Rotary die type concrete product forming machine

A technology for concrete products and forming machines, which is applied in the direction of ceramic forming machines, manufacturing tools, supply devices, etc. It can solve problems such as difficulties and the inability of forming machines to uniformly distribute and demould, achieve high production efficiency, save production sites and maintenance time, Reduce the effect of turnover mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

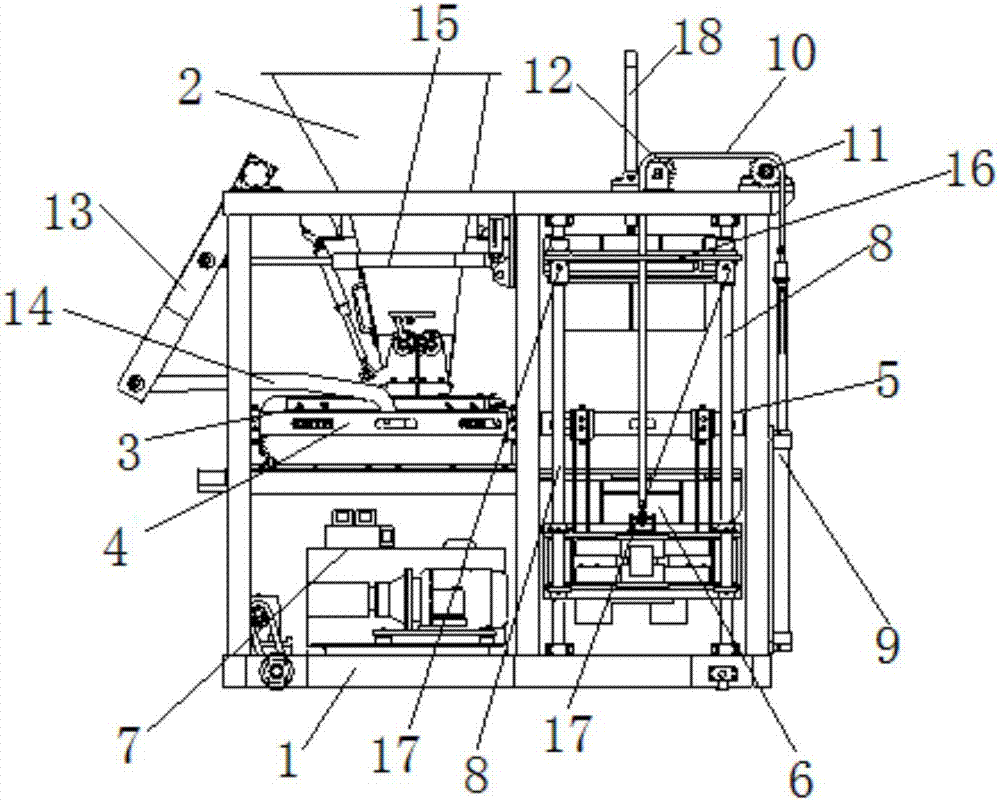

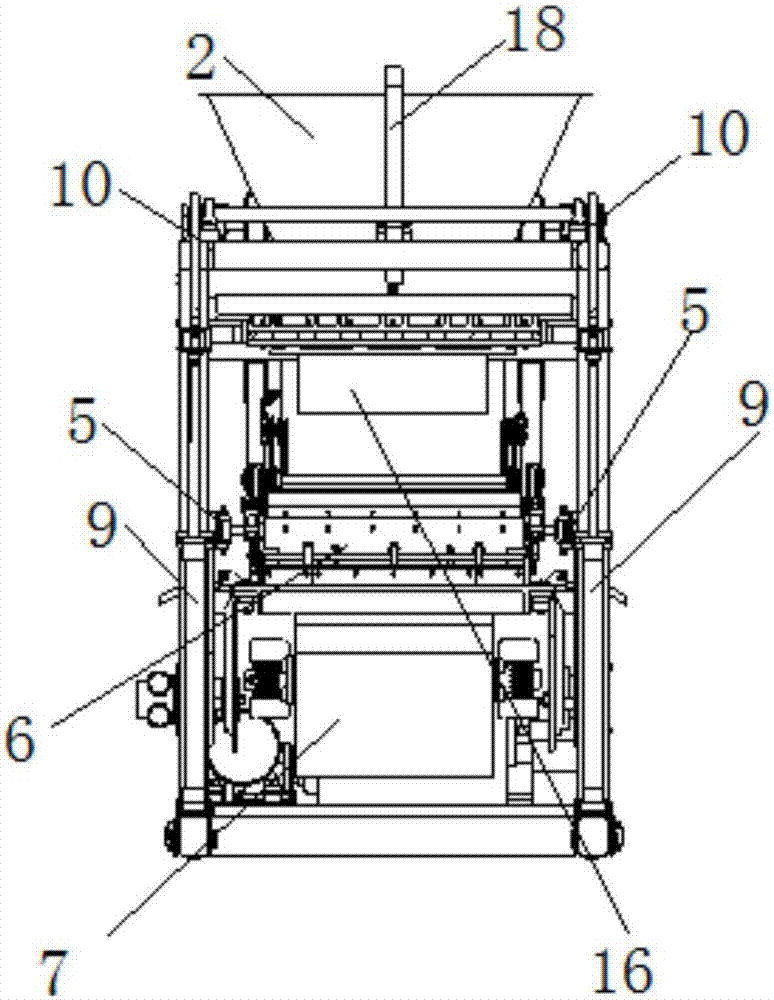

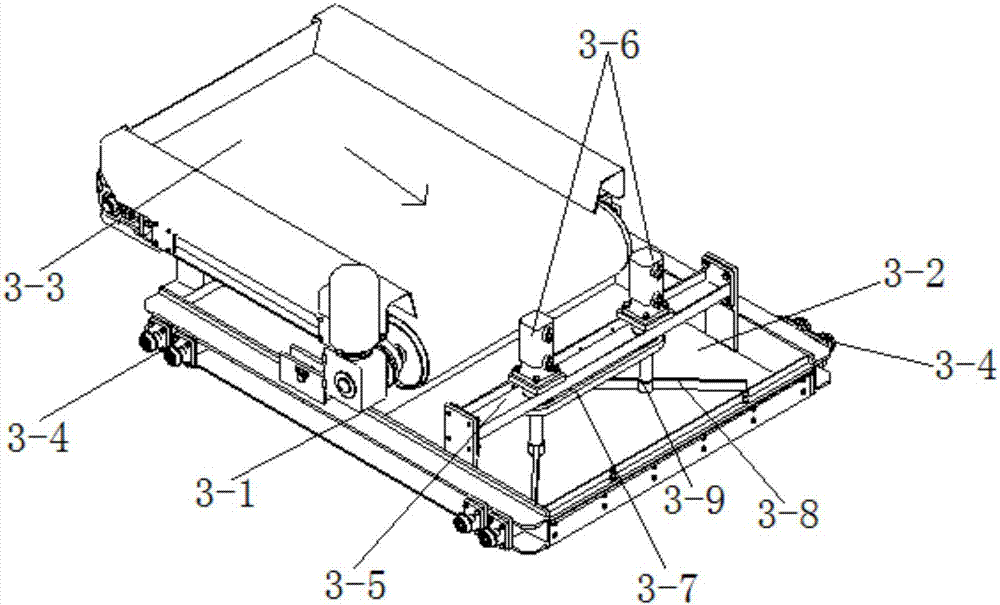

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0031] The present invention is a transfer mode concrete product molding machine, the structure is as follows figure 1 , 2 As shown, including frame 1, the upper end of frame 1 is provided with storage hopper 2, and the lower part of storage hopper 2 is provided with cloth trolley 3, and the middle part of frame 1 is provided with two parallel guide rails a4, which are at the same height as guide rail a4 There are two guide rails b5 parallel to each other, the guide rail a4 and the guide rail b5 are sequentially spliced on the same straight line, the two guide rails b5 are set on the rotary mold vibration forming device 6, and the rotary mold vibration forming device 6 is connected with a demoulding mechanism, A forming pressure head assembly is arranged above the rotary mold vibration molding device 6, and the rotary mold vibration moldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com