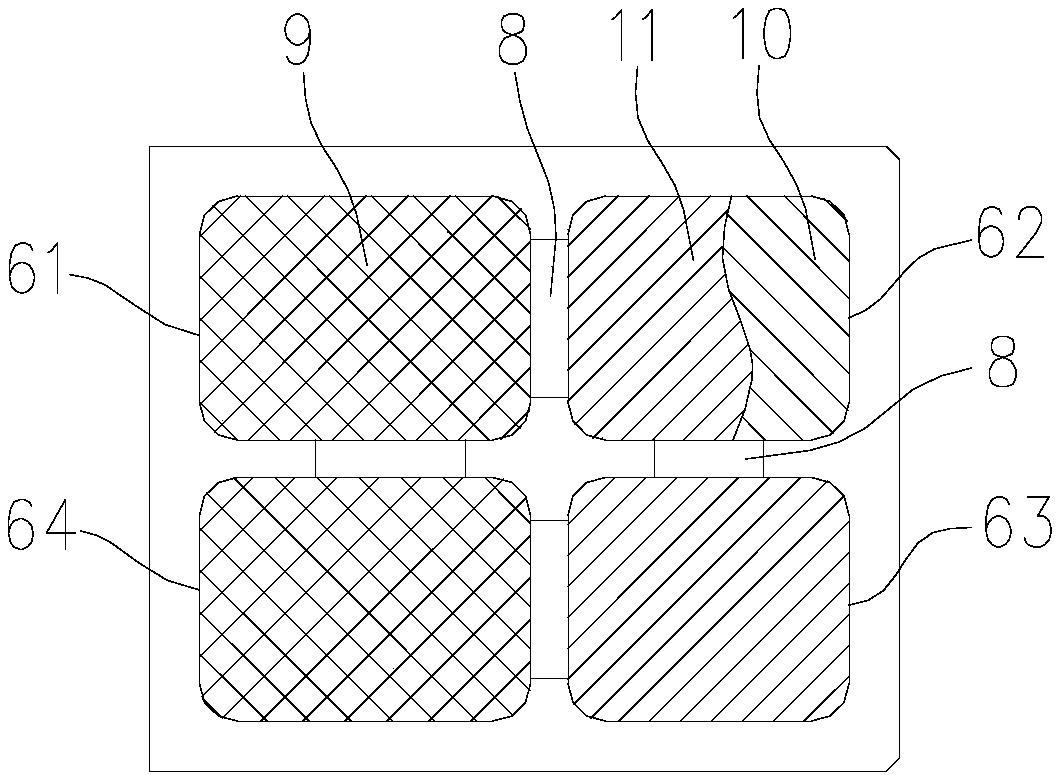

[0023] The resonance device includes a filter cavity 7 , a cover plate 4 , a resonance cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com